Patents

Literature

37results about How to "Reduce dishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

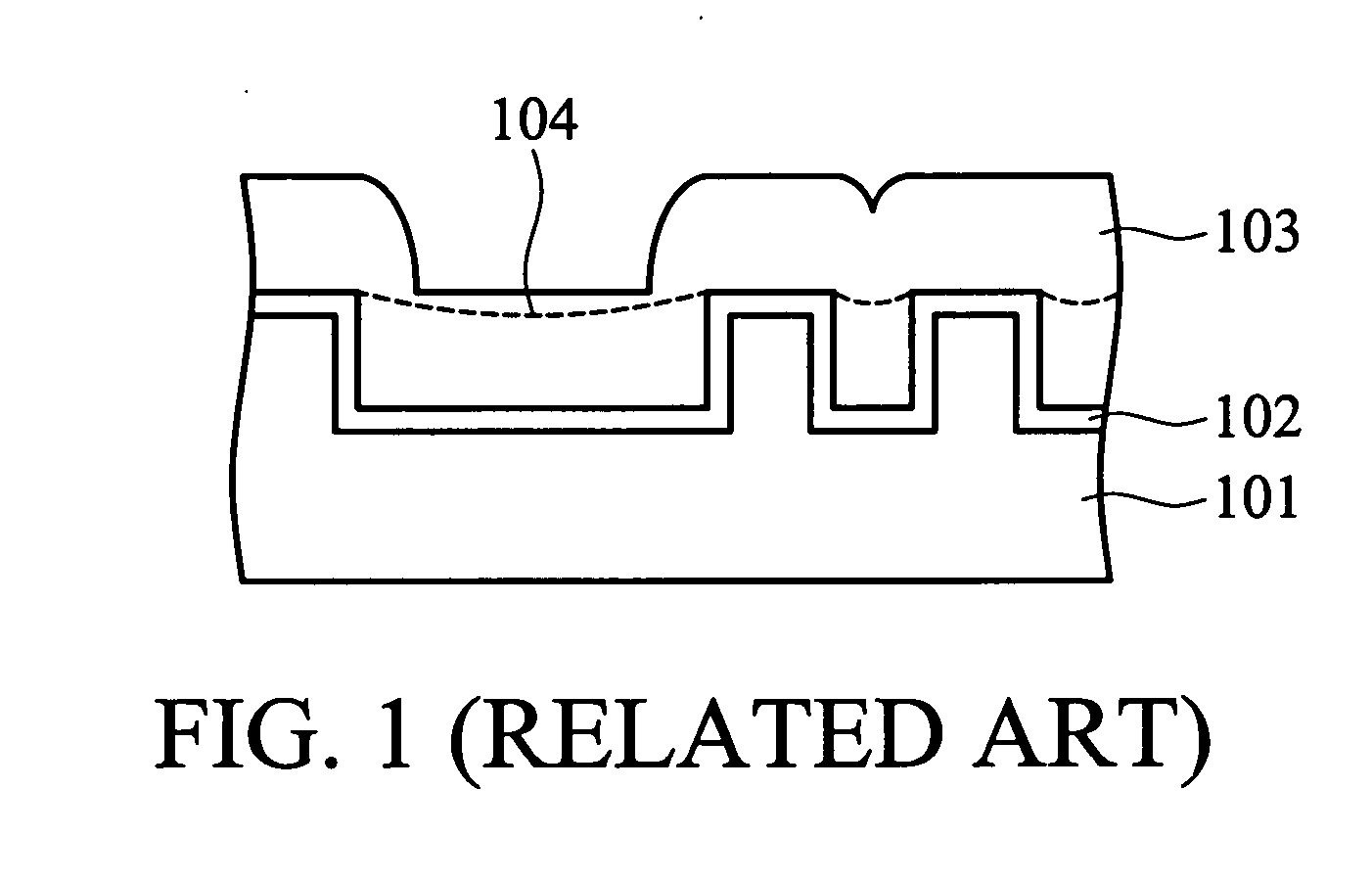

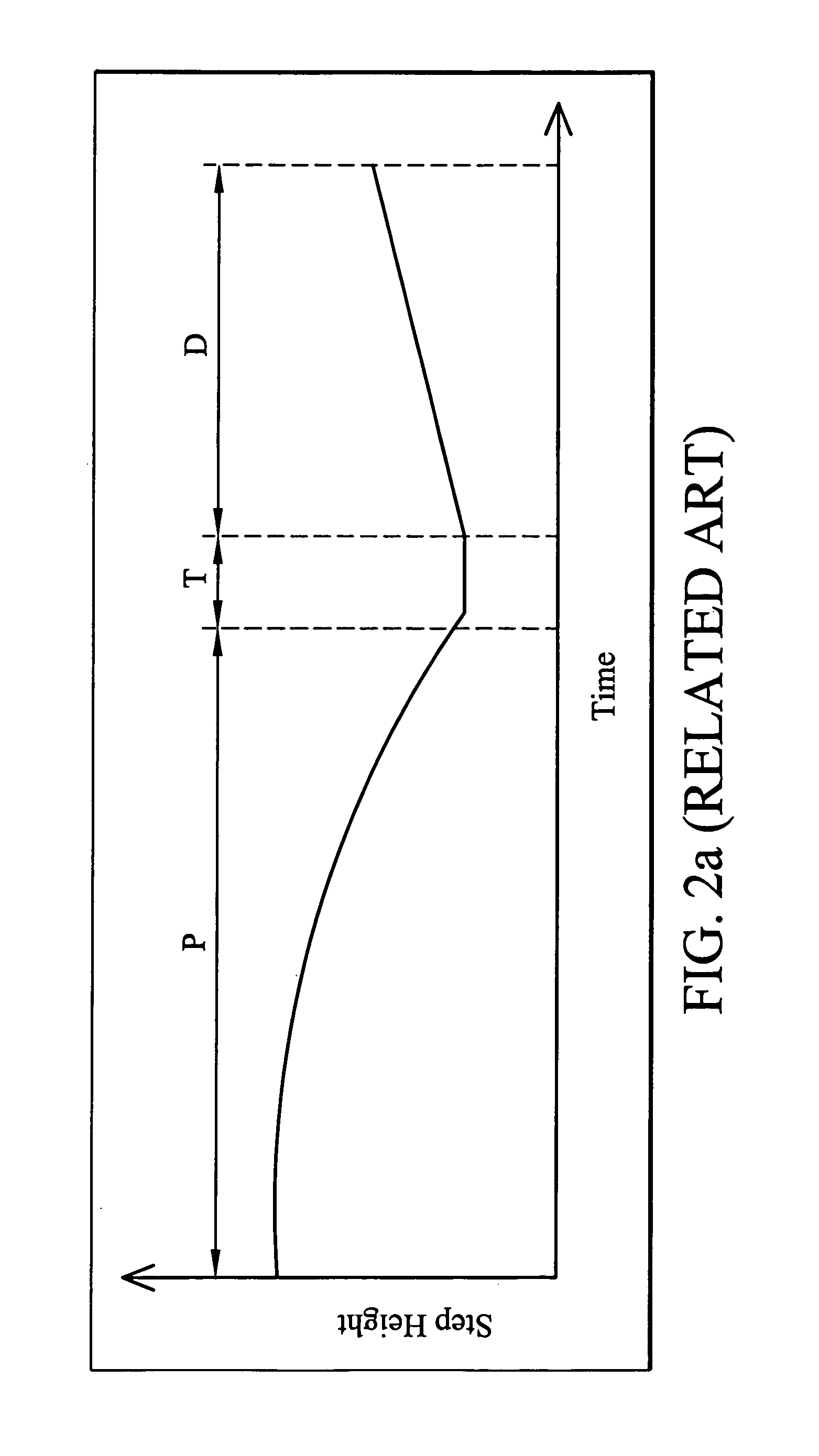

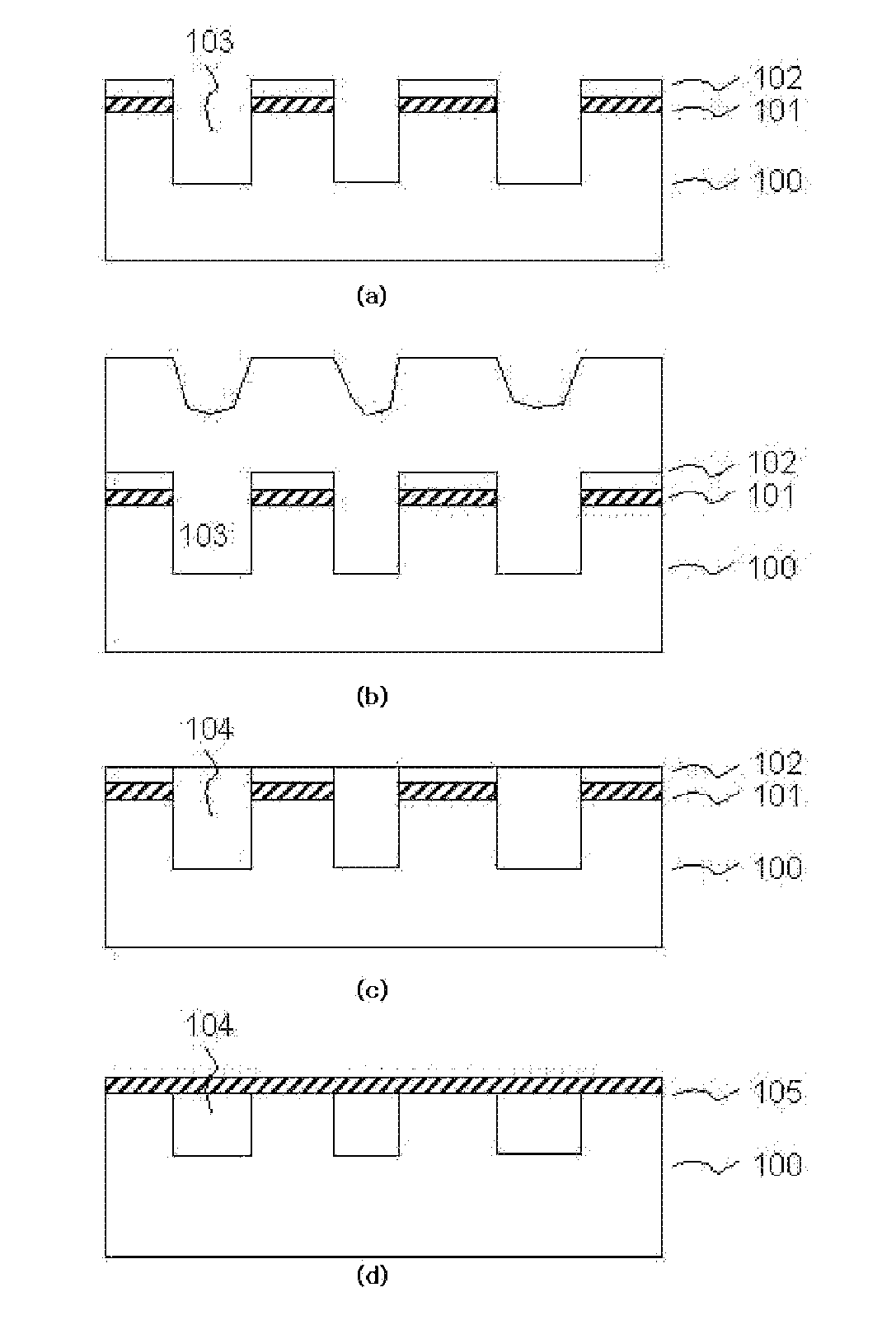

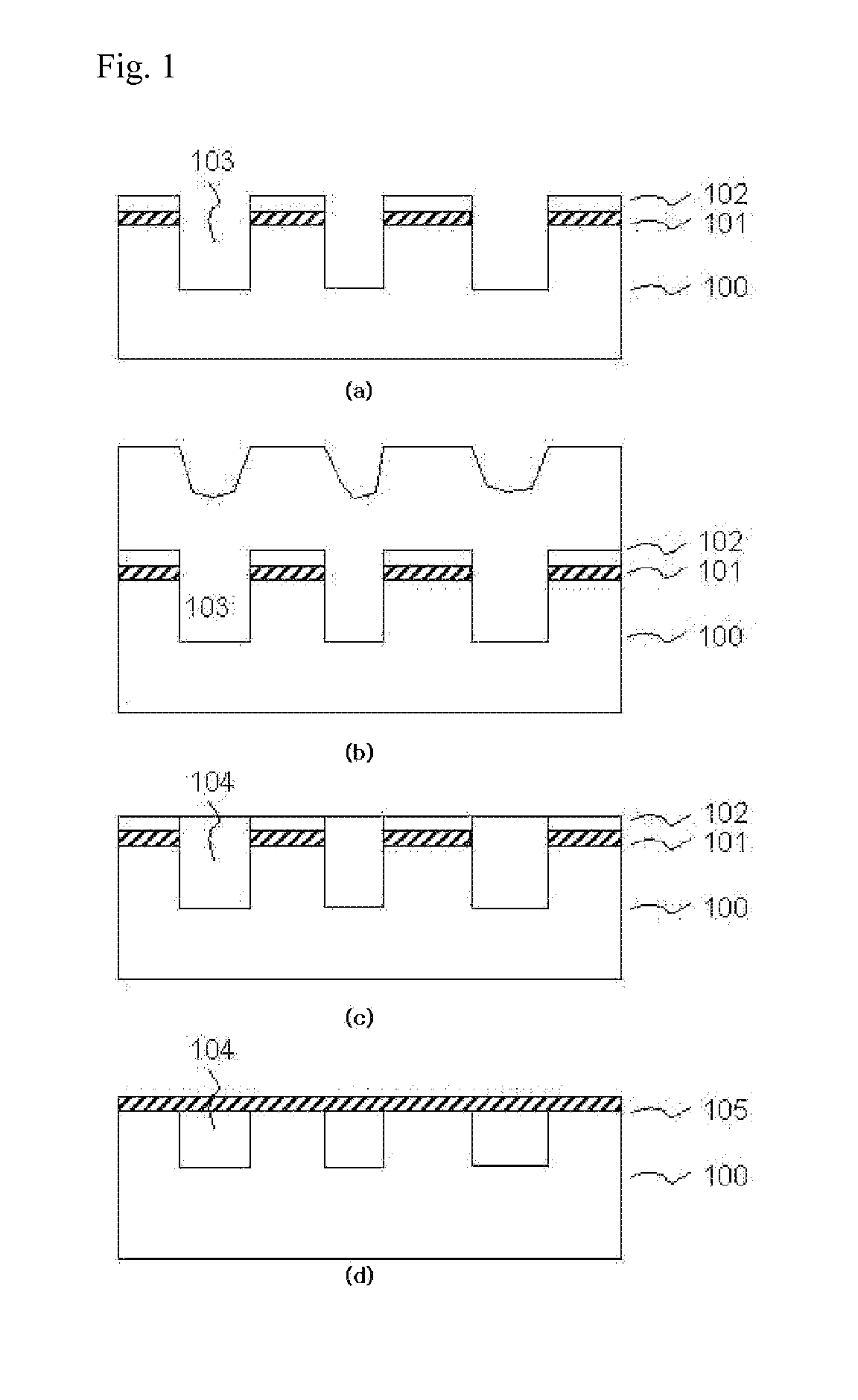

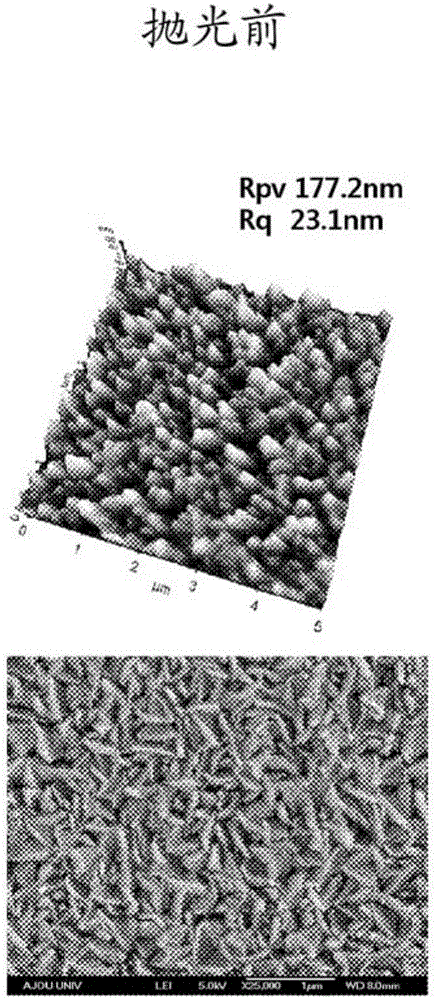

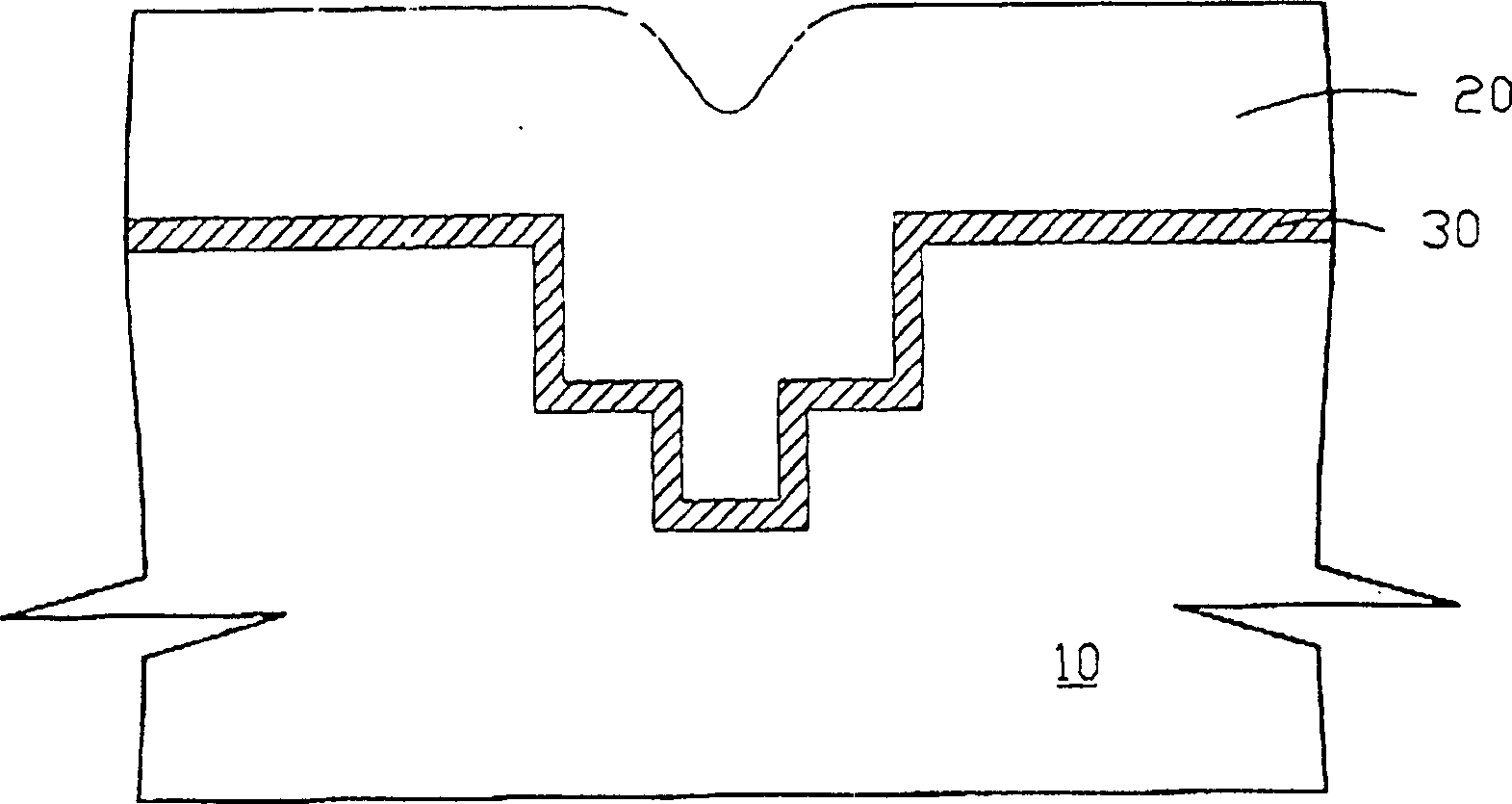

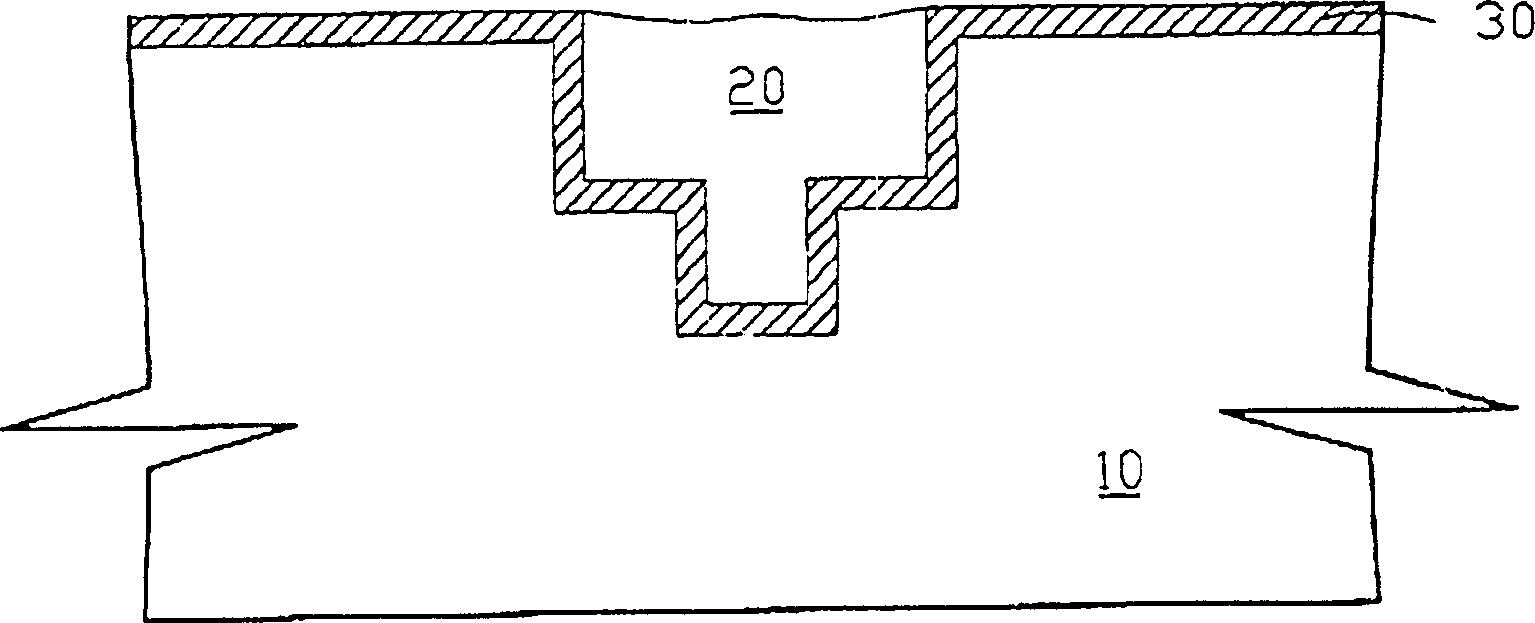

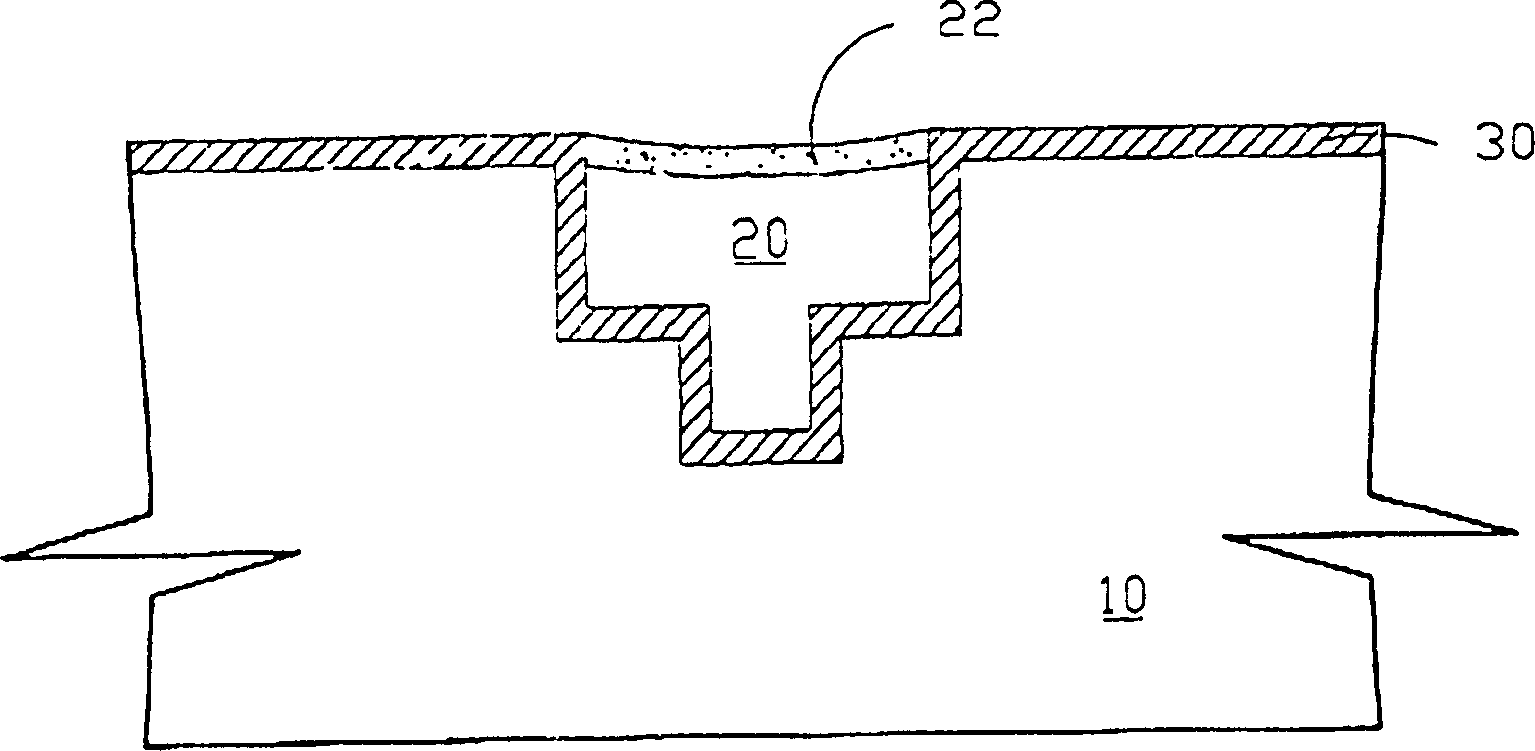

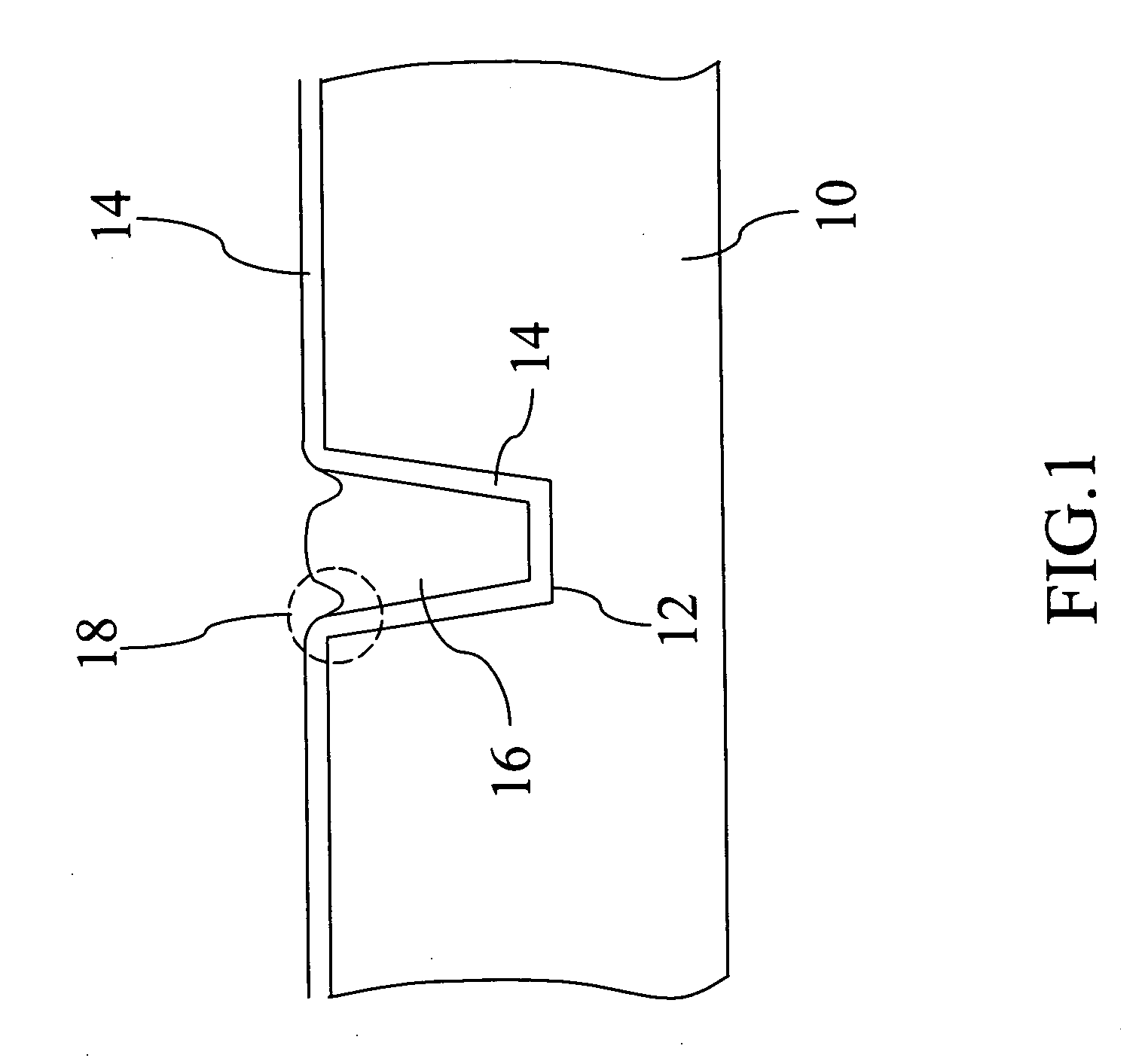

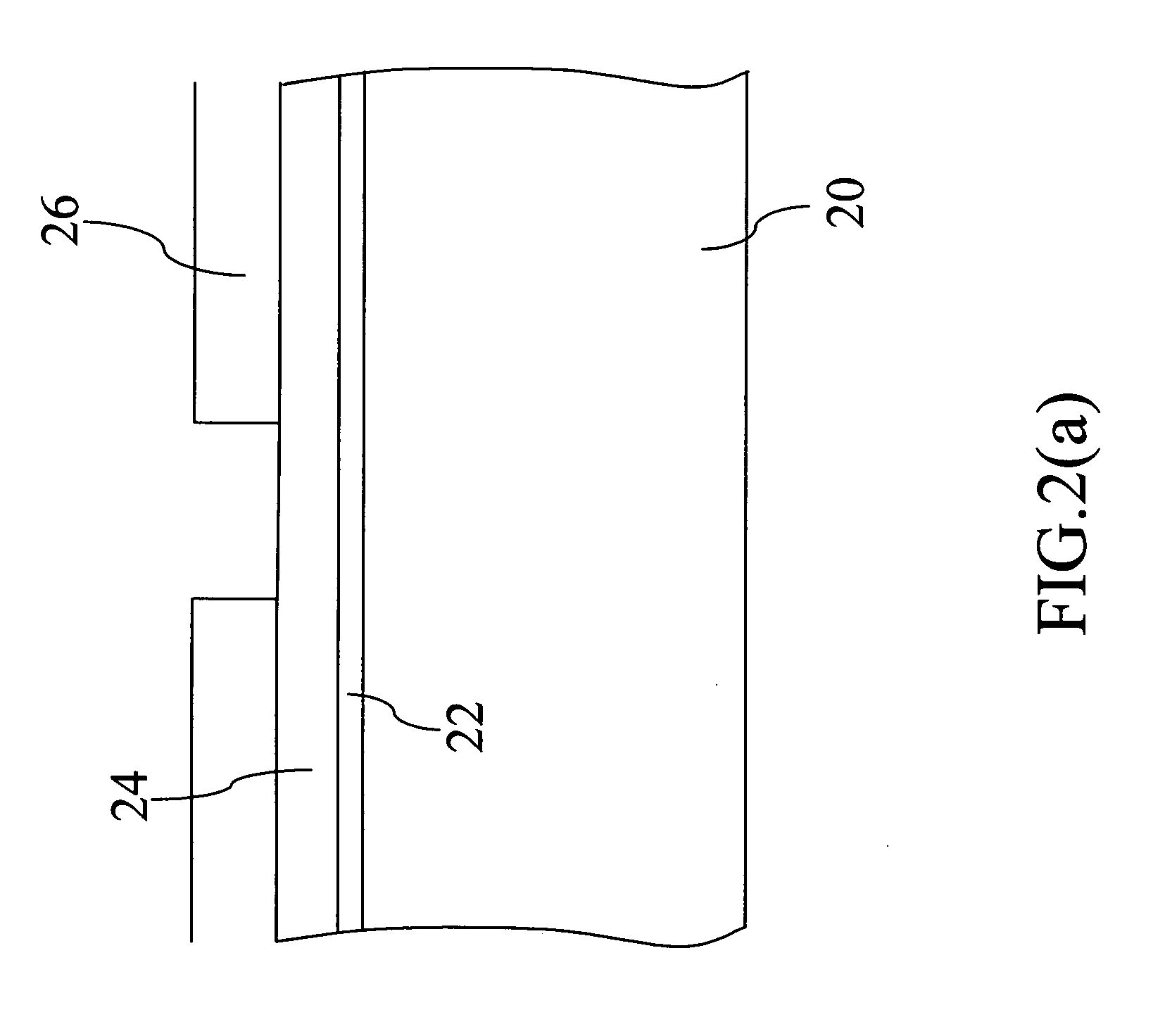

Method of reducing the pattern effect in the CMP process

InactiveUS20050118808A1Improves end-point detecting functionExtended durationSemiconductor/solid-state device manufacturingStep heightDielectric layer

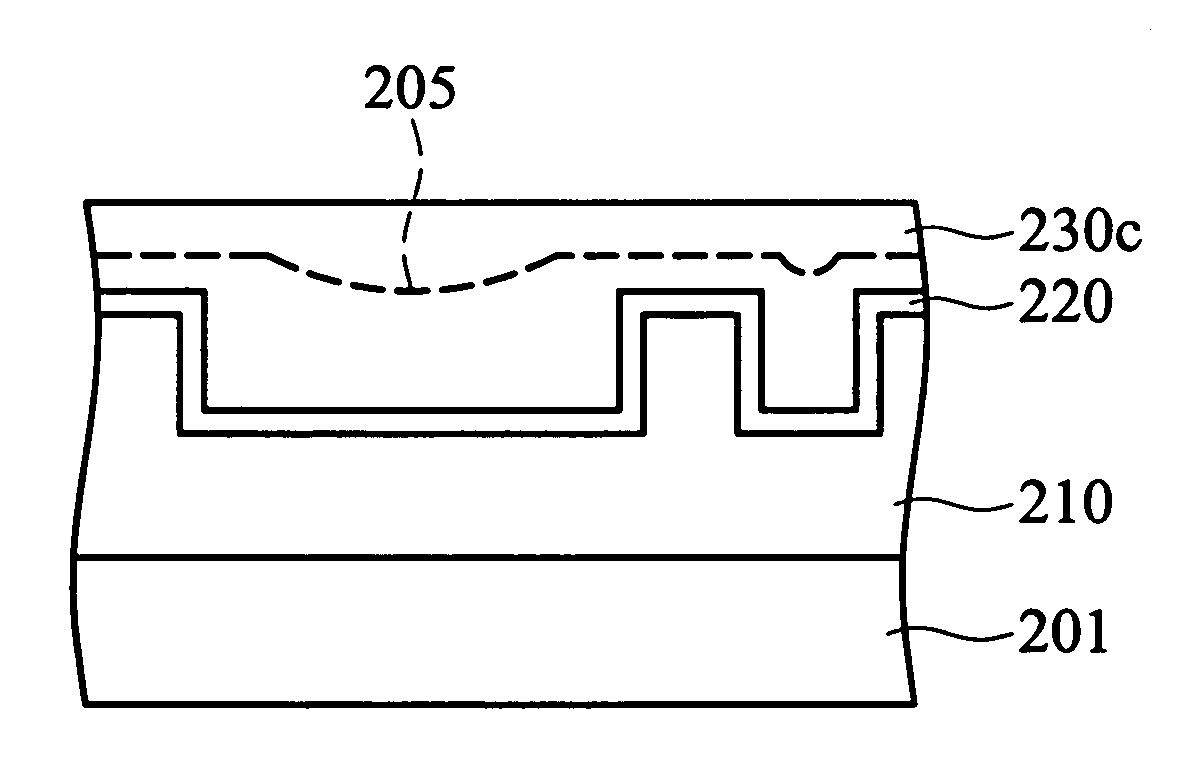

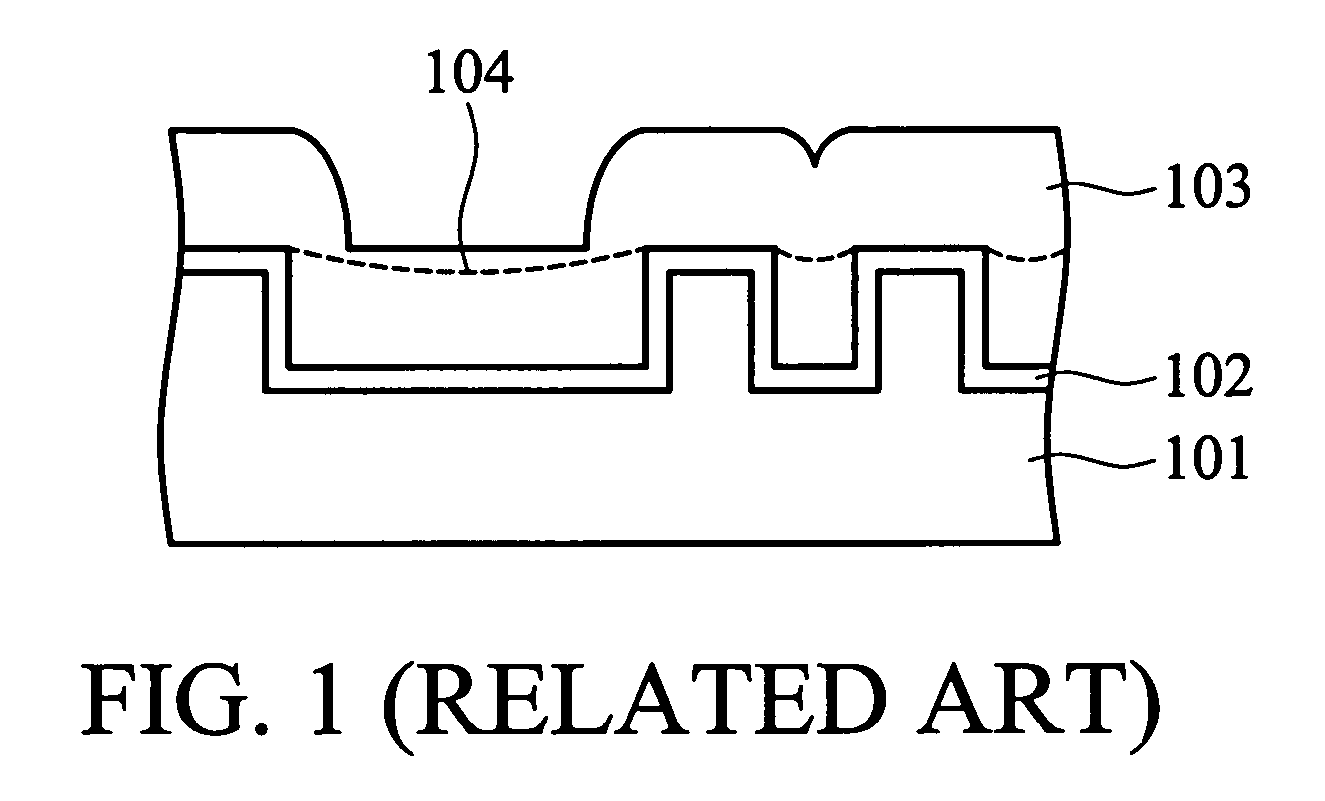

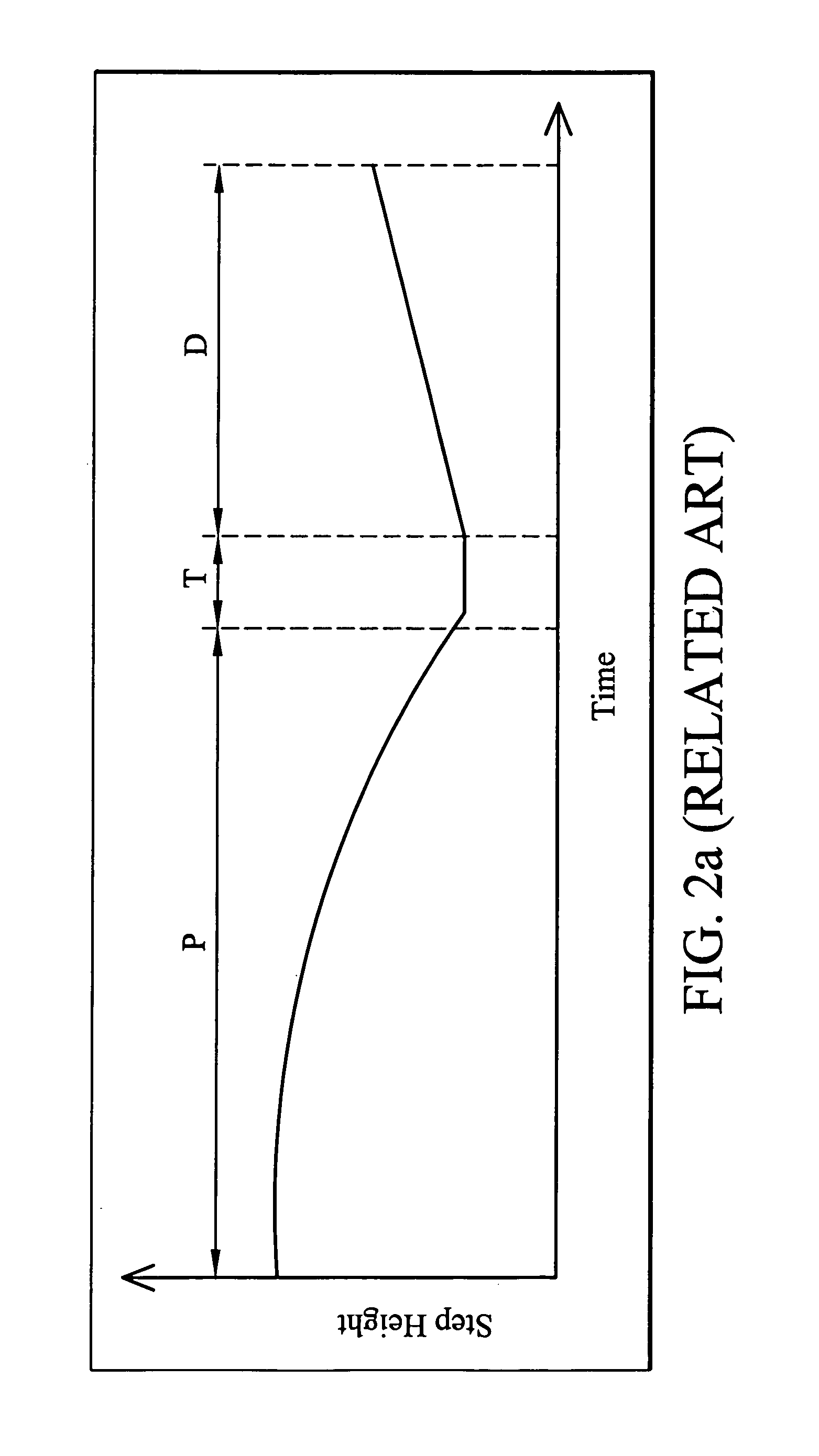

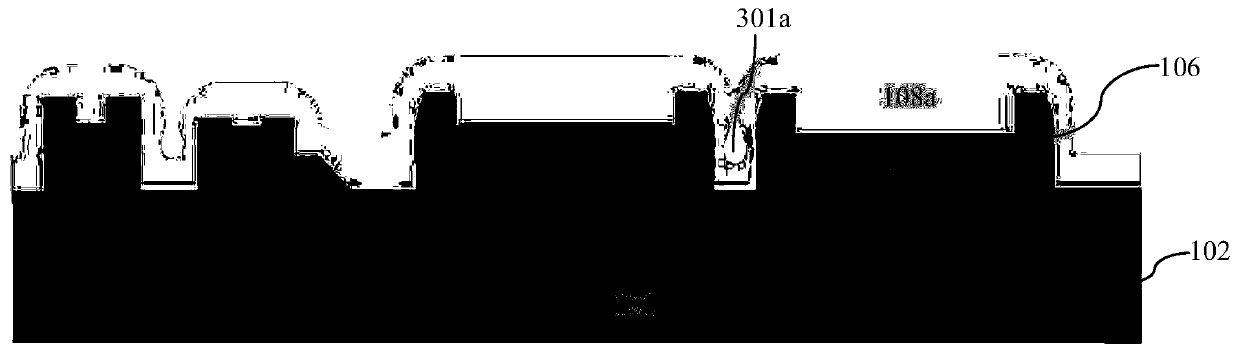

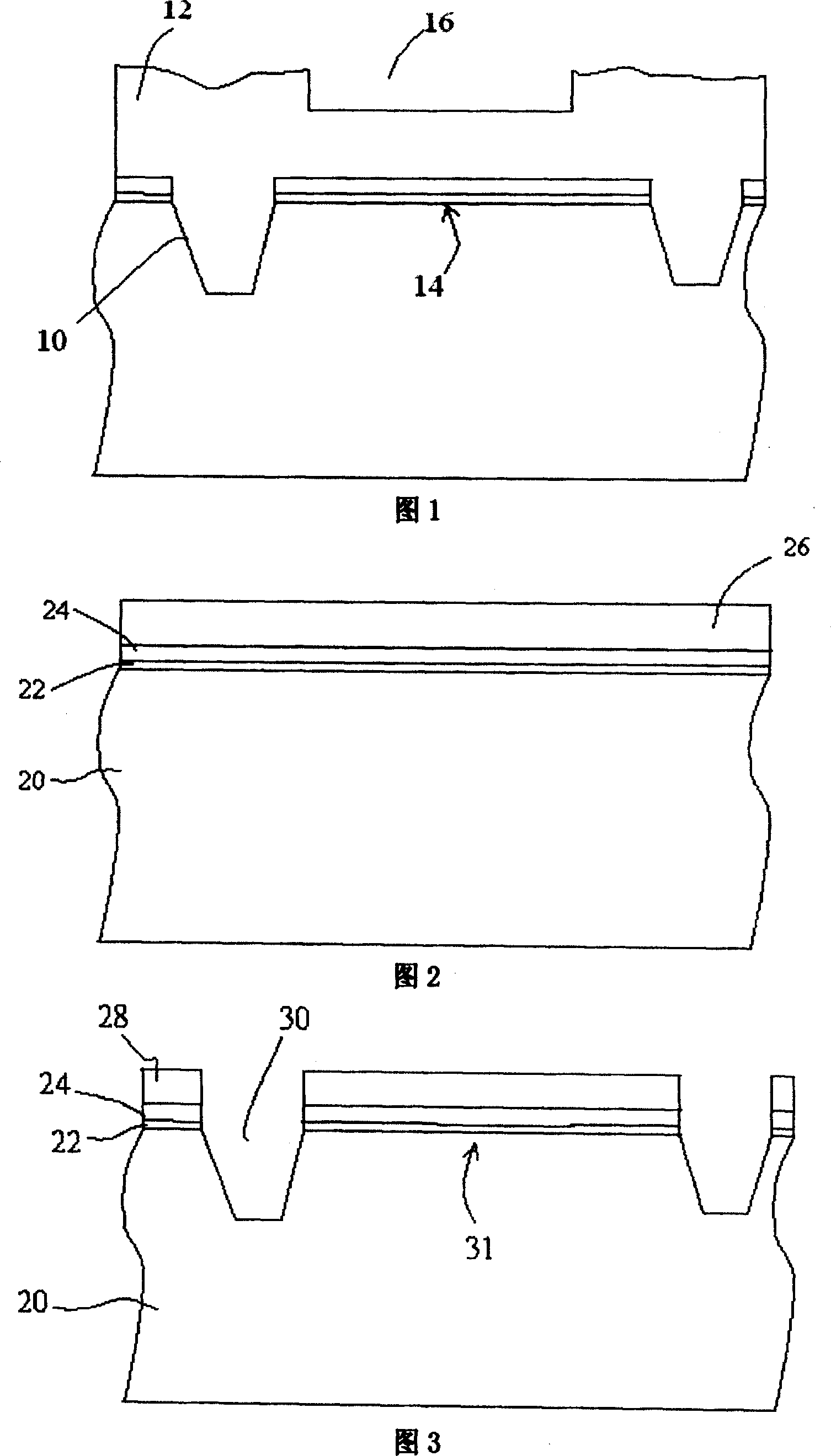

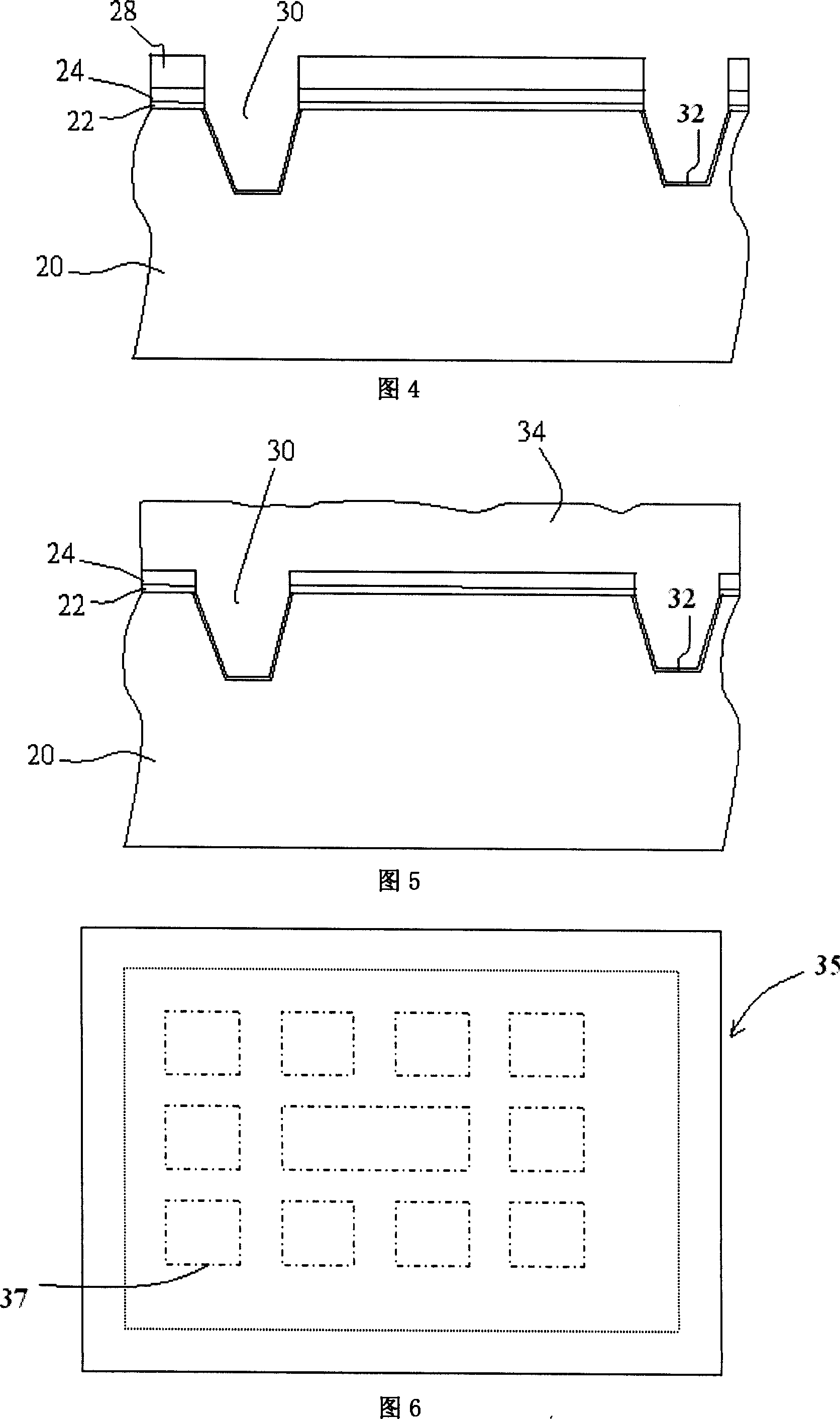

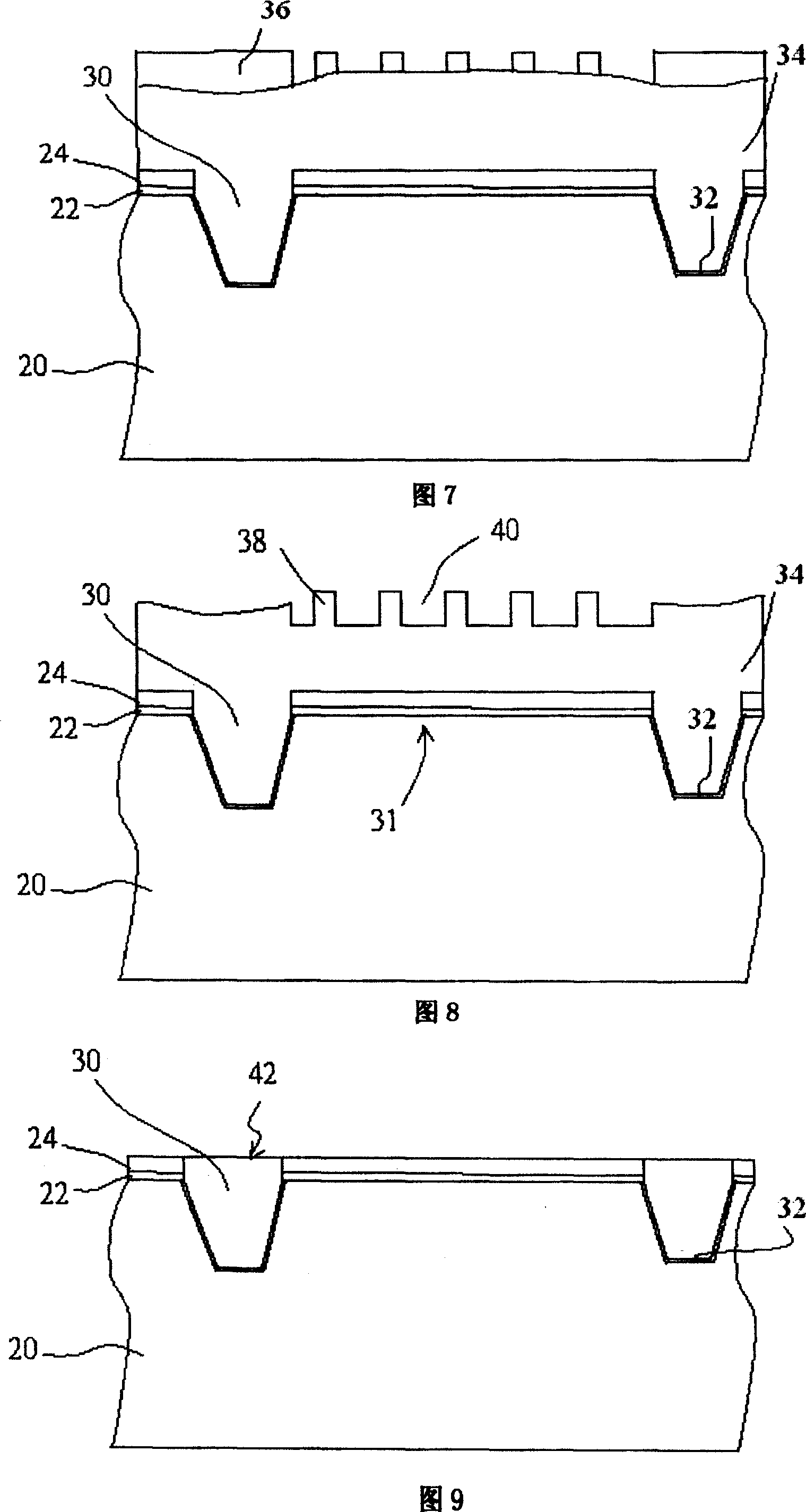

A method of reducing the pattern effect in the CMP process. The method comprises the steps of providing a semiconductor substrate having a patterned dielectric layer, a barrier layer on the patterned dielectric layer, and a conductive layer on the barrier layer; performing a first CMP process to remove part of the conductive layer before the barrier layer is polished, thereby a step height of the conductive layer is reduced; depositing a layer of material substantially the same as the conductive layer on the conductive layer; and performing a second CMP process to expose the dielectric layer. A method of eliminating the dishing phenomena after a CMP process and a CMP rework method are also provided.

Owner:TAIWAN SEMICON MFG CO LTD

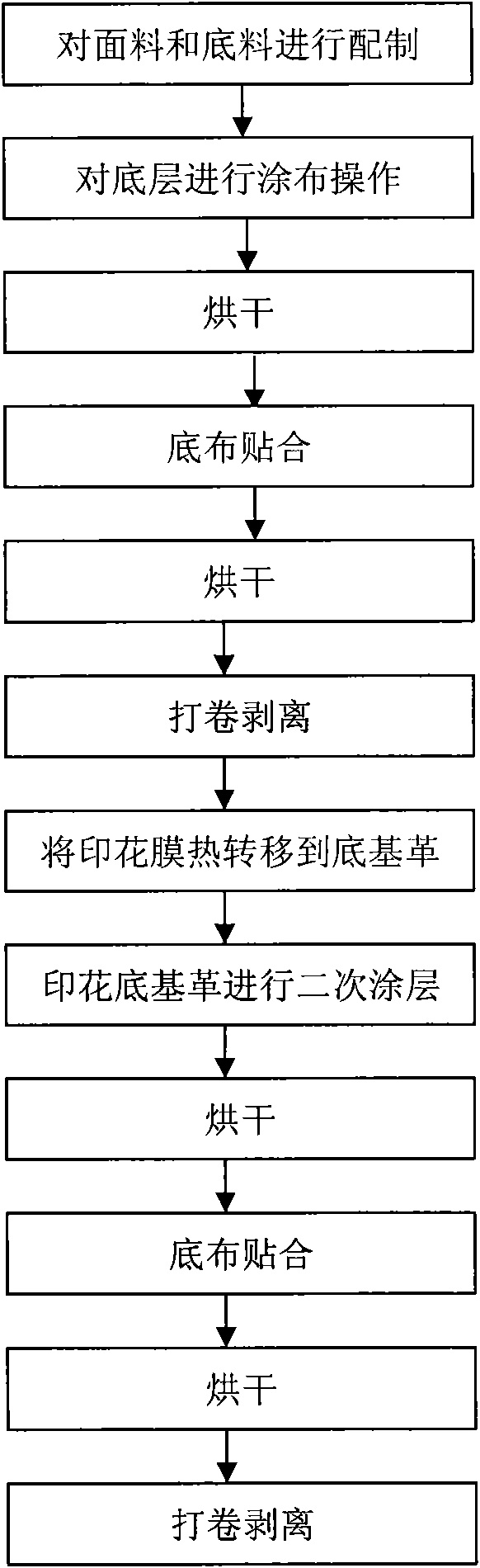

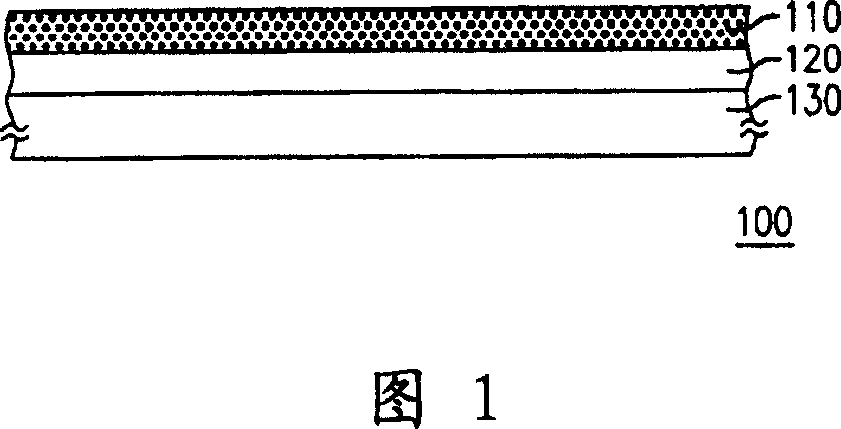

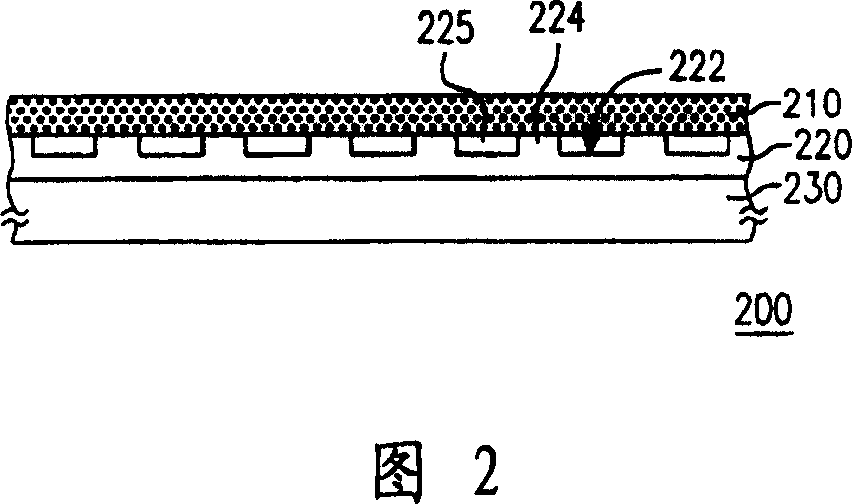

Novel PU printing waterproof and anti-crease fabric and preparation method thereof

InactiveCN101660277AImprove the three-dimensional effectRemove tensionSynthetic resin layered productsDyeing processDisperse dyeAlcohol

The invention discloses a novel PU printing waterproof and anti-crease new fabric, which comprises three layers: the first layer is PU surface layer mainly comprising PU polyurethane; the second layeris printing dyes; the third layer is a PU surface layer mainly comprising PU polyurethane. The printing dyes in the second layer are ink disperse dyes made of disperse dyes and water-soluble carrier,or ink disperse dyes made of the disperse dyes and alcohol-soluble carrier, or ink disperse dyes made of the disperse dyes and oil-soluble resin. The invention also discloses a method for preparing the novel PU printing waterproof and anti-crease fabric, comprising the following steps: firstly, preparing a shell fabric and a backing material; secondly, carrying out coating operation; thirdly, performing the backing lamination; fourthly, drying, rolling and stripping; fifthly, thermally transferring a printing film to base leather; and sixthly, performing the secondary coating on the printingbase leather. The novel PU printing waterproof, anti-crease fabric has advantages of terrific tensile strength and hydrostatic pressure, and is durable in use, fastness to washing, colorfast; and thepreparation method is easy to operate.

Owner:仪征新天地织物面料实业有限公司

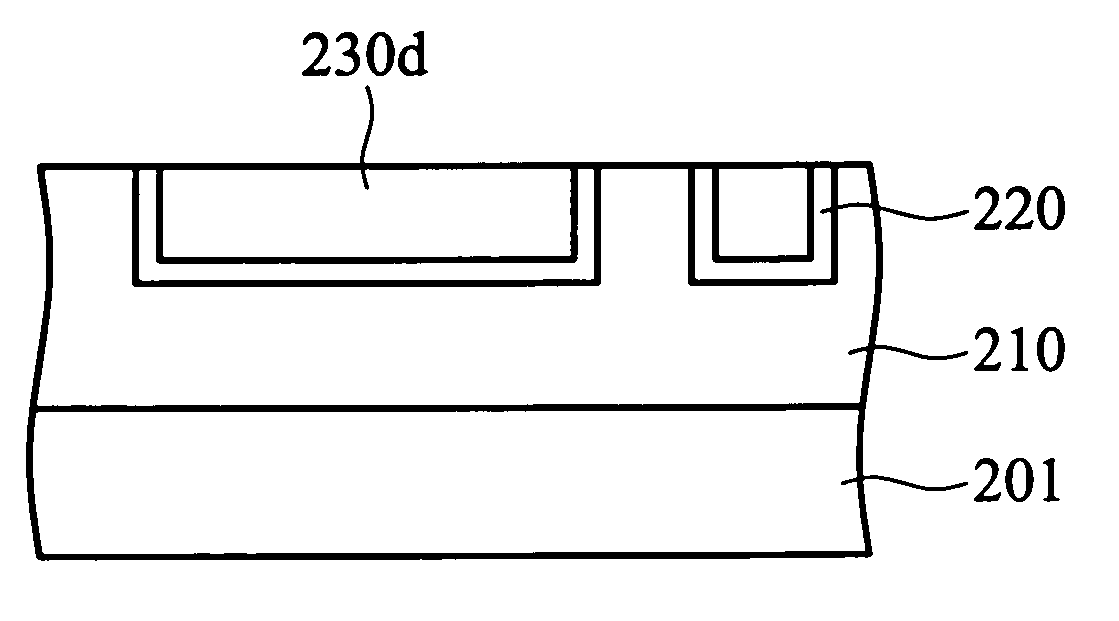

Method of reducing the pattern effect in the CMP process

InactiveUS7183199B2Improves end-point detecting functionReduce dishingSemiconductor/solid-state device manufacturingStep heightDielectric layer

A method of reducing the pattern effect in the CMP process. The method comprises the steps of providing a semiconductor substrate having a patterned dielectric layer, a barrier layer on the patterned dielectric layer, and a conductive layer on the barrier layer; performing a first CMP process to remove part of the conductive layer before the barrier layer is polished, thereby a step height of the conductive layer is reduced; depositing a layer of material substantially the same as the conductive layer on the conductive layer; and performing a second CMP process to expose the dielectric layer. A method of eliminating the dishing phenomena after a CMP process and a CMP rework method are also provided.

Owner:TAIWAN SEMICON MFG CO LTD

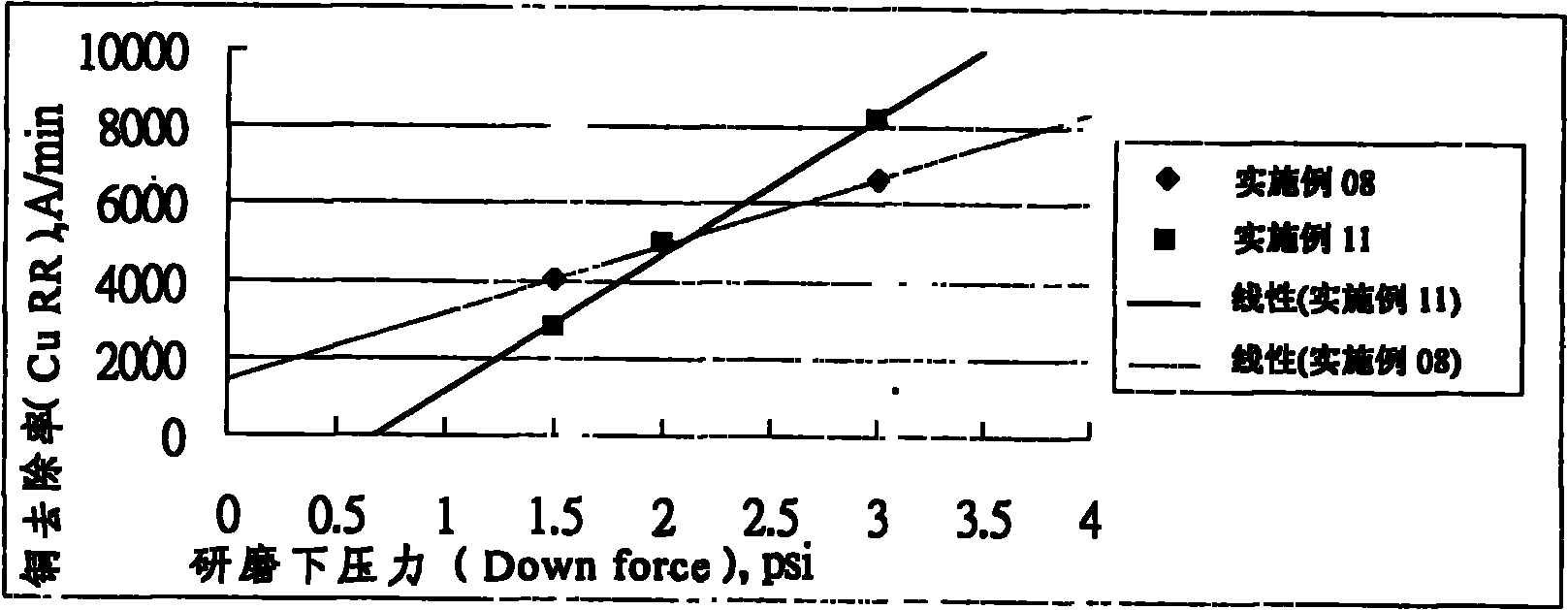

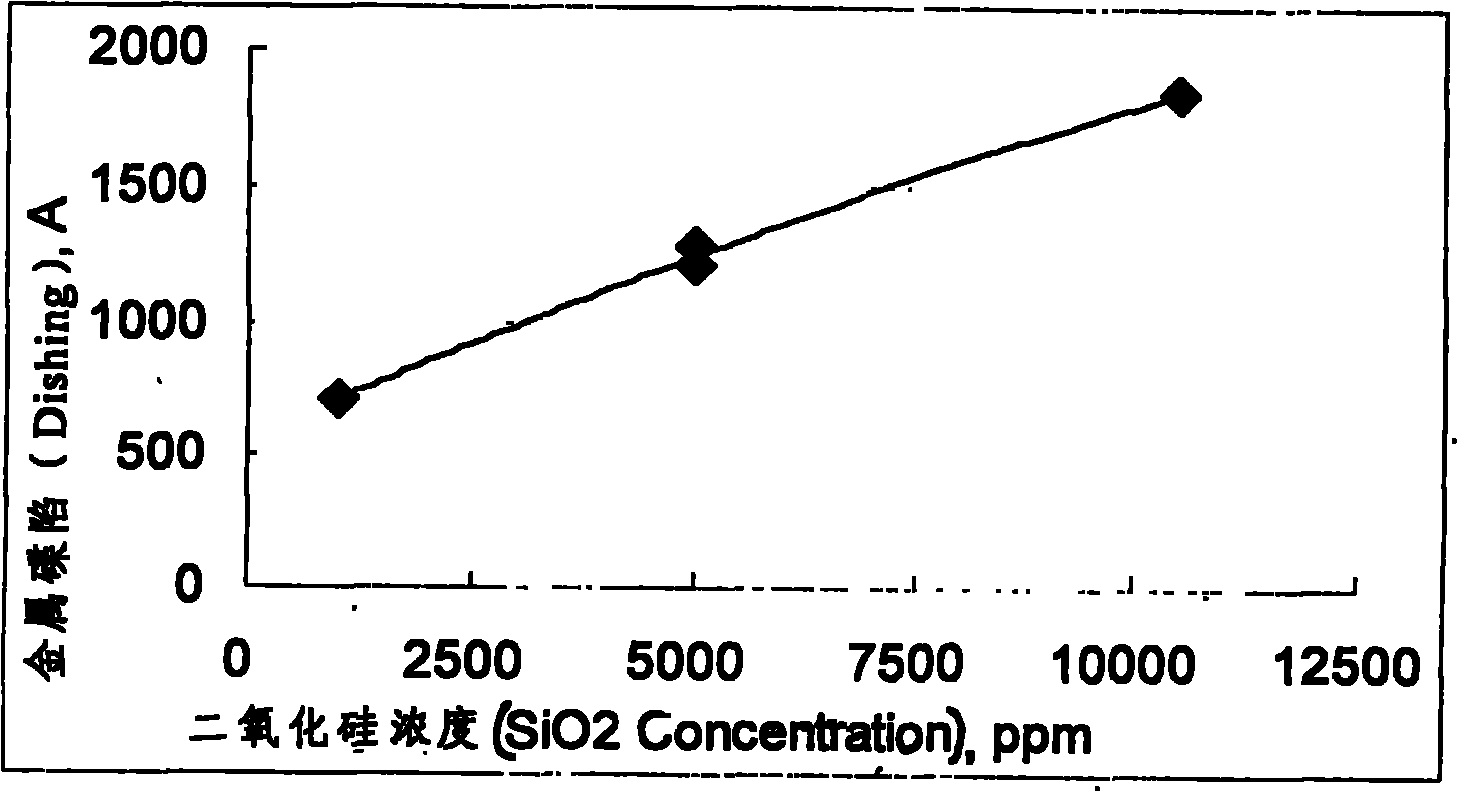

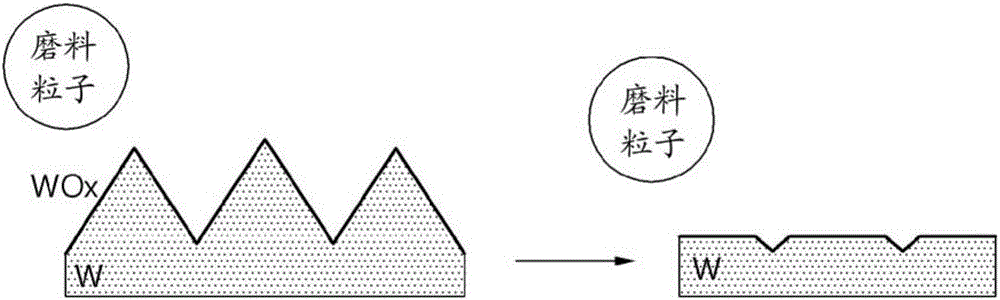

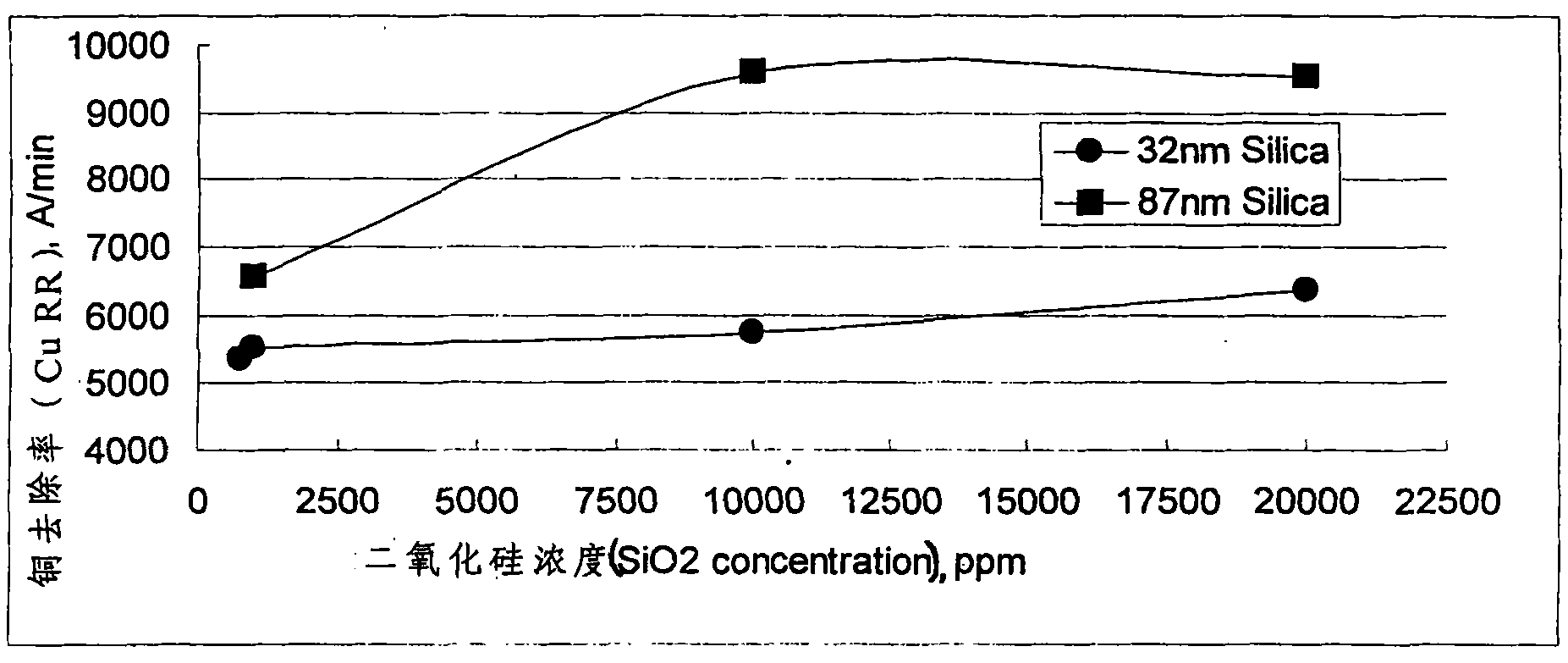

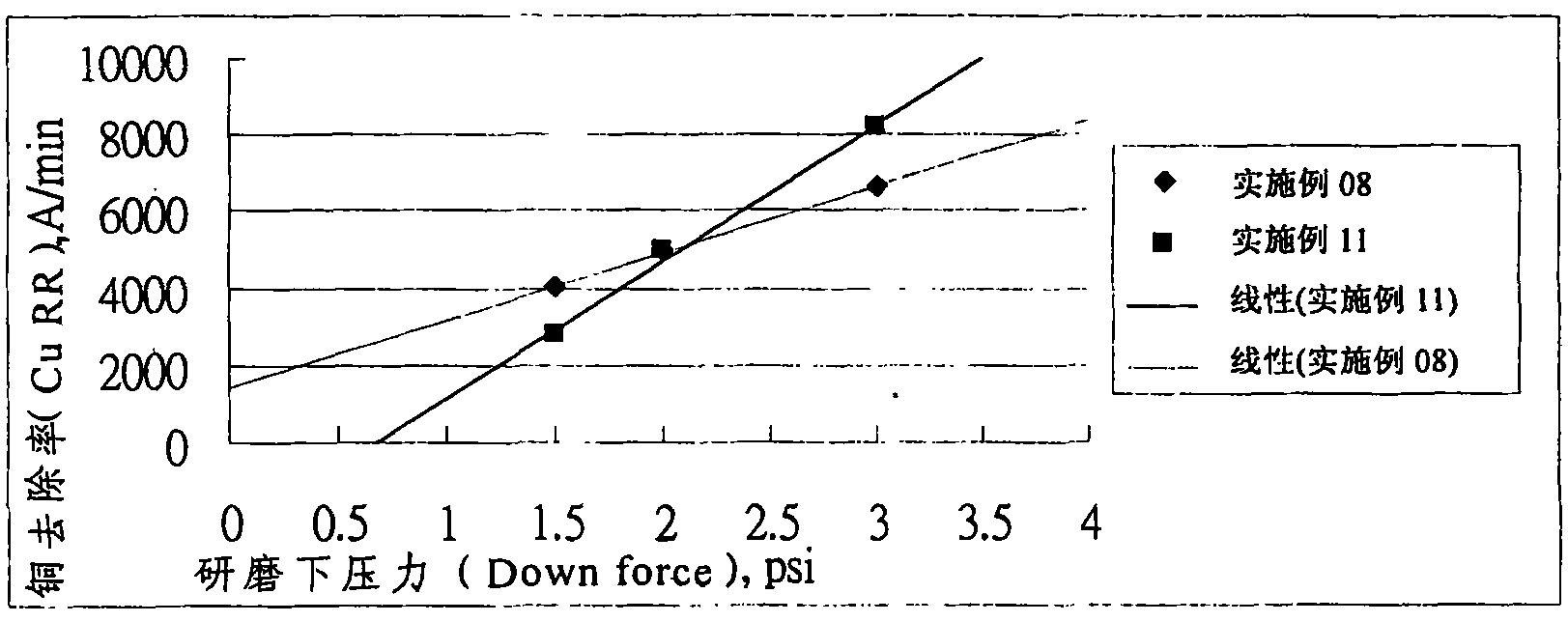

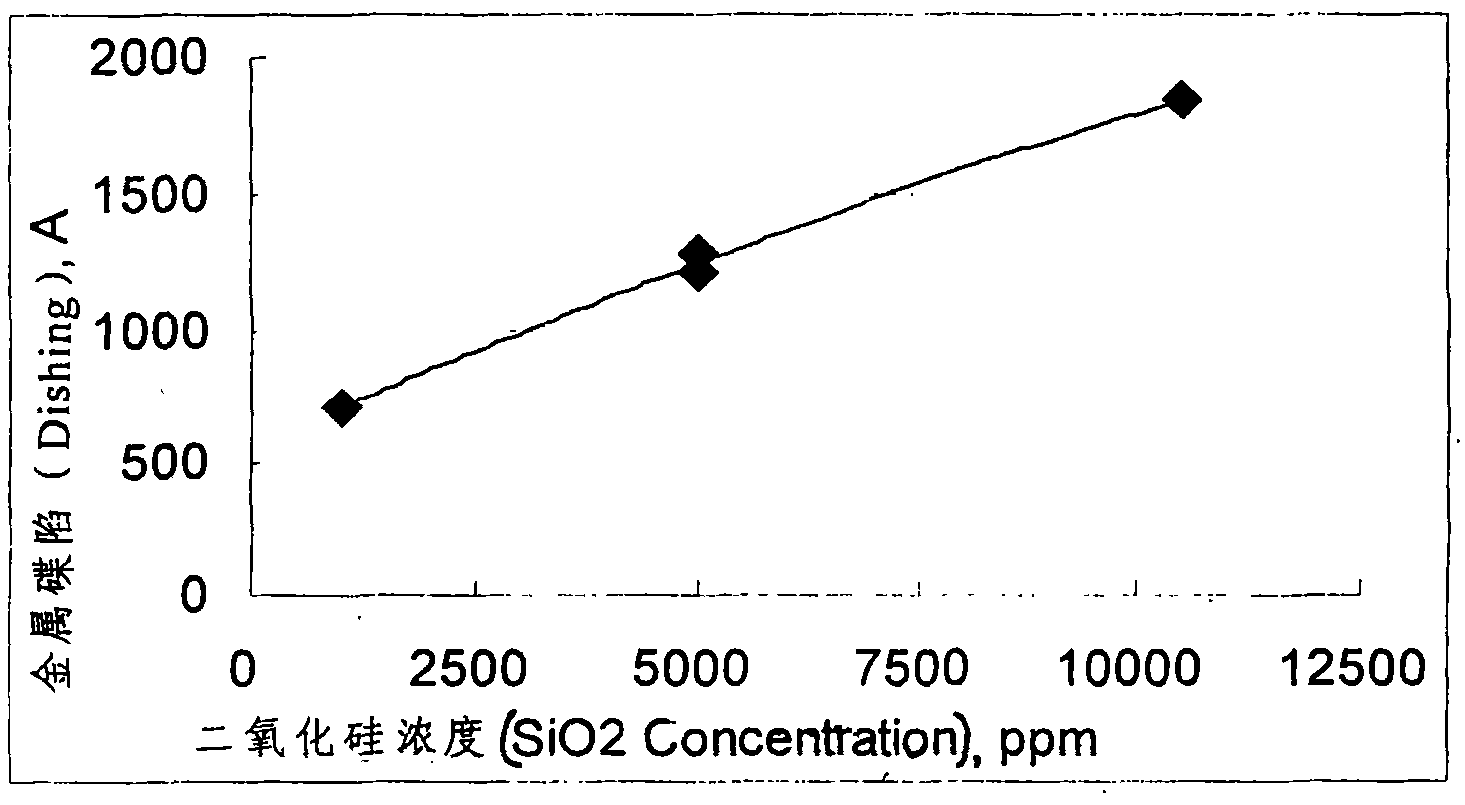

Grinding composite for planarization metal layer

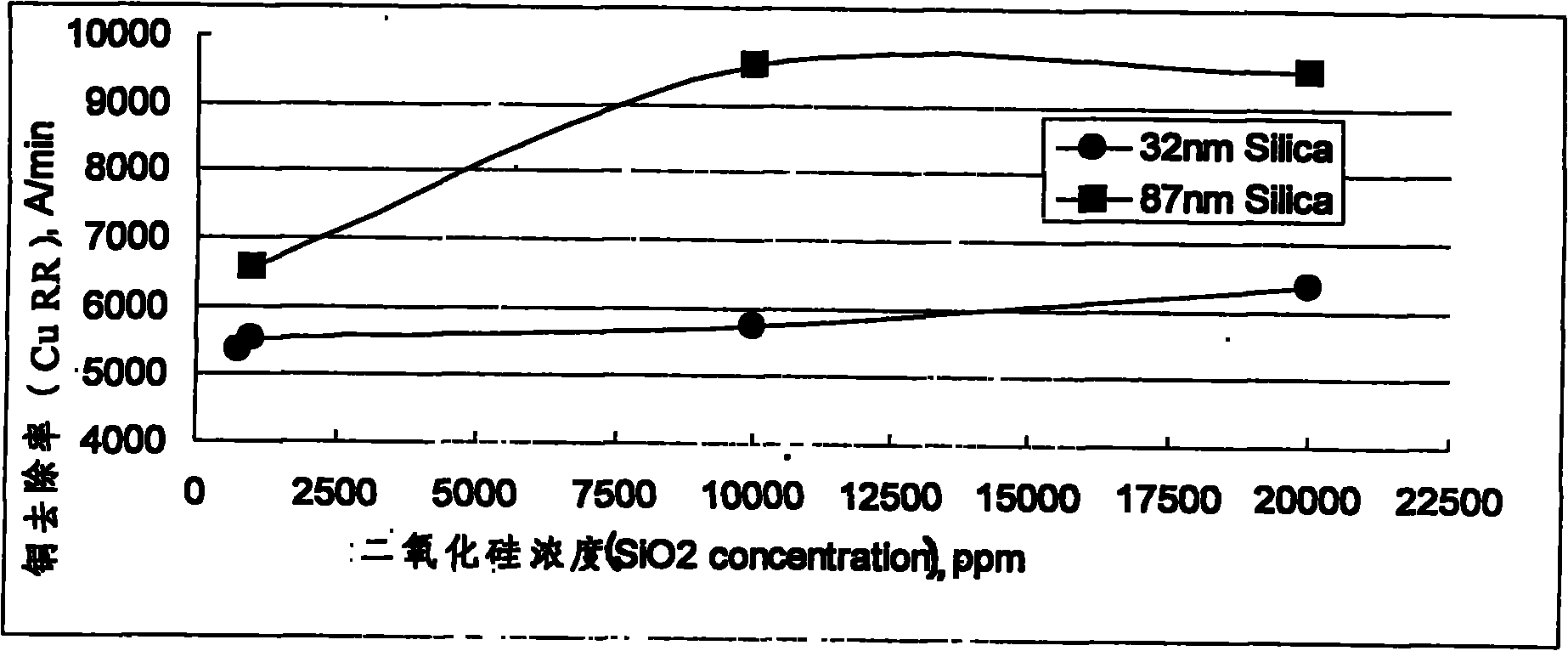

ActiveCN101928520AHigh grinding removal rateReduce dishingPolishing compositions with abrasivesEtchingMaterials science

The invention discloses a grinding composite for planarization metal layer. The grinding composite at least comprises 7,500ppm to less than 5,000ppm by weight of gridding granules, hydrogen peroxide, accelerator, co-corrosion inhibitor and water, wherein the co-corrosion inhibitor comprises a first corrosion inhibitor and a second corrosion inhibitor, and the co-corrosion inhibitor is applied to the planarization metal layer. The composite is capable of maintaining a high grinding removing rate for the metal layer and inhibiting metallic etching; moreover, the composite is capable of reducing gridding deficiencies including dish down, abrasion and the like.

Owner:UWIZ TECH

Cmp slurry and a polishing method using the same

ActiveUS20110008967A1Reduce dishingReduce saggingOther chemical processesSemiconductor/solid-state device manufacturingPhosphoric acidSilicon nitride

The present invention relates to a CMP slurry that is able to reduce dishing generation, when it is applied to polishing or planarization of silicon oxide layer, for example, and a polishing method.The CMP slurry includes a polishing abrasive, a linear anionic polymer, a compound including a phosphoric acid group, and water, and the ratio of CMP polishing speed to a silicon oxide layer: CMP polishing speed to a silicon nitride layer is 30:1 to 50:1.

Owner:LG CHEM LTD

Chemical mechanical polishing composition

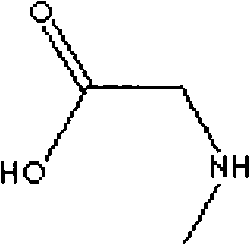

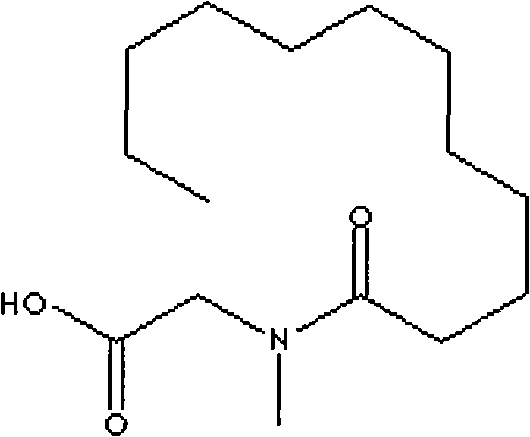

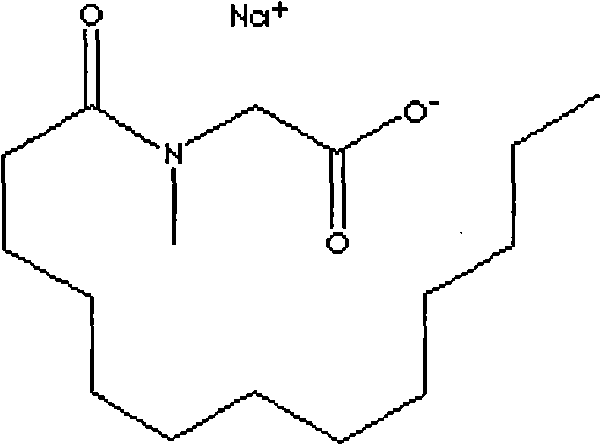

ActiveCN101580700AHigh grinding removal rateInhibit etch rateOrganic chemistryOther chemical processesEtchingCompound (substance)

The invention relates to a chemical mechanical polishing composition, in particular to an inhibitor composition which at least contains an imidazoline compound or a triazole compound or a composition of the imidazoline compound and the triazole compound, sarcosine and a salt compound thereof or a composition of the sarcosine and the salt compound thereof. The inhibitor composition is applied to chemical mechanical polishing, can maintain the high polishing removal rate of a metal layer, has the characteristic of metal etching inhibition and can reduce the polishing defects of dish down, ablation, and the like.

Owner:UWIZ TECH

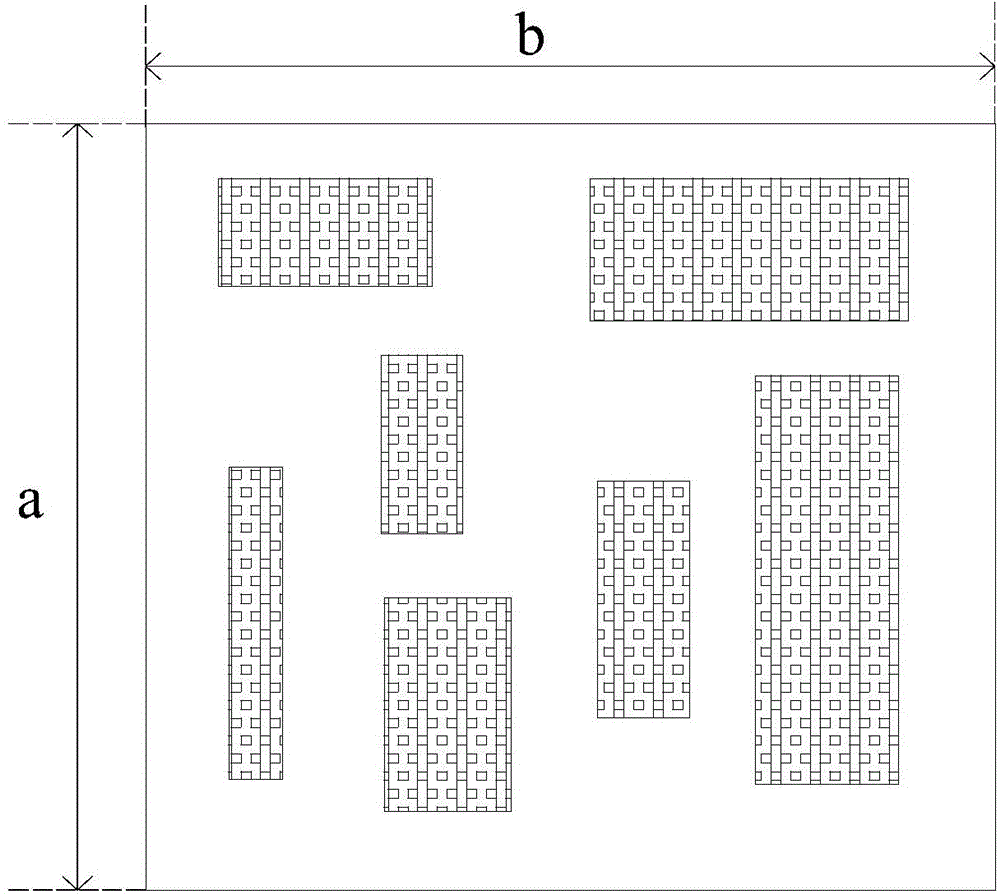

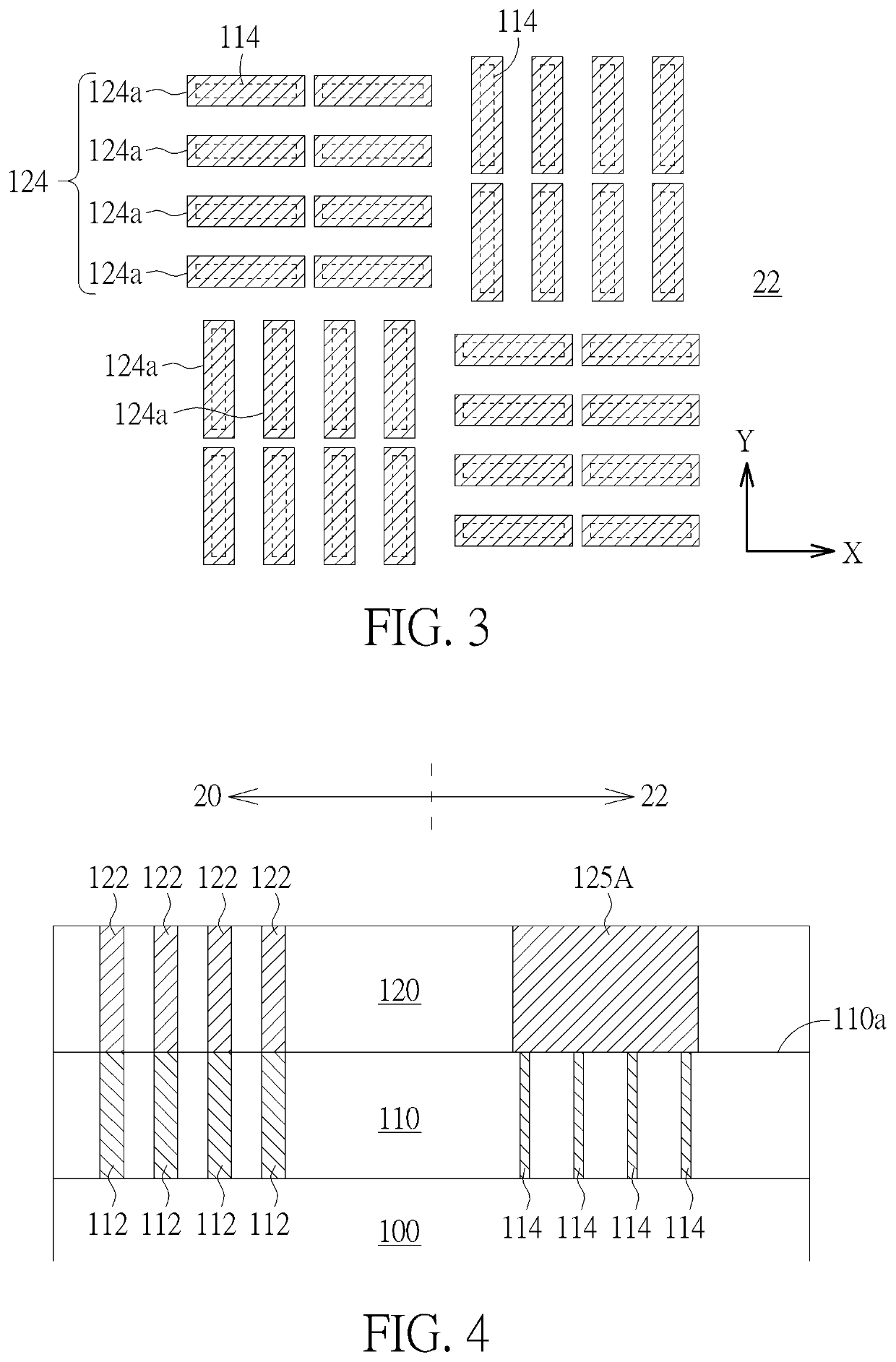

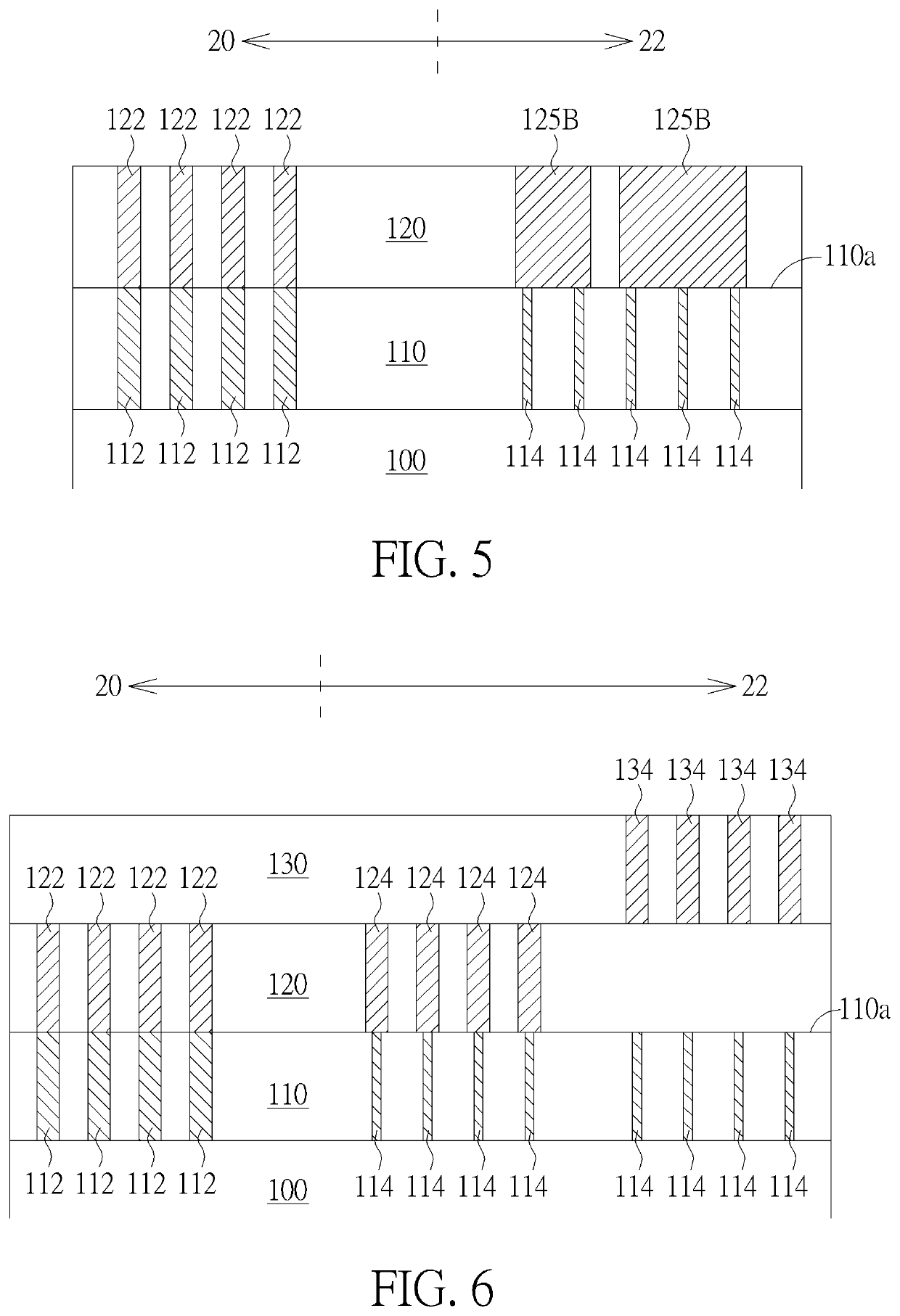

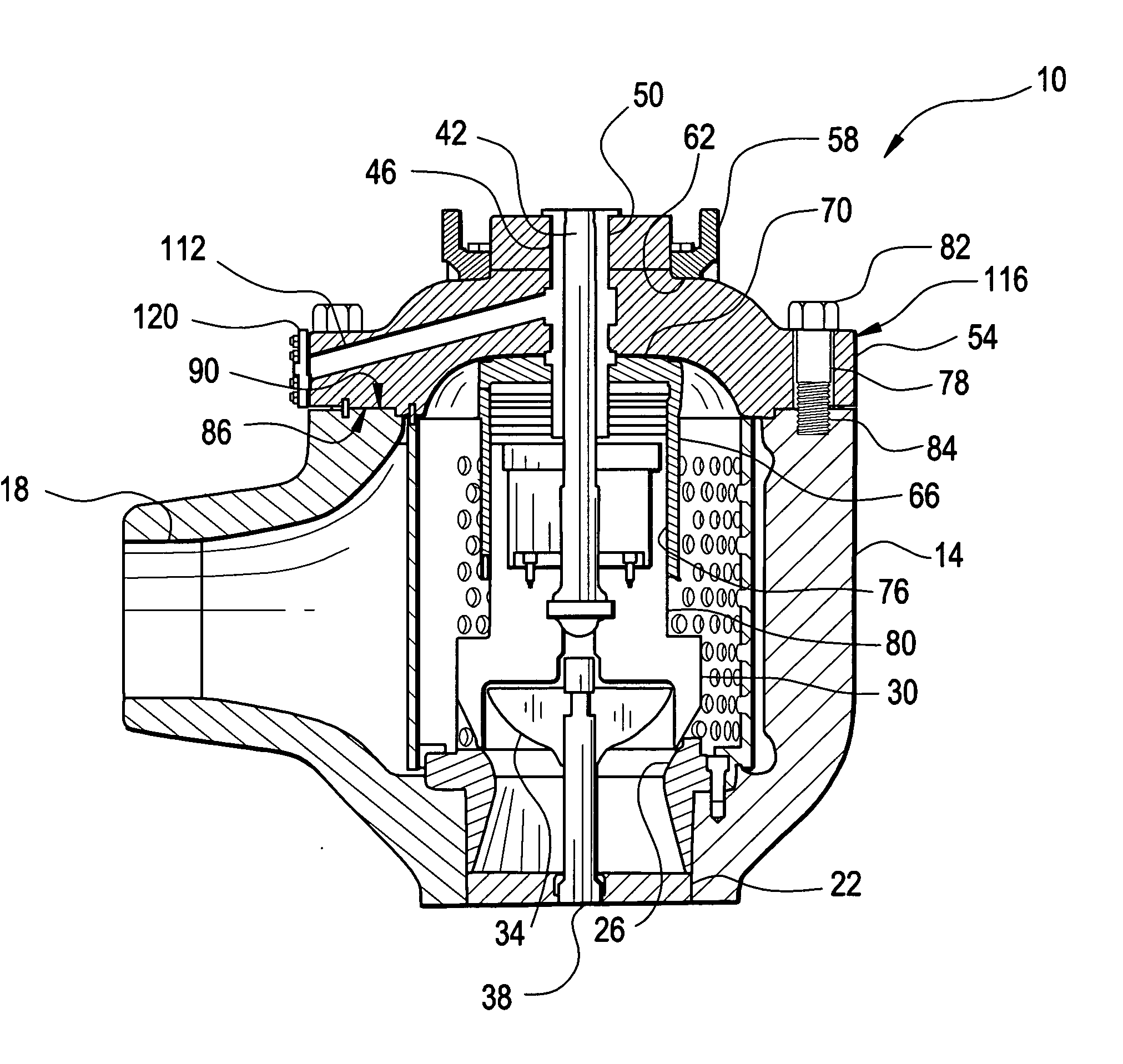

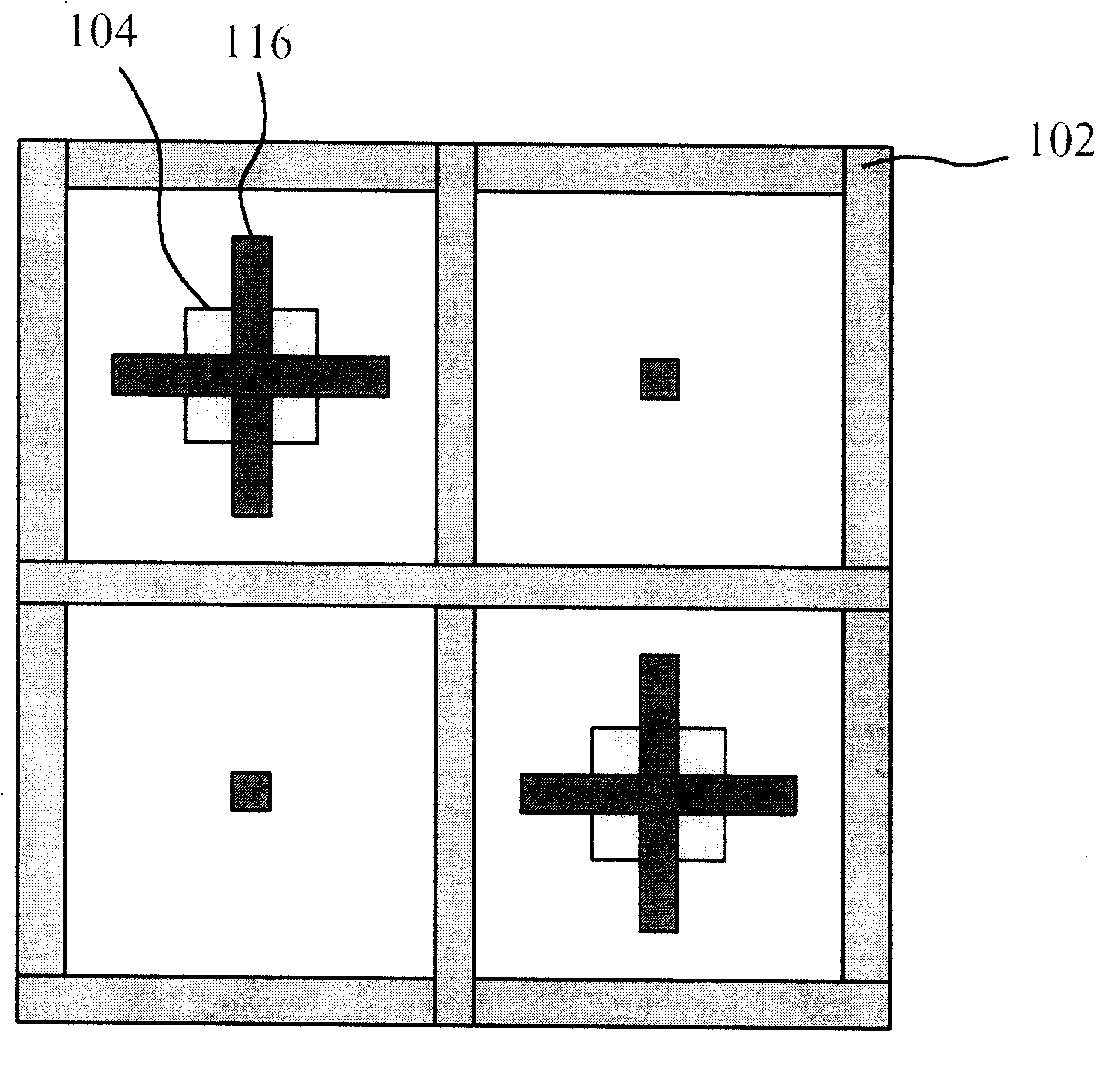

Method for adding redundancy patterns to photoetching map

InactiveCN104465650AReduce graphics erosionReduce dishingSolid-state devicesSpecial data processing applicationsGraphicsAlgorithm

The invention provides a method for adding redundancy patterns to a photoetching map. The method comprises the steps that S1 the photoetching map containing multiple design patterns is provided, and the photoetching map is divided into at least two areas; S2 the total area, the total perimeter and the region area of the design pattern in each area are obtained; S3 the ratio of the total area and the region area of the design pattern in each area is obtained through calculation; S4 all areas with the correlative value within(A,1)are not filled with the redundancy patterns, all areas with the correlative value smaller than A are filled according to the principle that the smaller the total perimeter is, the larger the filled redundancy pattern is, and the ratio of the total area of the design pattern and the corresponding redundancy pattern in any area and the region area of the area is within(A,1), and the value range of A is within (0,1). The method enables the surface density distribution of a wafer to be more even, and a chemical mechanical grinding effect is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

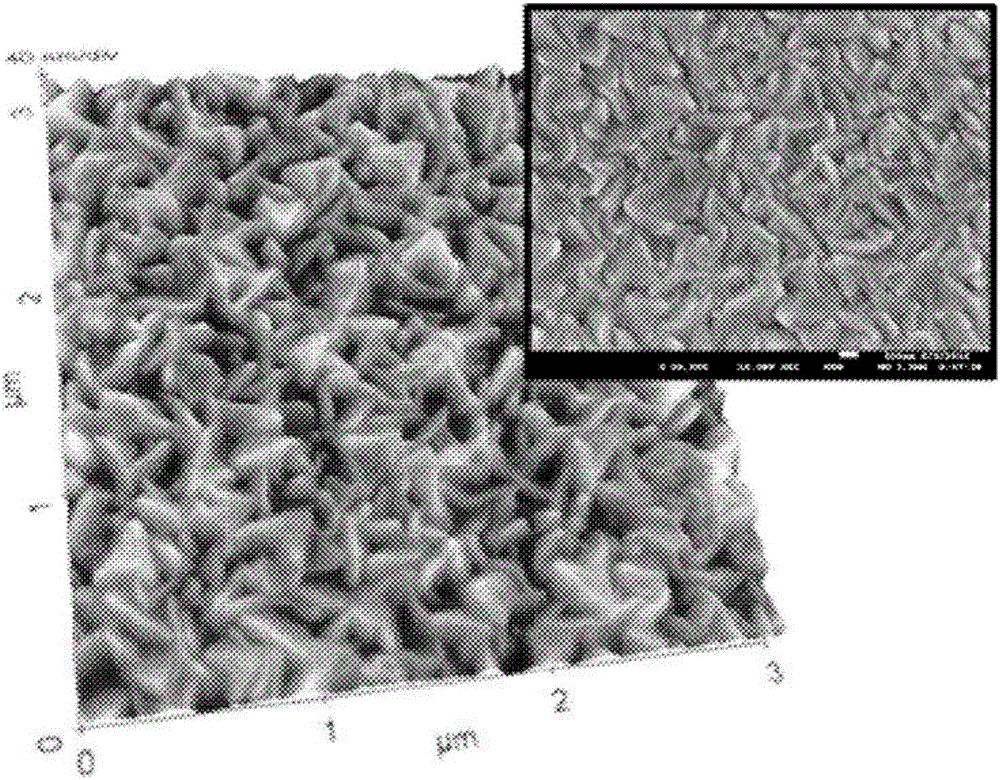

Polishing slurry composition

ActiveCN106661429AImprove short circuitHigh yieldOther chemical processesSemiconductor/solid-state device manufacturingSlurryTungsten

The present invention relates to a polishing slurry composition. A polishing slurry composition according to a first aspect of the present invention comprises abrasive particles and an oxidant, polishes tungsten having a thickness of 10-1,000 , and improves the topography of tungsten. Additionally, the polishing slurry composition according to a second aspect of the present invention comprises: at least two abrasive particles among first abrasive particles, second abrasive particles and third abrasive particles; and an oxidant, wherein the primary particle size of the first abrasive particles is 20 nm or more and less than 45 nm, the primary particle size of the second abrasive particles is 45 nm or more and less than 130 nm, and the primary particle size of the third abrasive particles is 130 nm or more and less than 250 nm.

Owner:K C TECH +1

Method for decreasing disc defect in chemicomechanical copper grinding

InactiveCN1397994AReduce grinding rateEasy to removeOther chemical processesSemiconductor/solid-state device manufacturingElectrical conductorOptoelectronics

This invention provides a reducing conductance structure dishing and erosion method in chemical mechanical grinding containing at least a dielectric layer with at least a dielectric window hole; forming a barrier layer on dielectric layer and the window hole; forming a conductive layer such as a copper layer on the barrier layer to fill in the dielectric window hole to form a conductive structure and removing part of conductive layer to expose part of the barrier layer to be polished as well as the conductive structure. With a reacted reagent so as to form a metal compound on the conductive structure prevented from dishing or erosion.

Owner:UNITED MICROELECTRONICS CORP

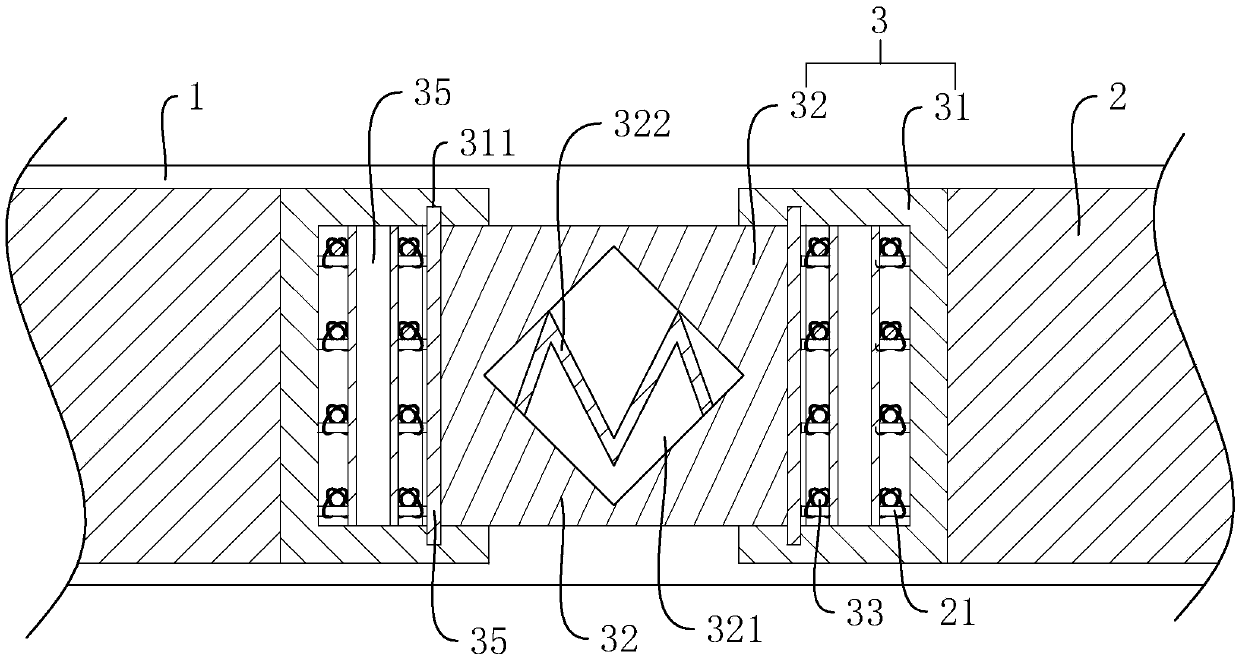

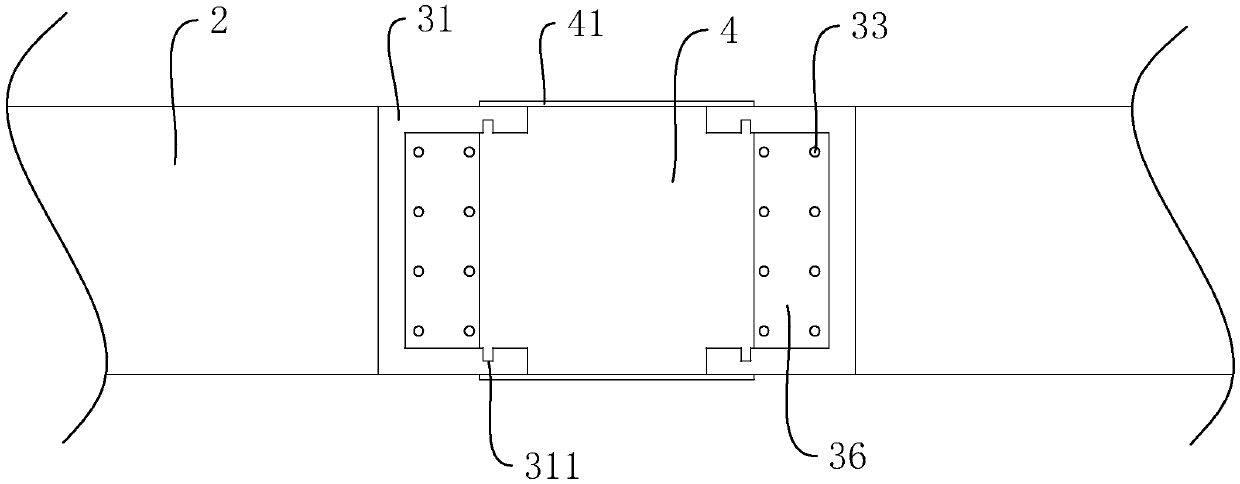

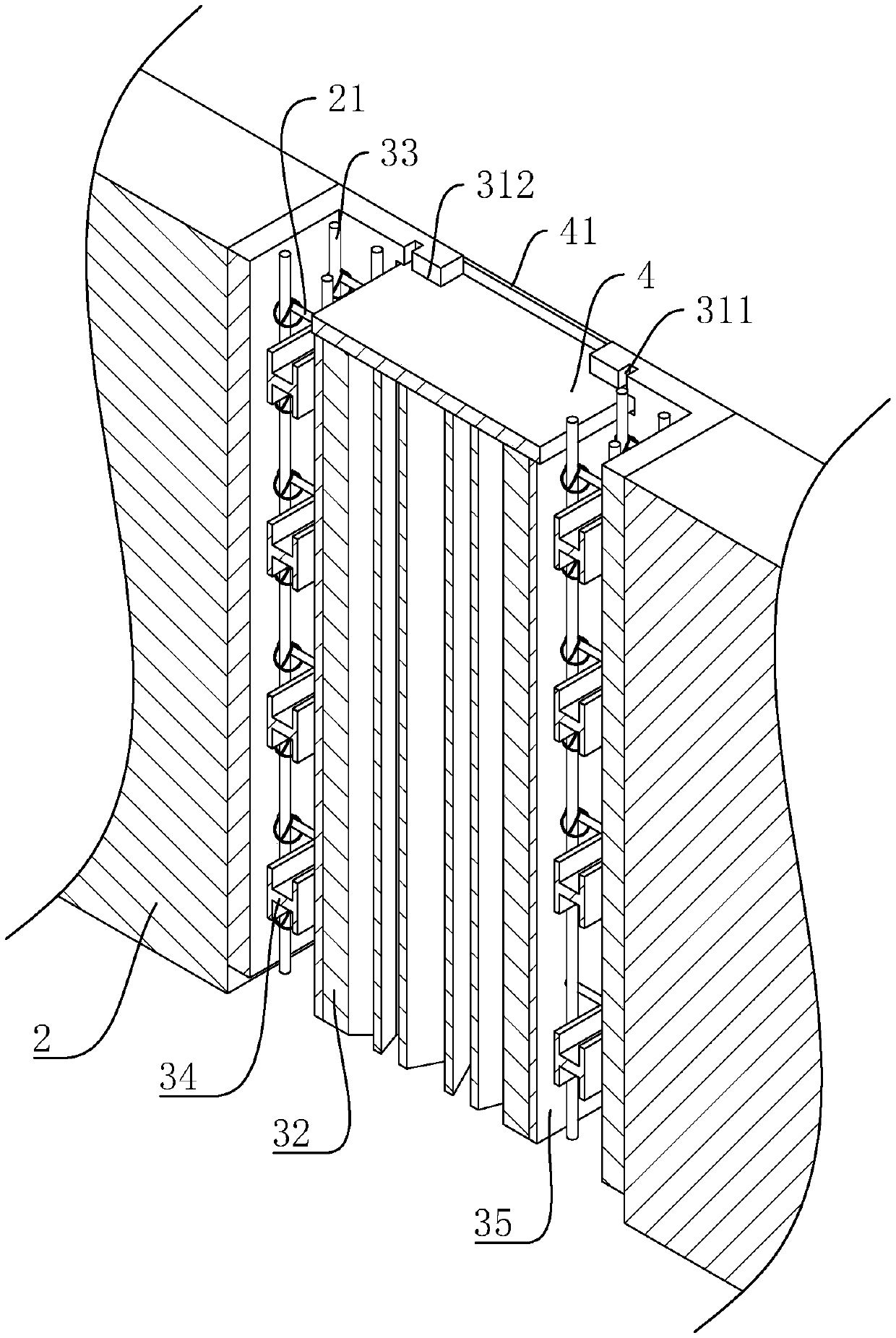

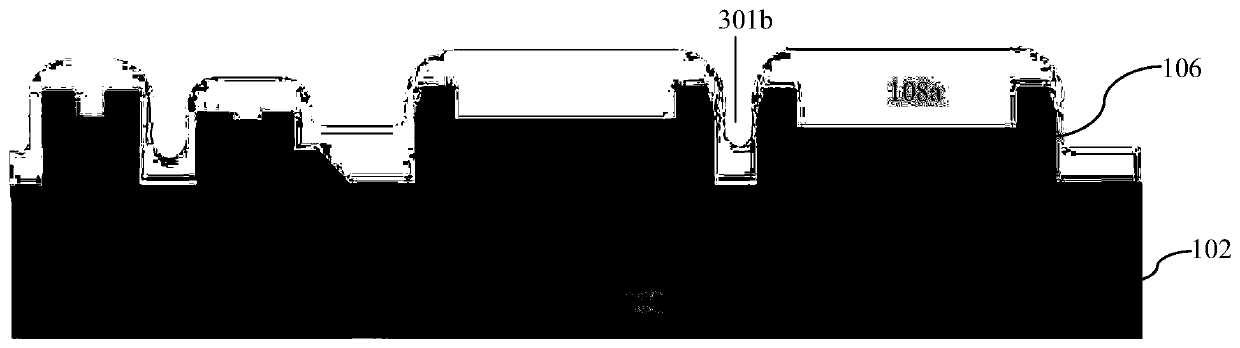

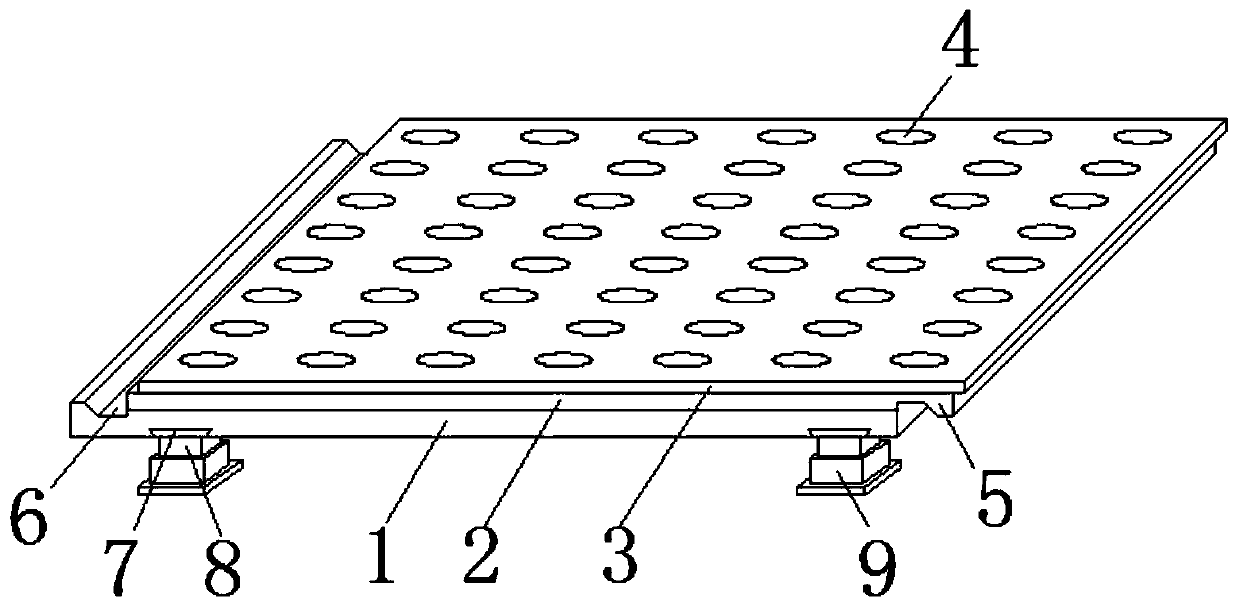

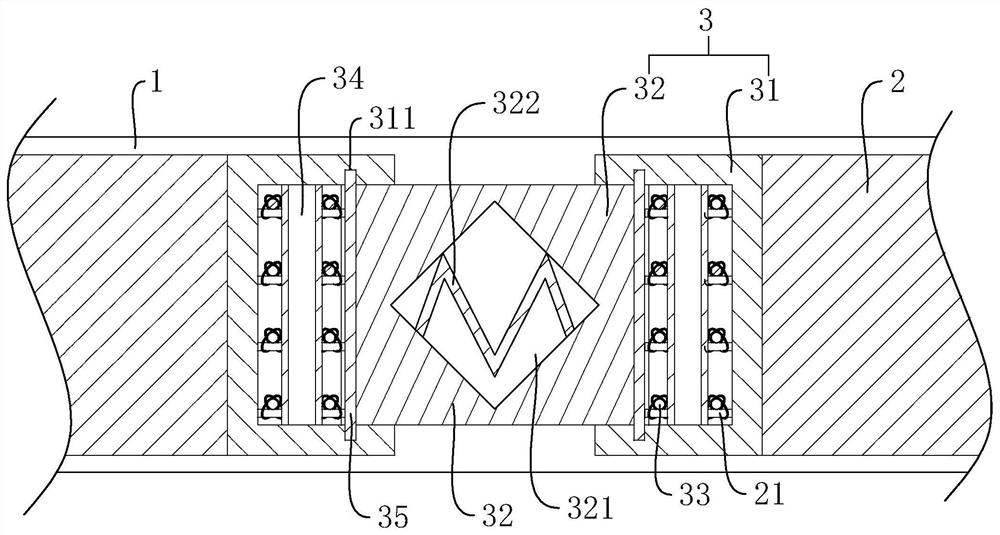

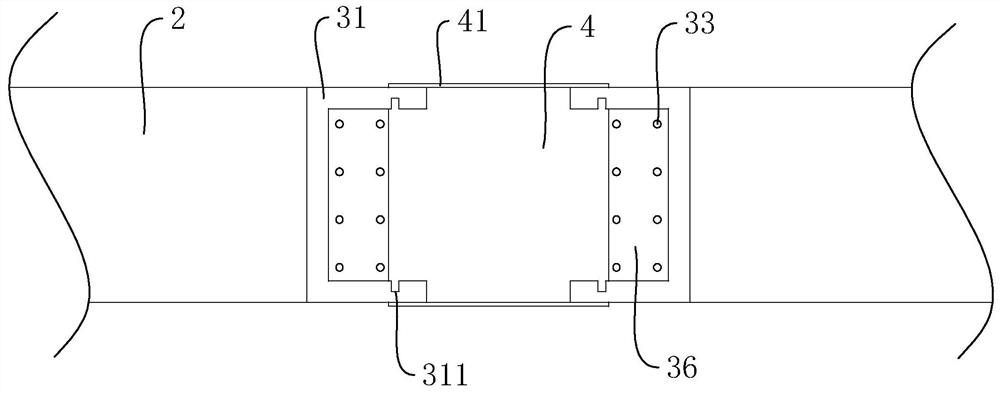

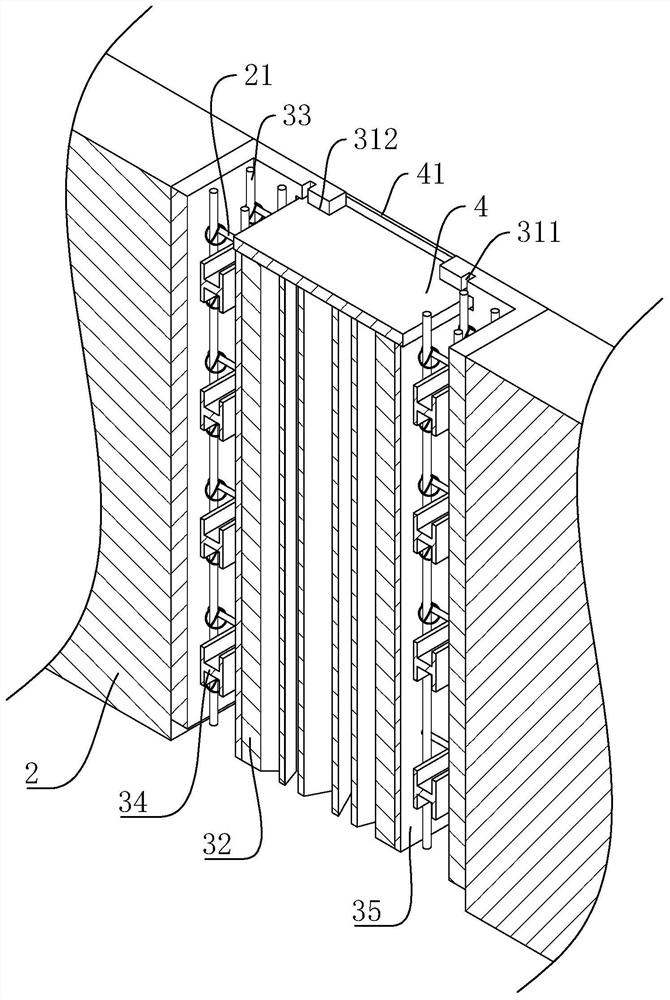

Fabricated underground continuous wall and construction method thereof

ActiveCN109653192AImprove progress and intensityImprove construction efficiencyBulkheads/pilesSlurry wallThermal expansion

The invention relates to the technical field of civil engineering and aims at providing a fabricated underground continuous wall and a construction method thereof. The technical scheme of the construction method of the fabricated underground continuous wall is characterized by comprising forming a mounting ditch in the ground, sequentially mounting a plurality of continuous wall units inside the mounting ditch, and clamping extension modules between every two neighboring continuous wall units, wherein every extension module comprises two mounting plates and an extension rubber strip, the extension rubber strip is clamped between the two mounting plates, and the two mounting plates are attached onto the opposite side walls of the corresponding two continuous wall units. According to the construction method of the fabricated underground continuous wall, the extension rubber strips can adapt to thermal expansion and contraction between the continuous wall units to reduce upheaval and depression between the continuous wall units.

Owner:江苏城归设计有限公司

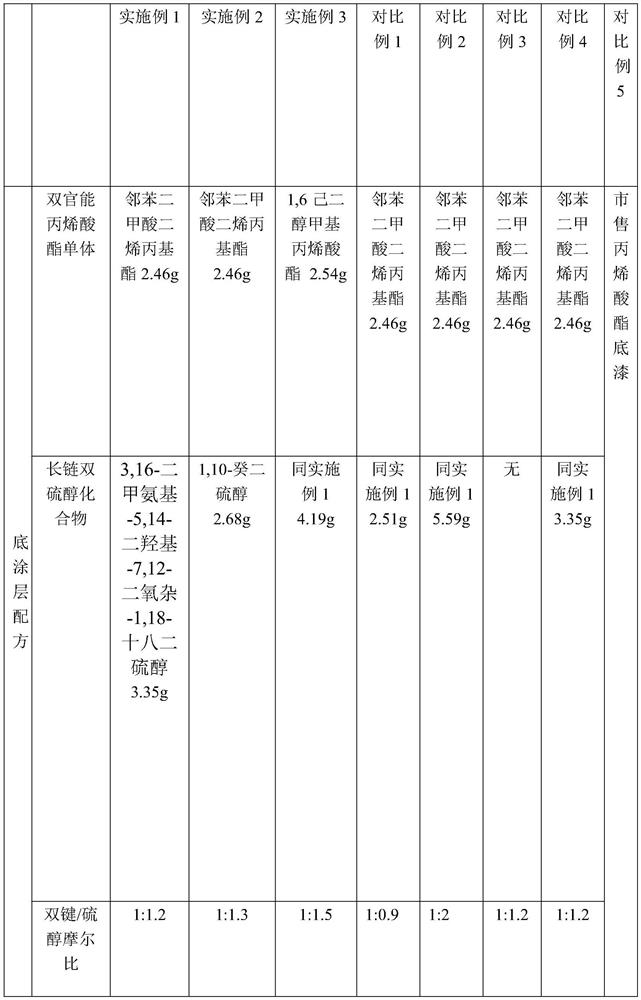

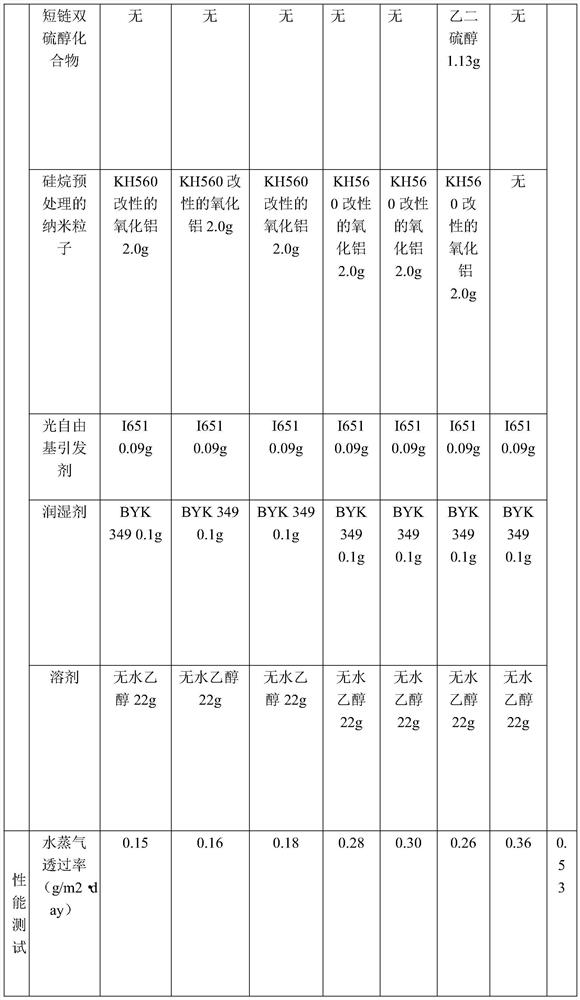

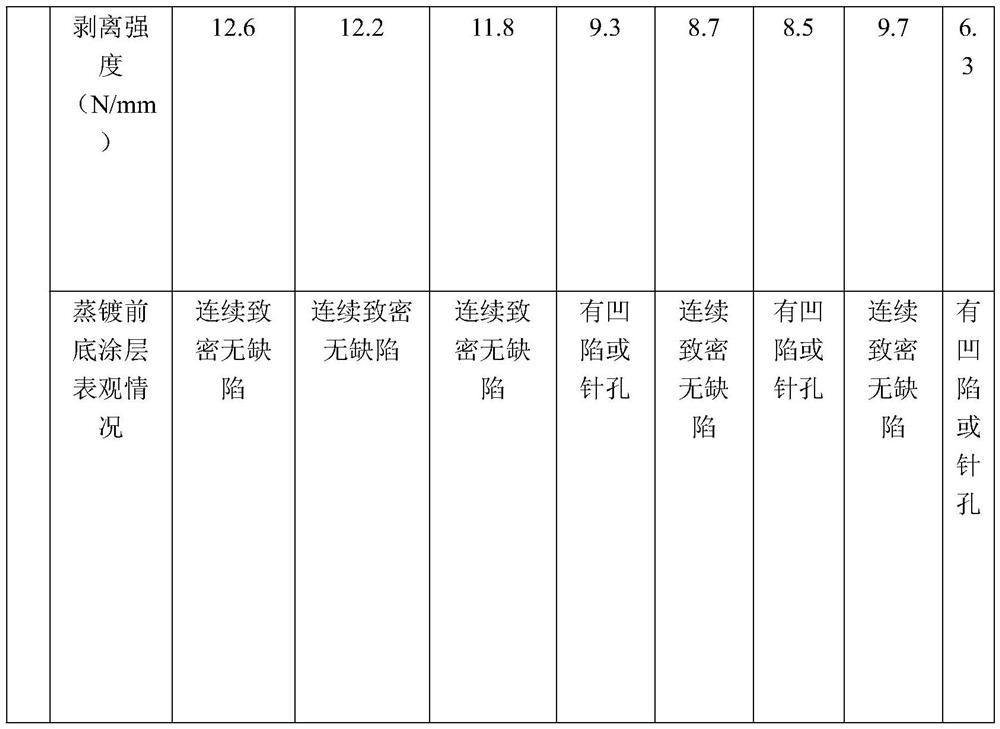

Coating liquid used before film evaporation and preparation process thereof

ActiveCN111978857AImprove adhesionImprove barrier propertiesVacuum evaporation coatingSputtering coatingPhotoinitiatorDouble bond

The invention relates to a coating liquid used before evaporation of CPP and PET matrixes and a preparation process of the coating liquid; the coating liquid mainly comprises bifunctional acrylate, along-chain dithiol compound, a photoinitiator, silane coupling agent pretreated nanoparticles, other auxiliaries and a solvent. wherein the molar ratio of double bonds to thiol groups in the bifunctional acrylate and the long-chain dithiol compound is controlled in a range of 1: 1.1-1: 1.5, and after ultraviolet and visible light irradiation, a priming coat is formed on the surface of the matrix.In the evaporation process of the surface of the base coating, the flexible long-chain sulfydryl chemically bonded in the acrylate coating can be bonded with inorganic metal or nonmetal of an evaporation layer to form -S (M-S) or metal O-S (M-O-S), wherein M represents the chemical bond of the inorganic metal or nonmetal of an evaporation film layer, and the bonding strength of the coating and thematrix is improved; and the adhesive force of the inorganic coating is improved, so that a more excellent barrier property is obtained.

Owner:杭州星点包装材料有限公司

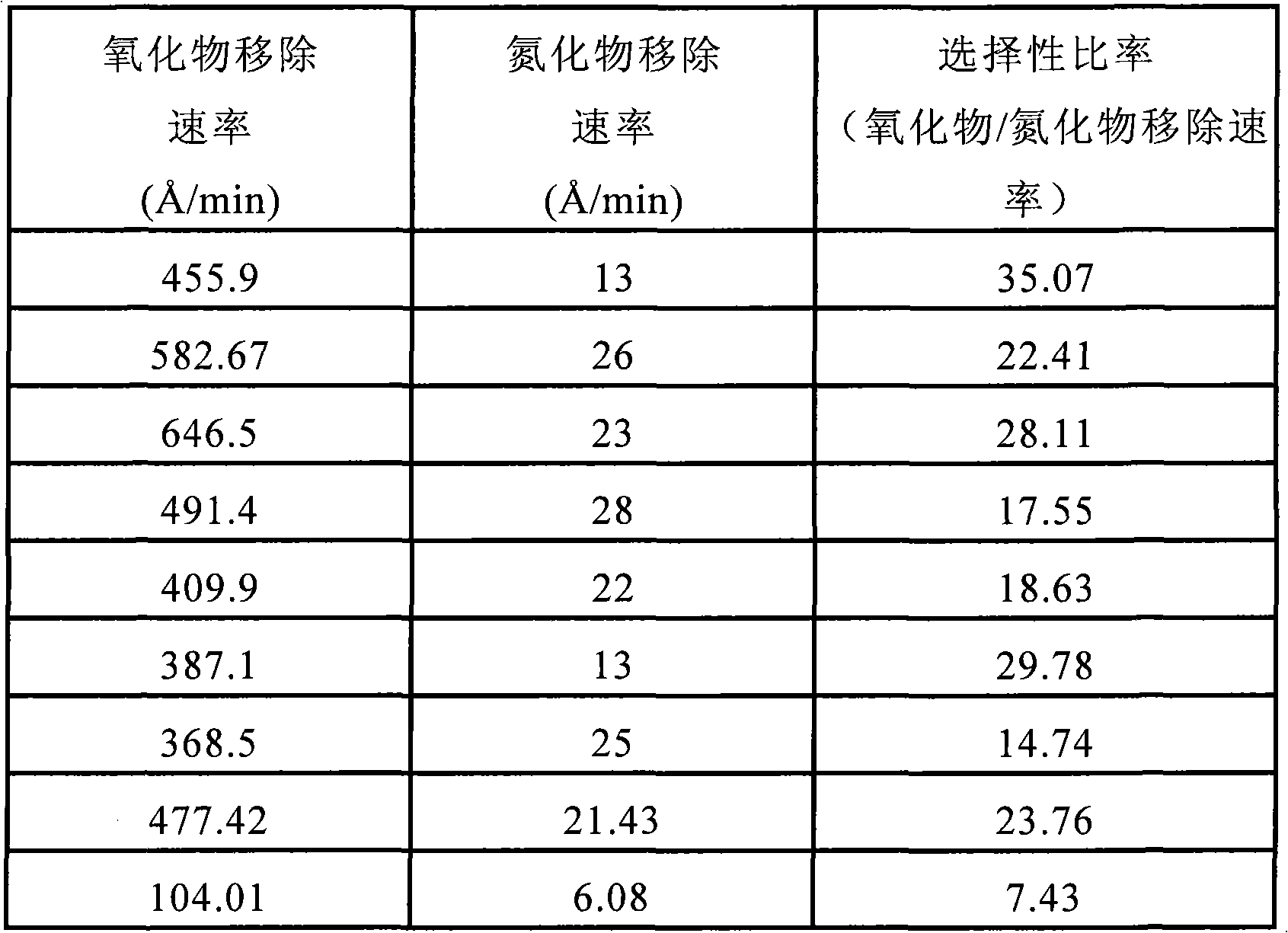

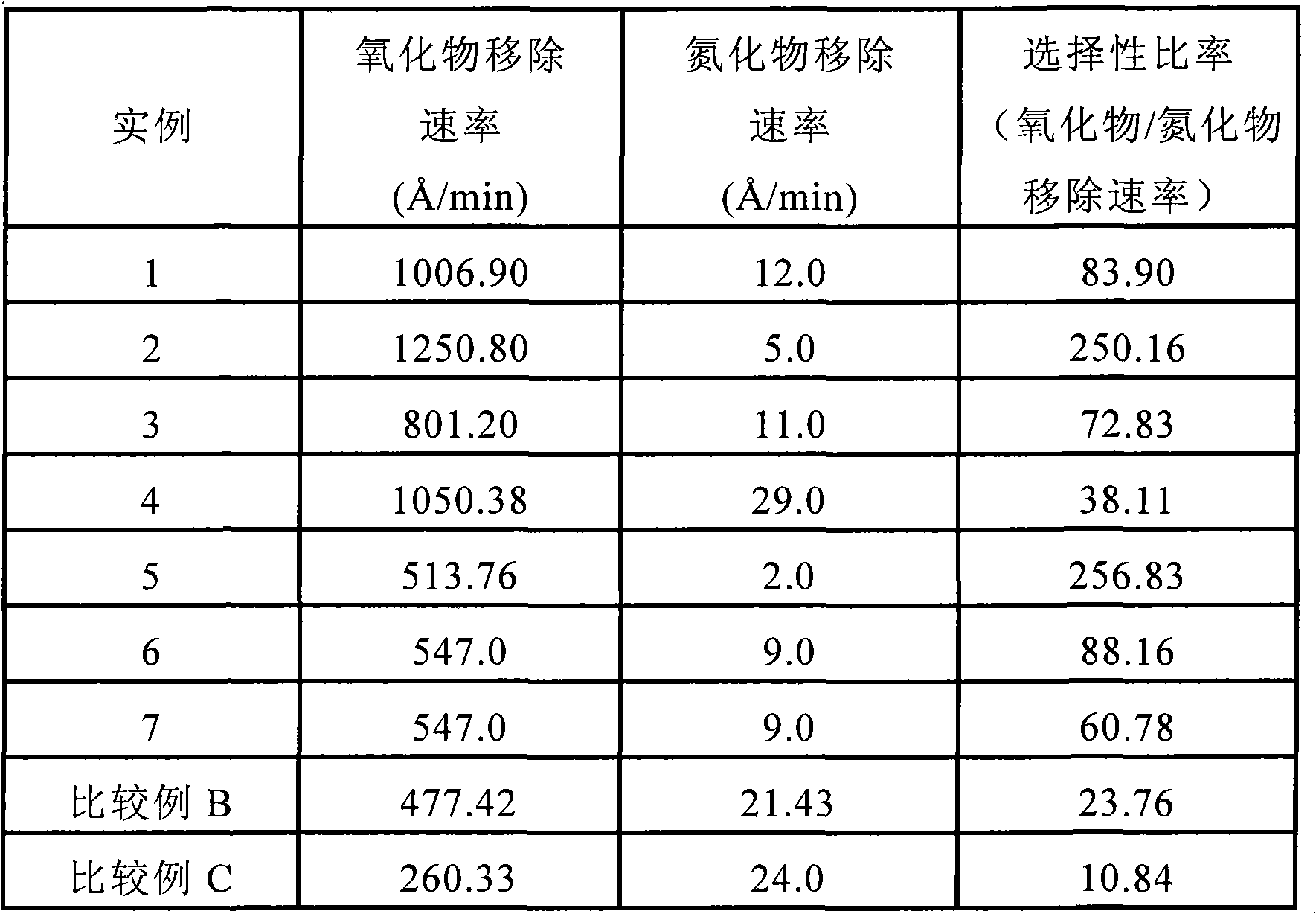

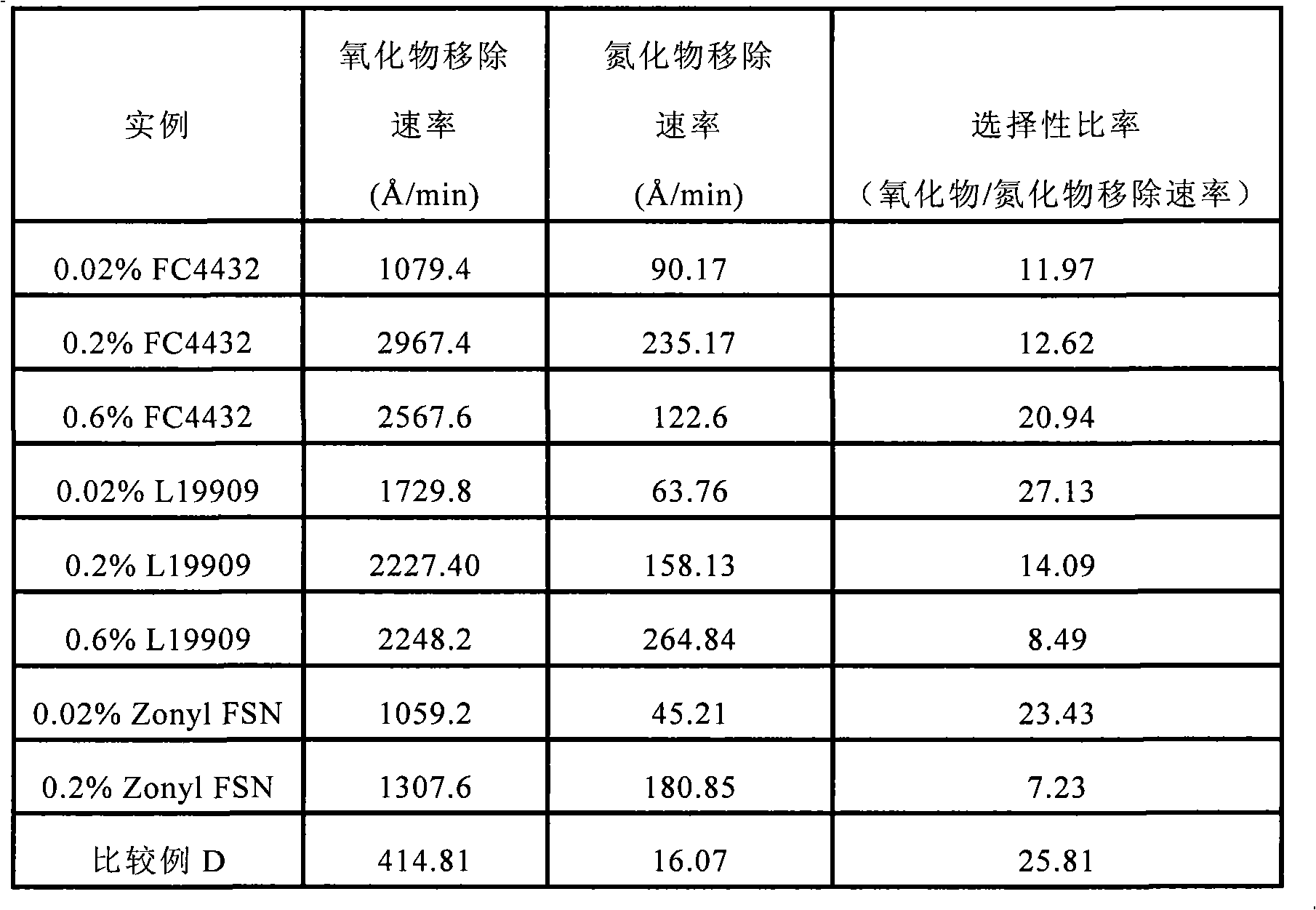

Chemical mechanical planarization composition, system, and method of use

InactiveCN101568613APreserve optionalityEnhanced chemical-mechanical planarization performanceOther chemical processesSemiconductor/solid-state device manufacturingSURFACTANT BLENDNitride

The disclosure relates to chemical mechanical planarization (CMP) polishing compositions including proline and a fluorochemical surfactant. The wafer polishing composition may be used as a solution substantially free of abrasive particles, the composition of which can be adjusted to control Oxide Removal Rate and oxide over nitride Selectivity Ratio in Shallow Trench Isolation (STI) processing ofsemiconductor wafers using a fixed abrasive CMP process. In certain embodiments, the disclosure provides a working liquid for fixed abrasive CMP including proline and a fluorochemical surfactant at apH from 9 to 11. When used in a fixed abrasive CMP system and method for STI, exemplary working liquids may yield an Oxide Removal Rate of at least 500 angstroms per minute, and an oxide over nitrideSelectivity Ratio of at least 5.

Owner:3M INNOVATIVE PROPERTIES CO

Process for removing a bulk material layer from a substrate and a chemical mechanical polishing agent suitable for this process

InactiveUS20120231627A1Reduce scratchesReduce dishingOther chemical processesSemiconductor/solid-state device manufacturingMaterial removalCompound (substance)

An aqueous chemical mechanical polishing (CMP) agent (A) comprising solid particles (a1) containing (a11) a corrosion inhibitor for metals, and (a12) a solid material, the said solid particles (a1) being finely dispersed in the aqueous phase; and its use in a process for removing a bulk material layer from the surface of a substrate and planarizing the exposed surface by chemical mechanical polishing until all material residuals are removed from the exposed surface, wherein the CMP agent exhibits at the end of the chemical mechanical polishing, without the addition of supplementary materials, —the same or essentially the same static etch rate (SER) as at its start and a lower material removal rate (MRR) than at its start, —a lower SER than at its start and the same or essentially the same MRR as at its start or—a lower SER and a lower MRR than at its start; such that the CMP agent exhibits a soft landing behavior.

Owner:BASF AG

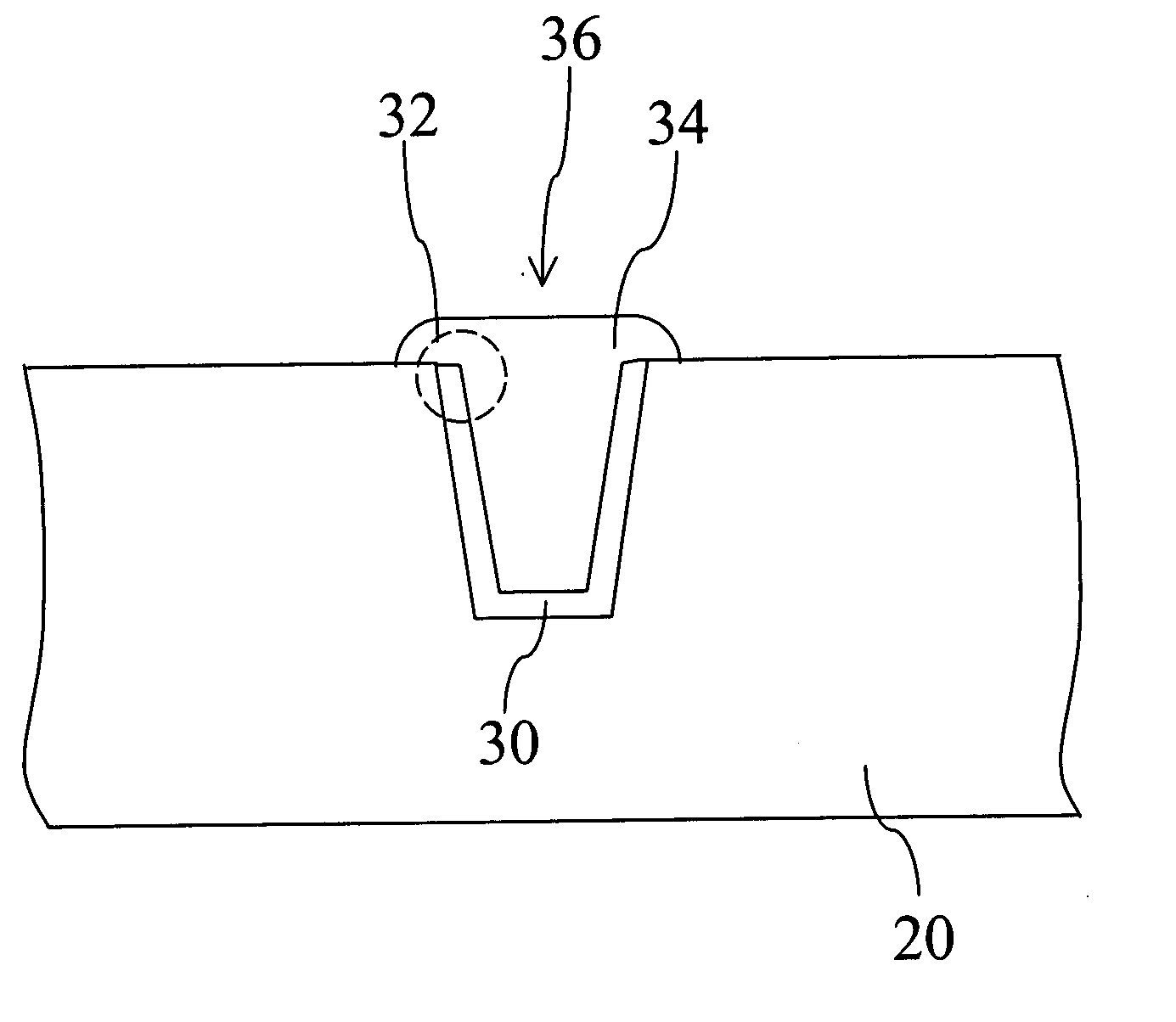

Method of forming trench isolation device capable of reducing corner recess

InactiveUS20060134881A1Reduce corner recessReduce recess phenomenonSemiconductor/solid-state device manufacturingSilicon nitrideOxide

A method of forming a trench isolation device capable of reducing corner recess comprising forming a pad oxide layer and a silicon nitride mask layer on a semiconductor base, and forming a trench by etching. Next, a liner oxide layer is formed on the semiconductor base and on the surface of the shallow trench. Then, the silicon nitride mask layer will be etched to reveal the corner. Finally, a layer of oxide is formed on the base to fill up the trench so that the trench isolation device can be completed. The present invention is designed to solve the corner recess problem, reduce generation of kick effect, and enhance the device characteristics and electrical quality.

Owner:GRACE SEMICON MFG CORP

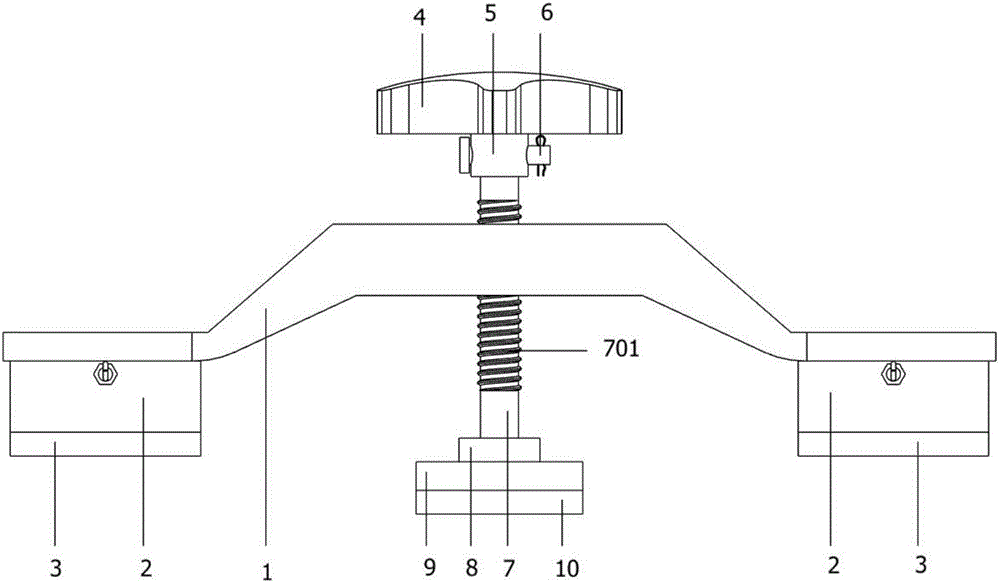

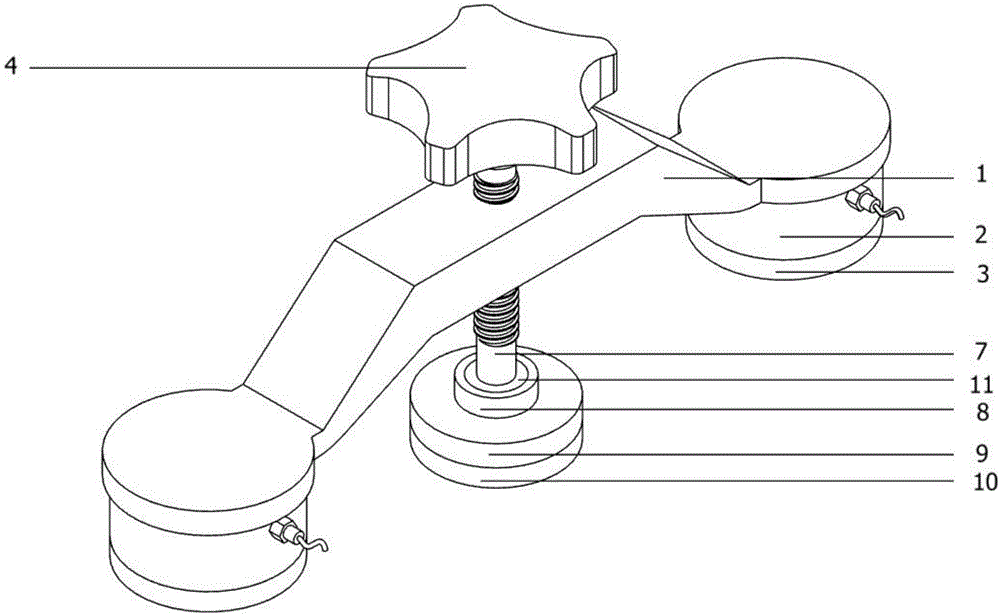

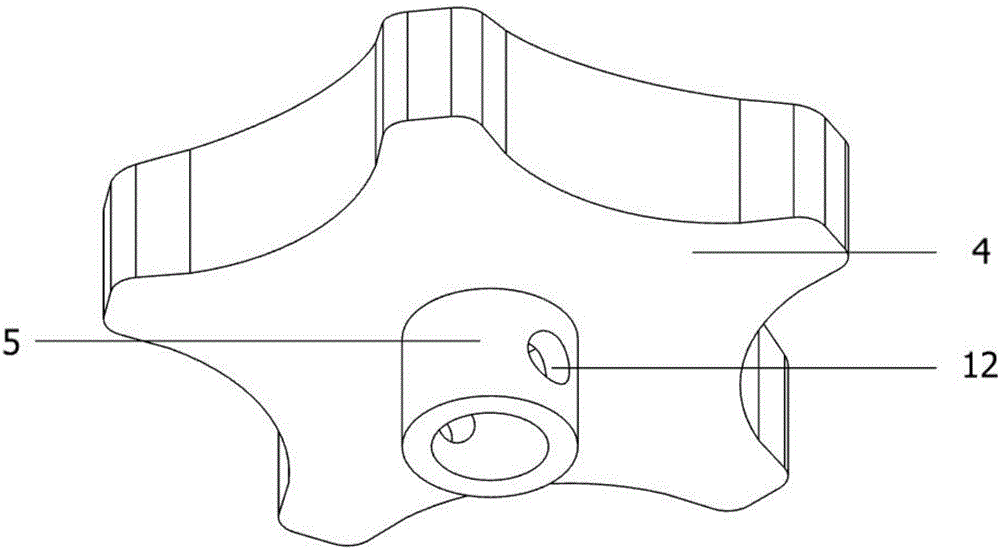

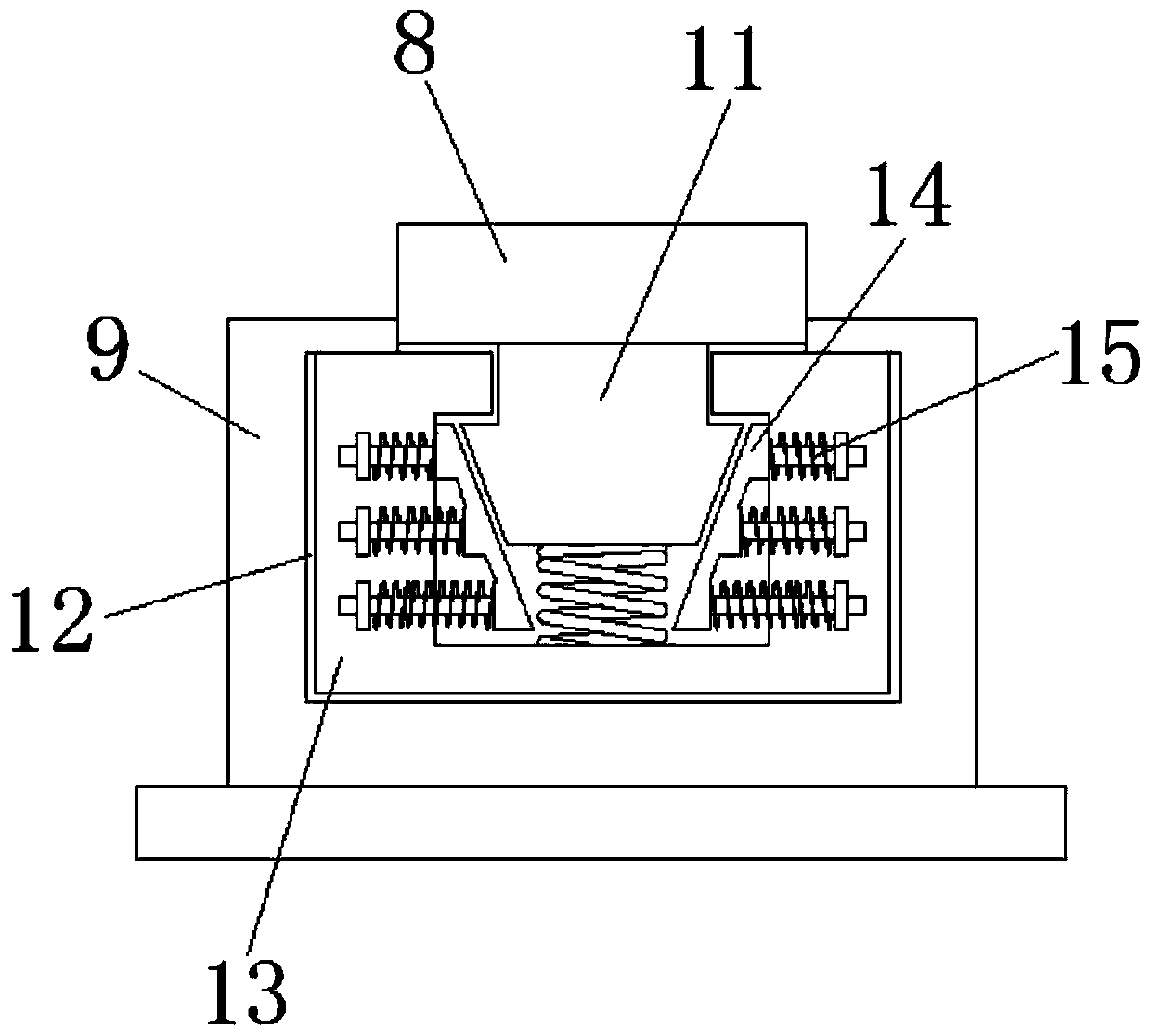

Gentle twisting type vehicle door pit overhauling equipment

The invention provides gentle twisting type automobile door pit overhauling equipment. The gentle twisting type automobile door pit overhauling equipment comprises a traction tensile force bridge and outer threads, wherein a threaded hole is formed in the center of the top of the traction tensile force bridge; disc-shaped bottoms on two sides of the traction tensile force bridge are fixedly connected with electromagnetic suckers separately; the tail end of a cylindrical rod is rotatably connected with a second cylinder through a bearing; and the bottom of the second cylinder is fixedly connected with the top of a disc. The traction tensile force bridge is fixed on an automobile end surface at the position of a recessed edge of an automobile through the electromagnetic suckers, then a rotating knob twists to drive the cylindrical rod to ascend together, rotation of the cylindrical rod is converted into linear movement through a bearing, therefore, a rubber mat which is in adhesion connection with an automobile pit is slowly and uniformly driven to ascend, and the position of a concave surface of the automobile is driven to recover.

Owner:湖北瑞兴达特种装备科技股份有限公司

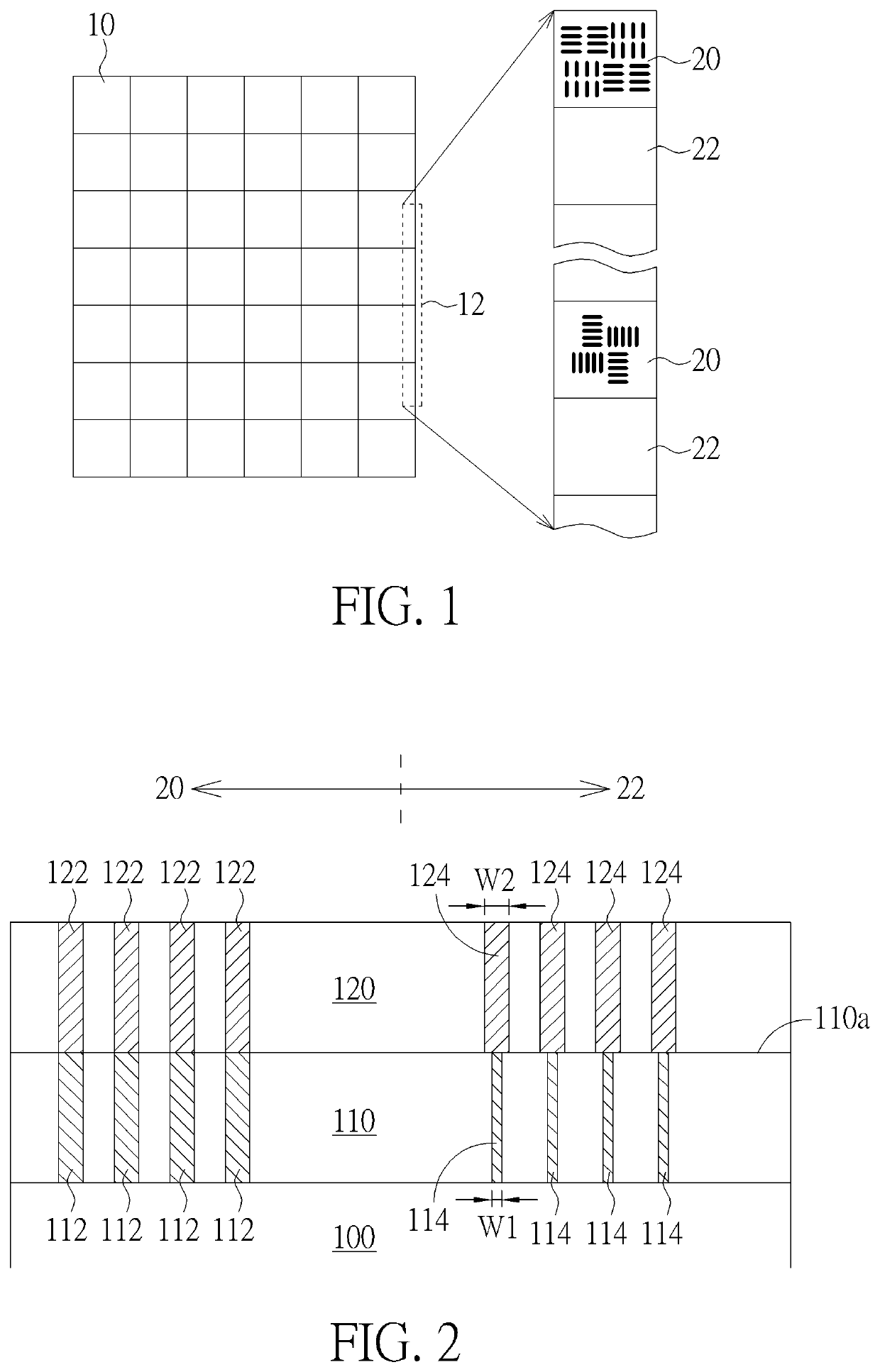

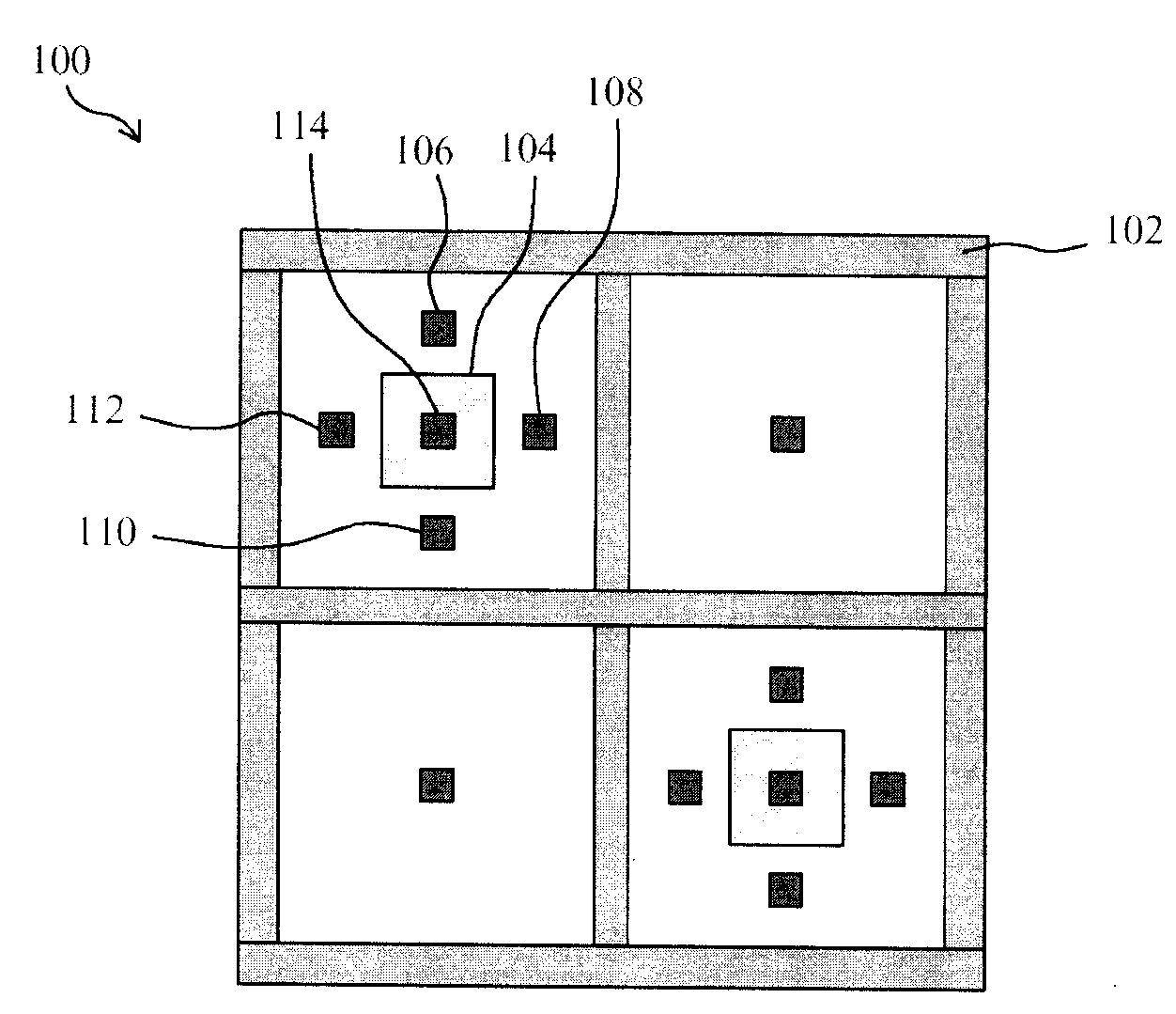

Alignment mark and measurement method thereof

ActiveUS10566290B2Reduce dishingImprove alignment accuracyMeasurement devicesSemiconductor/solid-state device testing/measurementMarking outElectrical and Electronics engineering

Owner:UNITED MICROELECTRONICS CORP

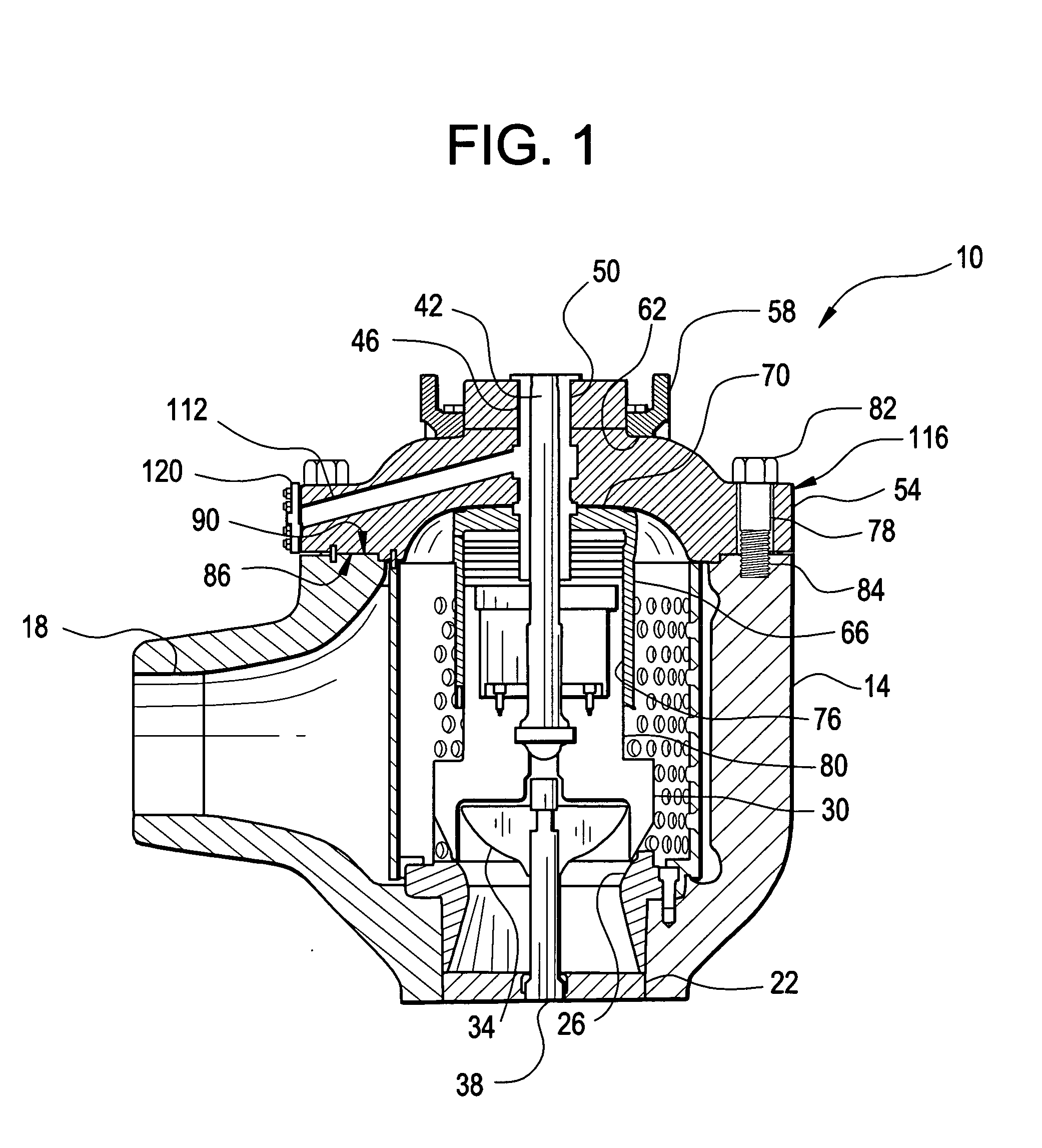

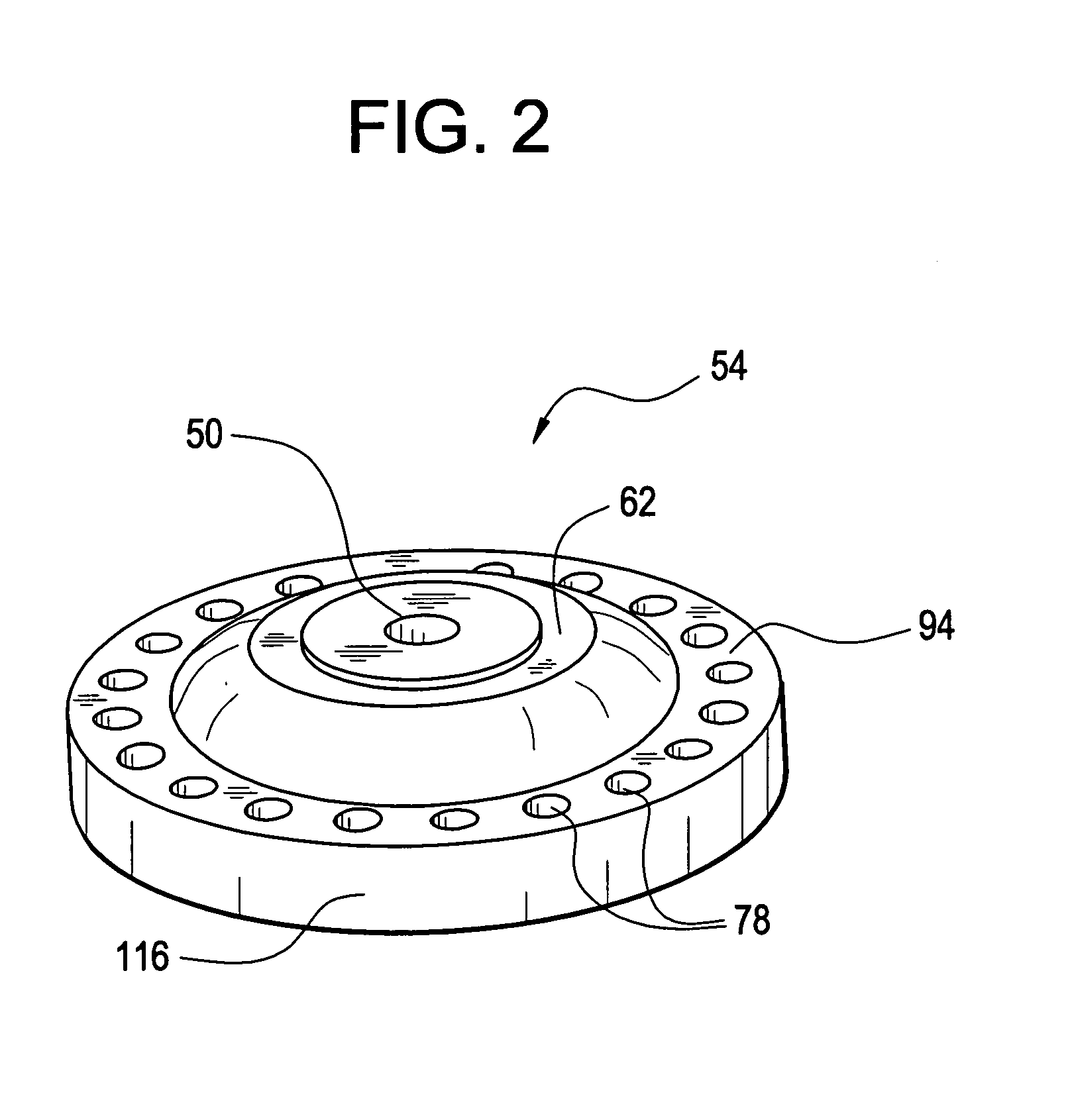

Method and apparatus for covering a pressure vessel

InactiveUS20070272687A1Less cost to manufactureAvoid excessive massContainer filling methodsPressure vesselsEngineeringPressure vessel

An apparatus disclosed herein relates to a pressure vessel cover comprising, a periphery of the cover, a first surface of the periphery for sealing on a first side of the cover and a second surface on a second side of the cover opposite from the first side, a third surface on the first side of the cover and located radially inwardly from the periphery, the third surface being displaced axially from the first surface in the direction of the second surface, a fourth surface on the second side of the cover radially inwardly positioned from the periphery, and a bore through the cover in fluidic communication with the third surface and the fourth surface.

Owner:GENERAL ELECTRIC CO

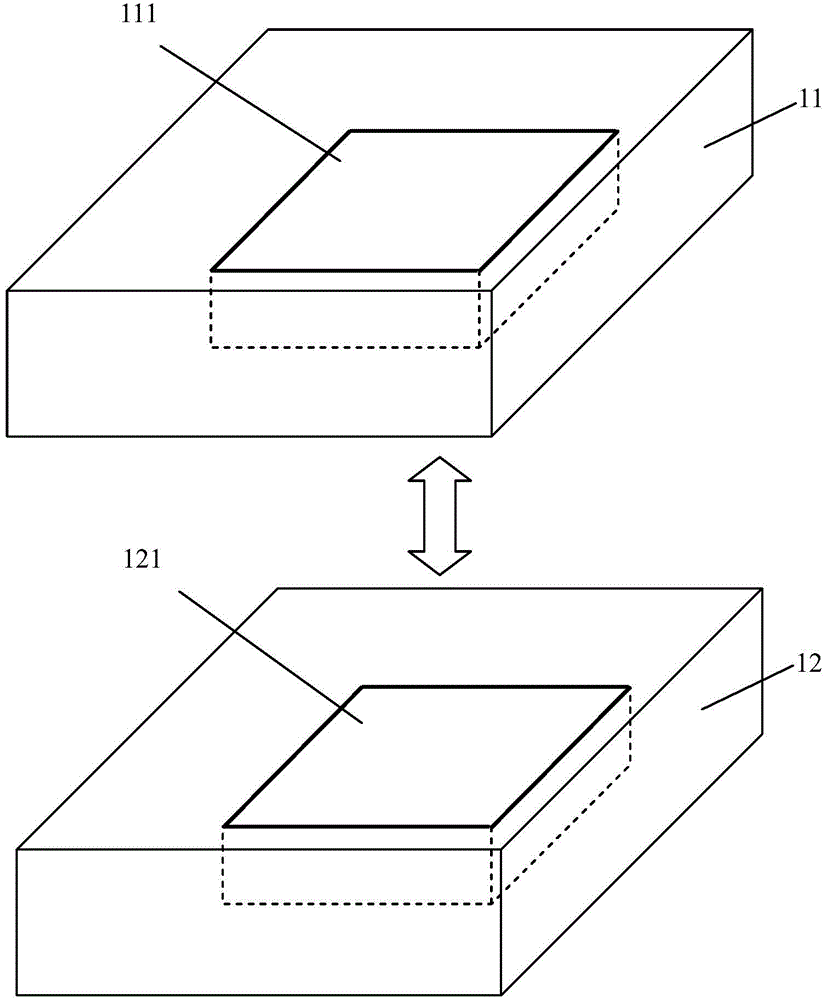

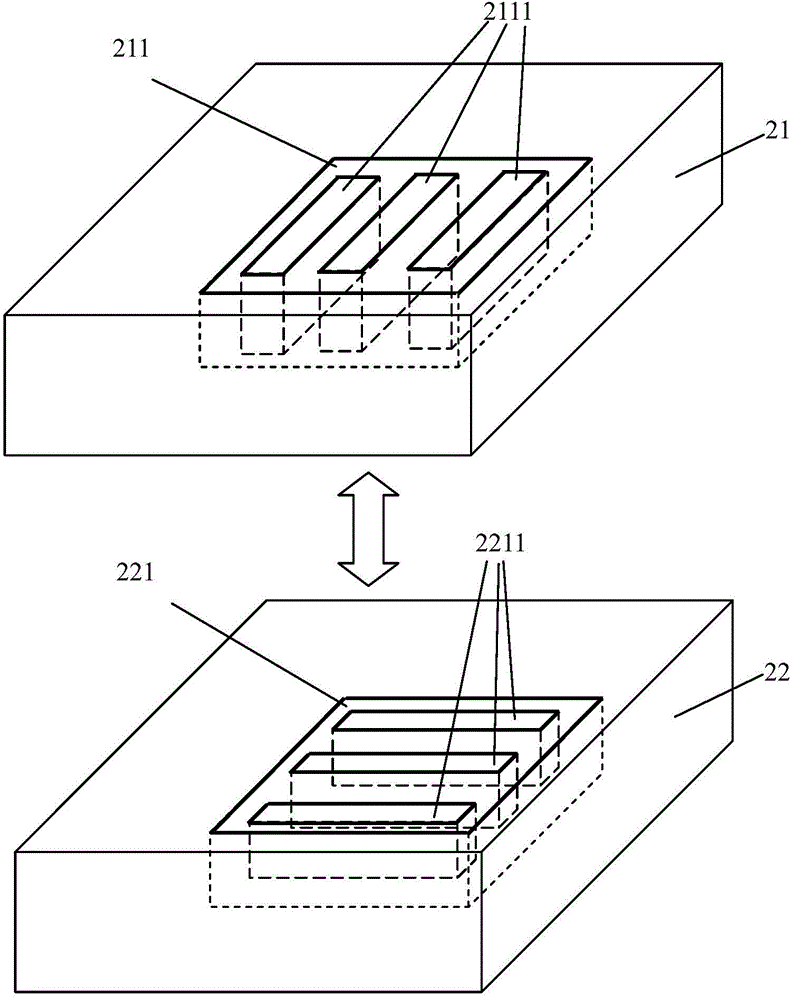

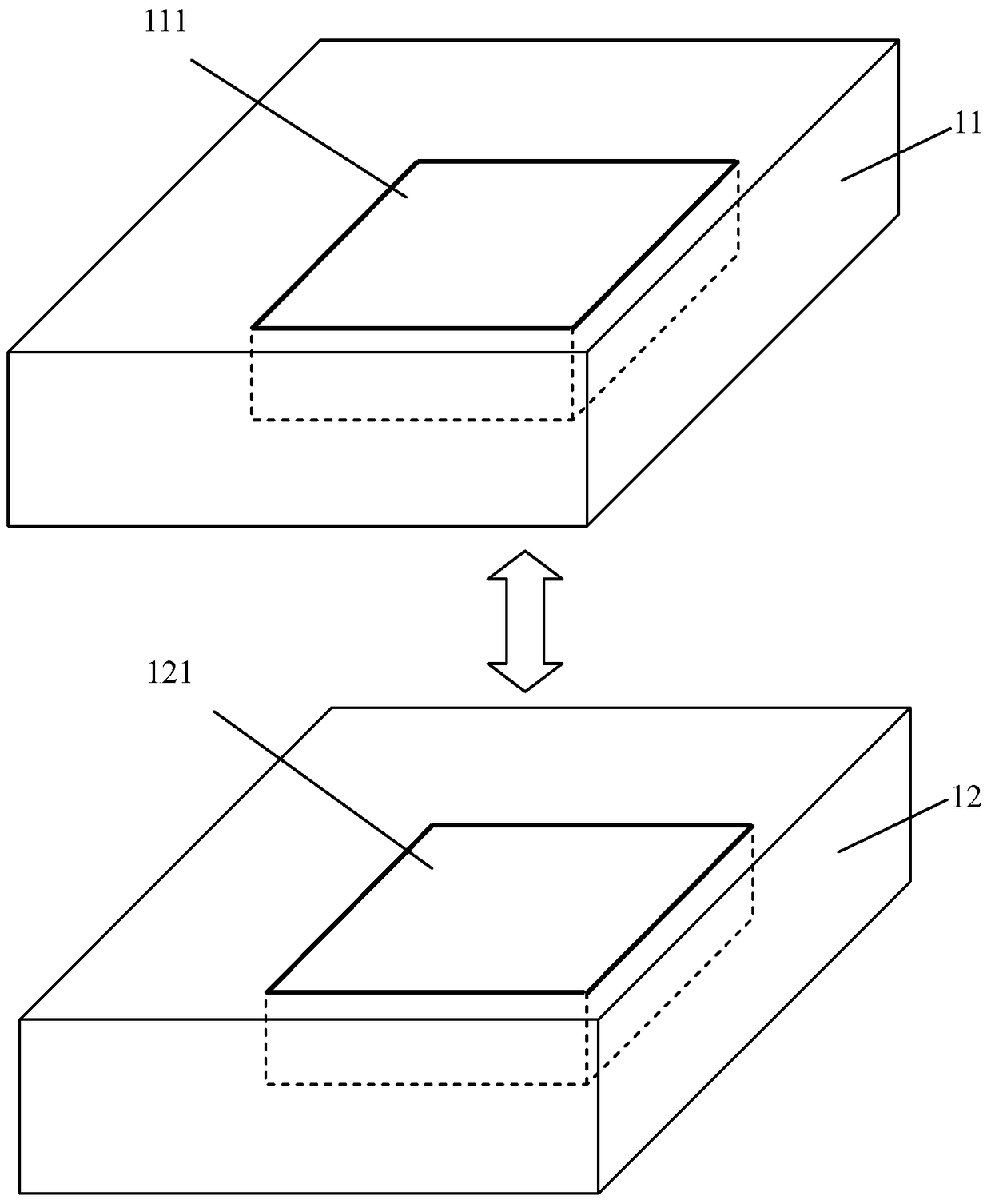

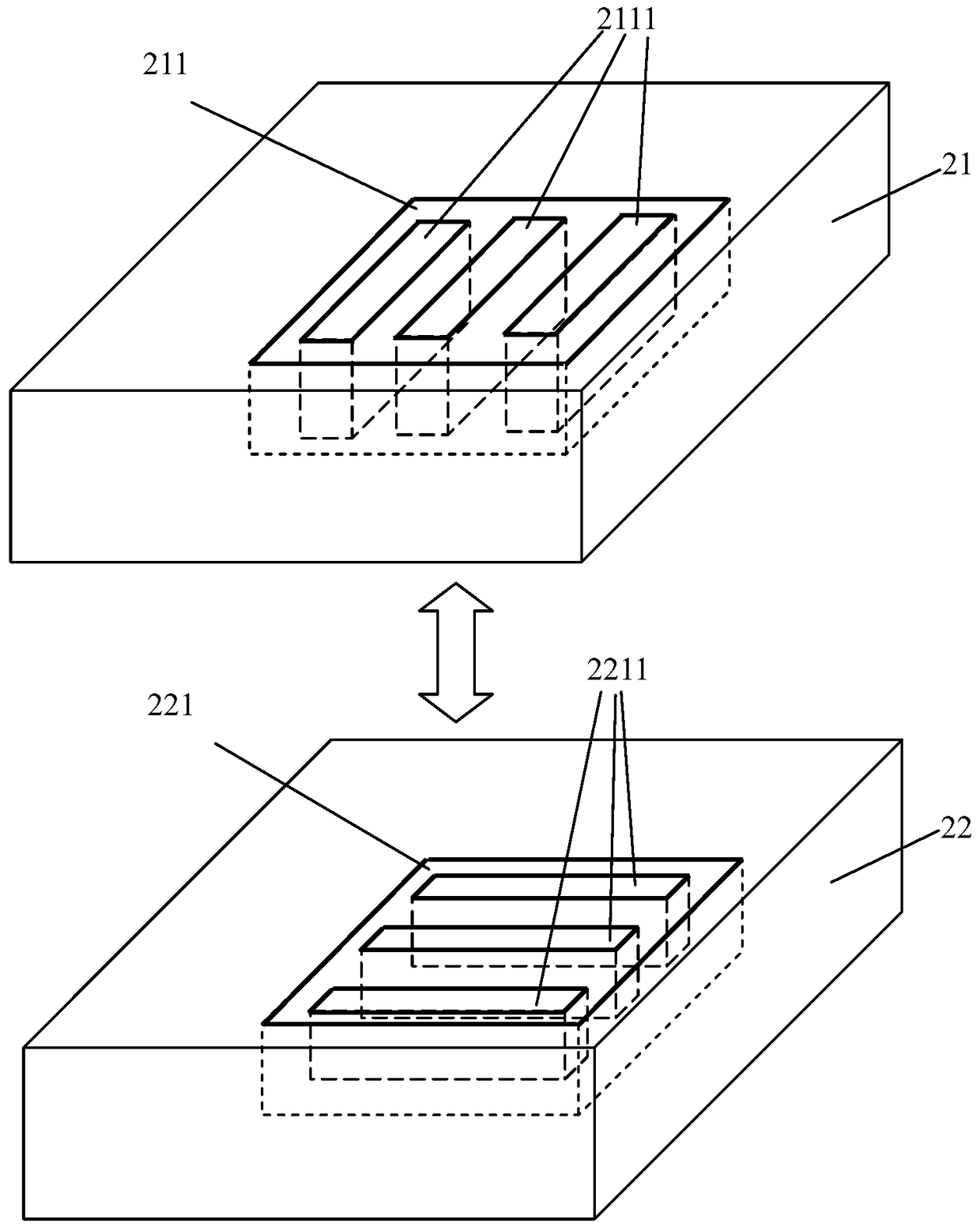

Semiconductor device bonding structure and bonding method

ActiveCN105810649AReduce line widthMinimize electrical interconnection failureSemiconductor/solid-state device detailsSolid-state devicesVertical alignmentMaterials science

The invention discloses a semiconductor device bonding structure and a bonding method. The bonding structure comprises a first metal layer and a second metal layer; the surface of the first metal layer is provided with a first welding pad which has a first opening pattern; the surface of the second metal layer is provided with a second welding pad which has a second opening pattern; the surfaces of the first metal layer and the second metal layer are connected by bonding; the first wielding pad and the second welding pad are bonded in a vertical alignment manner; and the first opening pattern of the first bonding pad and the second opening pattern of the second bonding pad are mutually staggered on the bonding contact surface.

Owner:GALAXYCORE SHANGHAI

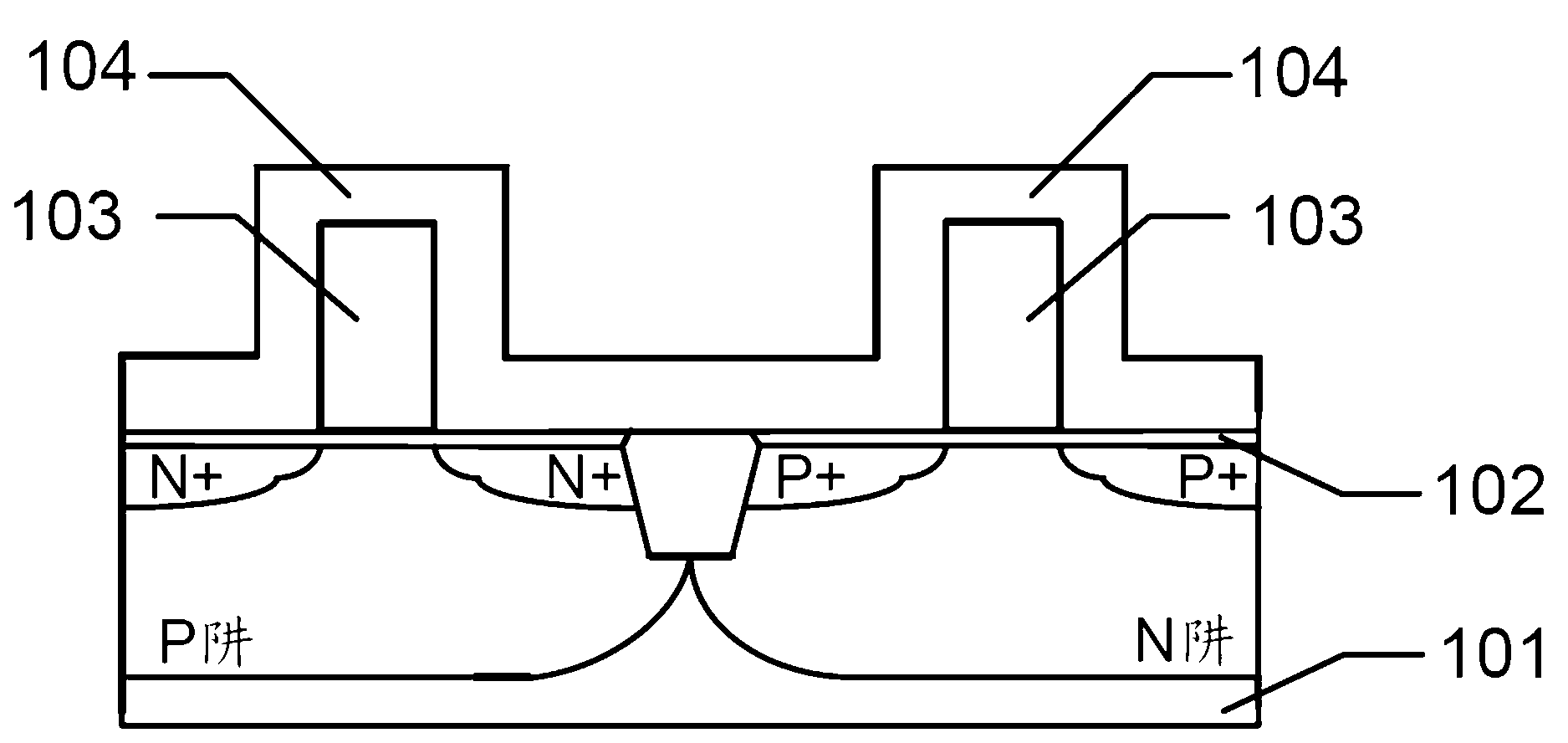

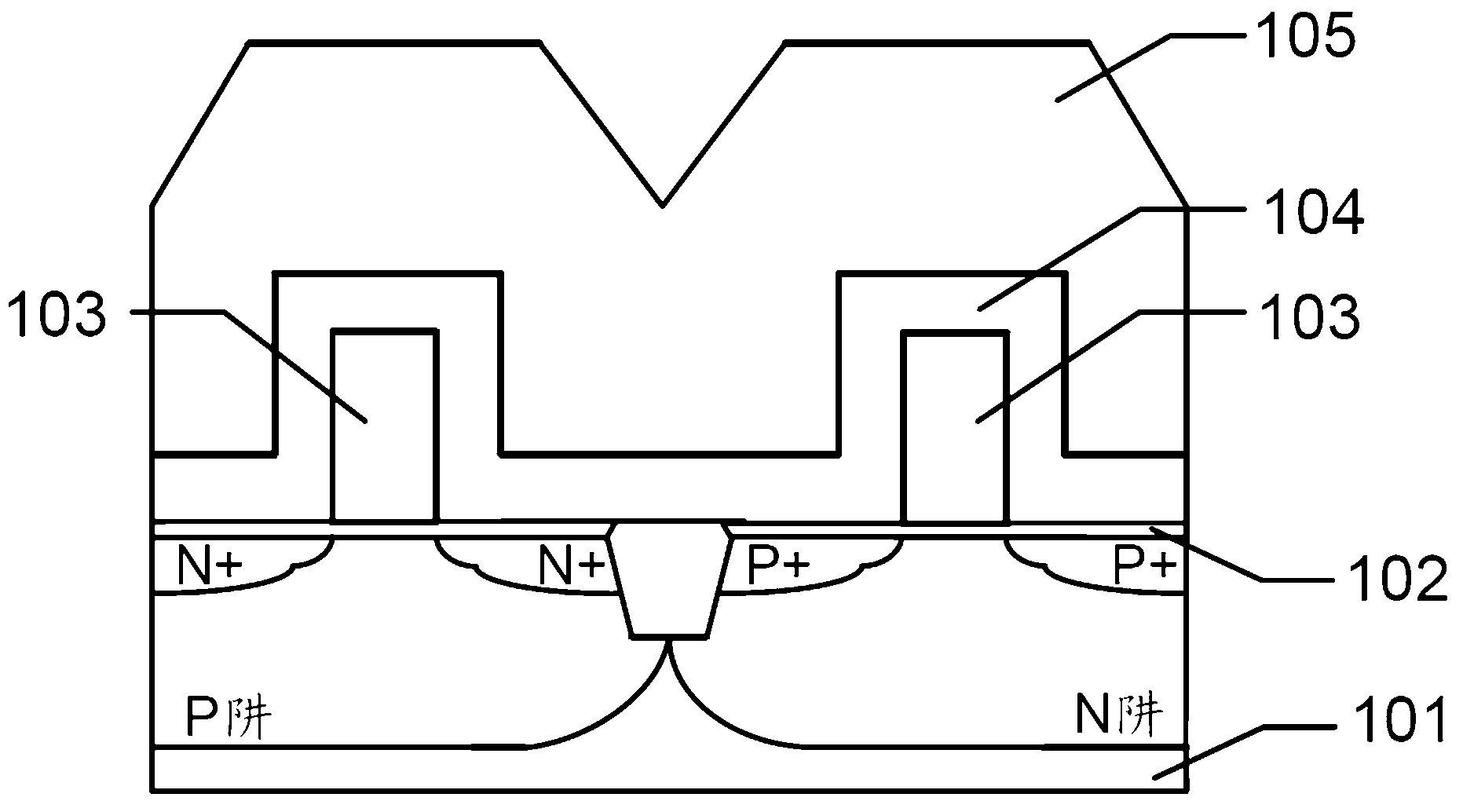

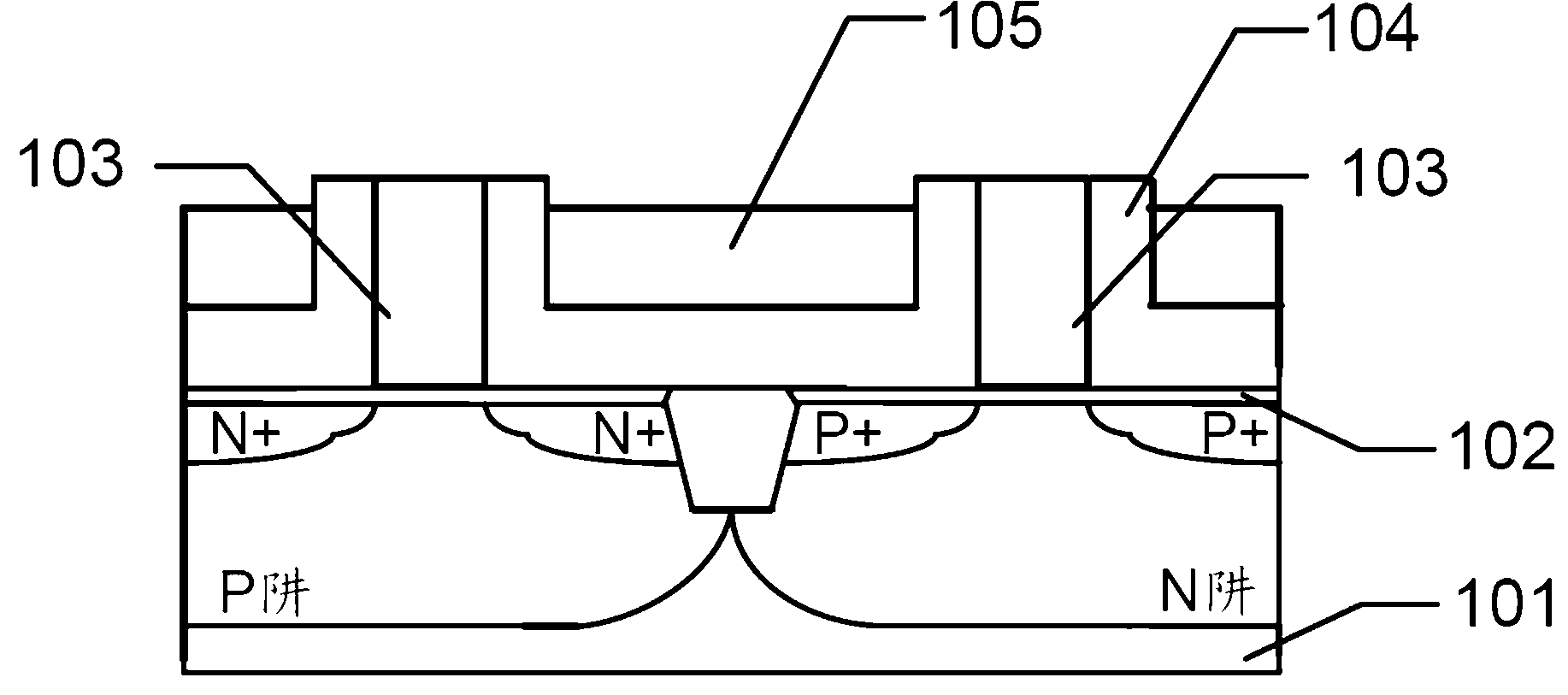

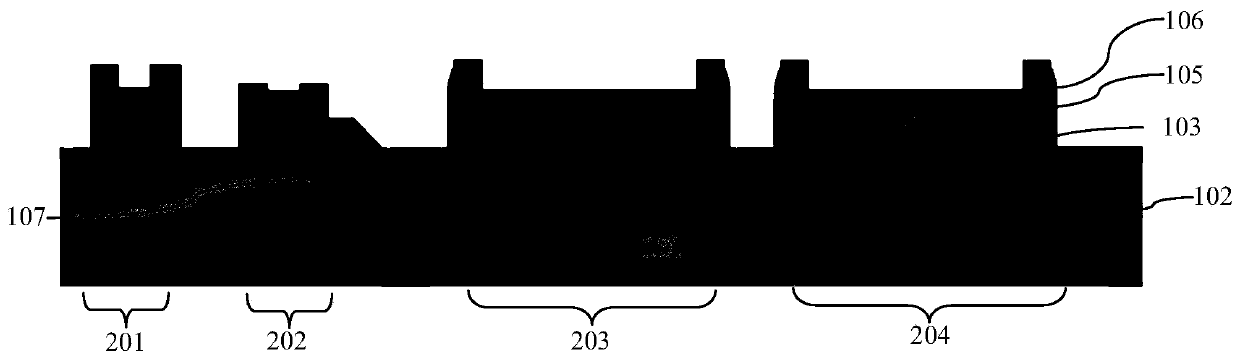

Method for manufacturing semiconductor device

ActiveCN102737994AReduce dishingImprove performanceSemiconductor/solid-state device manufacturingGate dielectricPhotoresist

The invention relates to a method for manufacturing a semiconductor device, comprising the steps of: a) providing a substrate, forming a gate dielectric layer on the substrate, forming a dummy gate on the gate dielectric layer, and forming an etch stop layer covering the gate dielectric layer and the dummy gate; b) forming a pre-metal dielectric layer on a front-end device layer structure; c) planarizing the pre-metal dielectric layer until the upper surface of the dummy gate is exposed; d) removing the dummy gate to form an opening for accommodating a metal gate; e) forming a photoresist layer within the opening and on the surface of the pre-metal dielectric layer; f) planarizing the photoresist layer and the protruding etch stop layer; g) removing the photoresist layer within the opening; and h) forming a metal gate within the opening. The method, after the dummy gate is removed, can help effectively reduce dishing phenomenon in dense areas, overcome the defects caused by residue of metal used for forming gates and reduction on the thickness of gates, and improve performance of semiconductor devices.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Manufacturing method of interlayer film

ActiveCN110473829AHigh hardnessReduce or eliminate butterfly defectsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

The invention discloses a manufacturing method of an interlayer film. The method comprises the following steps of step1, providing a semiconductor substrate forming a pattern structure; step2, using afirst insulating layer which has a high filling ability and is formed through a first growth technology to fill a pattern interval region and extending the first insulating layer to an outer portionof the pattern interval region, and forming a closed cavity while filling; step3, taking a pattern structure as an end point of grinding to carry out first chemical mechanical grinding, forming a dishing defect in a pattern structure region and at the same time, opening a cavity; step4, forming a second insulating layer by using a second growth technology, using the second insulating layer to completely fill the cavity, wherein hardness of the second insulating layer is higher than the hardness of the first insulating layer; and step5, taking the pattern structure as the end point of grindingto carry out second chemical mechanical grinding, and eliminating the dishing defect by using a characteristic that the hardness of the second insulating layer is increased. In the invention, the cavity formed through filling an interlayer film in the pattern interval region can be eliminated, and the dishing defect on an interlayer film surface of a top of the pattern interval region can be reduced or eliminated.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Vehicle floor structure convenient to clean

ActiveCN111469937AReduce generationReduce accumulationSuperstructure subunitsStructural engineeringMechanical engineering

The invention discloses a vehicle floor structure convenient to clean, which comprises a bottom supporting plate, wherein a middle reinforcing plate is arranged on the upper side of the bottom supporting plate, a surface anti-skid rubber pad is arranged on the upper side of the middle reinforcing plate, one end of the surface anti-skid rubber pad extends out of one end of the middle reinforcing plate, connecting clamping bulges are arranged at one end of the bottom supporting plate and one end of the middle reinforcing plate, one side of each connecting clamping bulge is provided with a connecting clamping groove, and one side of each connecting clamping groove is provided with an inclined surface. According to the invention, the connecting clamping bulges, the connecting clamping groovesand supporting springs are arranged, when the vehicle floor is installed, the connecting clamping bulges and the connecting clamping grooves are used for clamping, and gaps are reduced through the elastic force of the supporting springs in the connecting clamping grooves, clamping of the connecting clamping bulges and the connecting clamping grooves and the elastic force of the supporting springsduring thermal expansion and cold contraction, accumulation of dust in the gaps is further reduced through protruding of one end of the surface anti-skid rubber pad at the connecting position, and thecleaning is more convenient.

Owner:CHUZHOU YONGTONG TRAFFIC EQUIP

Grinding structural unit

InactiveCN100341667CIncrease grinding rateGood grinding rateSupport wheelsEngineeringStructural unit

Owner:FUJIAN JINHUA INTEGRATED CIRCUIT CO LTD

Improvement for shallow slot separated structure height homogeneity

InactiveCN1327503CDisadvantages of adjusting the rate of the planarization polishing process to be inconsistentDisadvantages of inconsistent process rate adjustmentSemiconductor/solid-state device manufacturingEngineeringOxide

When oxide layer locating out of shallow-trench is removed, complex number of arrayed oxide columns and oxide holes are formed on oxide layer on active region in order to acquire optimal polishing speed balance point when CMP crafts is made for semiconductor substrate with larger active region and higher density.

Owner:GRACE SEMICON MFG CORP

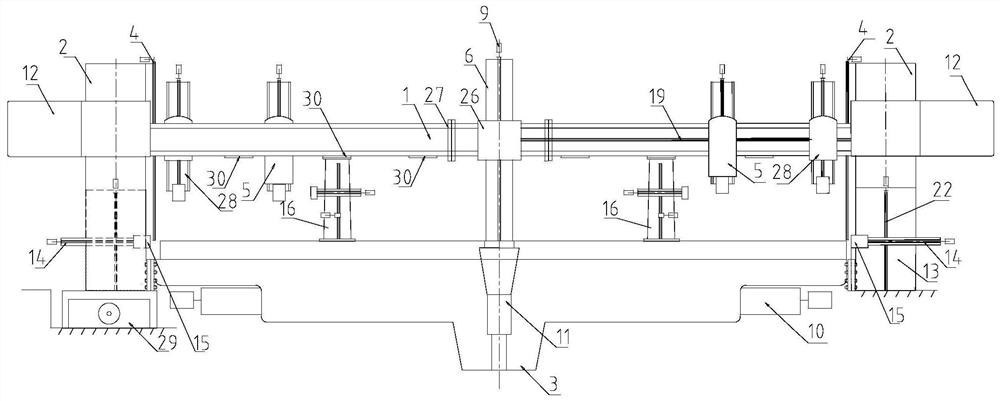

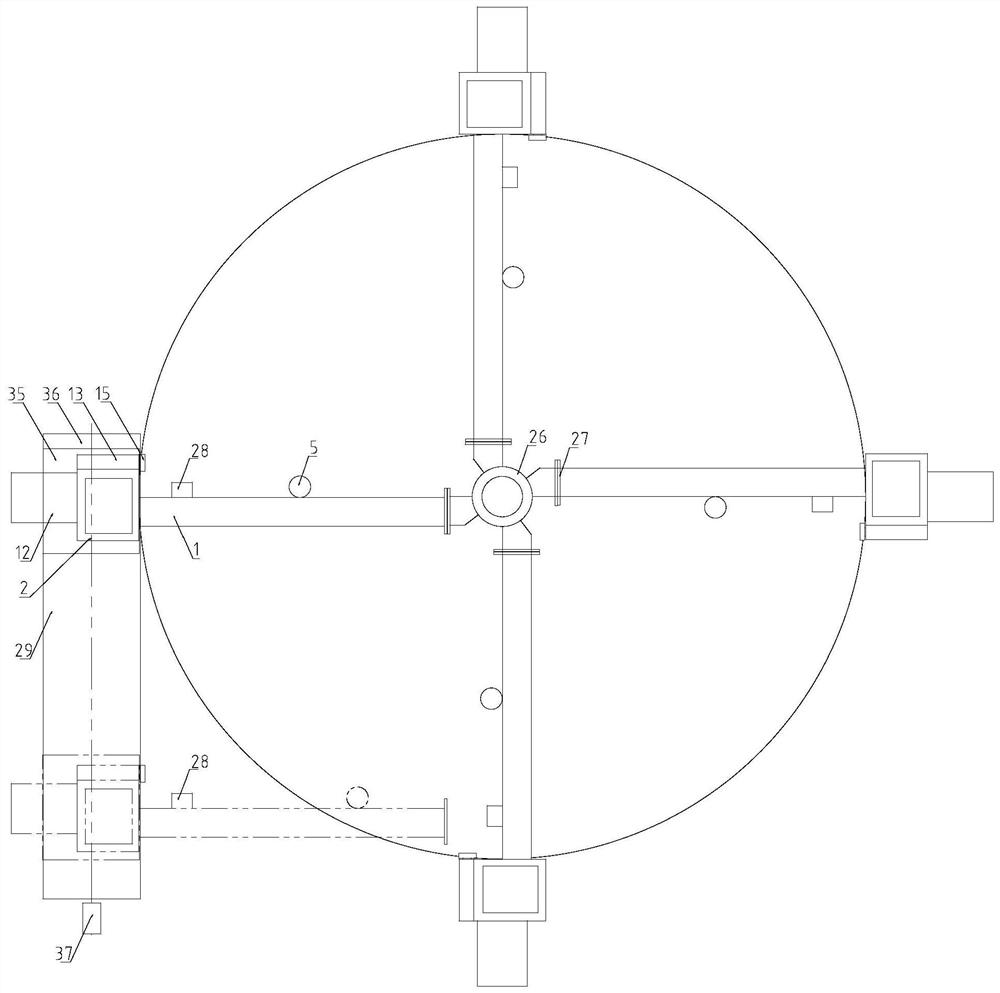

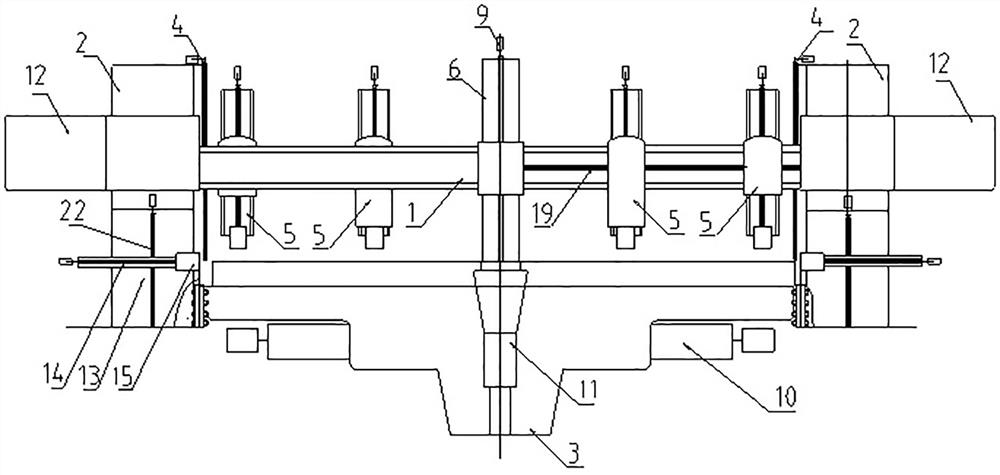

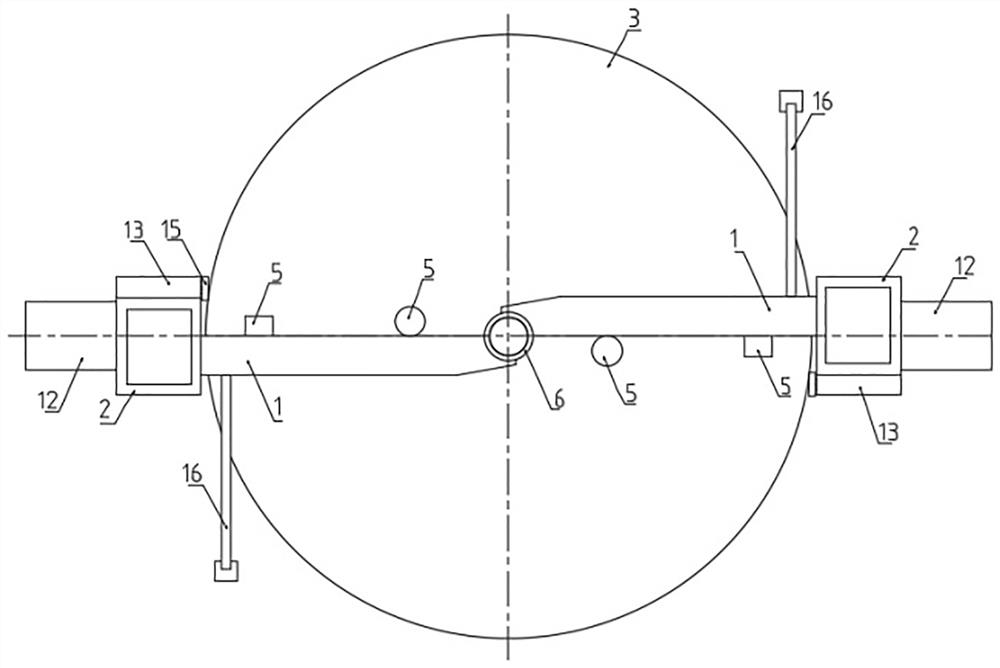

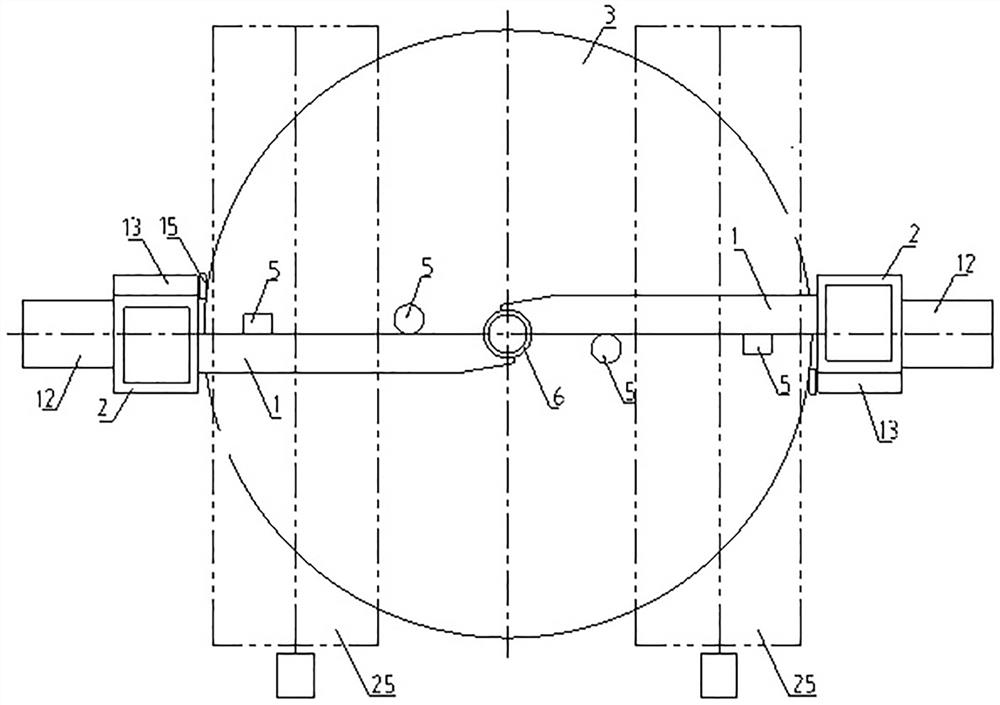

Multi-column and multi-tool high-efficiency composite machining center

ActiveCN112589448BGuaranteed rigidityEasy to processOther manufacturing equipments/toolsEngineeringMachine

The invention relates to the field of vertical lathes, in particular to a multi-column multi-tool high-efficiency composite machining center, comprising a beam, a column and a worktable, and a column lifting assembly is arranged between the beam and the column, and is characterized in that the column is 4-8 They are evenly arranged on the periphery of the worktable in the form of extremely symmetrical distribution; the worktable is provided with a central column in the center, and a central beam sleeve is arranged on the central column, and the central beam sleeve is connected with the lifting assembly of the central column. The flange is connected to the center beam sleeve, the lifting and lowering of the beam, the lifting and lowering of the boring and milling head on the beam, the horizontal movement of the boring and milling head and the turning tool holder, the column retraction operation of the column, and the rotation of the worktable are controlled by the numerical control system respectively. . Compared with the prior art, the beneficial effects of the present invention are as follows: equipped with different tools and accessories, it can realize five functions of gantry boring and milling, gear milling machine, radial drill, vertical turning and floor boring and milling, and becomes an efficient and multifunctional machine. The compound vertical lathe doubles the processing efficiency.

Owner:徐绍波

Semiconductor device bonding structure and bonding method thereof

ActiveCN105810649BReduce line widthMinimize electrical interconnection failureSemiconductor/solid-state device detailsSolid-state devicesMaterials scienceMetal

The present invention relates to a semiconductor device bonding structure and a bonding method thereof. The bonding structure includes: a first metal layer, the surface of the first metal layer has a first pad, and the first pad has a first Opening pattern; second metal layer, the surface of the second metal layer has a second welding pad, and the second welding pad has a second opening pattern; the surface of the first metal layer and the second metal layer are bonded and connected , the first pad and the corresponding second pad are aligned up and down for bonding connection, the first opening pattern of the first pad and the second opening pattern of the second pad are mutually bonded on the bonding contact surface stagger.

Owner:GALAXYCORE SHANGHAI

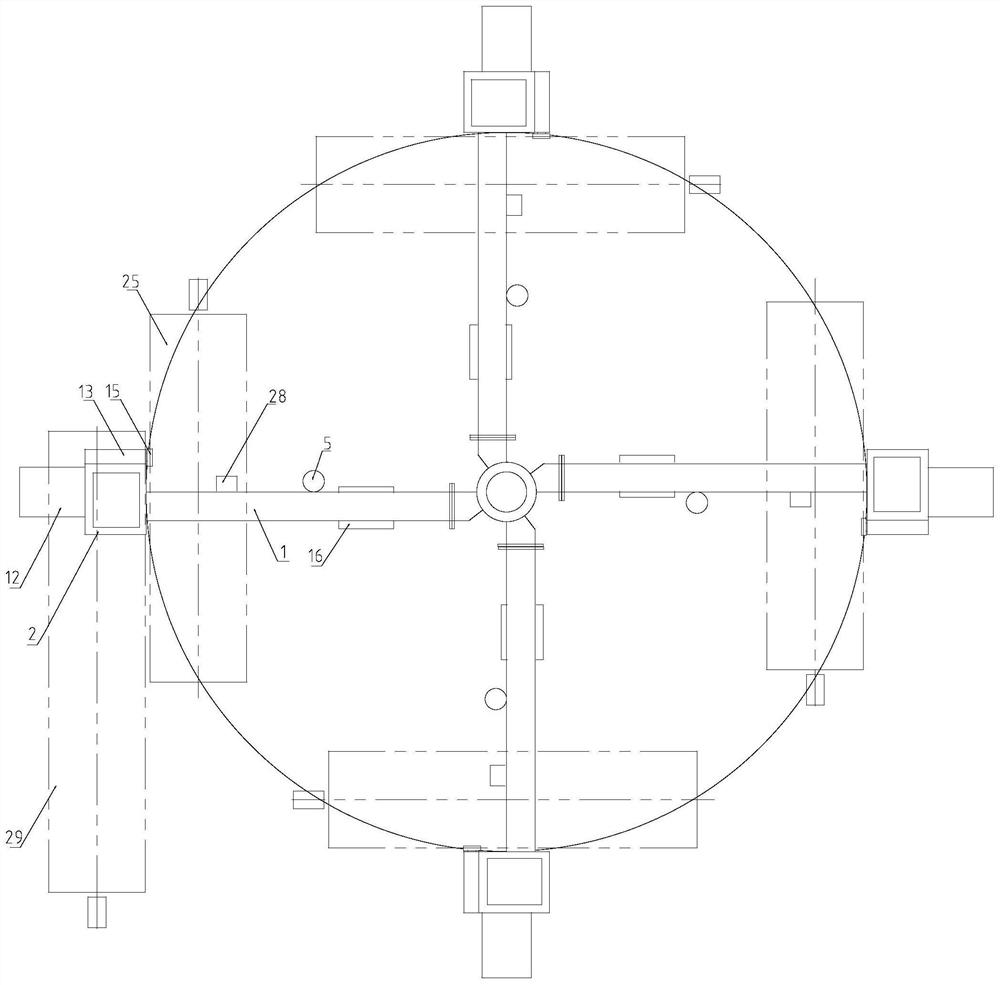

Two-column multi-cutter vertical machining center

InactiveCN112658807AGuaranteed rigidityEasy to processLarge fixed membersMetal working apparatusSynchronous controlClassical mechanics

The invention relates to the field of vertical lathes, in particular to a two-column multi-cutter vertical machining center. The two-column multi-cutter vertical machining center comprises a cross beam, two stand columns and a workbench, and the two stand columns are arranged on the two sides of the workbench respectively. The cross beam is of a horizontally-arranged integrated structure, a middle column lifting assembly is arranged between the cross beam and a middle column, a stand column lifting assembly is arranged between the cross beam and the stand columns, the middle column lifting assembly and the stand column lifting assembly are synchronously controlled to achieve lifting movement of the cross beam, four boring and milling heads are arranged on the cross beam, and every two boring and milling heads are symmetrically distributed relative to the middle column. The lifting movement of the cross beam, the horizontal movement of each boring and milling head on the cross beam, the lifting movement of a square ram of a side tool rest and the rotation of the workbench are respectively controlled by a numerical control system. Compared with the prior art, the two-column multi-cutter vertical machining center has the following advantages that different tools and accessories are arranged, five functions of gantry boring and milling, a gear milling machine, a radial drill, a vertical lathe and floor type boring and milling can be achieved, the combined vertical lathe is efficient and multifunctional, and the machining efficiency is improved by multiple times.

Owner:徐绍波

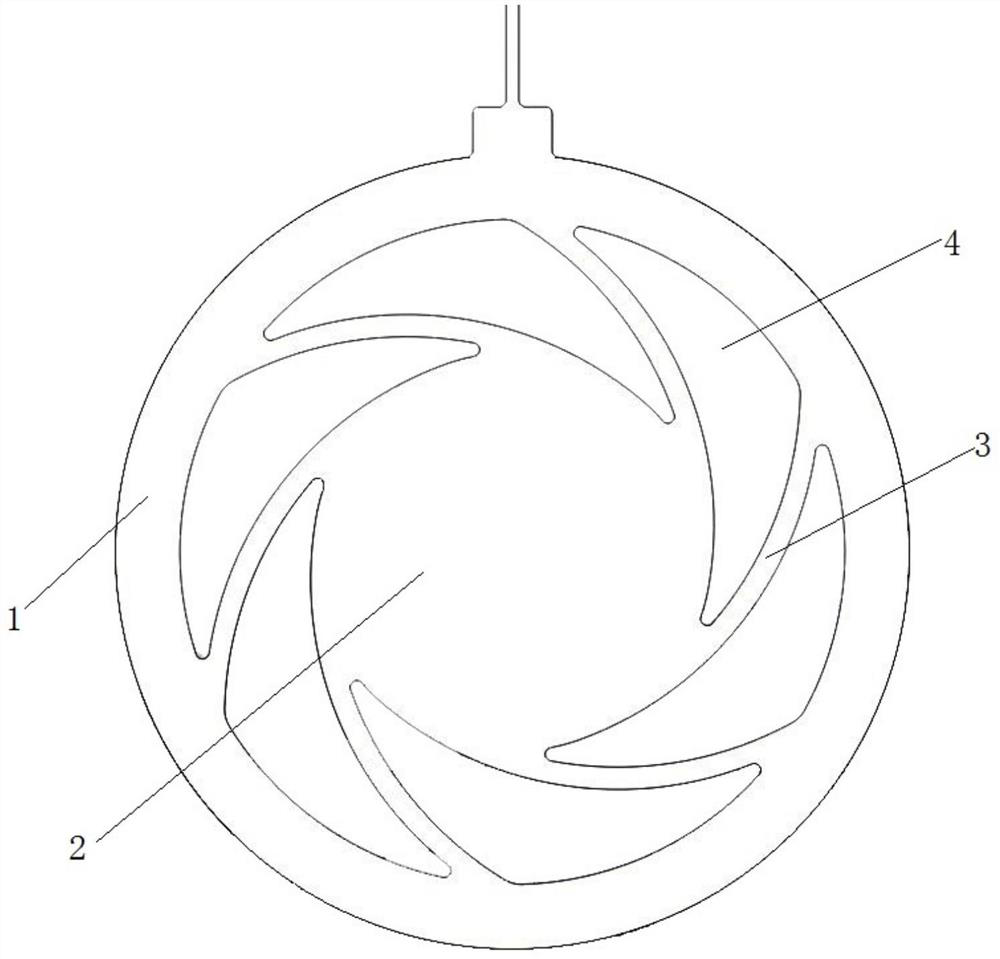

Faraday disk, ion mobility tube and ion mobility spectrometer

The invention relates to a Faraday disk, an ion migration tube and an ion mobility spectrometer. The Faraday disk comprises a mounting ring and an ion receiving electrode which are located in the sameplane, the mounting ring is suitable for being connected with the inner wall of a migration tube, connecting pieces are arranged between the ion receiving electrode and the mounting ring, and an avoidance space allowing the connecting pieces to deform is formed between the adjacent connecting pieces; under the action of high temperature, the mounting ring is heated to expand to apply first bias pressure towards the center of the mounting ring to the connecting pieces, the ion receiving electrode is heated to expand to apply second bias pressure away from the center of the mounting ring to theconnecting pieces, the first bias pressure and the second bias pressure are opposite in action direction and act on the connecting pieces at the same time, the connecting pieces are bent and deformed, stress is more uniform, deformation consistency of the multiple connecting pieces is better facilitated, the ion receiving electrode can rotate in the circumferential direction more easily, then thephenomenon that the surface of the ion receiving electrode protrudes or sinks is reduced, and the influence on an electric field between the ion receiving electrode and a front electrode is smaller.

Owner:SUZHOU WEIMU INTELLIGENT SYST CO LTD

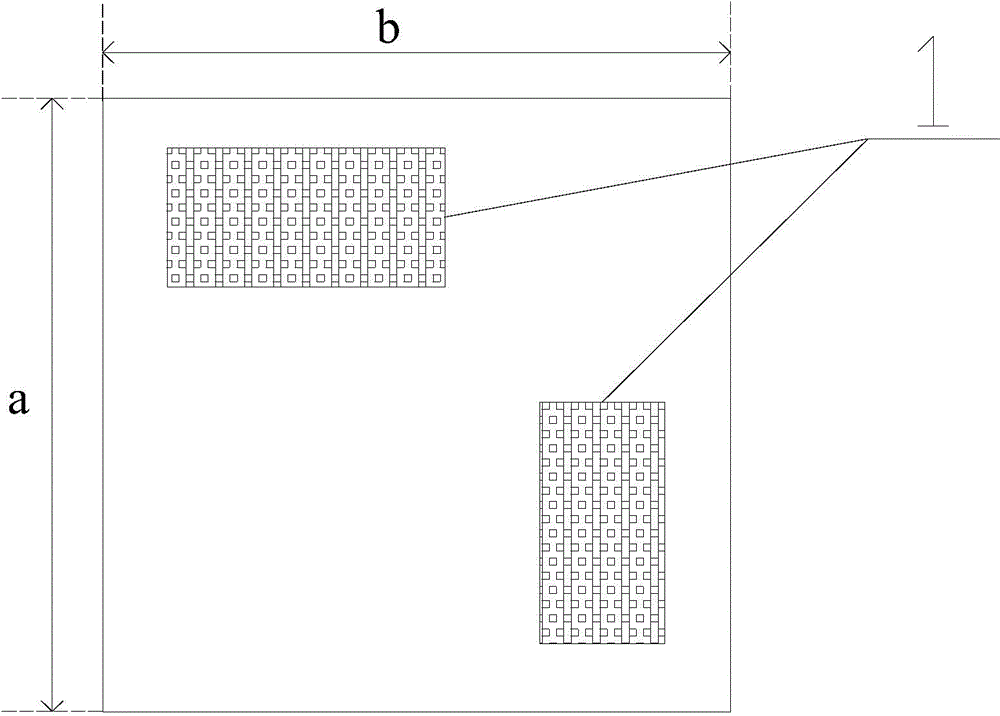

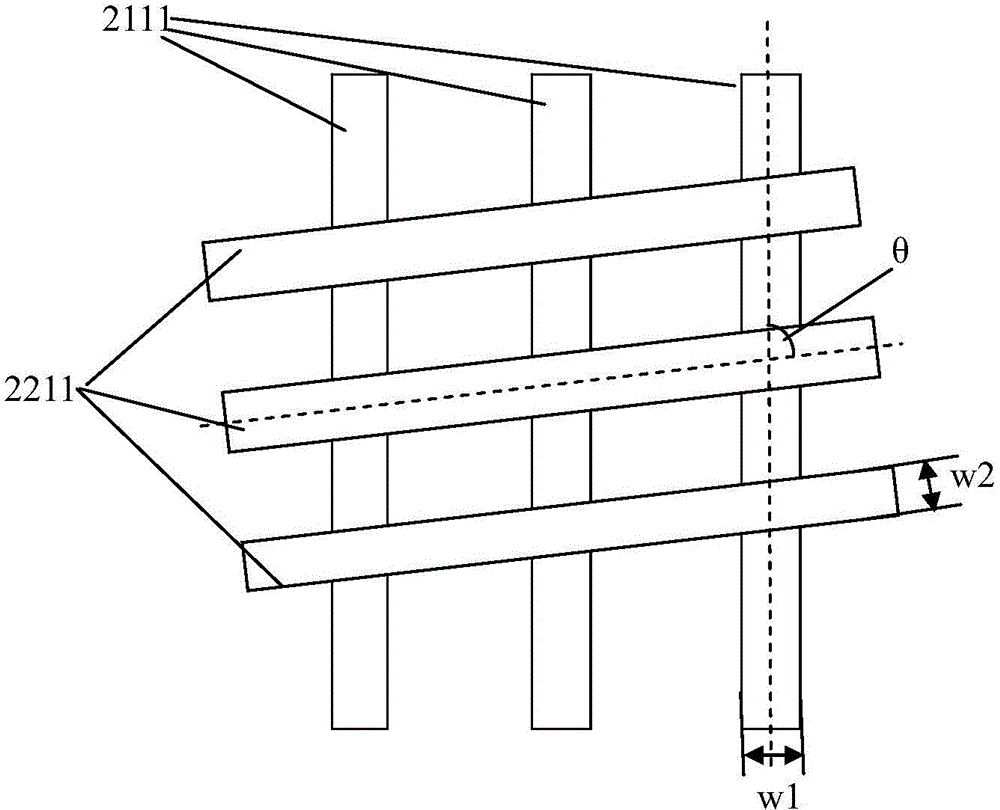

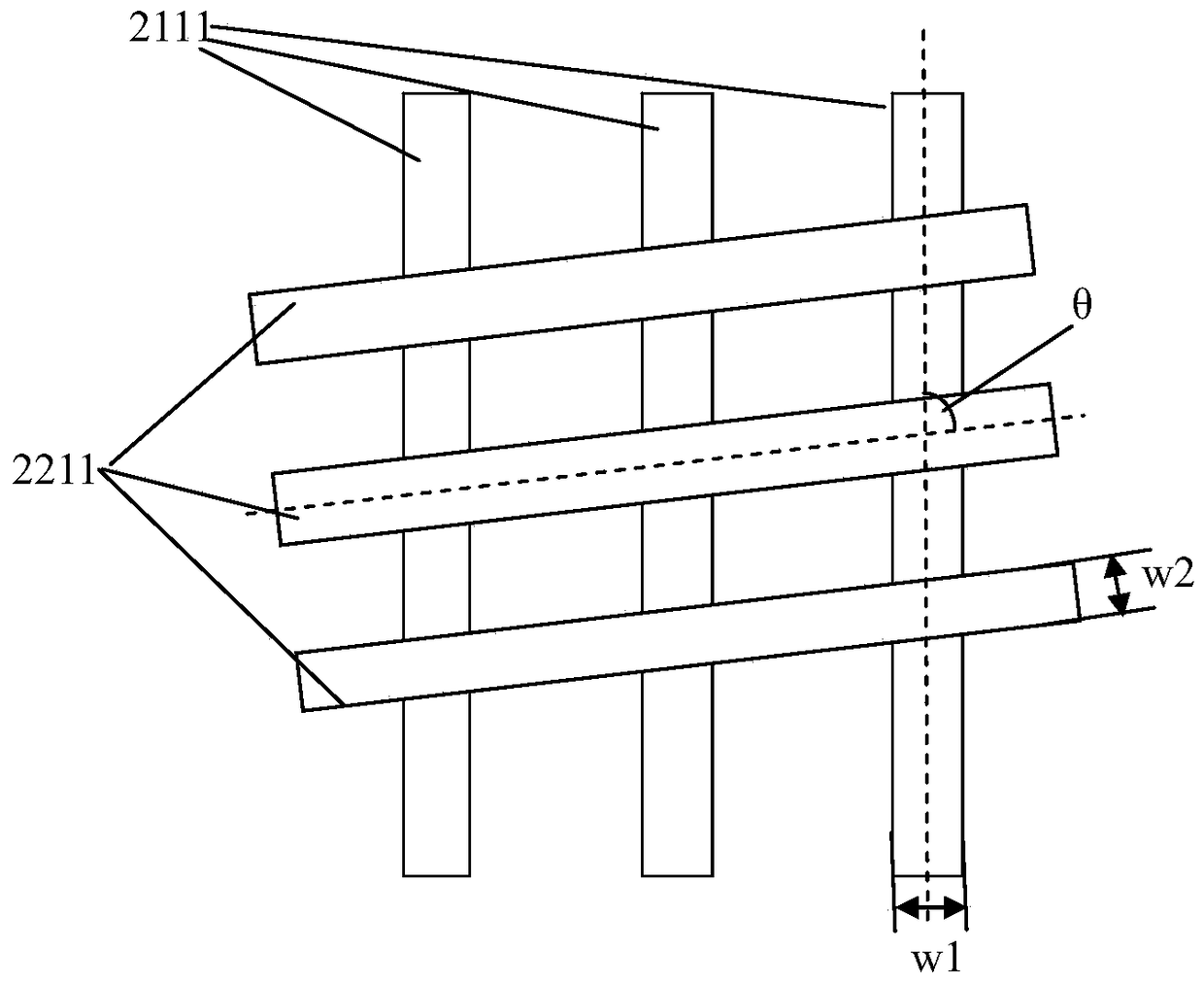

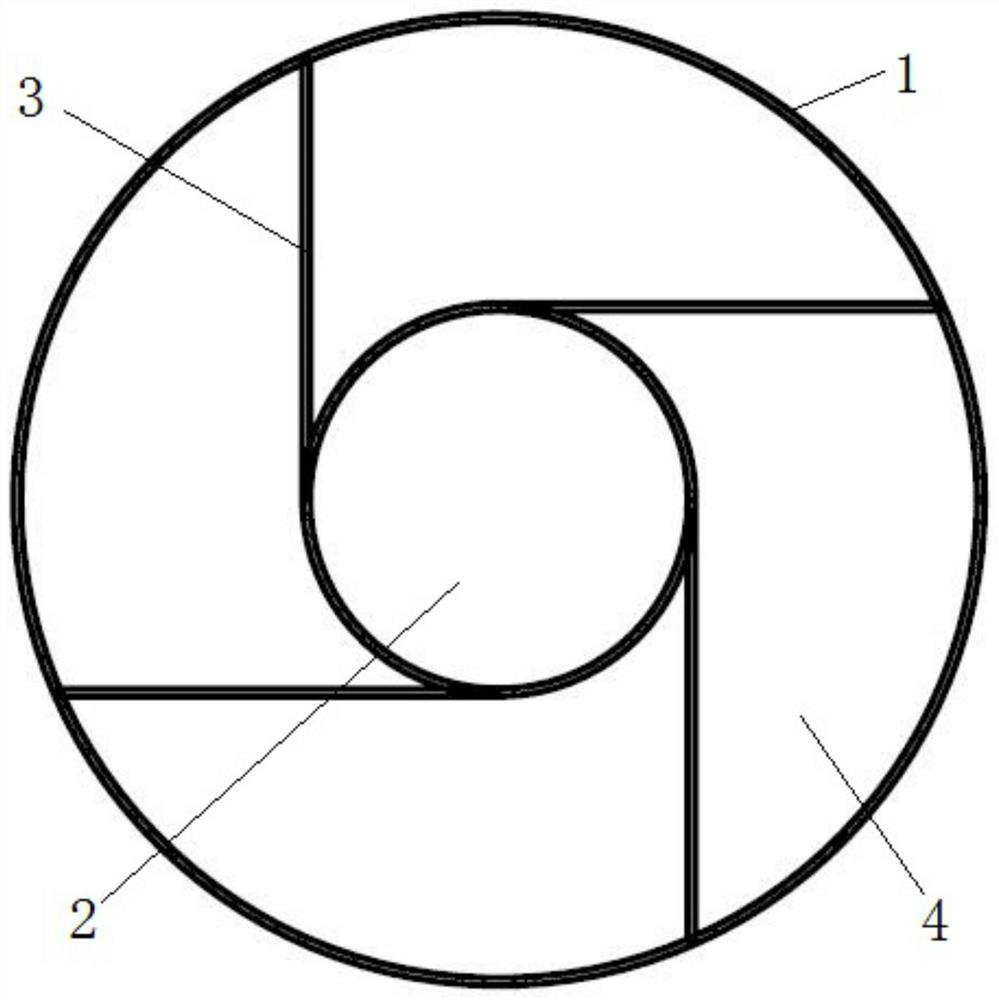

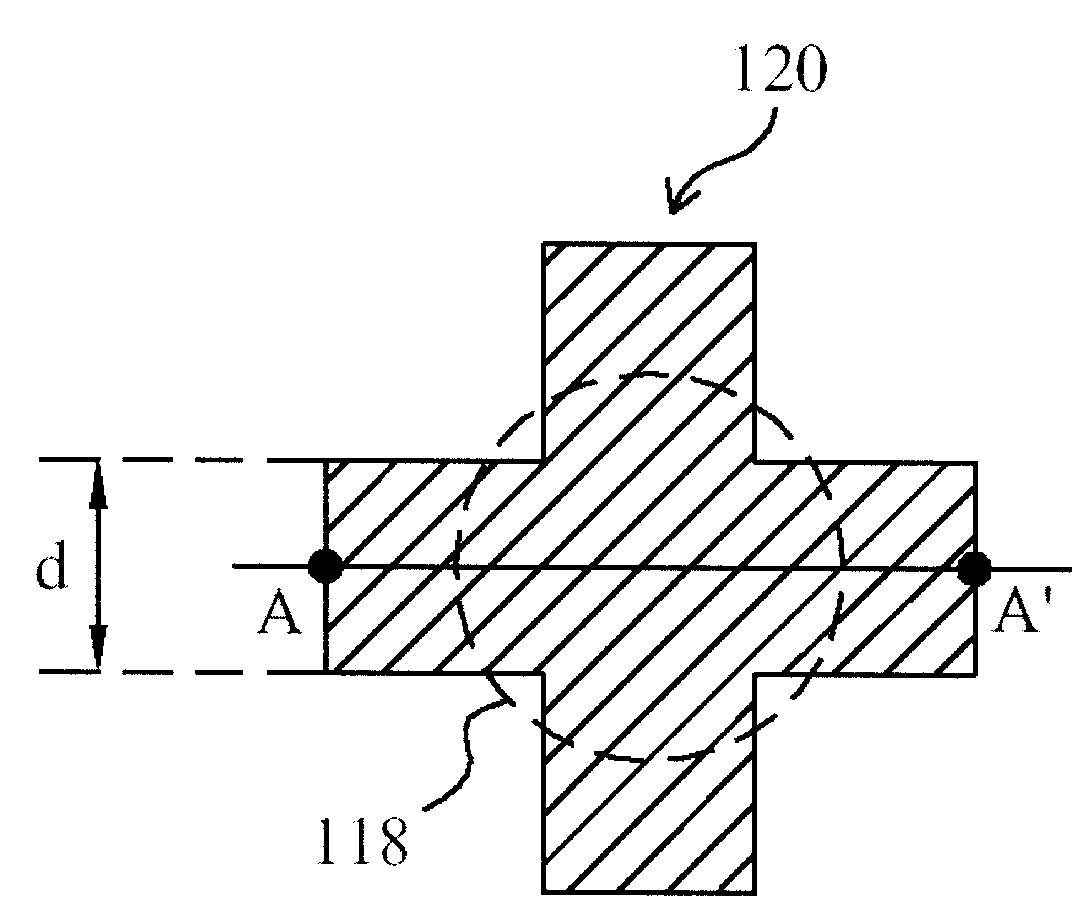

Light shield, hole arrangement and method for reducing dishing of metal plug

InactiveCN101587293BReduce dishingReduce manufacturing riskOriginals for photomechanical treatmentEngineeringPhotomask

A hole layout for reducing dishing of metal plugs, comprising a substrate and an insulating layer, wherein the insulating layer is on the substrate, and a hole for filling metal is provided in the insulating layer, and the hole is Having a profile in the horizontal plane defined by a closed boundary and a reduced critical portion within said boundary for reducing dishing of said metal plug. The hole layout for reducing metal plug dishing of the present invention has the advantages of reducing the dishing phenomenon of metal plugs filled in the holes, reducing the risk of the manufacturing process, increasing the freedom of photomask layout and reducing the chip area.

Owner:RICHTEK TECH

Prefabricated underground diaphragm wall and its construction method

The present invention relates to the technical field of civil engineering, and aims to provide a prefabricated underground diaphragm wall and its construction method. The key point of the technical solution is to set up an installation channel on the ground, and several diaphragm wall units are sequentially placed in the installation channel , a telescopic assembly is sandwiched between two adjacent continuous wall units. The telescopic assembly includes two mounting plates and a telescopic rubber strip. The telescopic rubber strip is sandwiched between two mounting plates. The panels are attached to the opposite side walls of the two continuous wall units respectively. In the present invention, the telescopic rubber strips can adapt to the effect of thermal expansion and contraction between the continuous wall units, thereby reducing the possibility of bulge or depression between the continuous wall units.

Owner:江苏城归设计有限公司

Grinding composite for planarization metal layer

ActiveCN101928520BHigh grinding removal rateReduce dishingPolishing compositions with abrasivesEtchingMetal

The invention discloses a grinding composite for planarization metal layer. The grinding composite at least comprises 7,500ppm to less than 5,000ppm by weight of gridding granules, hydrogen peroxide, accelerator, co-corrosion inhibitor and water, wherein the co-corrosion inhibitor comprises a first corrosion inhibitor and a second corrosion inhibitor, and the co-corrosion inhibitor is applied to the planarization metal layer. The composite is capable of maintaining a high grinding removing rate for the metal layer and inhibiting metallic etching; moreover, the composite is capable of reducing gridding deficiencies including dish down, abrasion and the like.

Owner:UWIZ TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com