Self-levelling egg skin machine

A self-leveling, egg skin technology, used in baking, pancakes, oil/fat baking, etc., can solve problems such as egg liquid accumulation, reduce supply, solve the problem of wire entanglement, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, so that those skilled in the art can implement it with reference to the description.

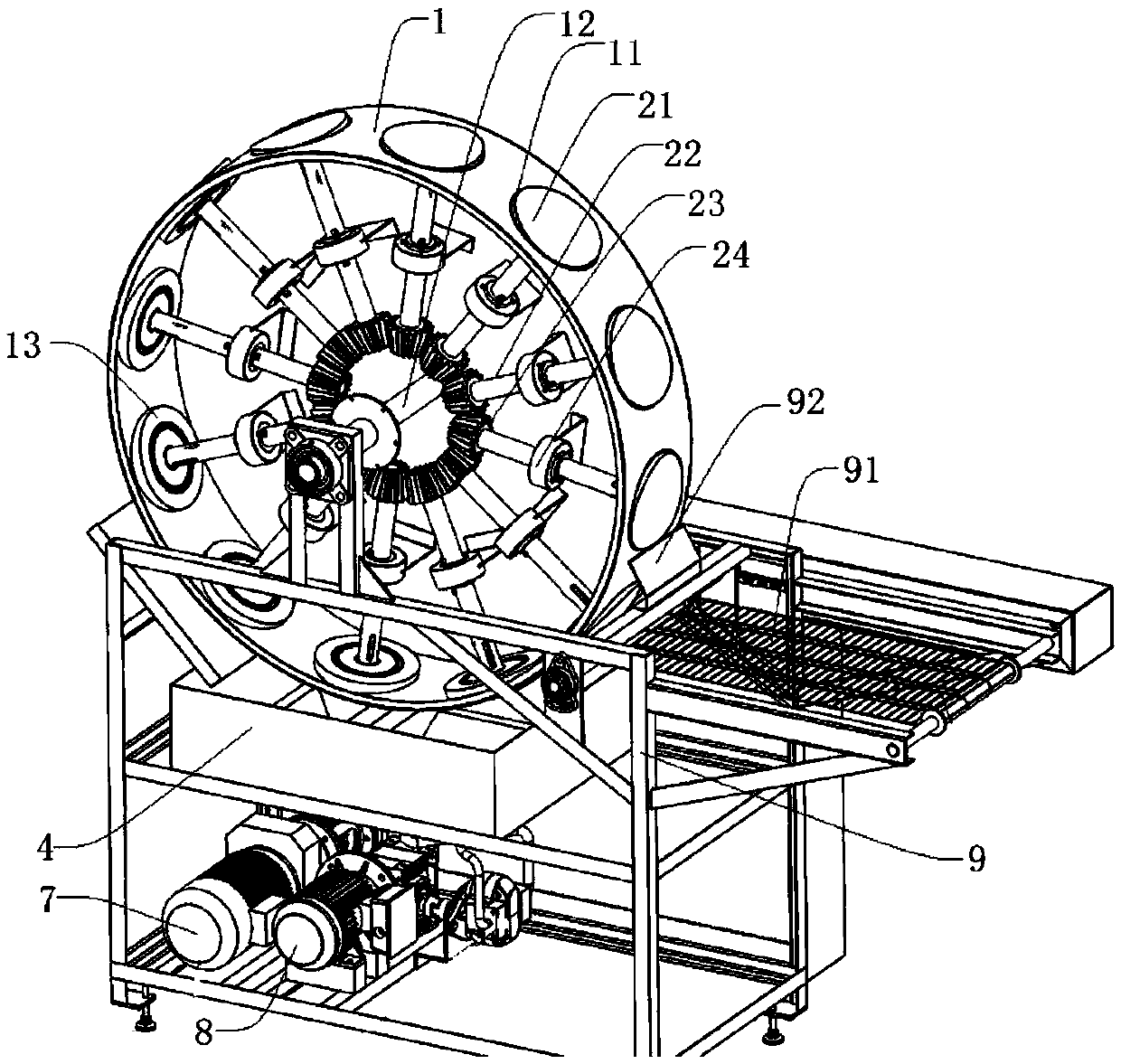

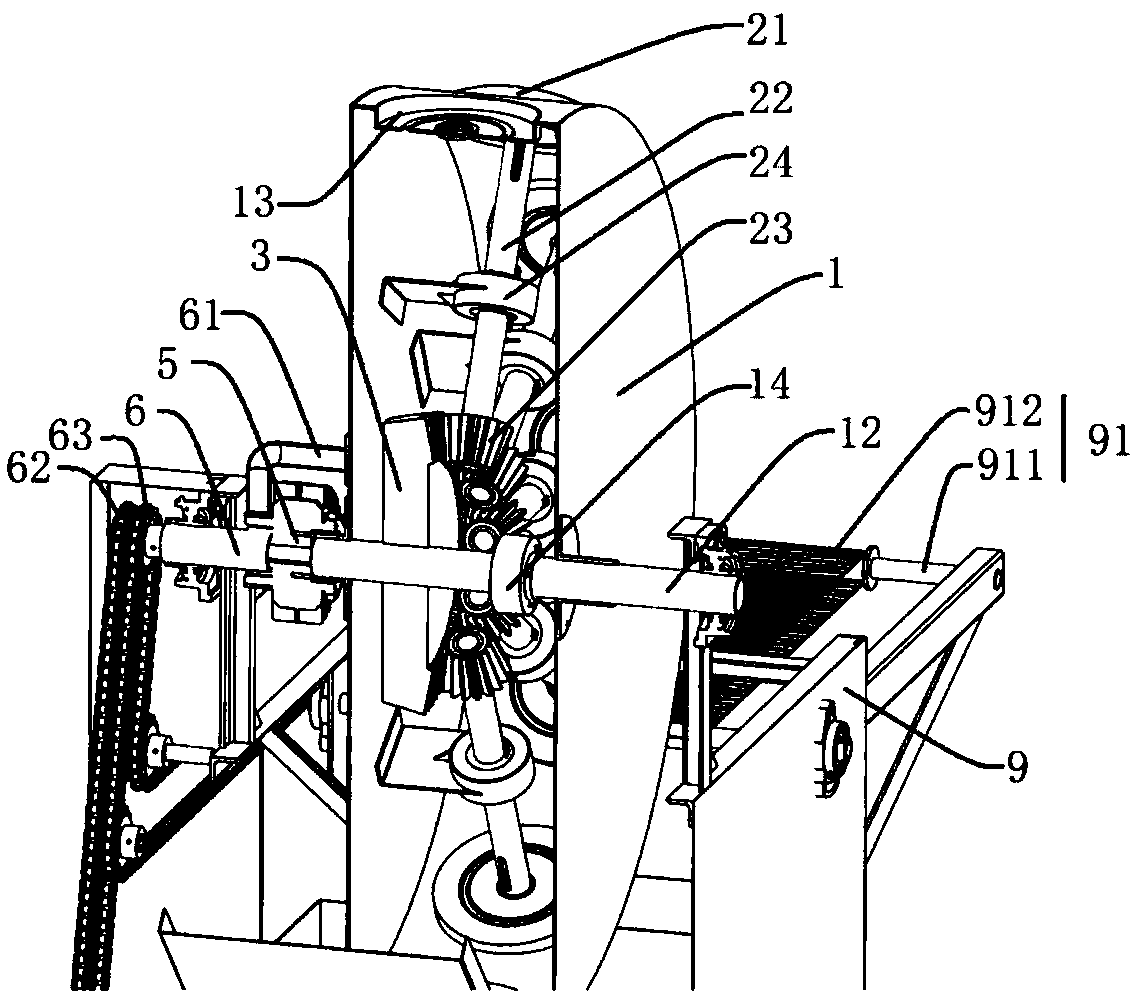

[0041] Such as Figure 1 to Figure 11 As shown, the invention provides a kind of self-leveling egg skin machine, comprising:

[0042] The egg skin forming roller 1 is hollow inside, the side wall of the egg skin forming roller 1 is provided with a plurality of first through holes 11 along the circumferential direction, the inner coaxially of the egg skin forming roller 1 is provided with a rotating shaft 12, and the egg skin forming The roller 1 can rotate around the shaft 12;

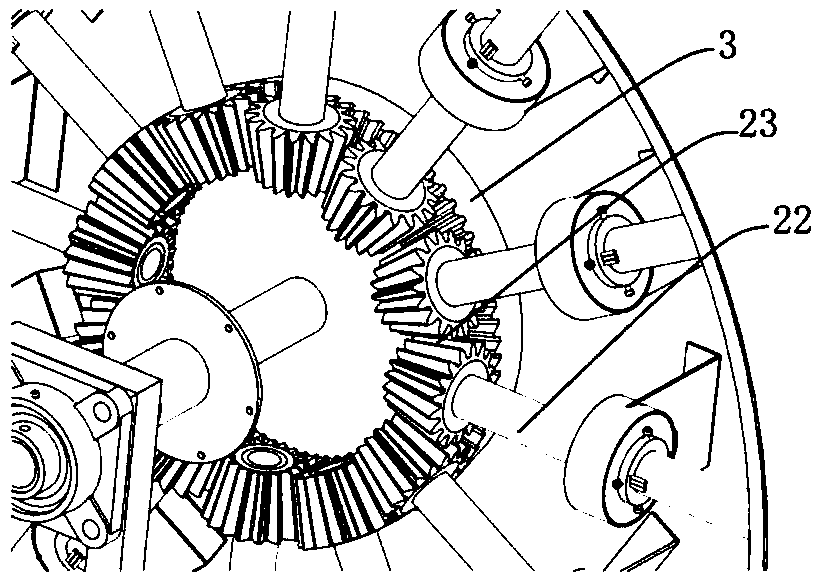

[0043] A plurality of heating mechanisms 2 correspond one-to-one to a plurality of first through holes 11, and each heating mechanism 2 includes:

[0044] An electric heating plate 21, which is arranged in the first through hole 11 and extends out of the first through hole 11;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com