Quantitative valve assembly

A technology of quantitative valves and components, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of tediousness, affecting the taste and beauty of dishes, wasting time and energy, etc., and achieve the effect of convenient and simple use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

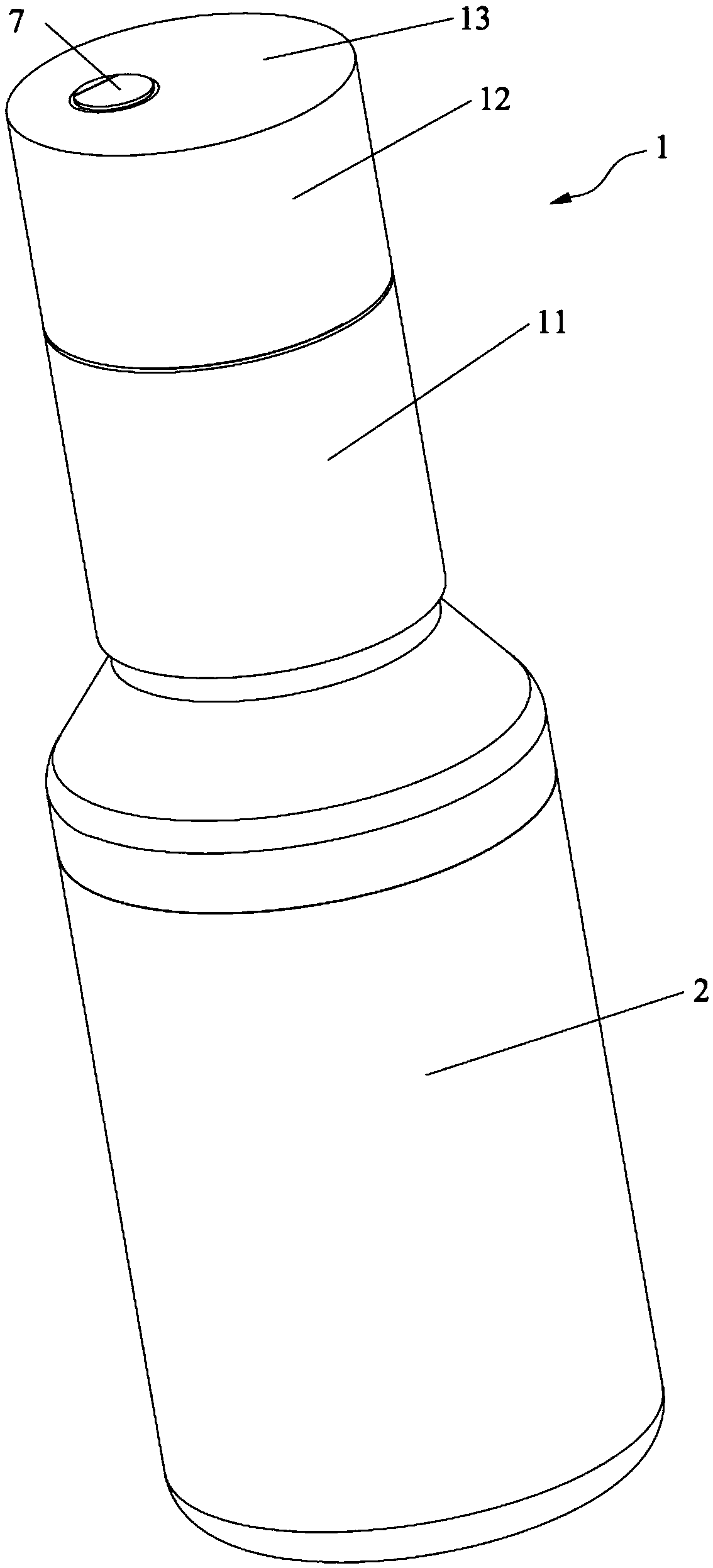

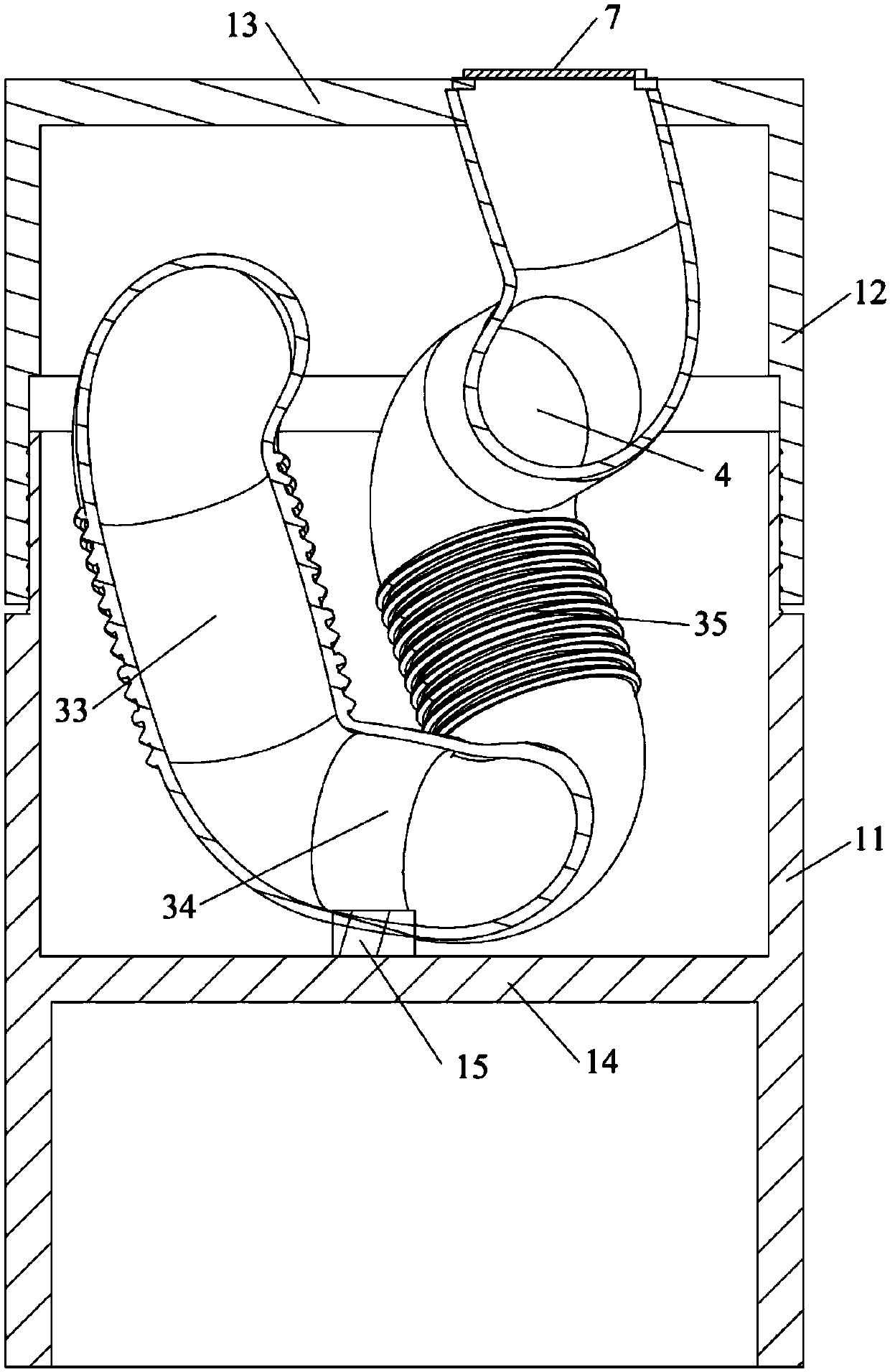

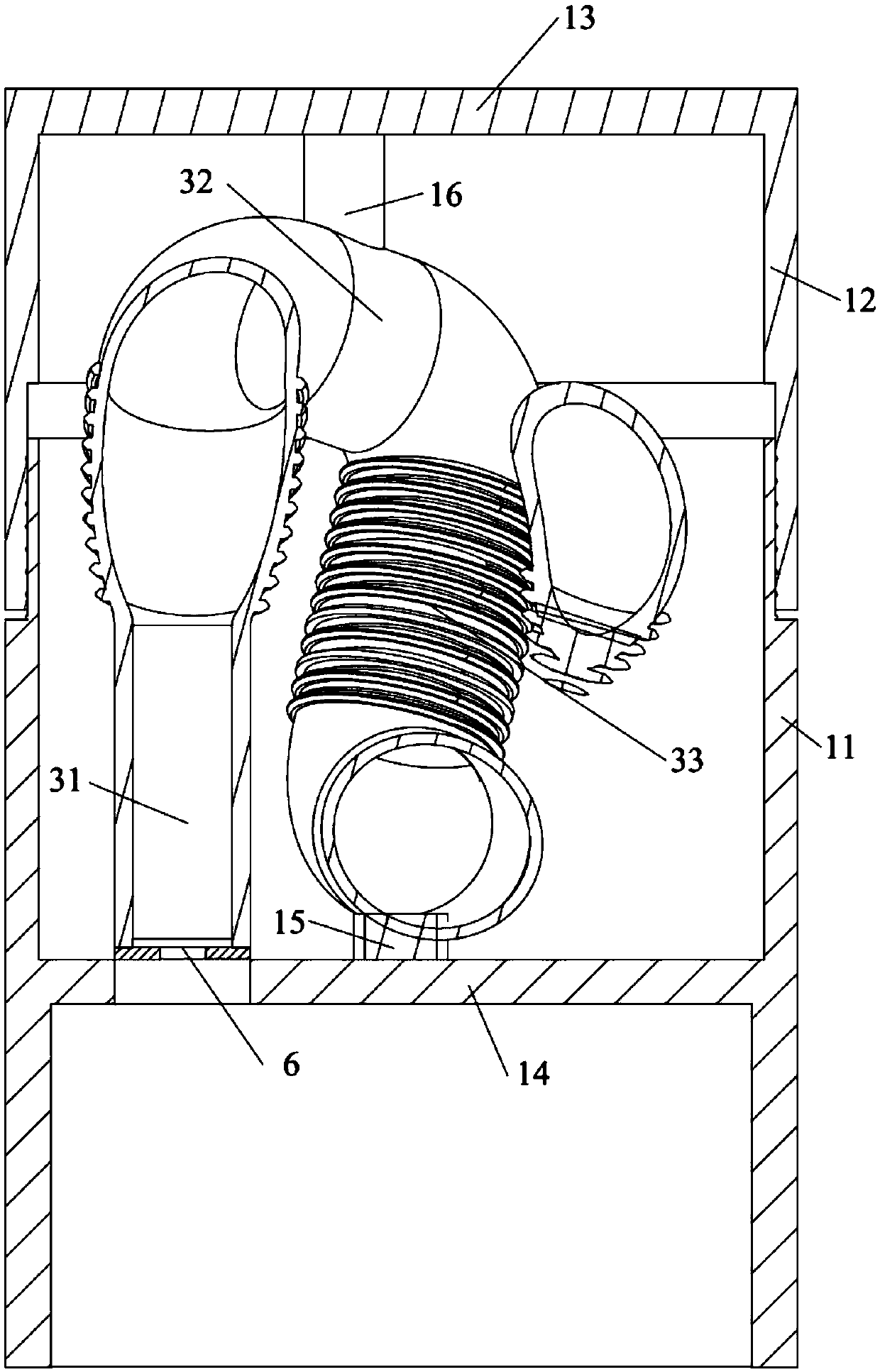

[0045] Such as Figure 1 to Figure 6 As shown, this embodiment discloses a quantitative valve assembly, which includes a bottle cap 1 , an adjustment mechanism, a fixing piece 14 , a first adjustment valve 5 and a second adjustment valve 6 .

[0046] Among them, such as Figure 2 to Figure 4 As shown, the adjustment mechanism is arranged in the bottle cap 1, and the adjustment mechanism includes a pouring part 4 and a temporary storage part 3 which are sequentially and smoothly connected. The end of the pouring part 4 away from the temporary storage part 3 is fixed on the top cover 13 of the bottle cap 1 and is arranged at the edge of the top cover 13 . A first regulating valve 5 is provided between the pouring part 4 and the temporary storage part 3 , and an end of the temporary storage part 3 away from the pouring part 4 is set toward the opening direction of the bottle cap 1 , and a second regulating valve 6 is provided at this end. When pouring over, the first regulating...

Embodiment 2

[0061] Such as Figure 7 and Figure 8 As shown, this embodiment discloses a quantitative valve assembly. The general structure of the quantitative valve assembly is the same as that in the first embodiment, except that an end cover 17 is provided on the top cover 13, and the on-off valve 7 is not provided. Furthermore, the structure of the adjustment mechanism is different. In this embodiment, a partition 18 is arranged inside the telescopic part 12. The partition 18 includes a vertical part 181 and a horizontal part 182. The first regulating valve 5 is arranged on the horizontal part 182. superior. The vertical part 181 is disposed at the center of the telescopic part 12 , the top end of the vertical part 181 is connected to the top cover 13 , the bottom end is connected to the horizontal part 182 , and the other parts of the horizontal part 182 are connected to the inner sidewall of the telescopic part 12 . The top cover 13 in this embodiment has a semicircular shape, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com