Automotive small table plate controlled by single motor and lead screw

A single-motor, small table technology, applied in the field of automotive accessories, can solve problems such as uncertain motion trajectory, complex structure and operation, and less support for functional parts, and achieve the effect of neat appearance, compressed space occupation, and fast movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

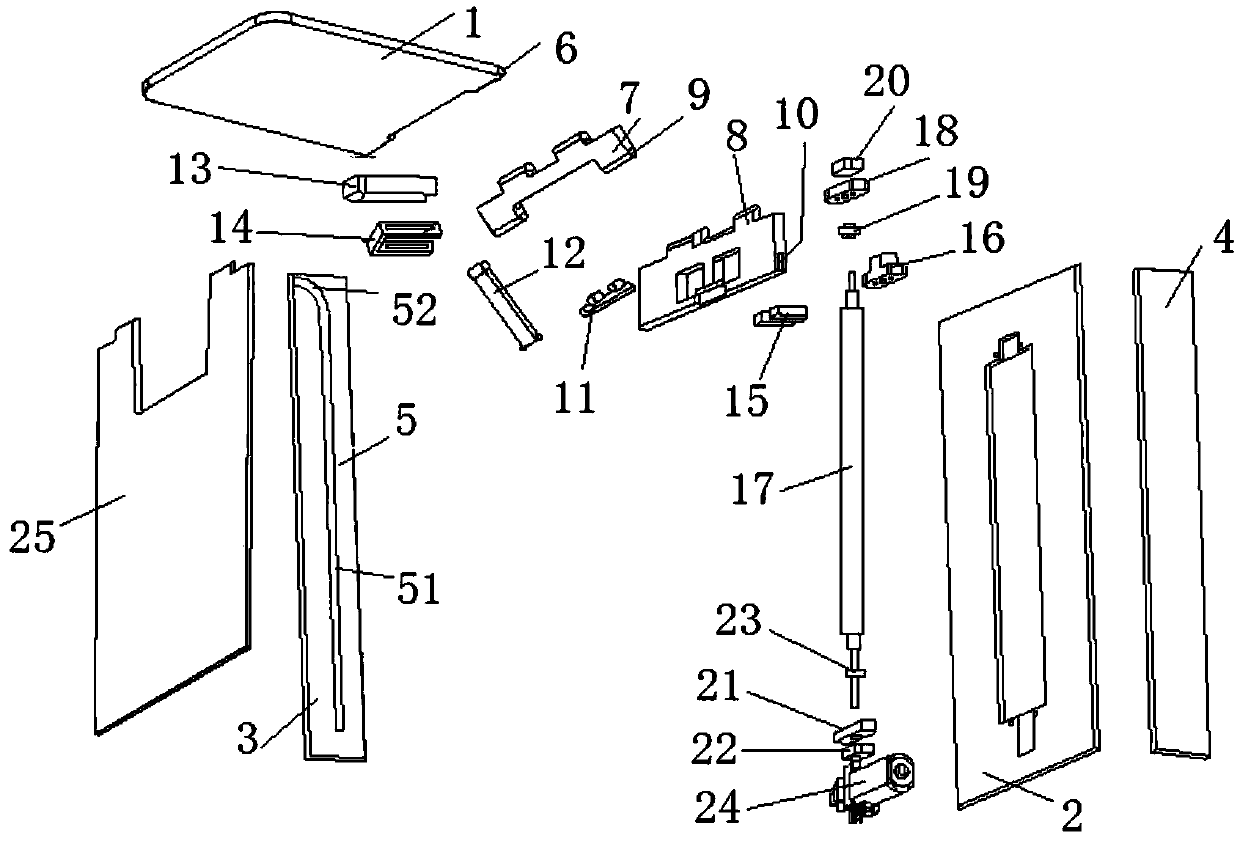

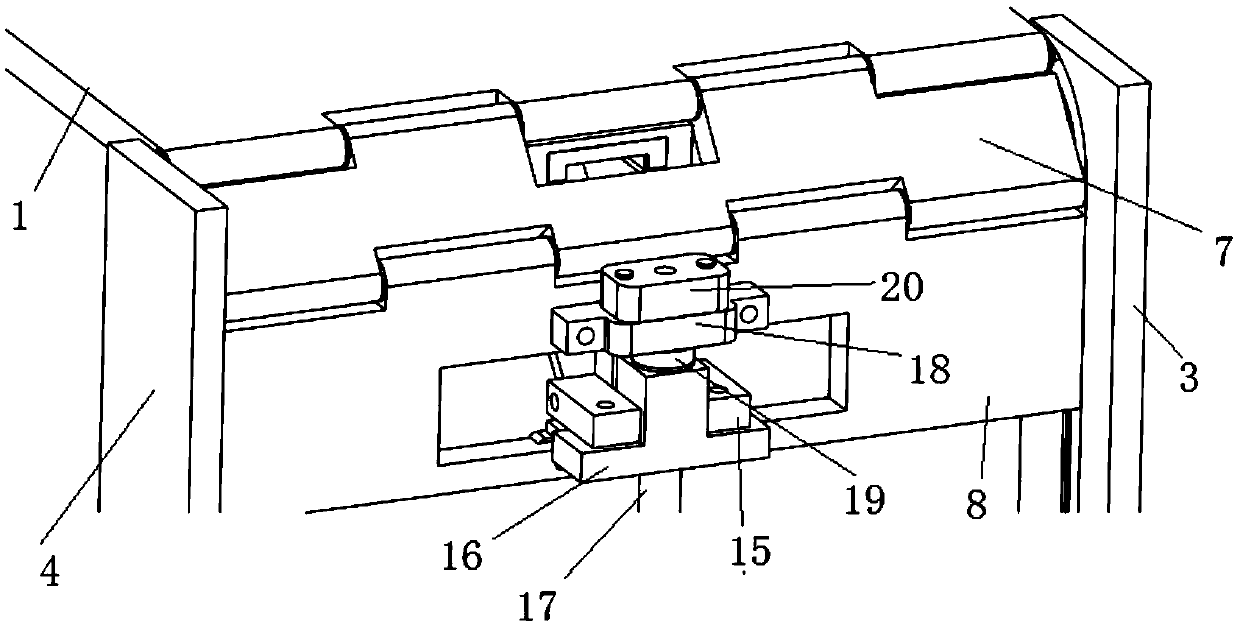

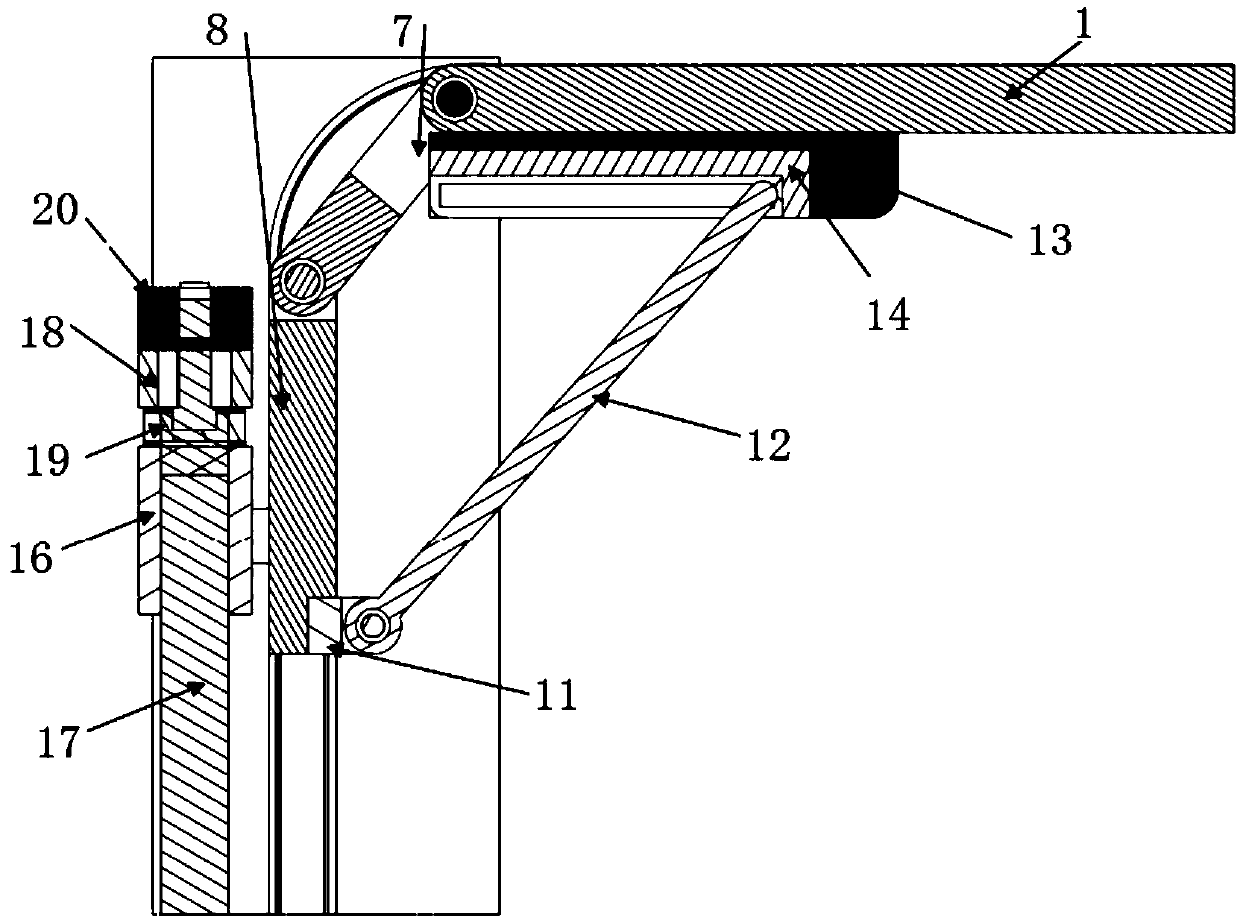

[0030] Embodiment 1: as figure 1 As shown, a small table board for automobiles controlled by a single motor and a screw rod, including a table board 1 and a rear structural board 2, and a symmetrical right structural board 3 and a left structural board 4 are fixedly connected to both sides of the rear structural board 2 There are symmetrical chute 5 on the inner surface of the right structural plate 3 and the left structural plate 4, the chute includes a vertical straight groove 51 at the lower end and an arc-shaped groove 52 curved forward and upward at the upper end, the arc-shaped groove 52 is divided into quarters One arc structure, the center line of the upper end is connected with the horizontal tangent, the center line of the lower end is connected with the vertical tangent, and the tail end of the arc groove 52 is connected with a small section of horizontal groove. The both sides of table board 1 rear end have bearing pin-6 and the arc groove 52 of both sides to slide...

Embodiment 2

[0036] Embodiment 2: The screw rod 17 is a double-ended or triple-ended threaded screw rod. Under the condition of the same pitch, the feed speed of double or triple threads can be multiplied according to the number of threads. All the other structures are with embodiment 1.

[0037] The key facilities of the device include arc-shaped grooves 52 for guiding and supporting and fixing, so only a single motor can realize many actions of table board rising, extending, turning over and horizontal fixing, with complete functions and self-locking function. For the table top 1, it is also a feature that this structural scheme is different from the prior art by setting the main support point at the middle part of the table board instead of the rear end; The special multi-head screw fast transmission is a major advantage of this structural scheme.

Embodiment 3

[0038] Embodiment 3: the upper end of the support arm 12 is hinged with the middle part of the lower side of the table plate through the hinge support 11, and the lower end of the support arm 12 is fixedly connected to the support arm slideway on the front side of the table plate drive plate 8 through the slideway connector 13 14 slip fit. All the other structures are with embodiment 1. see Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com