Gentle twisting type vehicle door pit overhauling equipment

A door, gentle technology, applied in the field of gently twisting door dent trimming equipment, to achieve the effect of reducing the dent phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

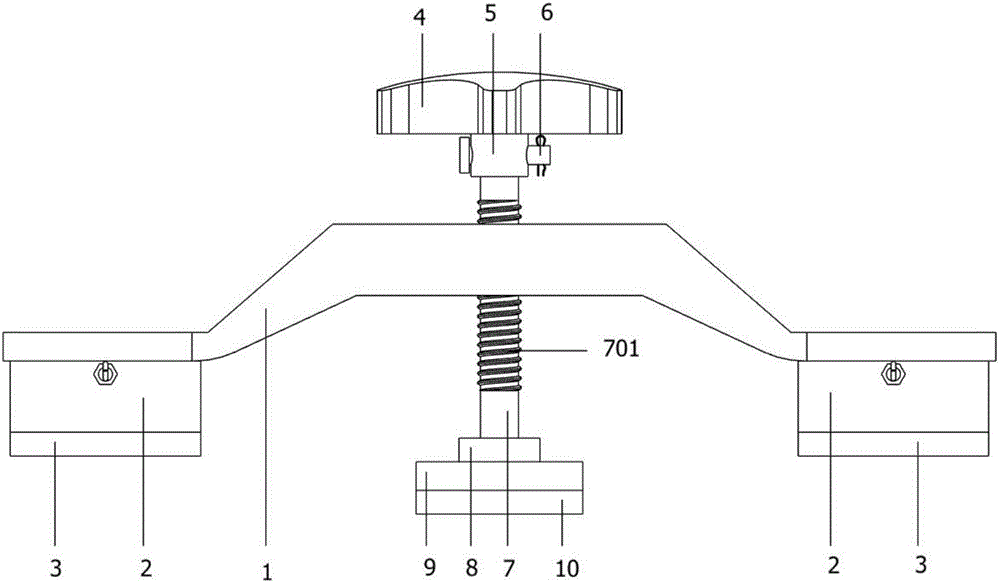

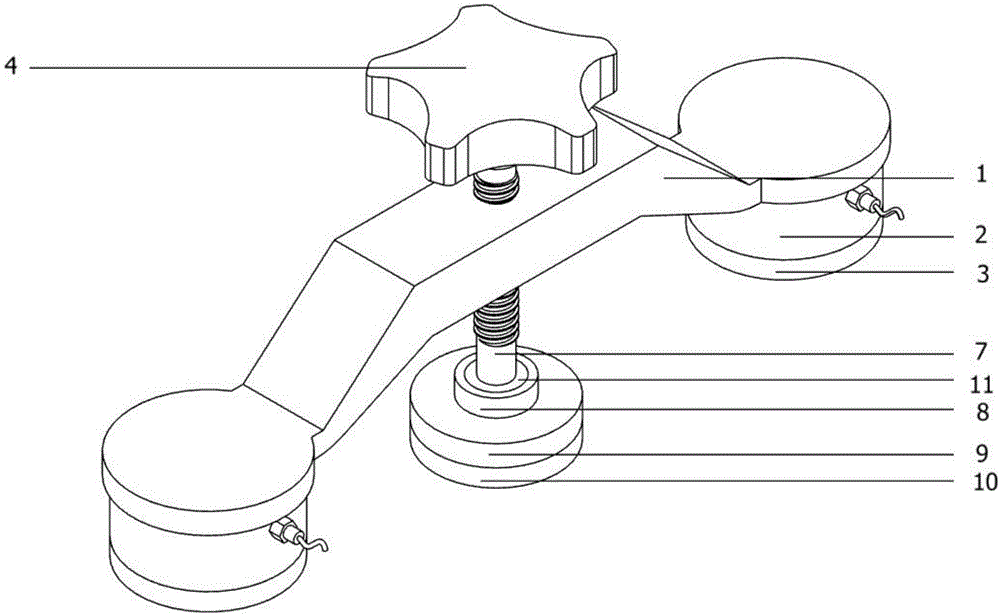

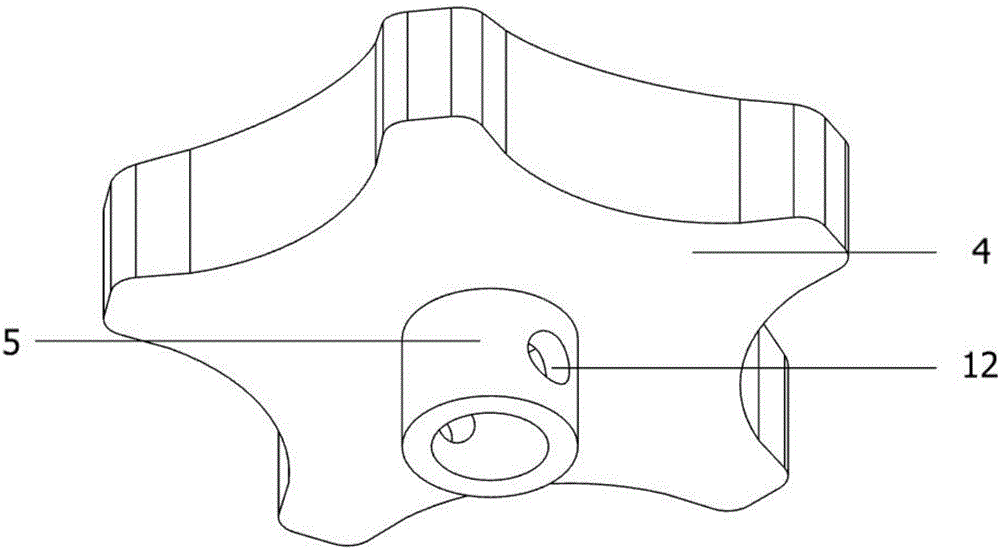

[0023] as attached figure 1 to attach Figure 5 Shown:

[0024] The invention provides a gentle twisting type car door dent repairing device, which includes a traction bridge 1, an electromagnetic sucker 2, a silicone cushion 3, a rotary twist 4, a first cylinder 5, a fixing pin 6, a cylindrical rod 7, and a second cylinder 8. Disk 9, rubber pad 10, bearing 11, through hole 12, threaded hole 13 and external thread 701; the top center position of the traction tension bridge 1 is provided with a threaded hole 13; the traction tension bridge A group of electromagnetic chucks 2 are fixedly connected to the circular disc-shaped bottoms on both sides of 1; a threaded hole 13 provided at the top center of the traction bridge 1 is provided with a cylindrical rod 7; 7 is provided with a rotary knob 4, and the bottom center of the rotary knob 4 is connected to the first cylinder 5; the head end of the cylindrical rod 7 is movably inserted into the inner wall of the first cylinder 5; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com