A high-pressure reaction kettle with a sampling and discharging device and a sampling and discharging method thereof

A technology of a high-pressure reaction kettle and a liquid draining device is applied in the field of in-situ leaching of uranium leaching, which can solve the problems of interruption of the leaching process, consumption of ore particles, cumbersome processes, etc., and achieve the effects of improving accuracy, maintaining stability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A high-pressure reactor with a sampling and discharging device and a sampling and discharging method thereof according to the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

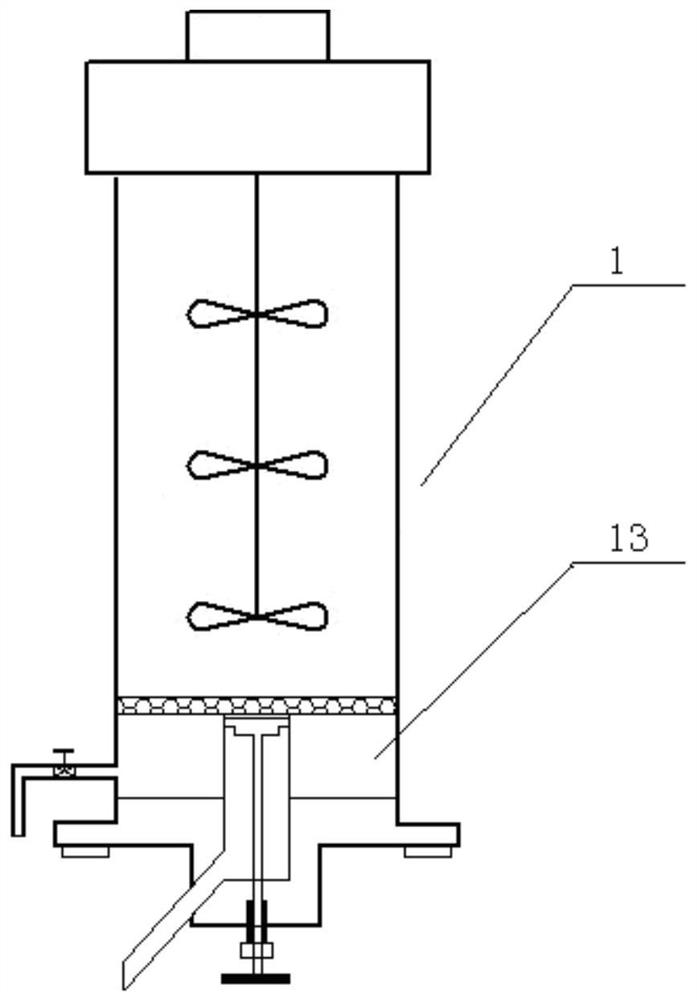

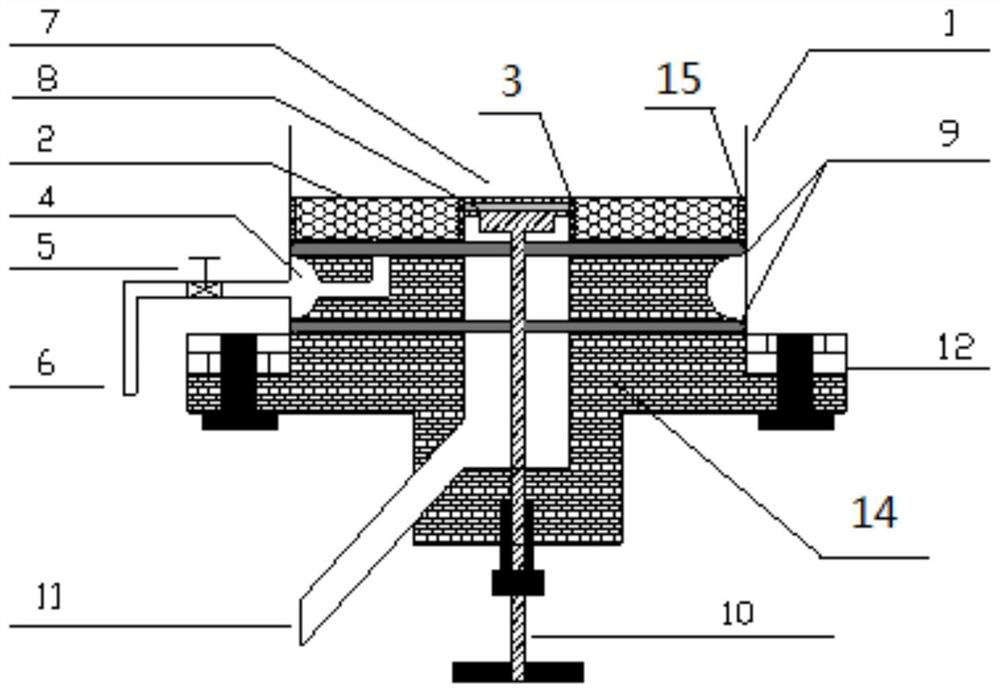

[0030] Such as figure 1 , 2 Shown in and 3, a kind of autoclave with sampling liquid discharge device, comprises still body 1 and the sampling liquid discharge device 13 that is installed at the bottom of still body 1;

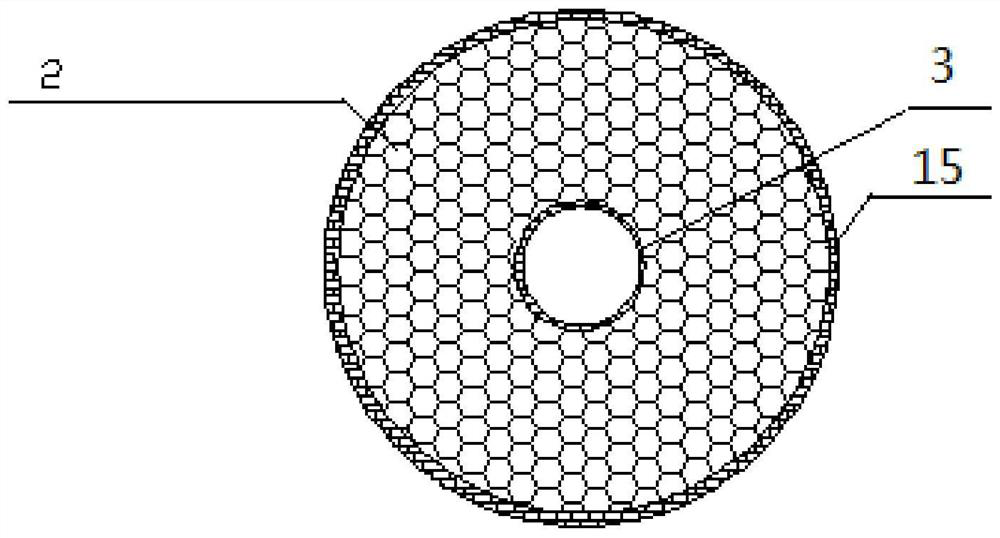

[0031] The sampling and discharging device 13 includes a filter plug 2, a filter plug ferrule A3, a filter plug ferrule B15, a groove 4, a sampling valve 5, a sampling port 6, a liquid discharge piston 7, a liquid discharge piston sealing ring 8, Sampling sealing ring 9, drain valve 10, drain port 11, base 14 and fixing device 12;

[0032] The sampling and draining device 13 has a main body structure of a base 14, and the top of the base 14 is a filter plug 2; the filter plug 2 is fixed on the base 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com