Liquid ejecting device and maintenance method of liquid ejecting device

A spraying device and a technology of a liquid spraying part, which are applied in printing and other directions, can solve the problems of not being able to perform good preliminary spraying, reducing the scraping ability of the scraping part, and hindering the rotation of the polygonal roller.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

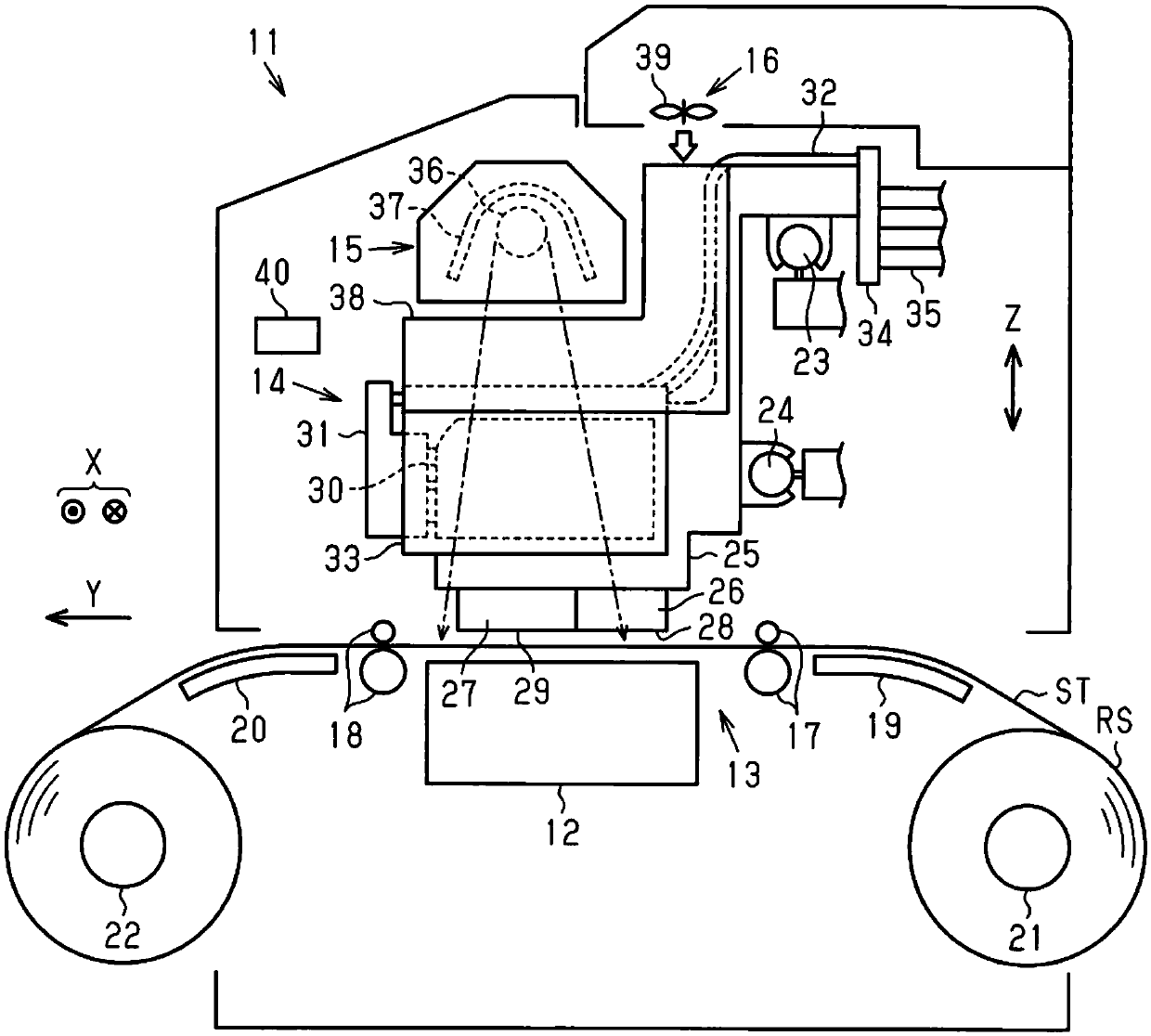

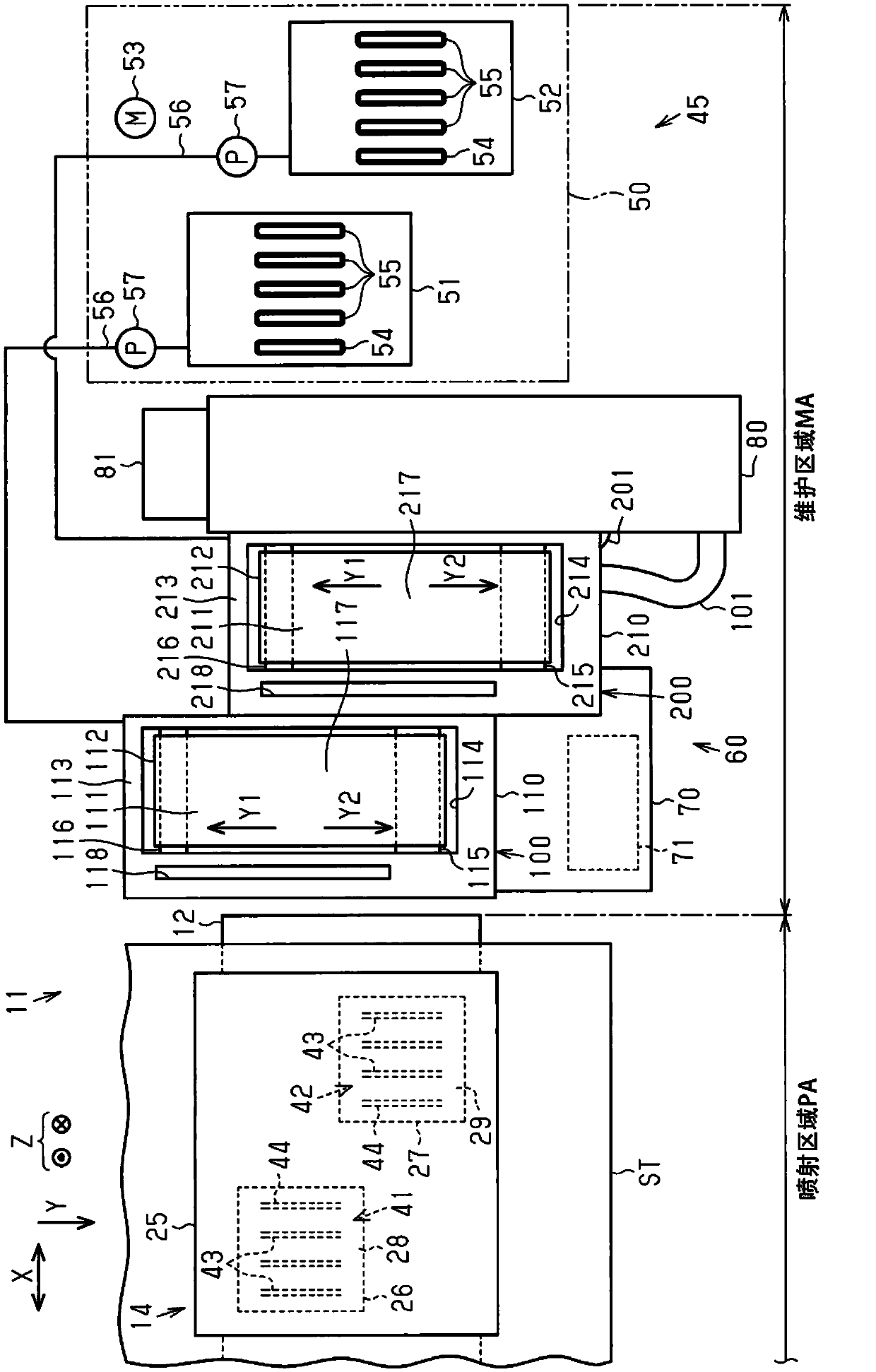

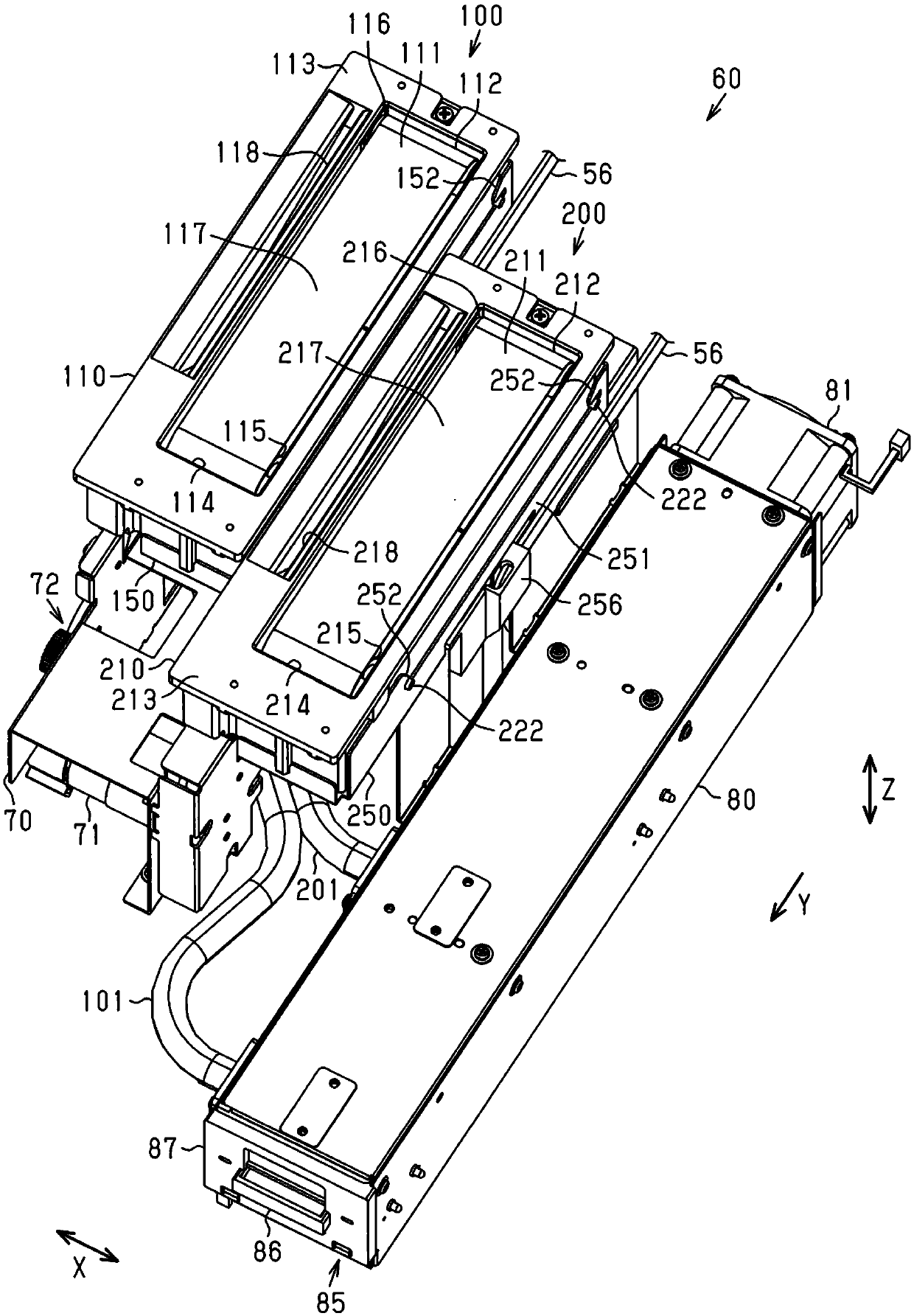

[0031] Hereinafter, a first embodiment of the liquid ejecting device will be described with reference to the drawings.

[0032] Such as figure 1 As shown, the liquid ejecting device 11 includes a support base 12 that supports the medium ST, and a transport unit 13 that transports the medium ST in the transport direction Y along the surface of the support base 12 . The liquid ejection device 11 includes a liquid ejection unit 14 that ejects a liquid to the medium ST transported by the transport unit 13 , a heat generating unit 15 and an air blower 16 for drying the liquid adhering to the medium ST.

[0033] The support table 12 is long in the width direction X which is a direction intersecting with the conveyance direction Y within a horizontal plane, and supports the medium ST in the vertical direction Z from below. The conveyance part 13 has conveyance roller pair 17,18 which is arrange|positioned at the upstream side and the downstream side rather than the support table 12 ...

no. 2 approach

[0109] Next, a second embodiment of the liquid ejecting device will be described with reference to the drawings. In addition, in this second embodiment, the timing at which the second turning movement is performed after the first turning movement is performed is different from the case of the first embodiment. In addition, since the other points are basically the same as those of the first embodiment, the same symbols are assigned to the same configurations, and overlapping descriptions will be omitted.

[0110] Figure 18 The maintenance processing program shown is executed when printing is started, as in the first embodiment.

[0111] Such as Figure 18 As shown, in step S201 to step S204, the control unit 40 executes and Figure 11Step S101 to step S104 in the maintenance processing program shown are the same processing.

[0112] In step S205 , the control unit 40 judges whether or not a predetermined period has elapsed after the first turning operation was performed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com