Accelerators for Hard Materials Grinding

A technology of hard materials and accelerators, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of deep material surface, increased post-polishing, and reduced yield, so as to reduce the interface damage layer, Improve production efficiency and improve the effect of mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Preparation of accelerator for hard material grinding: Weigh each raw material according to the weight ratio, add 5 parts of ethanolamine, 5 parts of triethanolamine, 10 parts of polyethylene glycol, 10 parts of propylene glycol, and 15 parts of polyethylene in 15 parts of water in sequence Alcohol, 3 parts of sodium polyacrylate, 30 parts of acrylic acid-acrylate copolymer, 5 parts of nonylphenol polyoxyethylene ether, 2 parts of hydroxyethyl cellulose, after stirring evenly, add nitric acid or sodium hydroxide solution to adjust the pH value is 8.5.

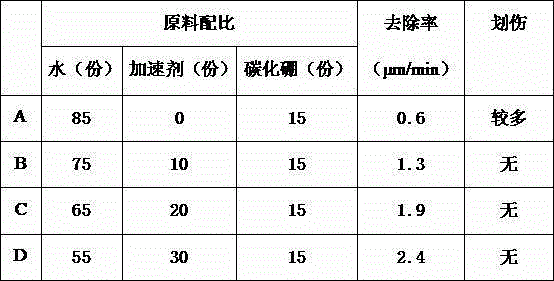

[0016] Prepare four grinds, A, B, C, D:

[0017] Add 0 parts, 10 parts, 20 parts, and 30 parts of accelerators to 85 parts, 75 parts, 65 parts, and 55 parts of water respectively, and add 15 parts of boron carbide with a particle size of 320 mesh (40-50 μm) after stirring evenly. After stirring evenly, add nitric acid or sodium hydroxide solution to adjust the pH to 7.5.

[0018] Grind the prepared sample on Yujing YJ2...

Embodiment 2

[0024] Preparation of accelerator for hard material grinding: Weigh each raw material according to the weight ratio, add 8 parts of ethanolamine, 8 parts of triethanolamine, 1 part of polyethylene glycol, 1 part of propylene glycol, and 2 parts of polyethylene in 2 parts of water in sequence Alcohol, 10 parts of sodium polyacrylate, 50 parts of acrylic acid-acrylate copolymer, 17 parts of nonylphenol polyoxyethylene ether, 1 part of hydroxyethyl cellulose, after stirring evenly, add nitric acid or sodium hydroxide solution to adjust the pH value is 8.5.

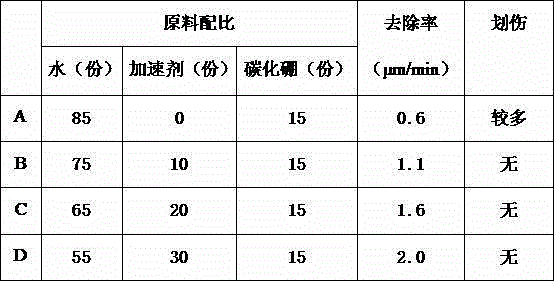

[0025] Prepare four grinds, A, B, C, D:

[0026] Add 0 parts, 10 parts, 20 parts, and 30 parts of accelerators to 85 parts, 75 parts, 65 parts, and 55 parts of water respectively, and add 15 parts of boron carbide with a particle size of 320 mesh (40-50 μm) after stirring evenly. After stirring evenly, add nitric acid or sodium hydroxide solution to adjust the pH to 7.5.

[0027] Grind the prepared sample on Yujing YJ2M16B-...

Embodiment 3

[0033] Preparation of accelerator for hard material grinding: Weigh each raw material according to the weight ratio, add 2 parts of ethanolamine, 2 parts of triethanolamine, 10 parts of polyethylene glycol, 10 parts of propylene glycol, and 20 parts of polyethylene in 27 parts of water in sequence Alcohol, 1 part of sodium polyacrylate, 10 parts of acrylic acid-acrylate copolymer, 3 parts of nonylphenol polyoxyethylene ether, 15 parts of hydroxyethyl cellulose, after stirring evenly, add nitric acid or sodium hydroxide solution to adjust the pH value is 8.5.

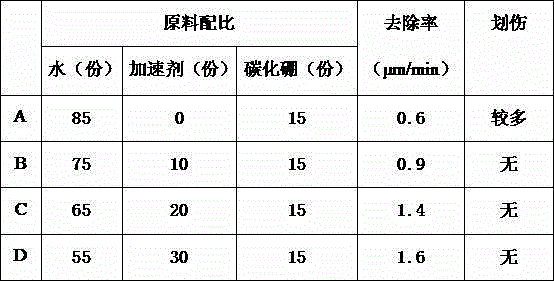

[0034] Prepare four grinds, A, B, C, D:

[0035] Add 0 parts, 10 parts, 20 parts, and 30 parts of accelerators to 85 parts, 75 parts, 65 parts, and 55 parts of water respectively, and add 15 parts of boron carbide with a particle size of 320 mesh (40-50 μm) after stirring evenly. After stirring evenly, add nitric acid or sodium hydroxide solution to adjust the pH to 7.5.

[0036] Grind the prepared sample on Yujing YJ2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com