Spur differential with non-destructively removable sun gear

A differential and spur gear technology, which is applied in the field of spur gear differentials, can solve problems such as limited structural space, and achieve the effects of simplifying installation and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] specific implementation plan

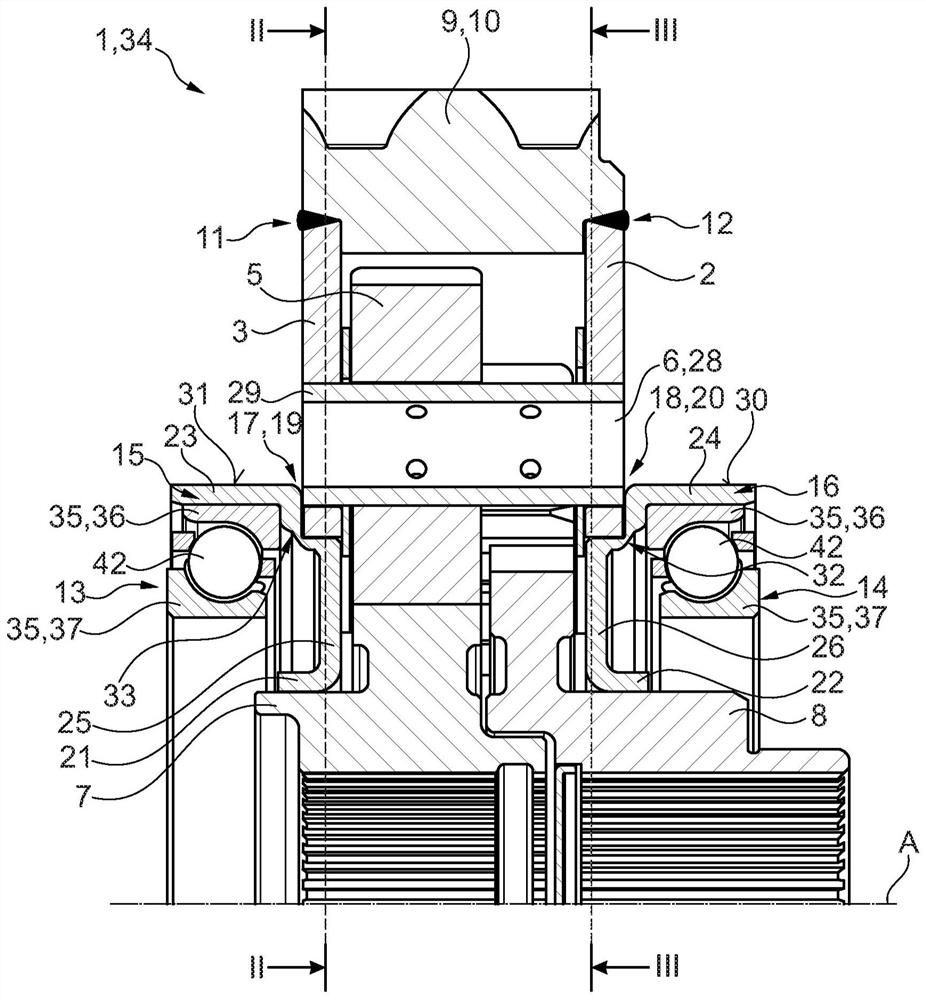

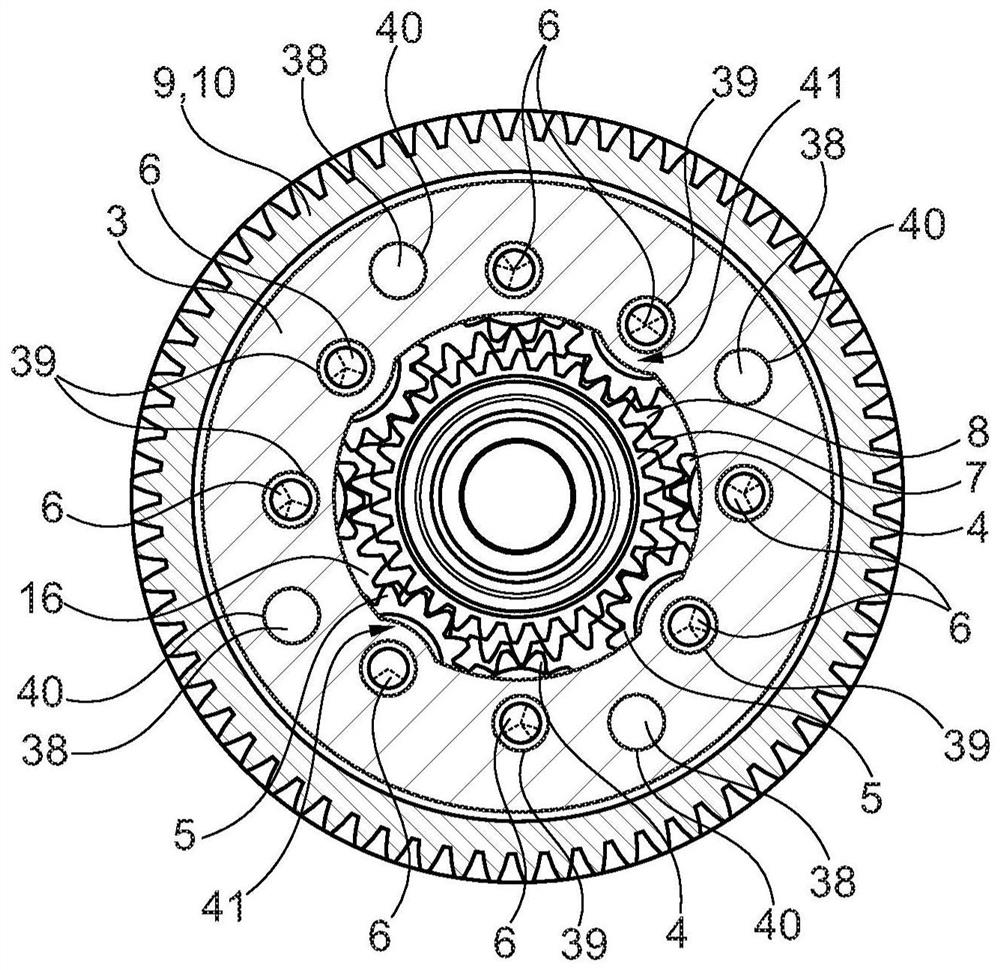

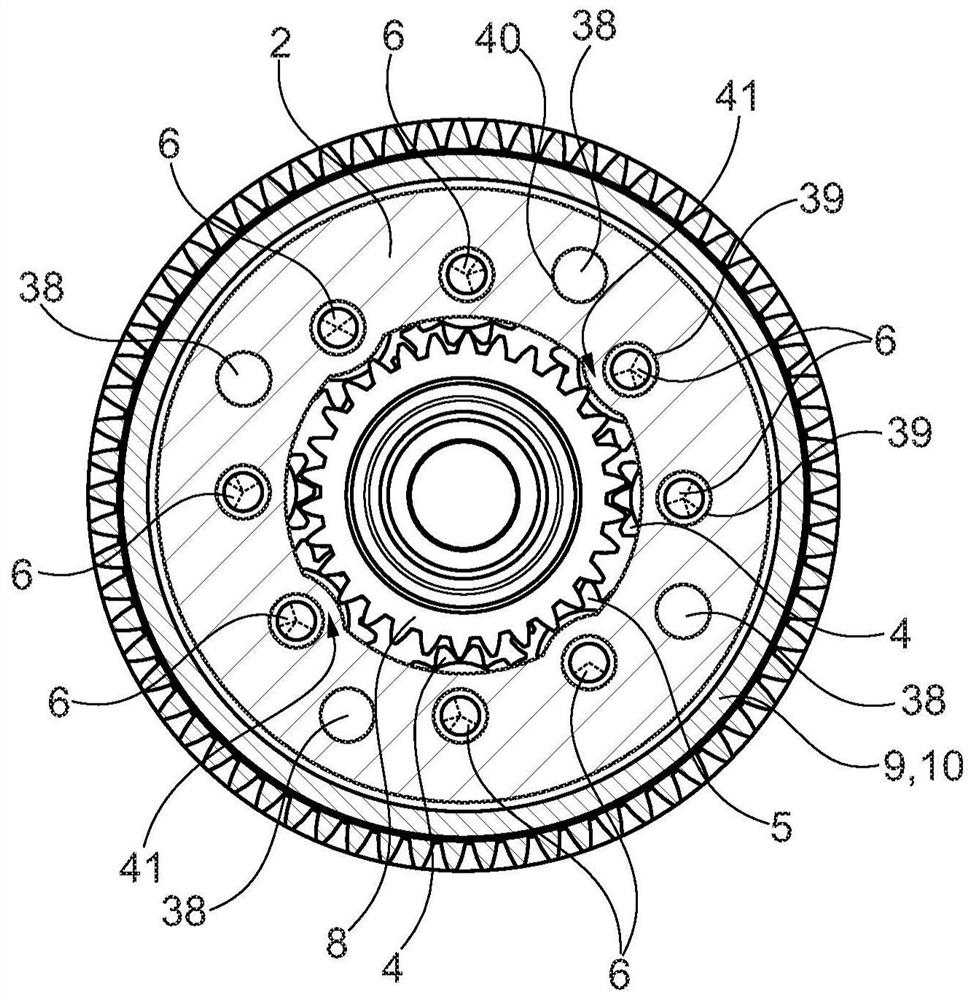

[0030] figure 1 A partial longitudinal sectional view of the planetary gear 1 according to the invention is shown. The planetary gear 1 has two planetary gear sets, which are constructed from a planetary carrier with a plurality of planetary gears 4 or 5, the planetary carrier comprising two planetary carrier halves 2, 3, the planetary wheels are respectively connected via planetary pins 6 is connected to the respective planetary carrier halves 2 and 3 in a rotatable manner. In this case, the planet gears 4 mesh with the sun gear 7 and the planet wheels 5 mesh with the sun gear 8 . Sun gears 7 , 8 are radially inward relative to planetary gear 1 compared to planet gears 4 , 5 . The drive wheel 9 in the form of an external ring gear 10 is radially further outward than the planet wheels 4 , 5 , which is fixedly connected to the respective planet carrier half 2 , 3 via welds 11 or 12 , by means of This enables torque transfer.

[0031] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com