Smashing device capable of reducing flying dust and provided with good smashing effect

A pulverizing and pulverizing cylinder technology, applied in the field of pulverizing devices, can solve the problems of dust scattering and poor dustproof effect, and achieve good pulverizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

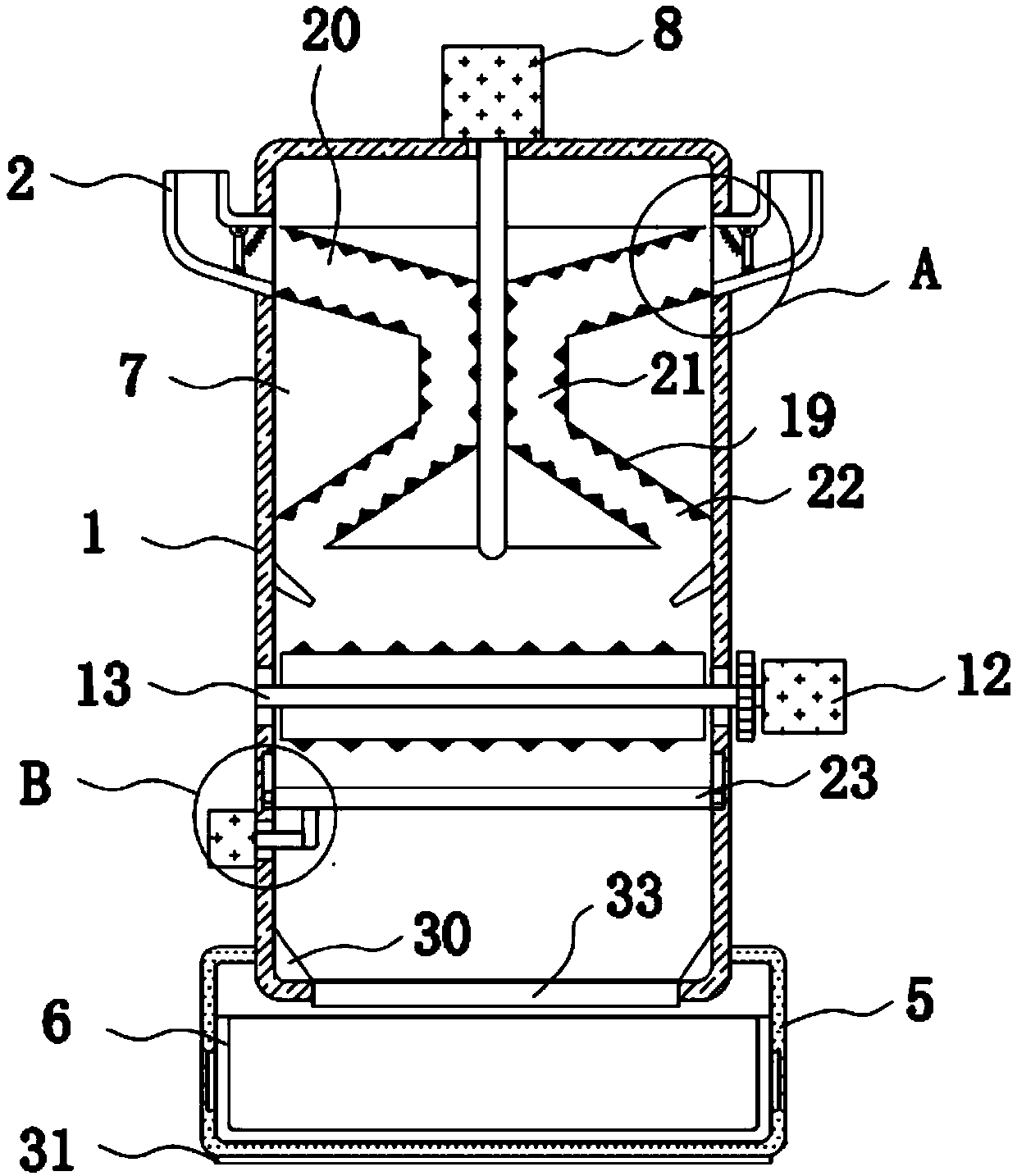

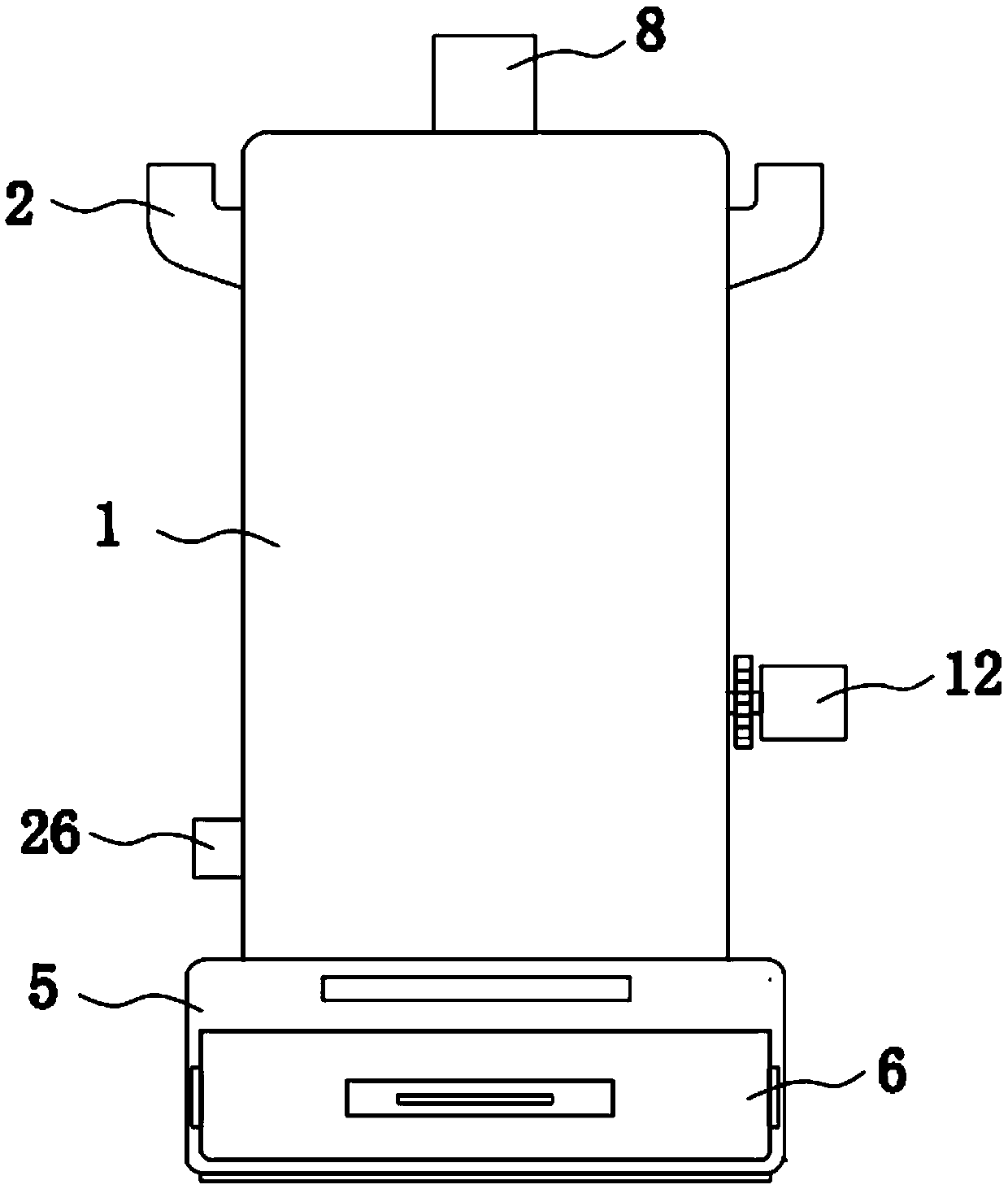

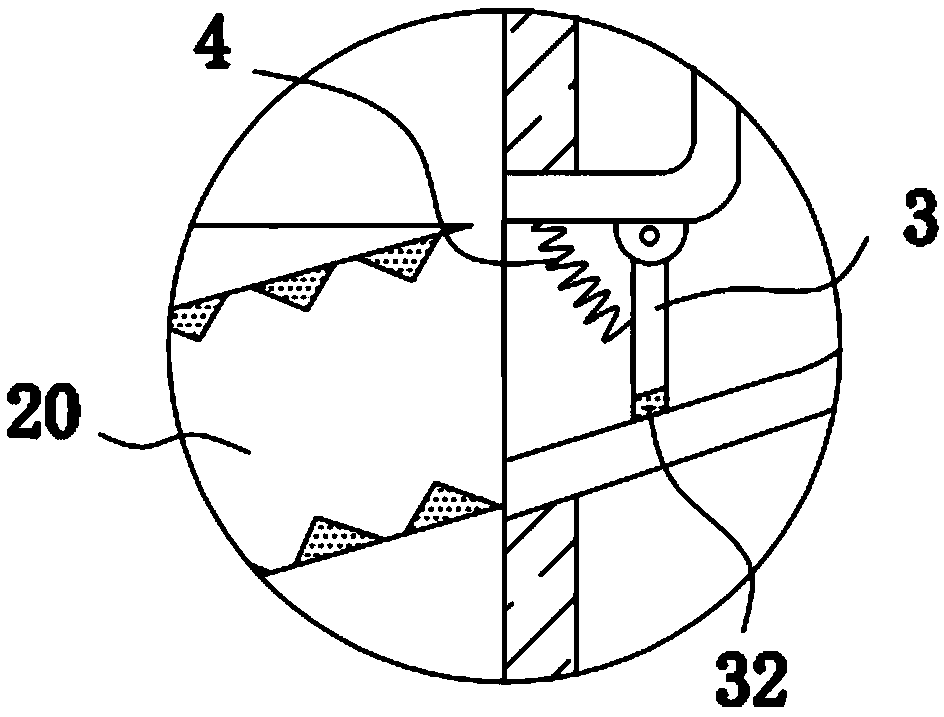

[0034] refer to Figure 1-6It can be seen that a pulverizing device capable of reducing dust and having a good crushing effect in the present invention includes a housing 1, and a feeding hopper 2 is provided on the left and right sides of the upper part of the housing 1, and the inner top of the feeding hopper 2 is passed through a pin. A shaft rotation is connected with a baffle plate 3, a spring 4 is obliquely welded between the rear end surface of the baffle plate 3 and the inner top of the feed hopper 2, and a discharge port 33 is connected to the bottom end of the shell 1, and the shell 1 The bottom is also welded with a dustproof cover 5, the front side of the dustproof cover 5 is drawn and connected with a storage drawer 6 directly below the discharge opening 33, the inner wall of the casing 1 is provided with an auxiliary block 7, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com