transmission line

A technology of transmission lines and waveguides, used in circuits, waveguides, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

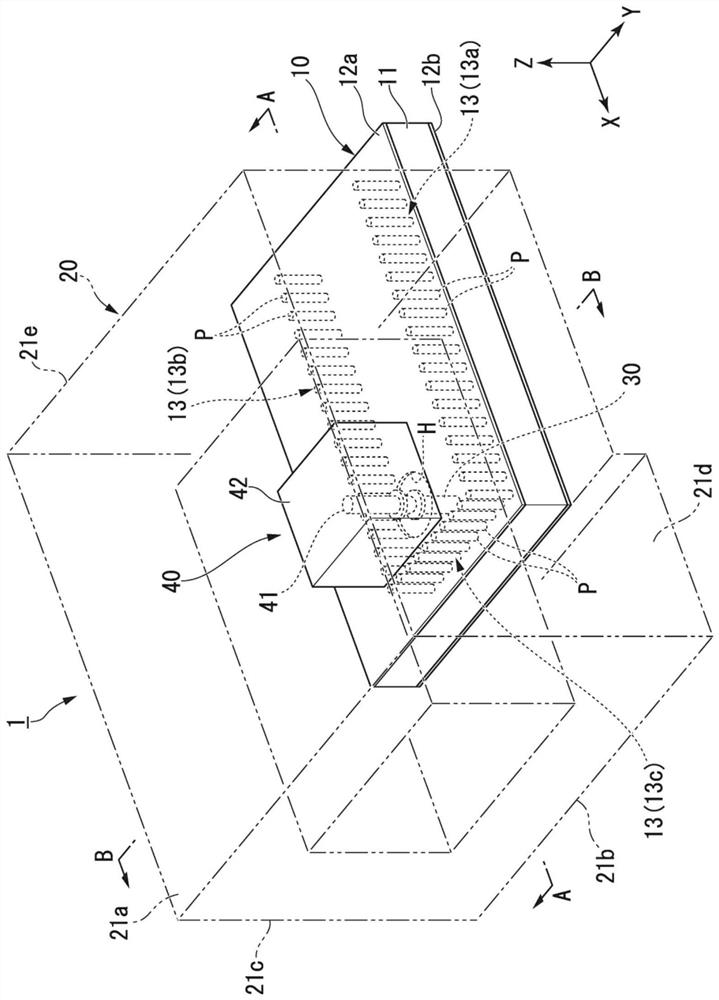

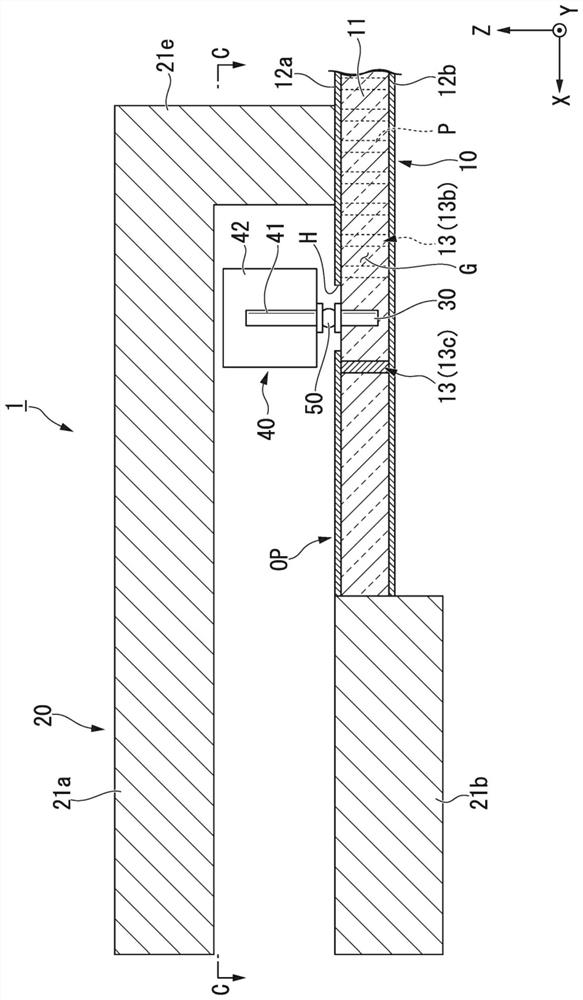

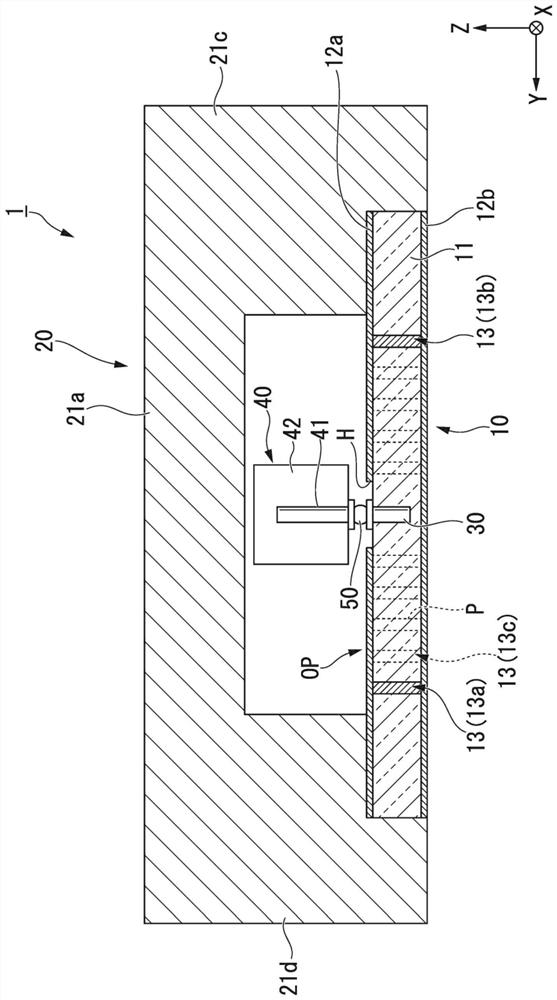

Embodiment 1

[0102] The inventors of the present application actually designed and simulated the transmission line of the above-mentioned first embodiment, and obtained the intensity distribution of a high-frequency signal transmitted through the transmission line, and the reflection characteristics and transmission characteristics of the transmission line. Design parameters of the transmission line 1 for simulation are as follows.

[0103] ·Pillar wall waveguide 10

[0104] Thickness of dielectric substrate 11: 520 [μm]

[0105] Relative permittivity of dielectric substrate 11: 3.82

[0106] Interval between the first column walls 13a, 13b (distance between centers): 1540 [μm]

[0107] The distance between the second column wall 13c and the blind hole 30 (center-to-center distance): 480 [μm]

[0108] Diameter of opening H (isolating disk AP): 340 [μm]

[0109] ·Waveguide 20

[0110] Height inside the tube: 1149[μm]

[0111] Width inside the tube: 2500[μm]

[0112] Distance from the...

Embodiment 2

[0131] In addition, the inventors of the present application actually designed the transmission line of the above-mentioned second embodiment, performed simulations, and obtained the reflection characteristics of the transmission line. Design parameters of the transmission line 1 for simulation are as follows.

[0132] ·Column wall waveguide 60

[0133] Thickness of dielectric substrate 11: 520 [μm]

[0134] Relative permittivity of dielectric substrate 11: 3.82

[0135] Interval between the first column walls 63a, 63b (distance between centers): 1540 [μm]

[0136] The distance between the second column wall 63c and the blind hole 30 (center-to-center distance): 480 [μm]

[0137] Diameter of opening H (isolating disk AP): 340 [μm]

[0138] ·Waveguide 20

[0139] Height inside the tube: 1149[μm]

[0140] Width inside the tube: 2500[μm]

[0141]Distance from the center of conductor post 41 to narrow wall 21e: 985 [μm]

[0142] Outer diameter of conductor post P: 100 [μm]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com