Superfine grinding wheel for hard and crisp crystal substrate

An ultra-precision, crystalline technology, used in bonded grinding wheels, abrasives, semiconductor/solid-state device manufacturing, etc., can solve the problem of high cost, and achieve the effect of low grinding wheel cost, high grinding removal rate, and low grinding surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

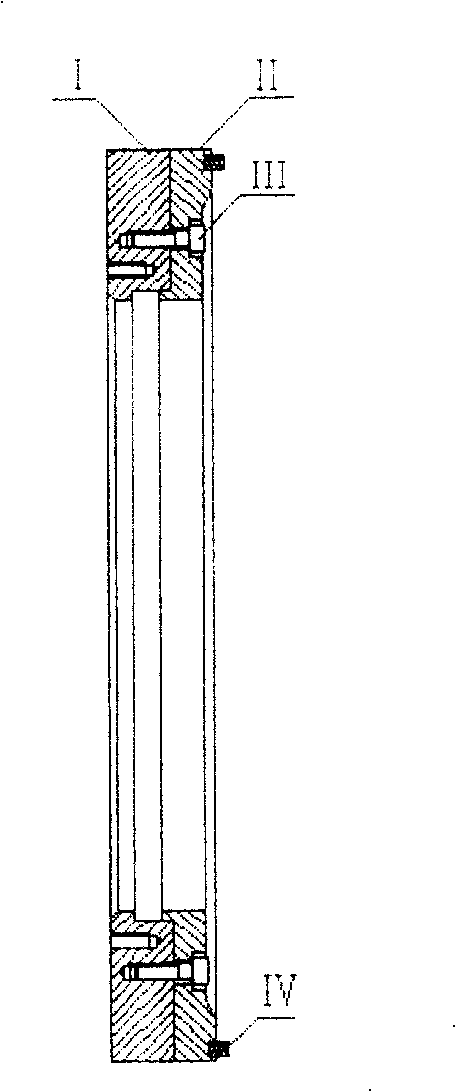

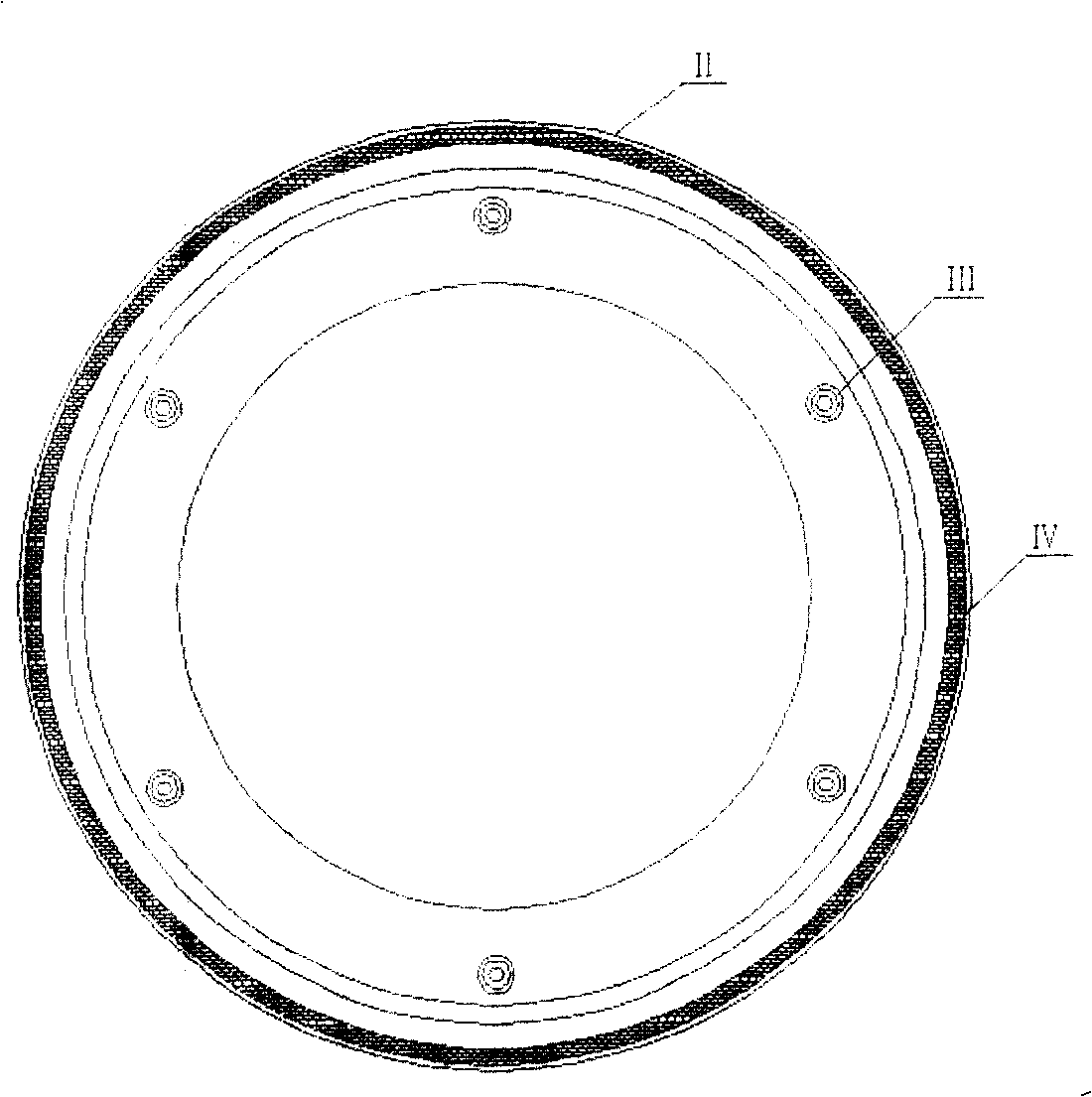

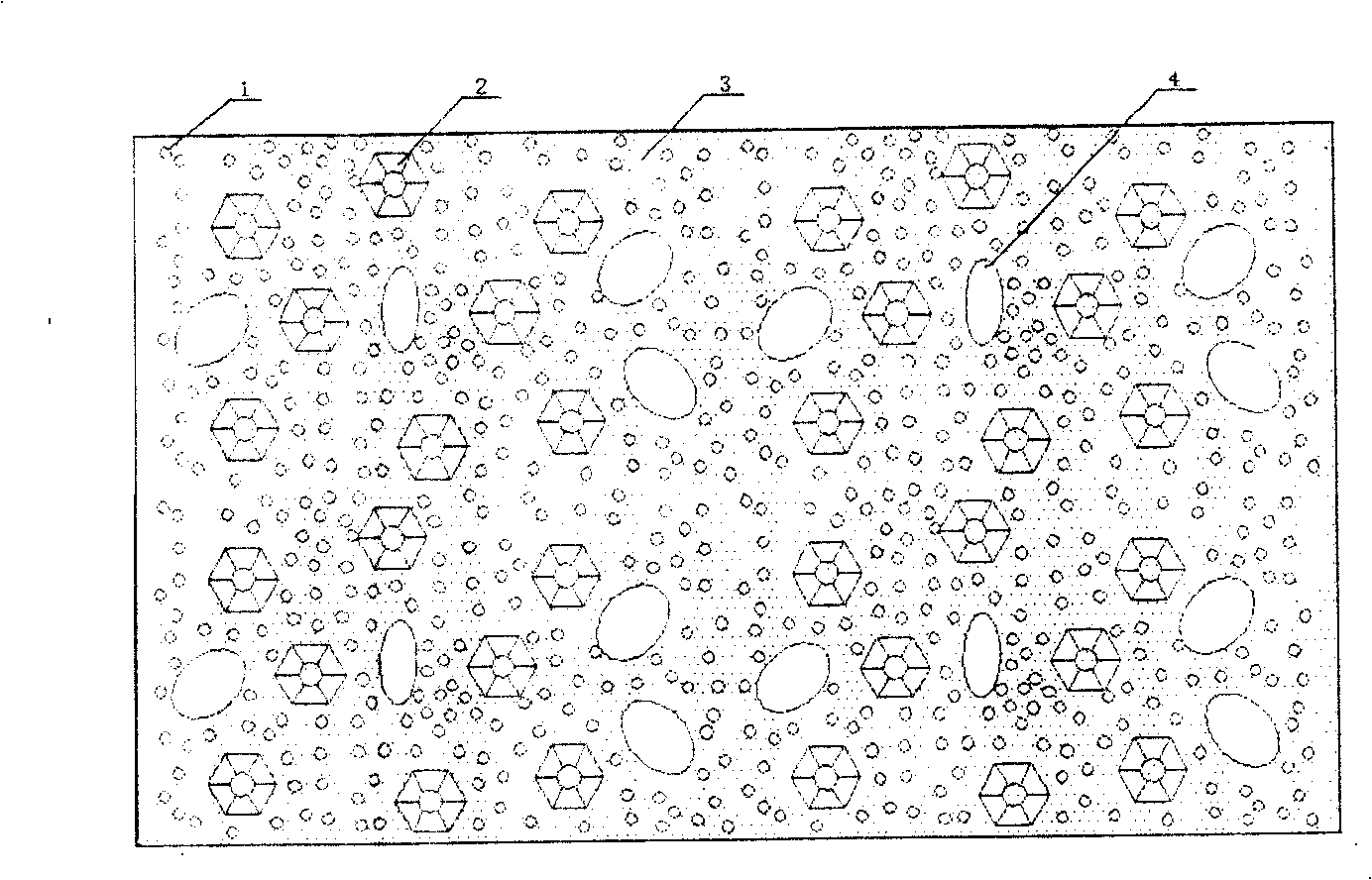

[0009] The specific implementation of the present invention will be described in detail in conjunction with the accompanying drawings. Configure the batching of 100g emery wheel grinding layer IV: take weight and be 40g cerium oxide abrasive, the particle diameter of abrasive grain is 3 μm; Take weight and be 20g sodium carbonate as pH regulator; Take weight and be that 10g sodium peroxide is as oxidant; Weigh 10g of talcum powder as a throwing aid; weigh 20g of phenolic resin as a binder; the PH value regulator in the grinding wheel filler 3 can provide an acidic or alkaline processing environment during the grinding process. Sodium carbonate. The oxidizing agent in the grinding wheel filler 3 can oxidize the surface of the crystal substrate during the grinding process to improve the material removal rate, and sodium peroxide is selected as the oxidizing agent. In the grinding process, in order to increase the polishing performance of the grinding wheel, reduce the friction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com