Method and apparatus for covering a pressure vessel

a pressure vessel and pressure technology, applied in valve housings, container discharging methods, transportation and packaging, etc., can solve the problems failure of lcf bolts, and failure of pressure vessels with thick flat covers with bores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

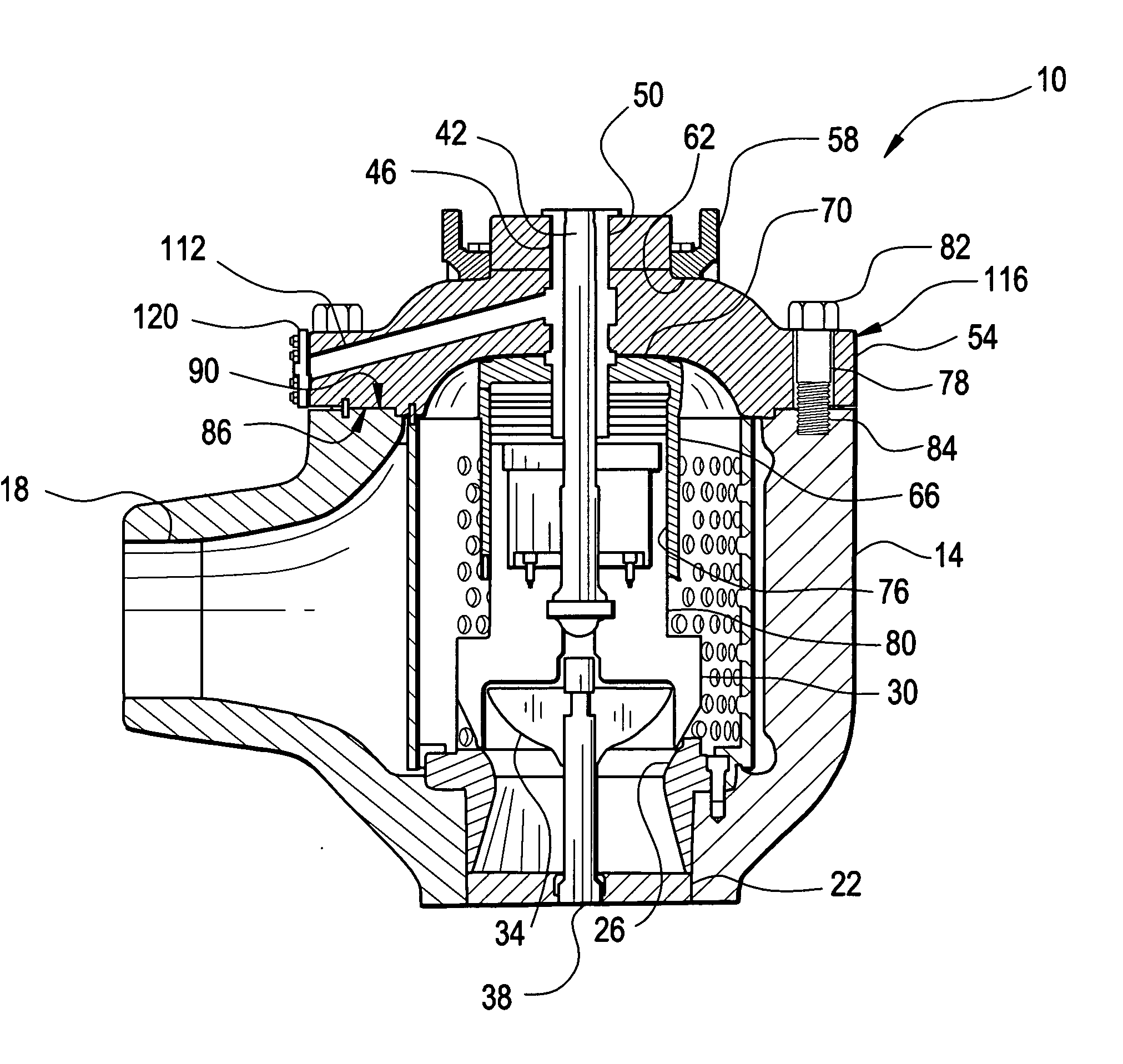

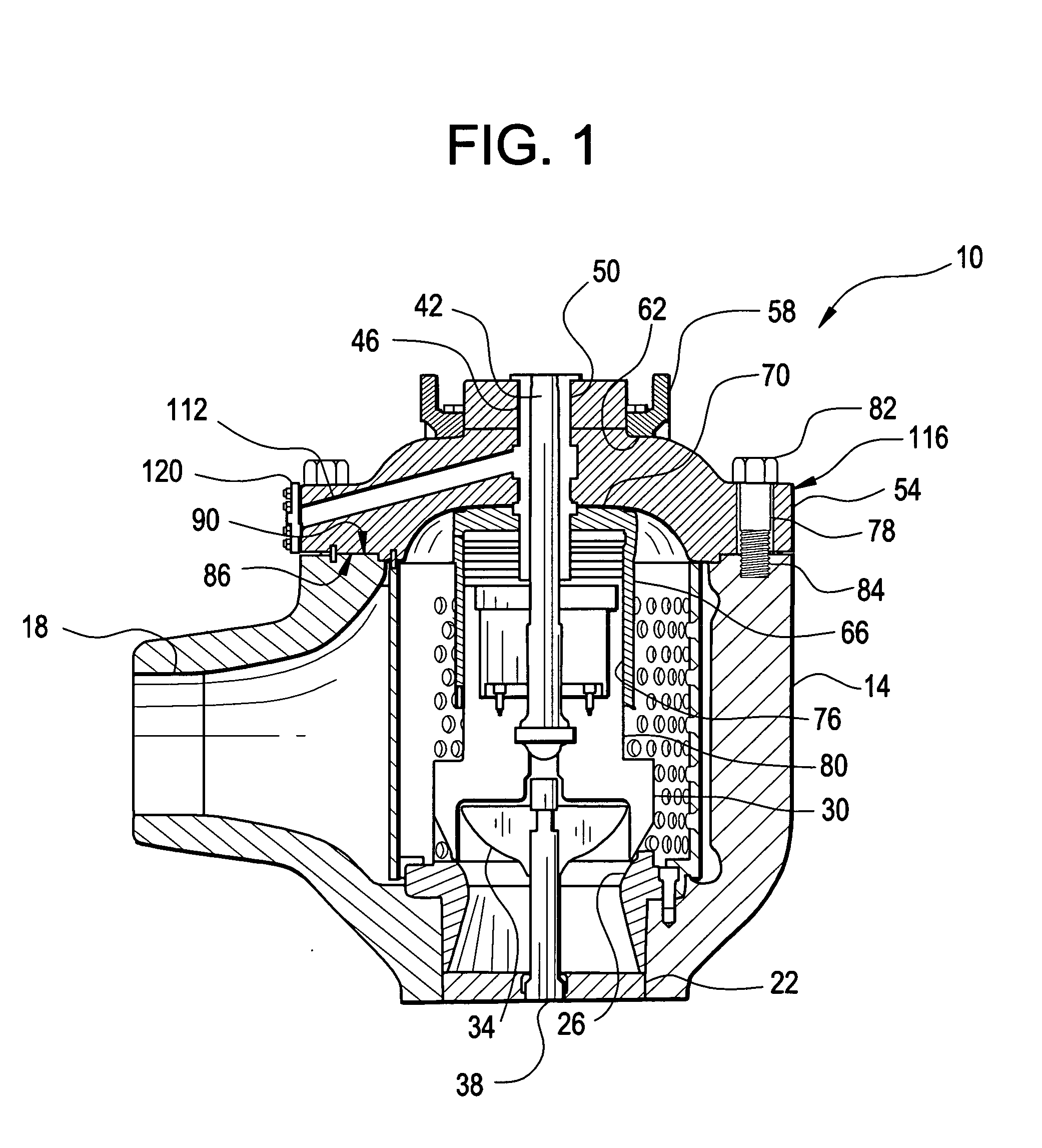

[0014]Referring to FIG. 1, a steam valve assembly in accordance with an embodiment of the invention is generally shown at 10. The valve assembly 10 includes a valve body 14 with an inlet 18 and an outlet 22. A seat 26, sealably attached to the body 14, may receive such as a control valve head 30 or a stop valve head 34. Flow through the valve 10 from the inlet 18 to the outlet 22 flows through the annular opening between the heads 30, 34 and the valve seat 26. Flow of steam is halted when either valve head 30, 34 contacts the seat 26. The stop valve head 34 is actuated through the stop valve stem 38 by a stop valve actuator (not shown). The stop valve is designed to be fully opened or fully closed and may be used as an emergency shut off valve. The control valve head 30 is actuated through control valve stem 42 by a control valve actuator (not shown). The control valve is designed to allow for variable levels of closure depending upon how far the control valve head 30 is from the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com