Medical gas manifold control system and gas switching control method thereof

A gas busbar and gas switching technology, which is applied in the field of busbars, can solve the problems of inconvenient management, increased production costs, complicated operation steps, etc., and achieves the effects of simple operation and maintenance, increased service life, and remote control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

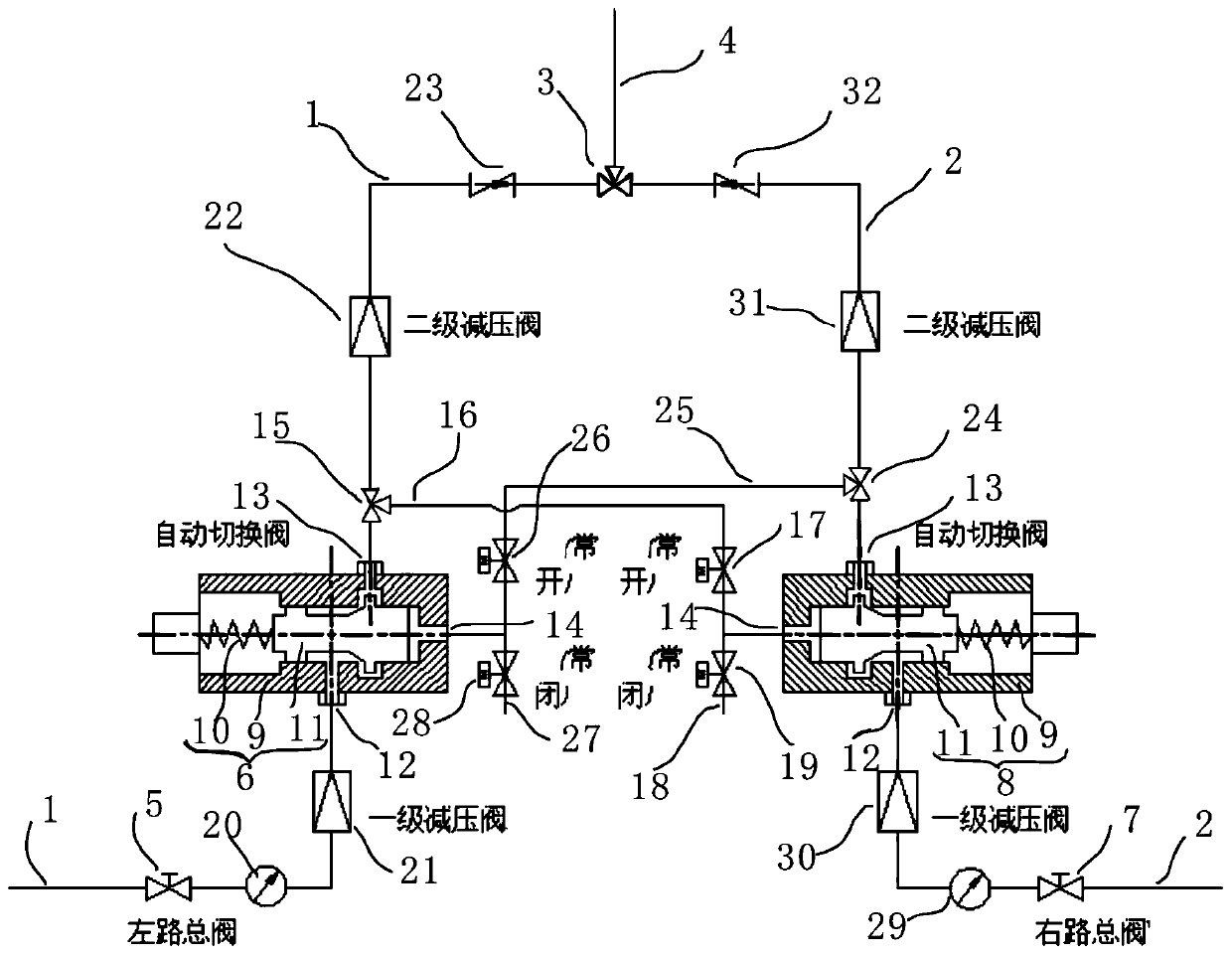

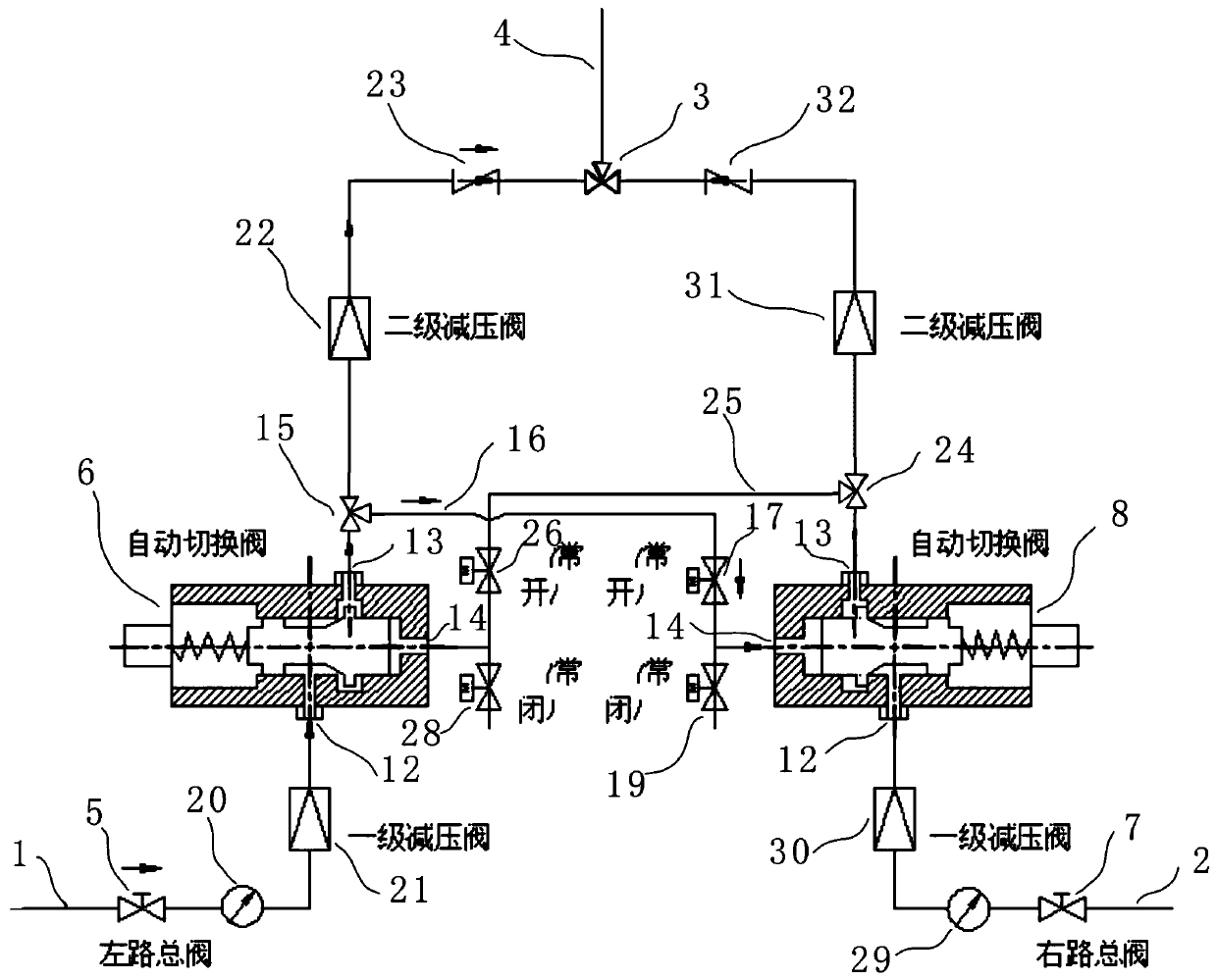

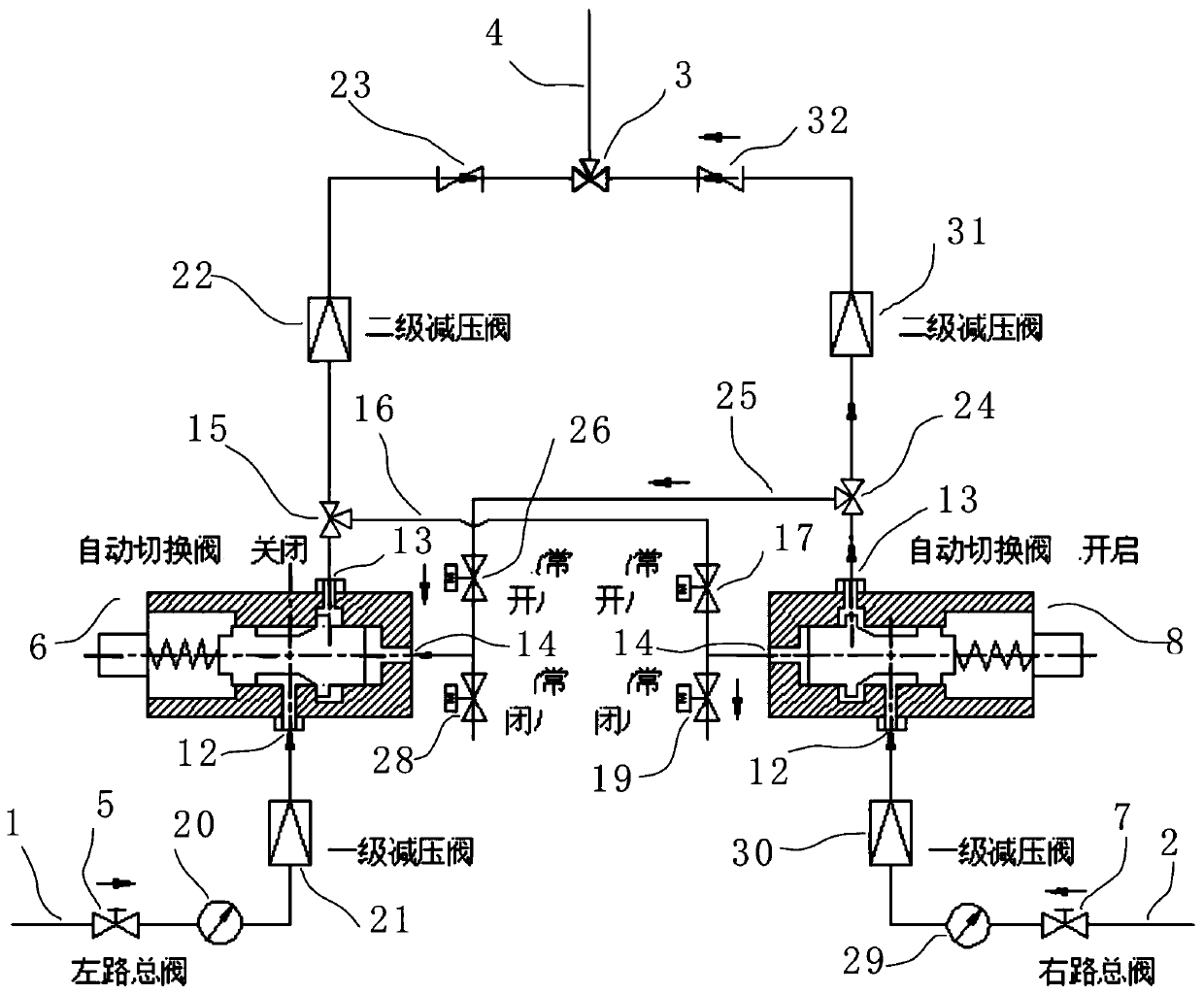

[0041] The medical gas manifold control system is mainly used in the medical gas pipeline with the left and right gas cylinders, such as figure 1 As shown, it includes a left trachea branch 1, a right trachea branch 2, a first three-way valve 3 and a confluence outlet pipeline 4. The left trachea branch 1 is provided with a left main valve 5 for controlling the on-off of the gas circuit. The left air pipe branch 1 on the rear side of the left main valve 5 is connected with a left automatic gas switching valve 6 which adopts pipeline gas for automatic control and is connected by a three-way connection; Road main valve 7, the right air pipe branch 2 on the rear side of the right main valve 7 is connected with the right automatic gas switching valve 8 that adopts pipeline gas for automatic control and three-way connection; the output pipeline of the left automatic gas switching valve 6 and the output pipeline of the right automatic gas switching valve 8 are respectively connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com