Construction waste sorting device

A sorting device and technology for construction waste, applied in grain processing, etc., can solve problems such as incomplete functions and no way to separate construction waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

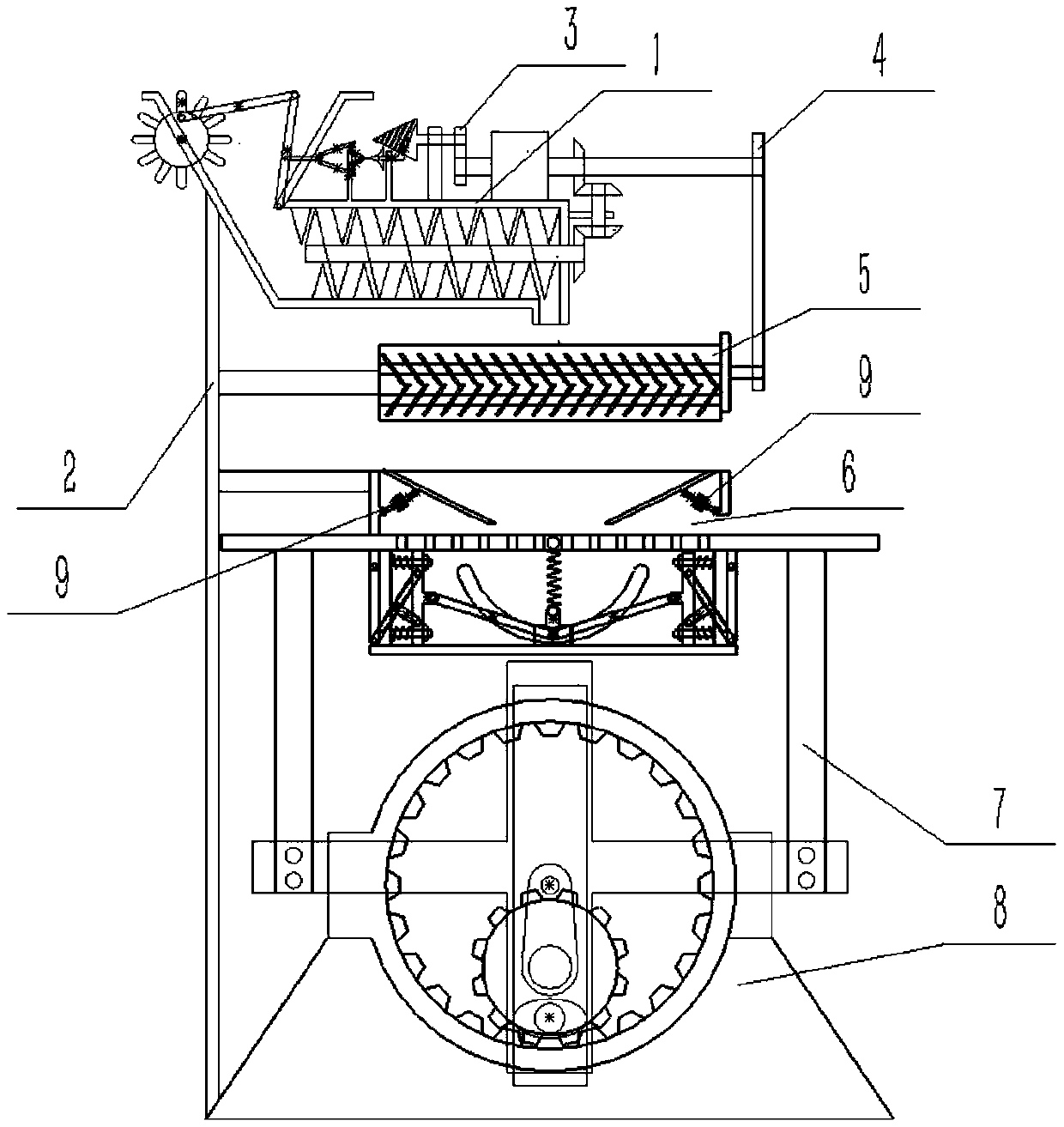

[0031] Combine below Figure 1-13 Describe this embodiment, a construction waste sorting device, including a transmission device 1, an outer fixed frame 2, a transmission belt 3, a transmission belt 2 4, a crushing device 5, a separation device 6, a mobile fixing frame 7, a lower turret 8 and a reset Push the combination 9, the transmission device 1 is fixedly connected with the outer fixed frame 2, the transmission belt 1 3 is connected with the transmission device 1 with interference fit, the transmission belt 2 4 is connected between the transmission device 1 and the crushing device 5, and the crushing device 5 is fixed to the outside The frame 2 is fixedly connected, the separation device 6 is fixedly connected with the outer fixed frame 2, the mobile fixed frame 7 is fixedly connected with the separation device 6, the lower turntable 8 is fixedly connected with the outer fixed frame 2, and the reset push combination 9 is hingedly connected with the separation device 6 . ...

specific Embodiment approach 2

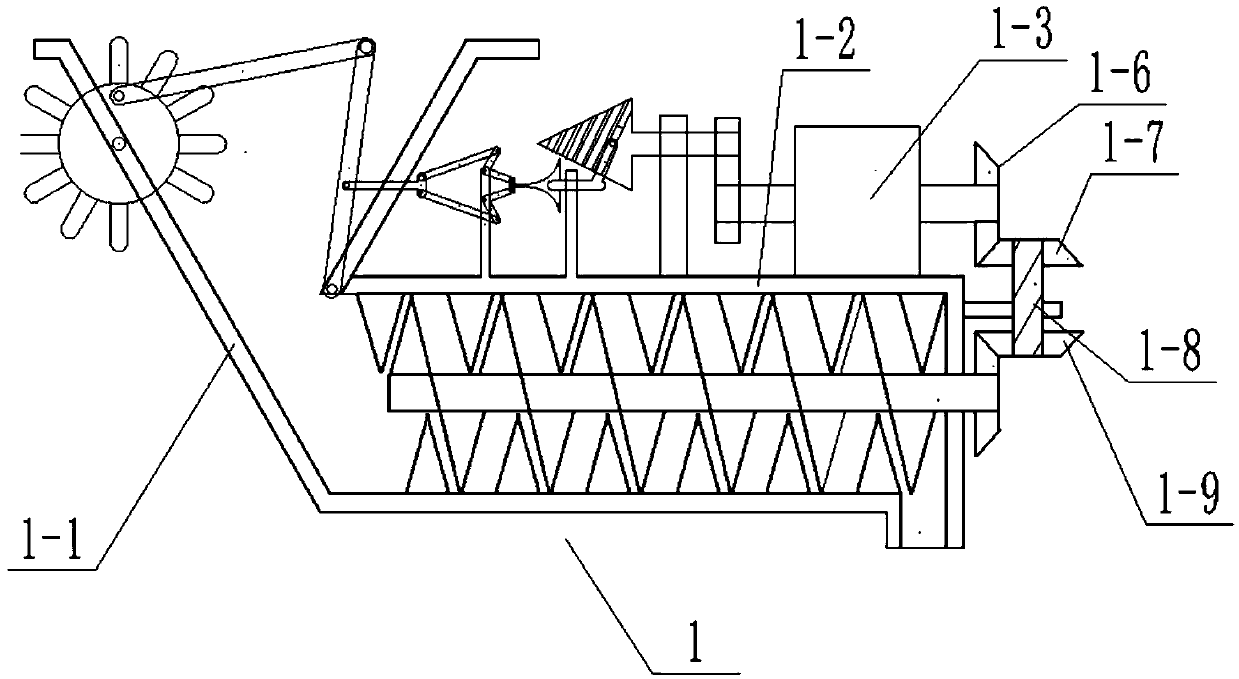

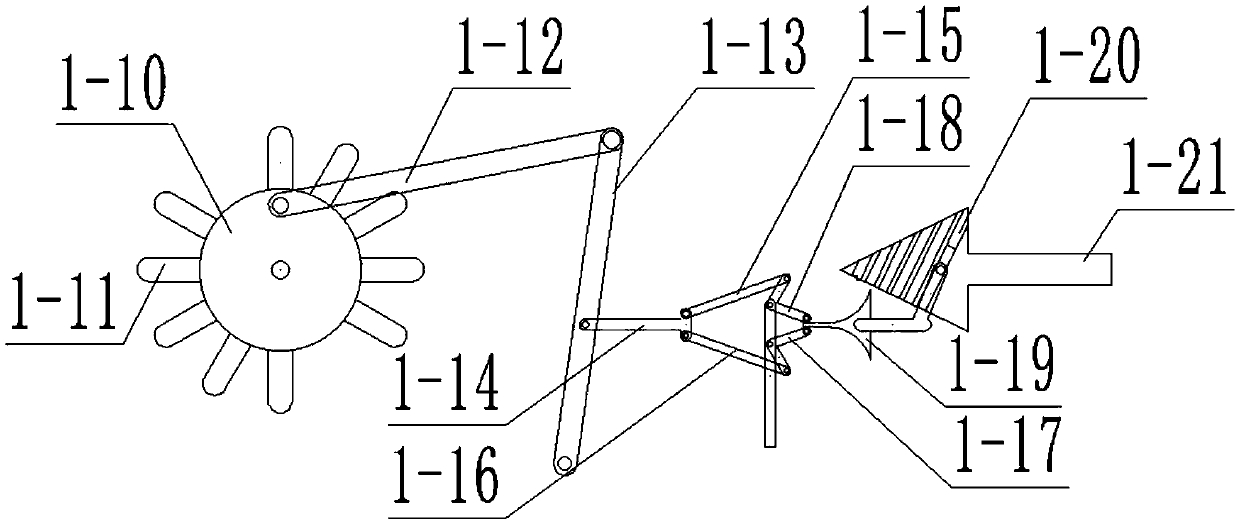

[0032] Combine below Figure 1-13 Describe this embodiment, this embodiment will further explain Embodiment 1, the transmission device 1 includes a transmission device outer frame 1-1, an upper side wall plate 1-2, a biaxial motor 1-3, and an output bevel gear 1-6 , Transmission bevel gear 1-7, transmission shaft 1-8, transmission bevel gear 2 1-9, dial 1-10, dial lever 1-11, middle connecting rod 1-12, hinged push rod 1- 13. Horizontal sliding rod 1-14, hinged connecting rod one 1-15, hinged connecting rod two 1-16, hinged connecting rod three 1-17, hinged connecting rod four 1-18, fader 1-19, spiral chute 1-20 and a rotating cone rod 1-21, the transmission device outer frame 1-1 includes a transmission device outer frame body 1-1-1, an inner hollow cavity 1-1-2, a fixed plate 1-1-3 , fixed plate 2 1-1-4, right end rotating hole 1-1-5, rotating shaft 1-1-6 with spiral leaves, outer frame discharge port 1-1-7 and rotating shaft bevel gear 1-1-8, The hollow cavity 1-1-2 at th...

specific Embodiment approach 3

[0034] Combine below Figure 1-13 This embodiment will be described. This embodiment will further describe Embodiment 1. The crushing device 5 includes a crushing device outer frame 5-1, a sun gear 5-2, a sun gear shaft 5-3, a crushing shaft 5-4, and a crushing device. Shaft 2 5-5, planetary gear 3 5-6, planetary gear 1 5-7, planetary gear 2 5-8, intermediate runner 5-9, crushing device hollow cavity 5-10, crushing shaft 3 5-11 and crushing The discharge port 5-12 of the device, the sun gear 5-2 is arranged at the right end of the crushing device outer frame 5-1, the sun gear rotating shaft 5-3 is rotationally connected with the crushing device outer frame 5-1, and the sun gear 5-2 is fixedly connected to the The left end of the sun wheel rotating shaft 5-3, the crushing shaft one 5-4 is rotatably connected in the crushing device outer frame 5-1, the crushing shaft two 5-5 is rotatably connected in the crushing device frame 5-1, and the crushing shaft three 5- 11 Rotationally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com