Prefabricated underground diaphragm wall and its construction method

An underground diaphragm wall, prefabricated technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of uplift of diaphragm wall components and reduce the overall performance of the diaphragm wall, so as to reduce the phenomenon of uplift or depression and improve construction. Efficiency, the effect of reducing the possibility of position shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

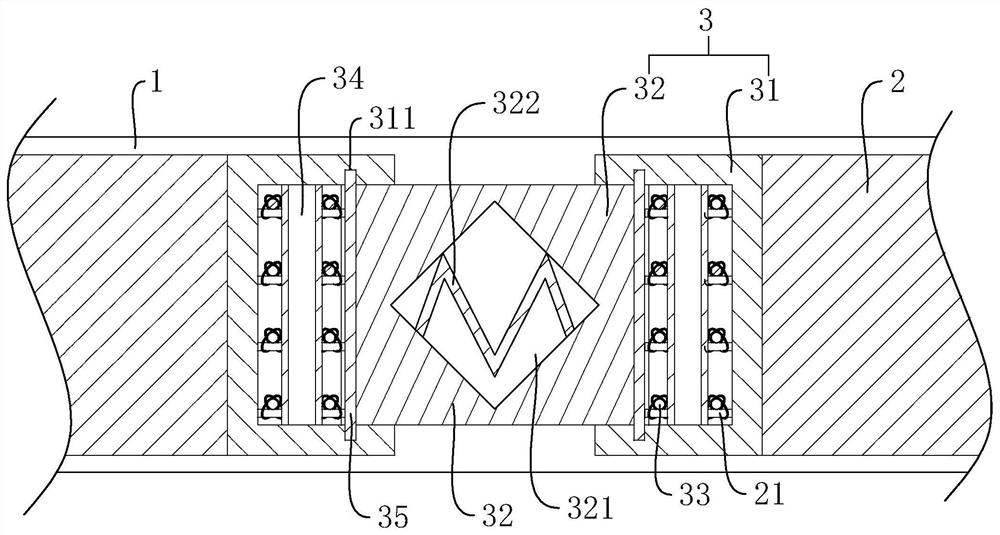

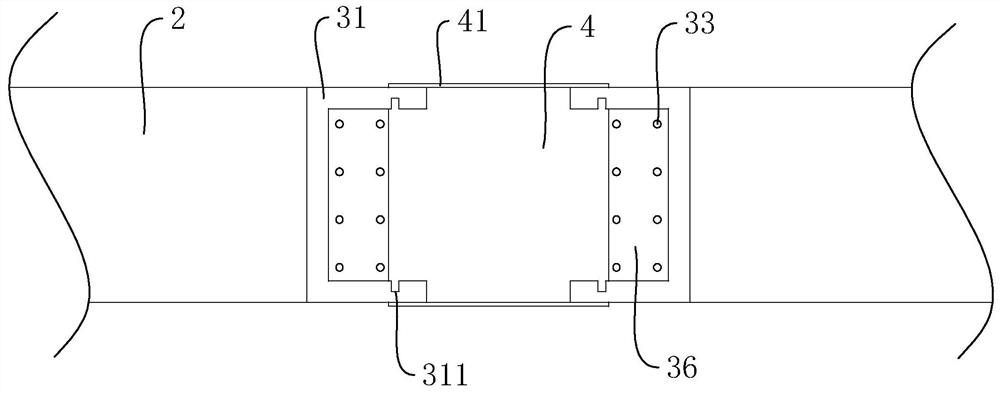

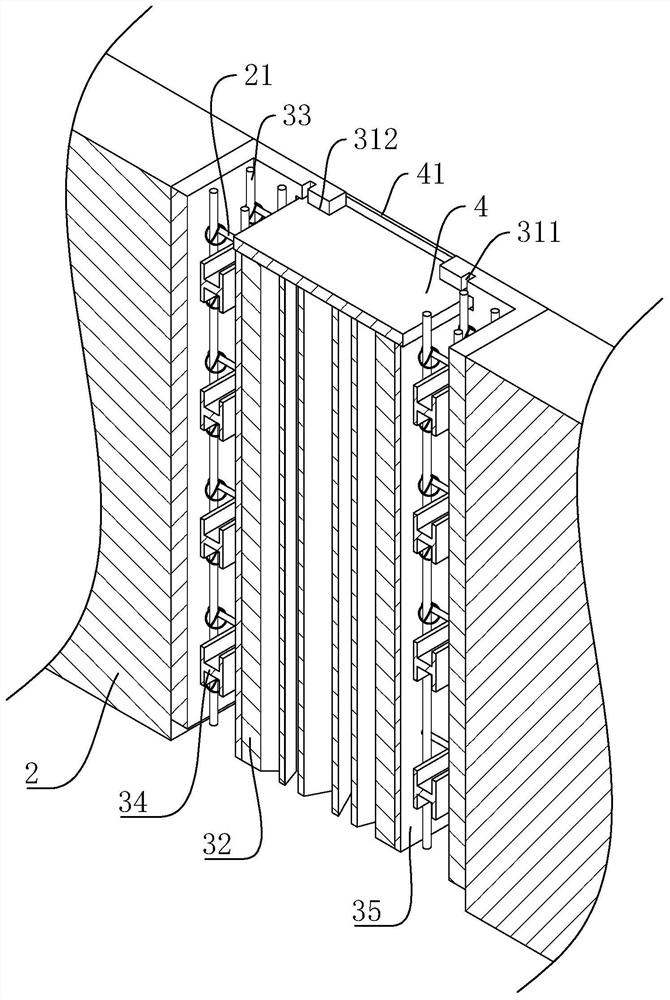

[0042] Embodiment 1: A kind of prefabricated underground diaphragm wall, refer to figure 1 , including the installation channel 1 opened on the ground, several continuous wall units 2 are placed in sequence in the installation channel 1, and a telescopic assembly 3 is sandwiched between two adjacent continuous wall units 2. The telescopic assembly 3 includes two installation Plate 31 and a telescopic rubber strip 32, two mounting plates 31 are attached to the opposite side walls of adjacent continuous wall units 2. The stretchable rubber strip 32 has elastic force and can produce corresponding changes according to the change of the gap between two adjacent continuous wall units 2 , so that the space between two adjacent continuous wall units 2 is always kept in a filled state.

[0043] refer to figure 1 , the transverse cross-sectional view of the mounting plate 31 is "U" shape, the opening of the mounting plate 31 faces the telescopic rubber strip 32, and the telescopic rubb...

Embodiment 2

[0048] Embodiment 2: a kind of construction method that is used for prefabricated underground diaphragm wall, its specific steps are as follows:

[0049] S1. Use an excavator to excavate and install the canal 1, and the side wall of the installation canal 1 is supported by supporting steel bars. When excavating, it should be ensured that the side wall of the installation channel 1 is vertical and the bottom is horizontal;

[0050] S2. Before hoisting the continuous wall unit 2, attach the installation plate 31 to the continuous wall unit 2. During the installation process, the reinforcement anchor bar 21 should pass through the installation plate 31, and then vertically place a strong steel bar 33 inside the installation plate 31 , the joint between the strong steel bar 33 and the reinforcement anchor bar 21 is wound and tightened by steel wire;

[0051] S3, after the installation of the reinforced anchor bar 21 and the strong steel bar 33 is completed, place the support stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com