Single bus grounding insulation monitoring method in three buses and monitoring device

A grounding insulation and monitoring device technology, applied in the direction of measuring devices, measuring electricity, measuring electrical variables, etc., can solve problems such as inability to monitor insulation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] This embodiment provides a single-bus-bar grounding insulation detection device in a three-bus bar, which includes a memory, a processor, and a computer program stored in the memory and running on the processor. The process implemented when the processor executes the computer program includes the above method The grounding insulation monitoring method of a single bus in the three bus bars provided in the embodiment.

Embodiment 2

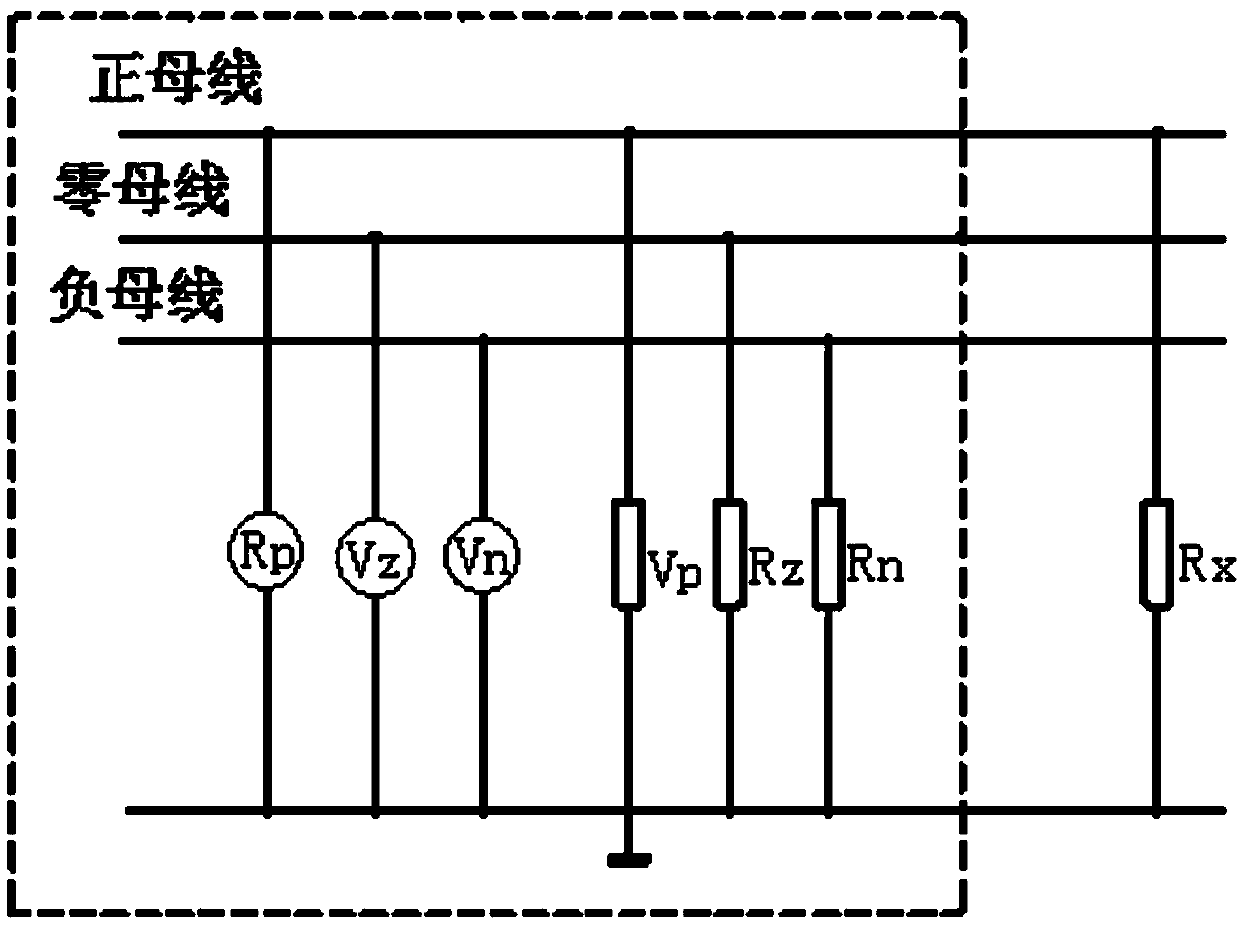

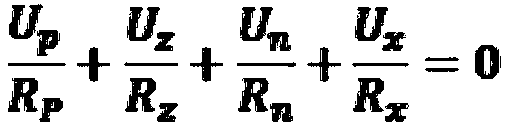

[0072] This embodiment provides a single-bus-bar grounding insulation monitoring device in a three-bus bar, and its structure principle is as follows figure 1 As shown, including the positive bus-to-ground voltage detection module V p , Negative bus-to-ground voltage detection module V n , Zero bus to ground voltage detection module V z And data processing module ( figure 1 Not given in), the positive bus-to-ground voltage detection module V p Used to detect the voltage of the positive bus to the ground U p , Negative bus to ground voltage detection module V n Used to detect the negative bus-to-ground voltage U n , Zero bus-to-ground voltage detection module V z Used to detect zero bus-to-ground voltage U z ; The data processing module detects the positive bus-to-ground voltage U p , Negative bus voltage to ground U n And zero bus-to-ground voltage U z Determine the grounded bus, and then according to the positive bus to ground voltage U p , Negative bus voltage to ground U p , Z...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com