Construction method for cable bridge bracket installation rail in utility tunnel

A technology for integrated pipe gallery and cable bridge, which is applied in the direction of cable laying equipment, artificial islands, water conservancy projects, etc. It can solve the problems affecting the stable support of the cable bridge by the bracket, and achieve the effect of stable and reliable support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

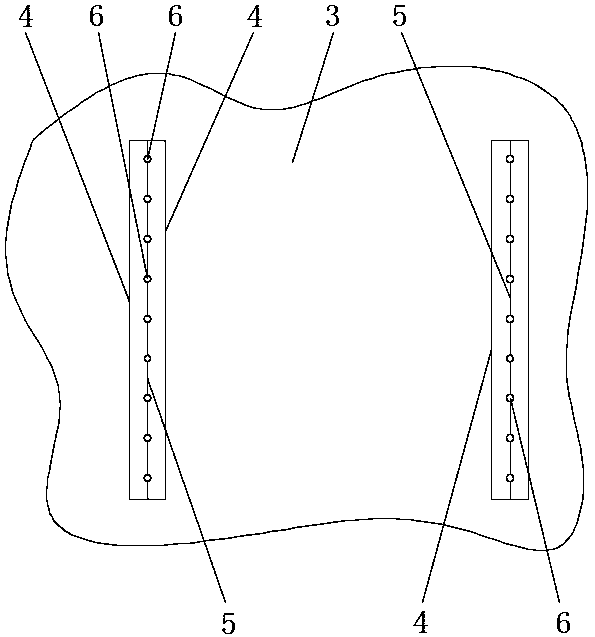

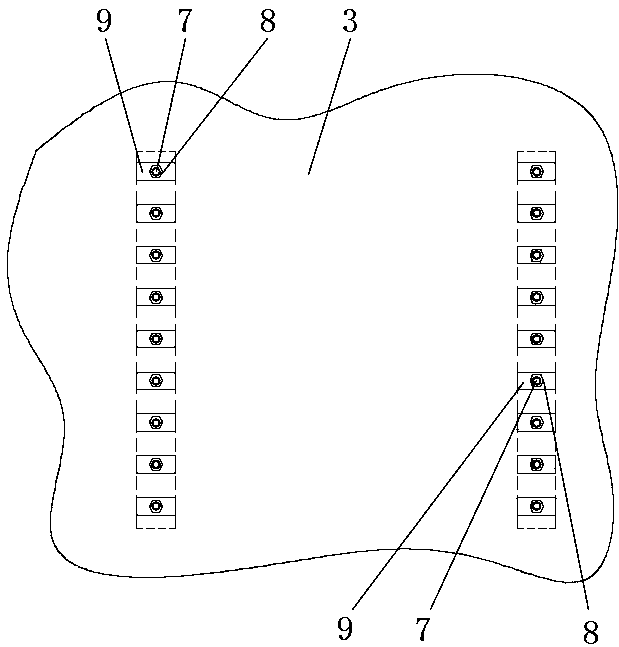

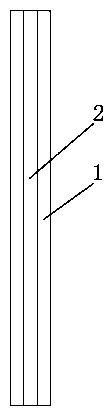

[0024] Such as Figures 1 to 6 As shown, the construction method of the installation track of the cable bridge bracket in the comprehensive pipe gallery, the installation track 1 has a T-shaped groove 2 opened along its length direction, and before installing the pouring formwork 3 of the internal side wall of the comprehensive pipe gallery, the pouring formwork 3 Measure and set out the line, measure and release the outline 4 of the installation track 1, and it is in a vertical state, and then detachably fix the installation track 1 in the area of the outline 4 and match it, and install the T-shaped slot 2 of the track 1 Closely attached to the inner surface of the pouring formwork 3, after the fixed connection between the installation track 1 and the pouring formwork 3 is completed, the openings at the upper and lower ends of the installation track 1 are blocked wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com