A Gas Turbine Bench Oil Tank System with Self-filtering Function

A gas turbine, self-filtering technology, applied in lubricating oil containers, engine lubrication, mechanical equipment, etc., can solve problems such as increased procurement costs, waste of lubricating oil, difficult cleaning, etc., to improve work reliability, improve cleanliness, market promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

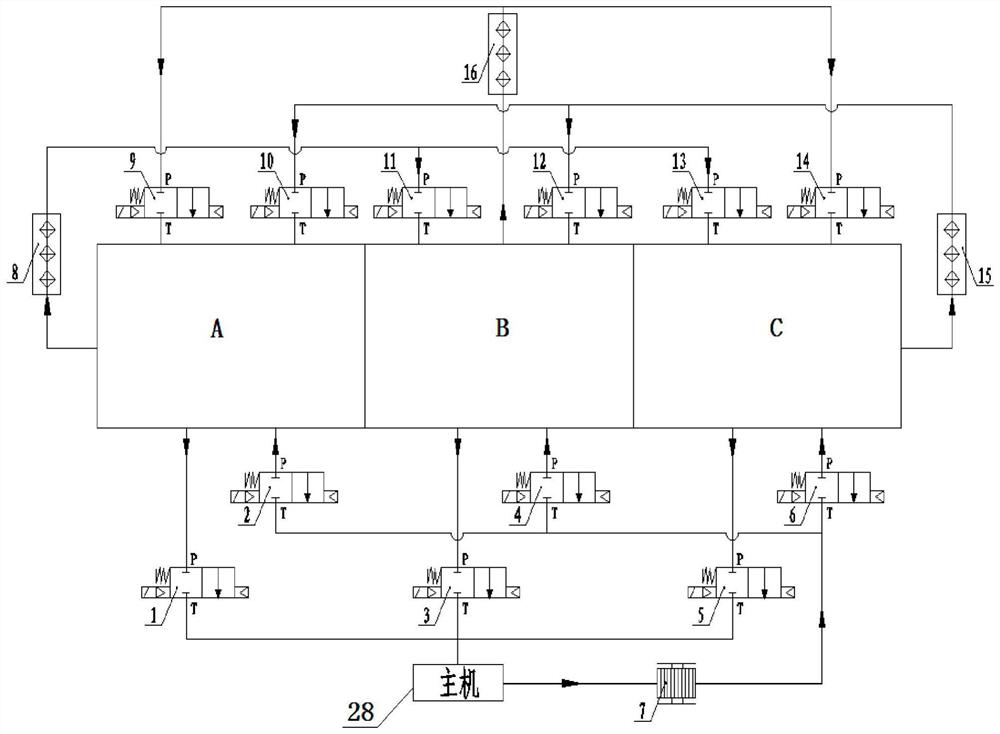

[0024] Such as figure 1 As shown, a gas turbine bench lubricating oil system with a self-filtering function of the present invention includes three oil filter vehicles and the first to third oil tanks A to C, wherein the first to third oil tanks A to C are three with the same volume 1. Separate oil tanks with the same structure, each oil tank is connected with the lubricating oil system through its own oil supply pipe and oil return pipe, and at the same time, each oil tank is connected with the other two oil tanks through its own filter lubricating oil inlet and filter lubricating oil outlet. The filter lubricating oil outlets of the first to third oil tanks are equipped with their own oil filter vehicles.

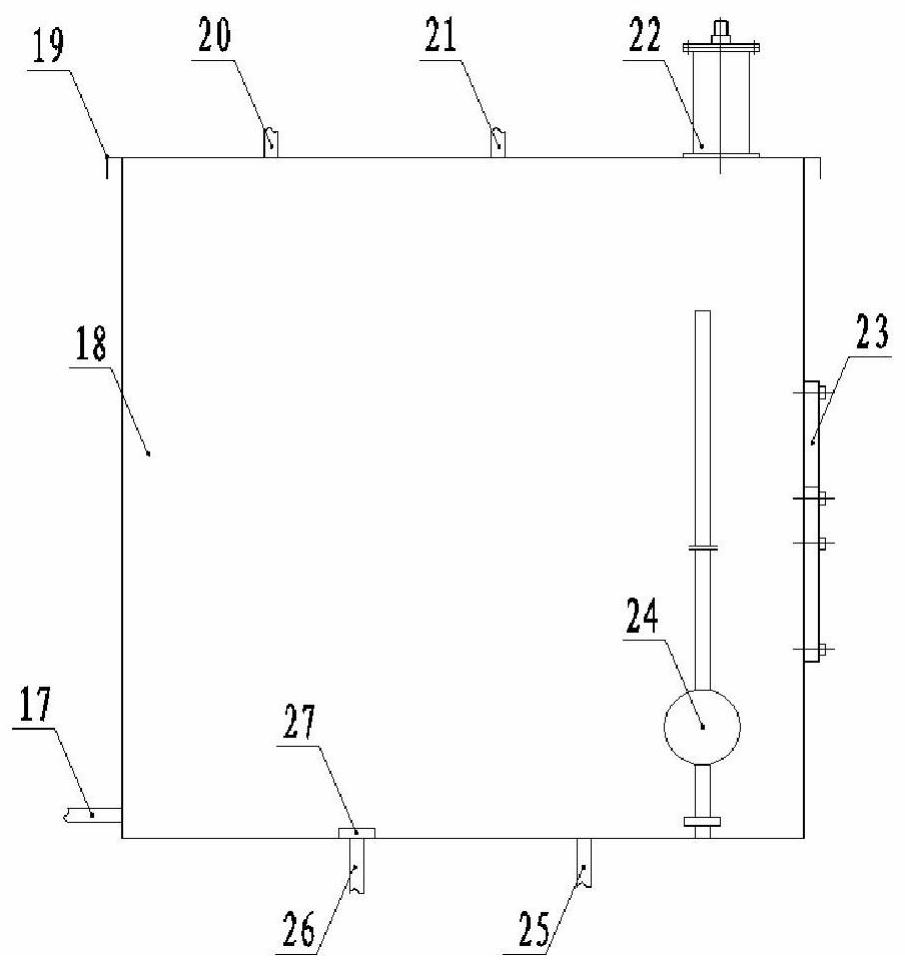

[0025] Such as figure 2 As shown, each fuel tank includes a lower casing 18, a casing cover 19, a filter lubricating oil outlet 17, first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com