System and method for trim loss optimization for metal industries

A technology for cutting and metal parts, applied in general control systems, metal rolling, metal processing equipment, etc., can solve the problems of energy consumption and high recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The drawings, discussed below, and the various embodiments used to describe the principles of the invention in this patent document are by way of illustration only and should not be construed in any way to limit the scope of the disclosure. Those skilled in the art will understand that the principles of the present disclosure may be implemented in any type of suitably arranged device or system.

[0018] For simplicity and clarity, some features and components are not explicitly shown in each figure, including those illustrated with respect to other figures. It will be understood that all of the features illustrated in the figures may be employed in any of the embodiments described in this patent document. The omission of a feature or component from a particular figure is for the sake of simplicity and clarity, and is not intended to imply that the feature or component cannot be employed in the embodiment(s) described with respect to that figure.

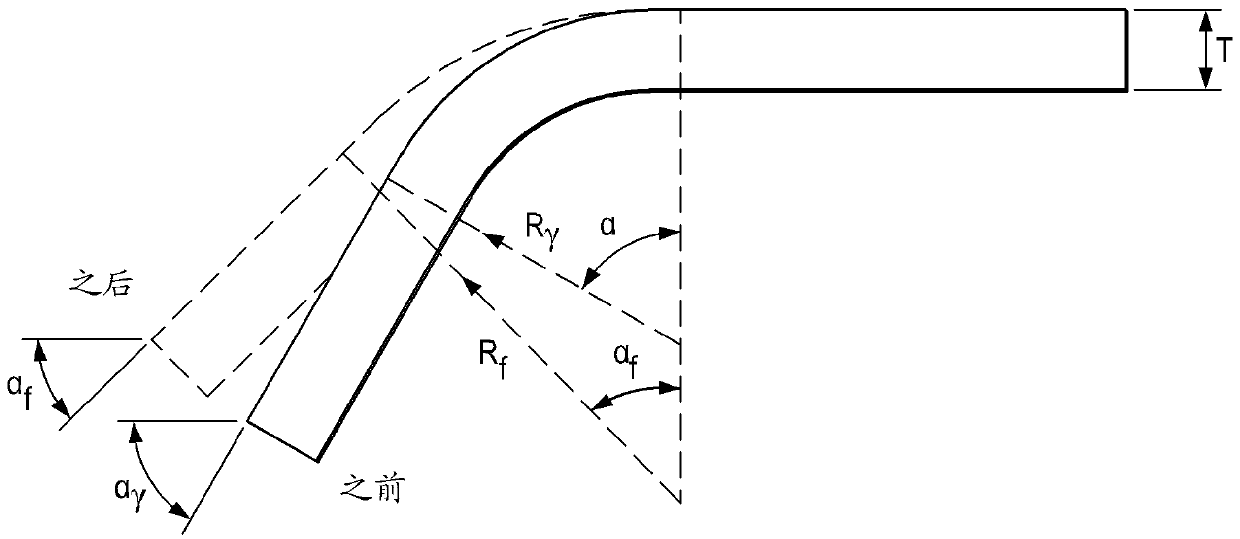

[0019] figure 1 An e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com