Chemical mechanical polishing composition

A technology of chemical mechanics and composition, applied in the direction of organic chemistry, other chemical processes, chemical instruments and methods, etc., can solve the problems of undisclosed and slow down the etching rate of abrasive composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

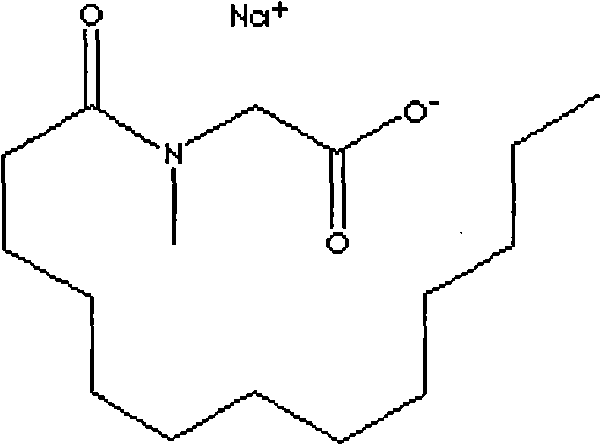

[0037] Listed according to Table 1, using the abrasive slurry composition control comprising silica sol abrasive grains, alanine, hydrogen peroxide, 1-H-benzotriazole, sodium cocoyl sarcosinate and solvent as water Samples are tested.

[0038]

[0039] Table 1

[0040] The grinding test was performed under the following conditions.

[0041] Grinding machine table: Mirra polisher (Applied Materials)

[0042] Wafer type: 8 o'clock Copper-clad thin film wafer (Ramco Co)

[0043] Grinding Downforce: 1.5psig and 0psig

[0044] Platform speed: 93rpm

[0045] Vehicle speed: 87rpm

[0046] Polishing pad: IC 1010 (Rodel Inc)

[0047] Slurry flow rate: 150ml / min.

[0048] The wafer uses a 4-point probe to measure the grinding rate, and the results are shown in Table 2:

[0049]

[0050] Table 2

[0051] Among them, the RR refers to the grinding removal rate (Removal Rate), WIWNU refers to the wafer surface uniformity (With-in-wafer-non-uniformity), and DER refers to the d...

Embodiment 2

[0054] Listed according to Table 3, using the abrasive slurry composition control comprising silica sol abrasive grains, alanine, hydrogen peroxide, 1-H-benzotriazole, sodium cocoyl sarcosinate and solvent as water Samples are tested.

[0055]

[0056] table 3

[0057] The grinding test was carried out according to the following conditions, and the results are recorded in Table 4.

[0058] Grinding machine table: Mirra polisher (Applied Materials)

[0059] Grinding Downforce: 3psig, 1.5psig and 0psig

[0060] Platform speed: 93rpm

[0061] Vehicle speed: 87rpm

[0062] Polishing pad: IC 1010 (Rodel Inc)

[0063] Slurry flow rate: 150ml / min.

[0064]

[0065]

[0066] Table 4

[0067] According to table 4 result, under fixed sarcosine concentration, grinding removal rate decreases along with the increase of benzotriazole concentration, can obtain a better composition (comparative example 6), has the high grinding removal rate of copper, and low etch rate, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com