Wire protecting and guiding device for take-up machine

A technology of guiding device and wire take-up machine, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc. Human and other issues, to achieve the effect of improving equipment matching ability, shortening equipment design cycle, and facilitating height and angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

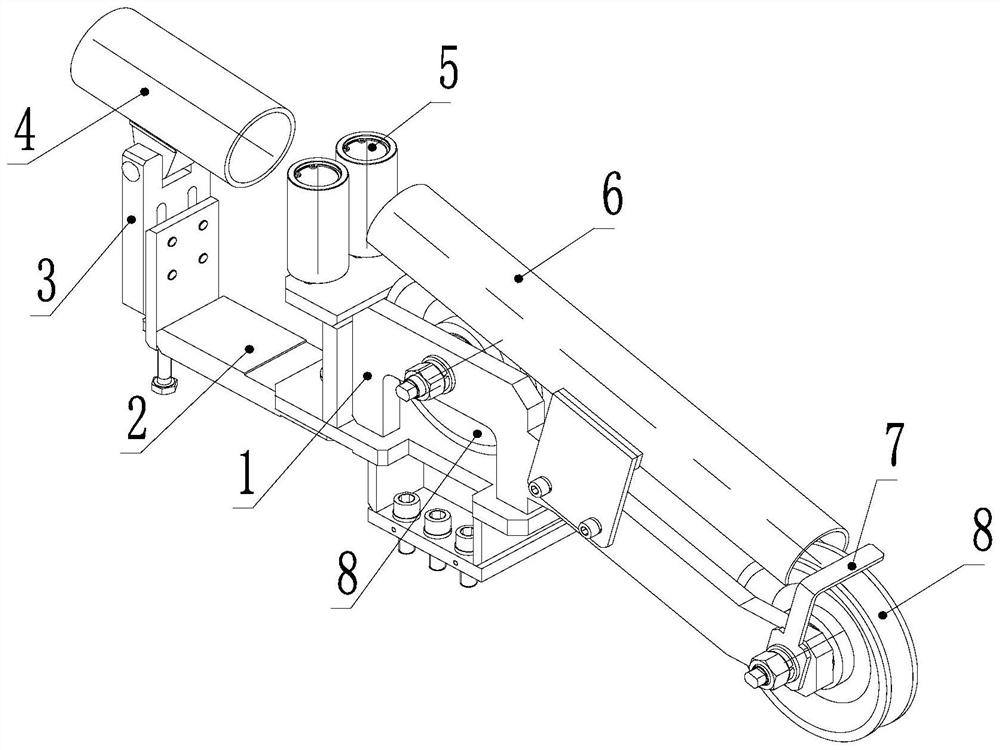

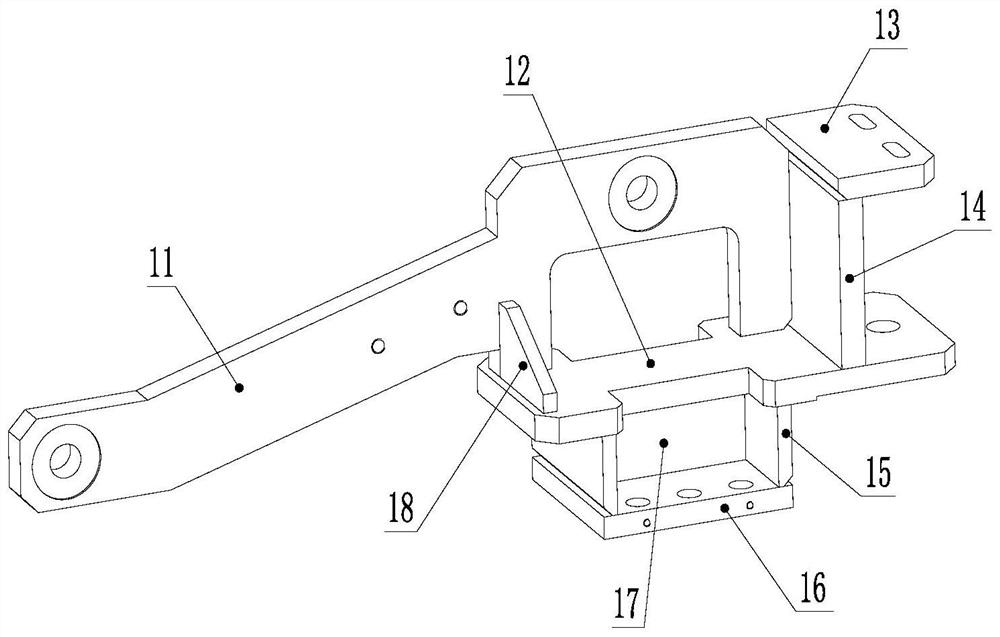

[0025] Such as Figure 1 to Figure 4 A wire protection guide for a wire take-up machine shown includes a fixed bracket 1, a swing bracket 2 and a wire protection frame 6; the swing frame 2 is fixed on the rear end of the fixed bracket 1, and the wire protection frame 6 is installed on Above the front part of the support 1, the front end position and the rear end position of the wire protection frame 6 have a wire wheel group 8 installed on the fixed support 1.

Embodiment 2

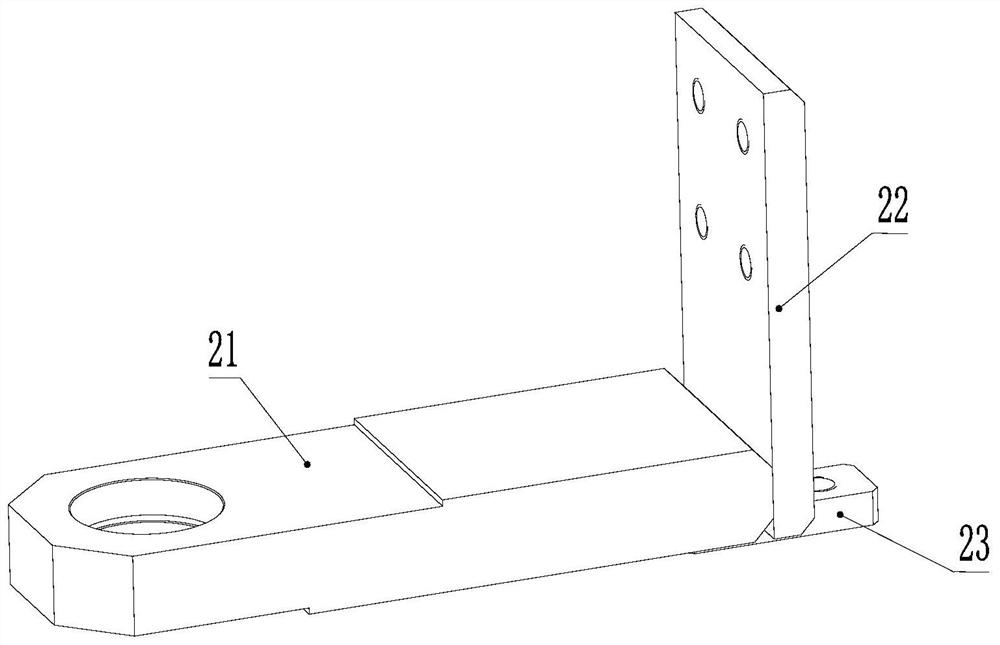

[0027] Based on Embodiment 1, a sliding sleeve 4 is installed above the rear end of the swing bracket 2 .

Embodiment 3

[0029] Based on the embodiment 2, the sliding sleeve 4 is installed through the adjusting plate 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com