Chain type casting machine and casting die

A casting machine and mold technology, which is applied in the direction of manufacturing tools, casting workshops, casting equipment, etc., can solve the problems of high production cost and fragile casting molds, and achieve the effects of saving costs, simple and convenient demoulding, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific embodiments of the present invention will be further described below in conjunction with the drawings.

[0033] Examples of the chain casting machine provided by the present invention:

[0034] In this embodiment, the chain casting machine is used for casting aluminum ingots.

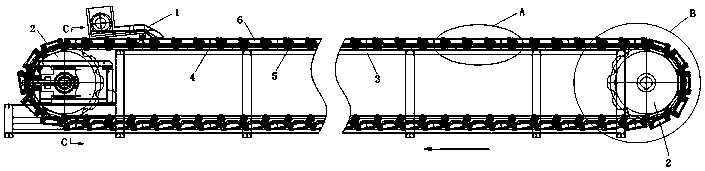

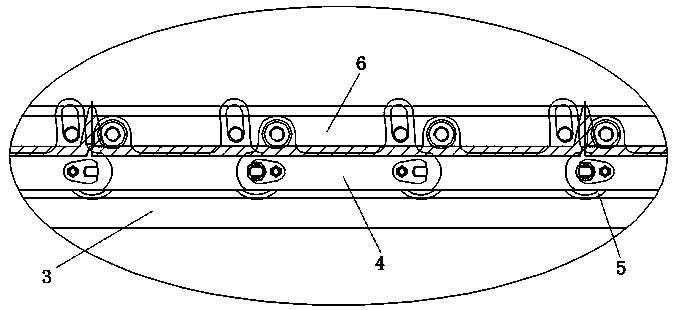

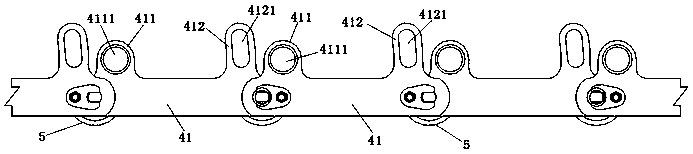

[0035] Such as figure 1 As shown, the chain casting machine includes an aluminum liquid distributor 1, a sprocket 2 and a transmission chain 4 wound on the sprocket 2. There are two sprocket wheels 2, and the two sprockets 2 drive the transmission chain 4 to reciprocate. Movement; a casting mold 6 is installed on the transmission chain 4. The casting mold 6 and the transmission chain 4 belong to the structure of the casting chain; the molten aluminum distributor 1 is used to pour molten aluminum into the casting mold 6, and the molten aluminum distributor 1 has a direction The casting nozzle for pouring aluminum liquid in the casting mold 6, while the casting mold 6 is walking with the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com