Coating liquid used before film evaporation and preparation process thereof

A preparation process and coating liquid technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problem of insufficient bonding fastness of aluminum layer and acrylic resin, acrylic resin and aluminum plating layer falling off, Insufficient barrier properties of products, etc., to achieve excellent adhesion and barrier properties, improve surface adhesion, and improve adhesion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

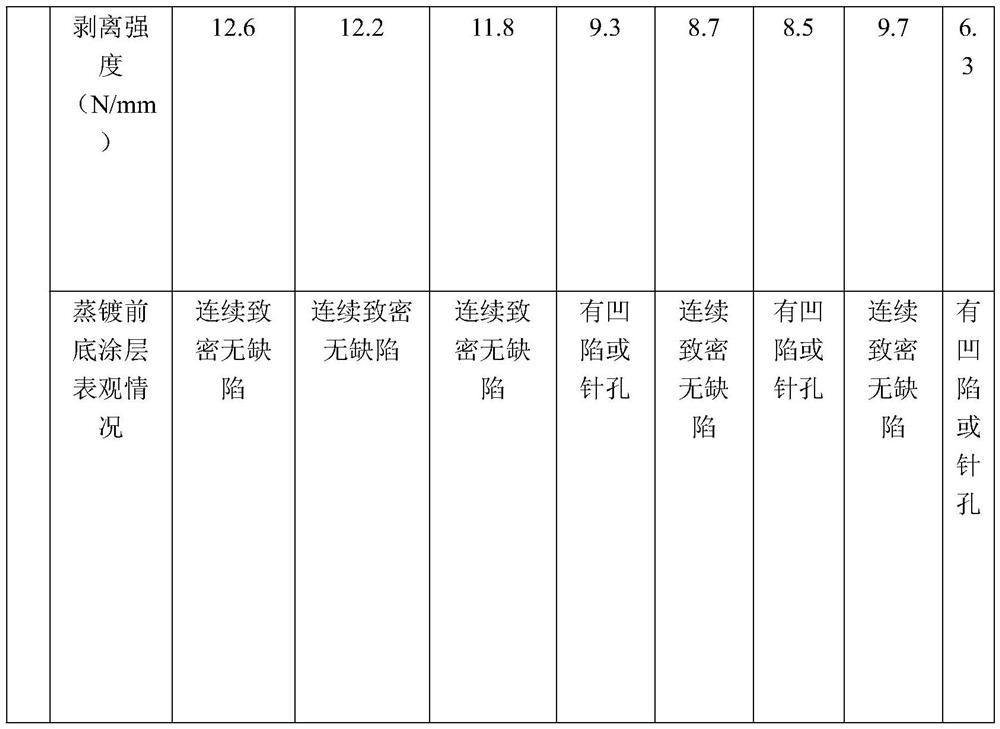

Examples

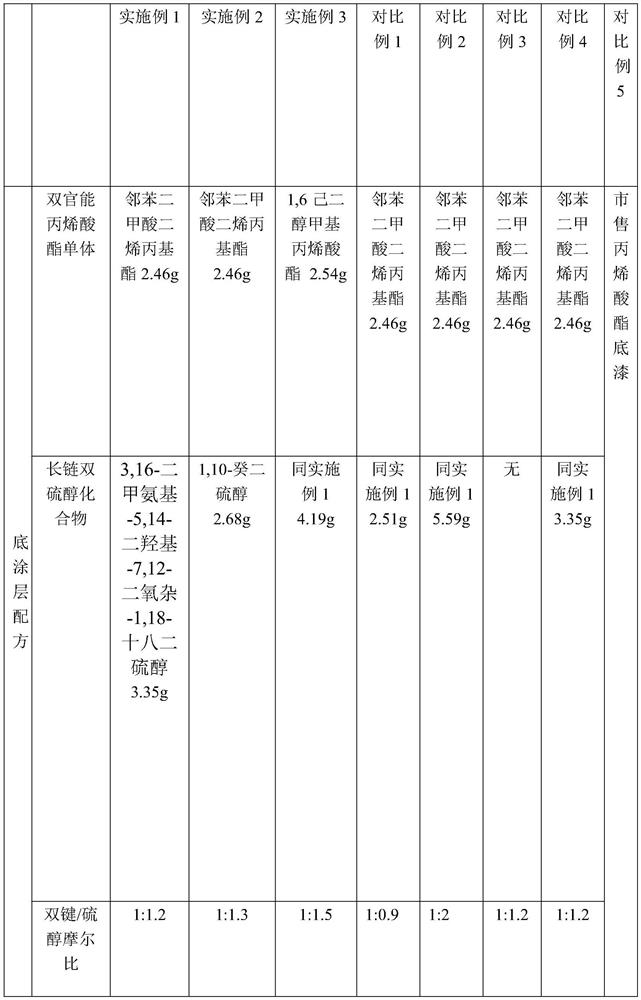

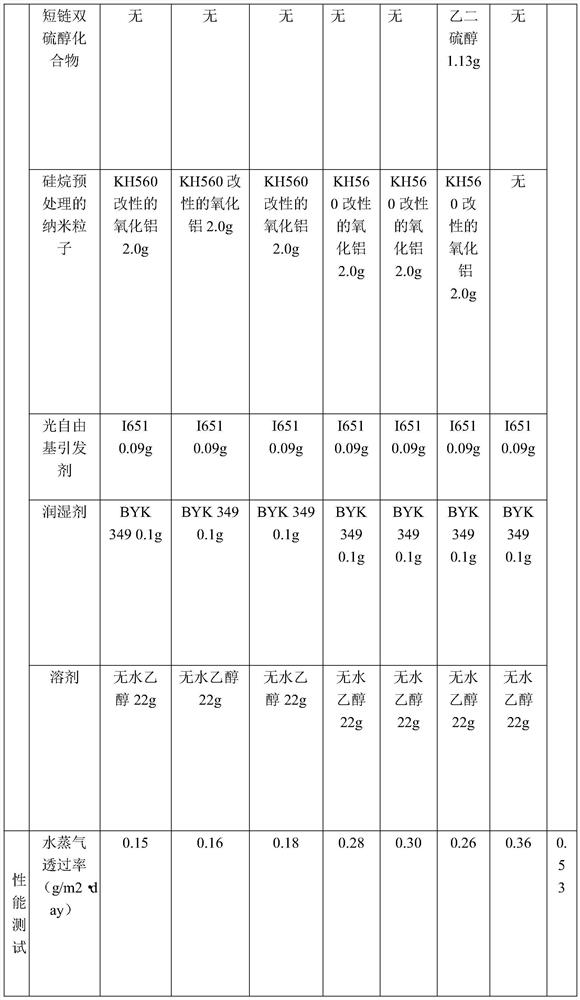

Embodiment 1

[0055] Step A: Preparation of Silane Coupling Agent-Treated Nanoparticles

[0056] Under the action of ultrasonic waves, add 0.2 parts by weight of nano-alumina to a mixed solution of 5 parts by weight of silane coupling agent KH560 and 20 parts by weight of ethanol and mix evenly, ultrasonically disperse for 0.5h, then filter, and the resulting filter out, dried in a vacuum environment for later use;

[0057] Step B: Prepare coating solution:

[0058] (1) Weigh diallyl phthalate (2.46g, about 10mmol, coating solution weight accounts for 8.2%) and 3,16-dimethylamino-5,14-dihydroxy-7,12 Dioxa-1,18-octadecanethiol (3.35g, about 12mmol, 11.2% by weight in the coating solution) was dissolved in 22g (73.3% by weight in the coating solution) without In water ethanol, the molar ratio of double bonds and thiol groups was set at approximately 1:1.2.

[0059] (2) Add 2.0 g of nano-alumina treated with the silane coupling agent in step A (6.67% by weight in the coating liquid), 3490.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com