A kind of LED lamp sealing glue printing process

A LED lamp and glue sealing technology, which is applied in the direction of adhesives, film/sheet adhesives, non-polymer adhesive additives, etc., can solve the problem of inaccurate alignment of the injection port, poor cavity filling, and unfavorable Problems such as industrial production, to achieve the effect of improving surface roughness, increasing strength, and better anti-adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

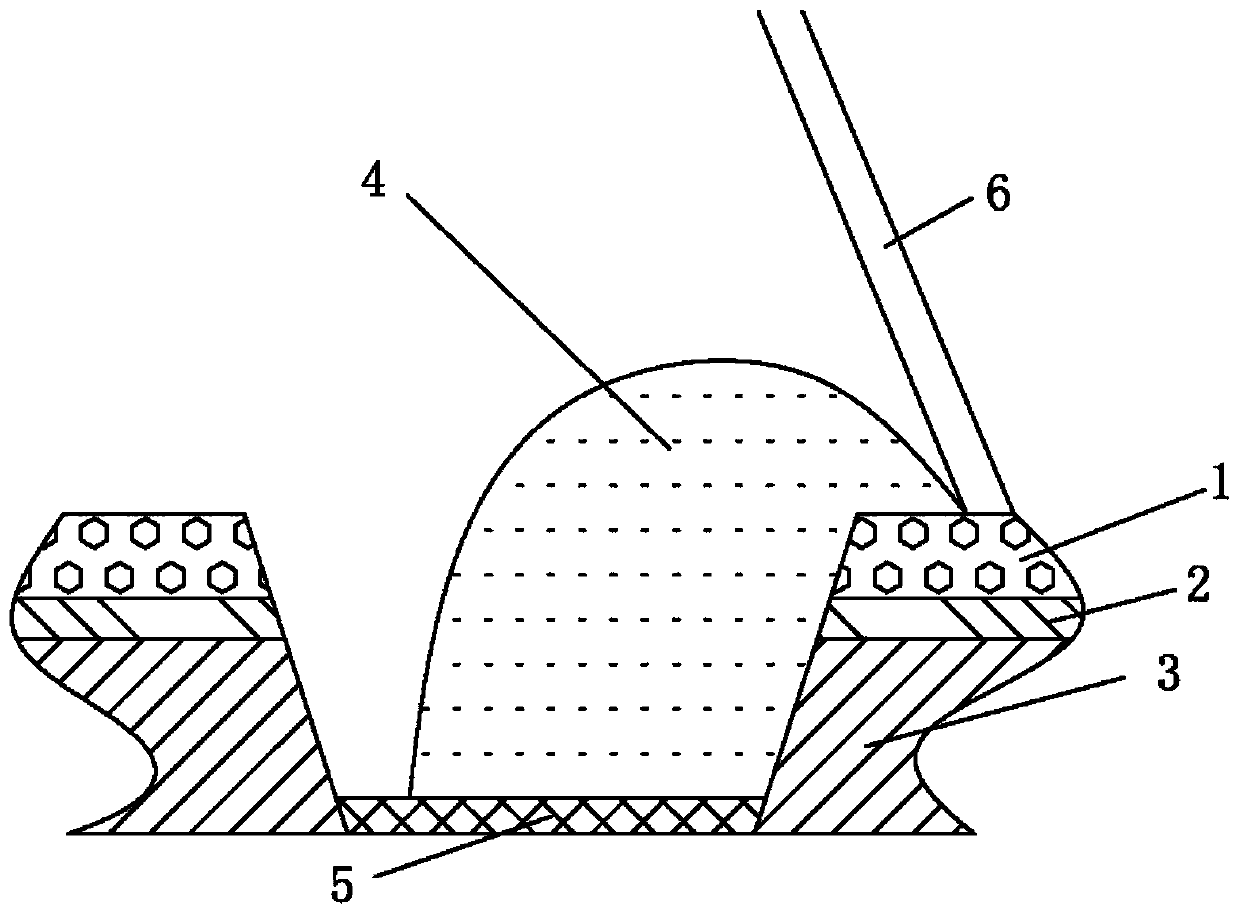

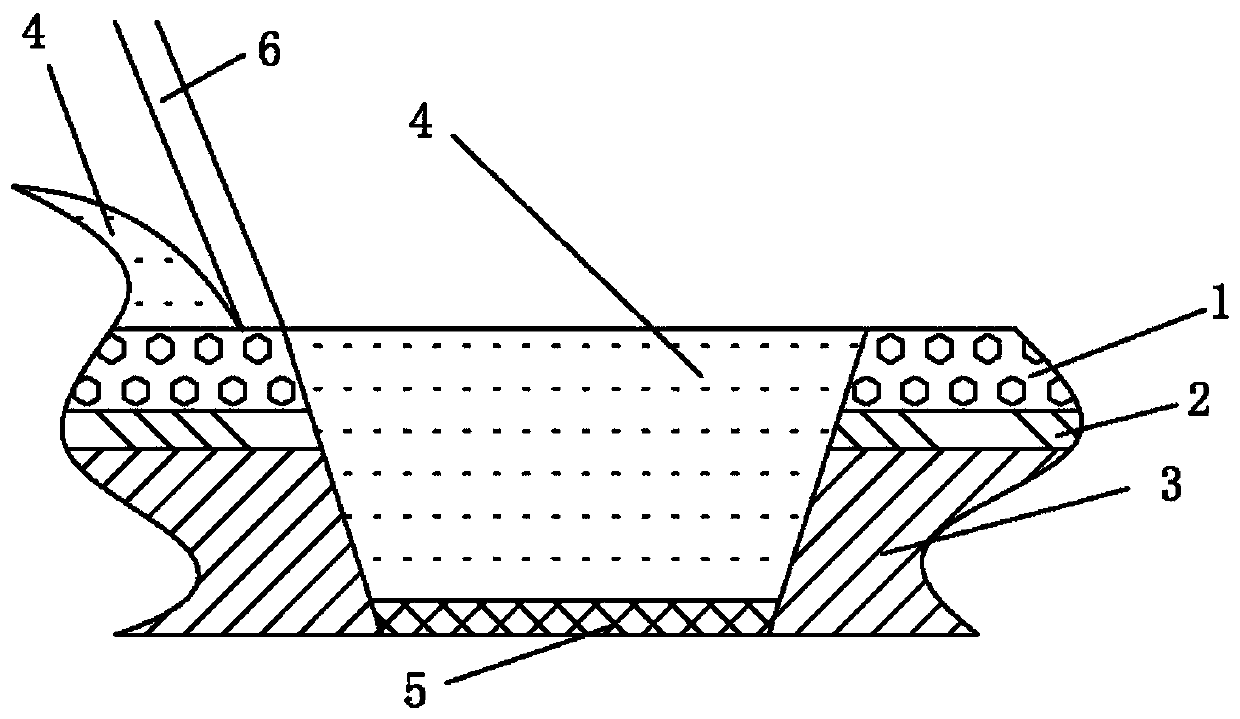

[0051] A LED lamp sealant printing process, the LED lamp includes an LED base 3, the LED base 3 is provided with several cavities, and an LED chip 5 is fixed in each cavity, the printing process includes the following steps:

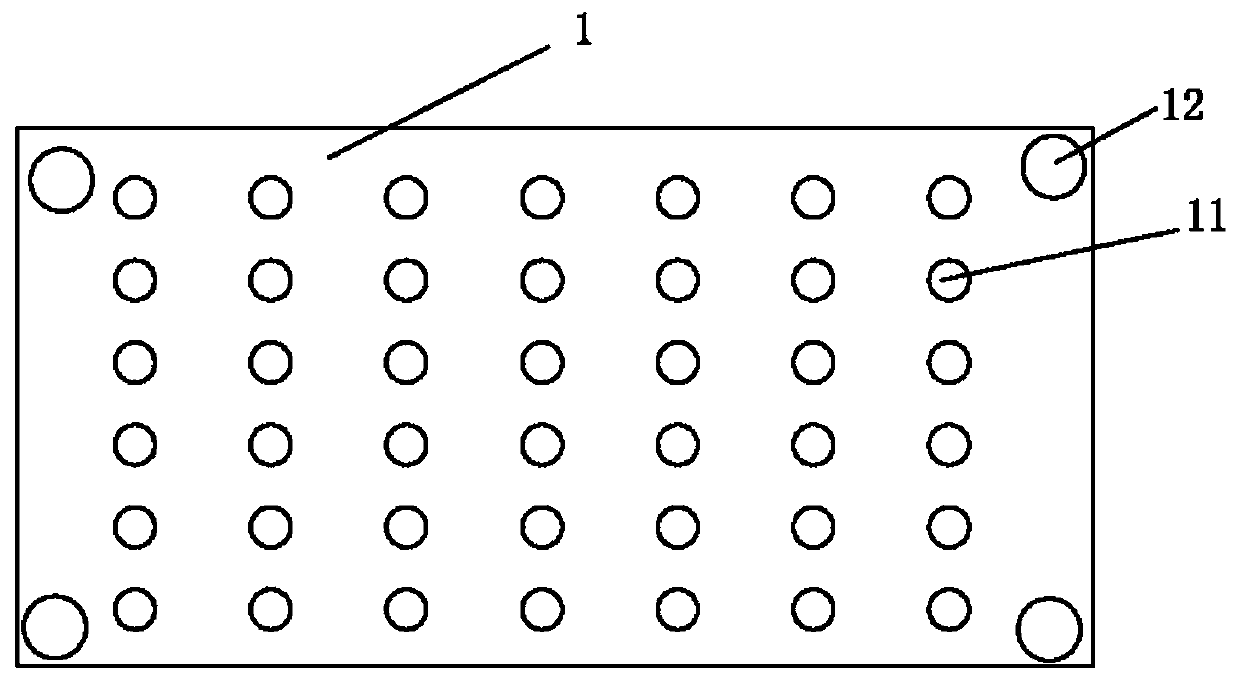

[0052] (1) design a tape film 1, described tape film 1 is provided with some through holes 11, one deck adhesive layer 2 is coated on one side of described adhesive tape film 1, described adhesive layer 2 and base 3 are carried out Fit and make the through hole 11 face the cavity of the LED base 3;

[0053] (2) Inject fluorescent glue 4 into the cavity;

[0054] (3) scrape coating on the surface of adhesive tape film 1 with scraper 6;

[0055] (4) The tape film 1 is peeled off.

[0056] Wherein, the end of the tape film 1 is also provided with a positioning hole 12 .

[0057] Wherein, described adhesive tape film 1 is made up of the raw material of following parts by weight:

[0058]

[0059] The concrete steps of the preparation method of tape fi...

Embodiment 2

[0083] A LED lamp sealant printing process, the LED lamp includes an LED base 3, the LED base 3 is provided with several cavities, and an LED chip 5 is fixed in each cavity, the printing process includes the following steps:

[0084] (1) design a tape film 1, described tape film 1 is provided with some through holes 11, one deck adhesive layer 2 is coated on one side of described adhesive tape film 1, described adhesive layer 2 and base 3 are carried out Fit and make the through hole 11 face the cavity of the LED base 3;

[0085] (2) Inject fluorescent glue 4 into the cavity;

[0086] (3) scrape coating on the surface of adhesive tape film 1 with scraper 6;

[0087] (4) The tape film 1 is peeled off.

[0088] Wherein, the end of the tape film 1 is also provided with a positioning hole 12 .

[0089] Wherein, described adhesive tape film 1 is made up of the raw material of following parts by weight:

[0090]

[0091] The concrete steps of the preparation method of tape fi...

Embodiment 3

[0115] A LED lamp sealant printing process, the LED lamp includes an LED base 3, the LED base 3 is provided with several cavities, and an LED chip 5 is fixed in each cavity, the printing process includes the following steps:

[0116](1) design a tape film 1, described tape film 1 is provided with some through holes 11, one deck adhesive layer 2 is coated on one side of described adhesive tape film 1, described adhesive layer 2 and base 3 are carried out Fit and make the through hole 11 face the cavity of the LED base 3;

[0117] (2) Inject fluorescent glue 4 into the cavity;

[0118] (3) scrape coating on the surface of adhesive tape film 1 with scraper 6;

[0119] (4) The tape film 1 is peeled off.

[0120] Wherein, the end of the tape film 1 is also provided with a positioning hole 12 .

[0121] Wherein, described adhesive tape film 1 is made up of the raw material of following parts by weight:

[0122]

[0123] The concrete steps of the preparation method of tape fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com