Bicycle crank shaft rod assembly

A technology for crankshafts and bicycles, which is applied to crank structures, vehicle components, transportation and packaging, etc., can solve the problems of increased mechanical performance requirements, many manufacturing processes, and increased processes, and achieves low mechanical performance requirements, and the manufacturing process is suitable for, Good overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

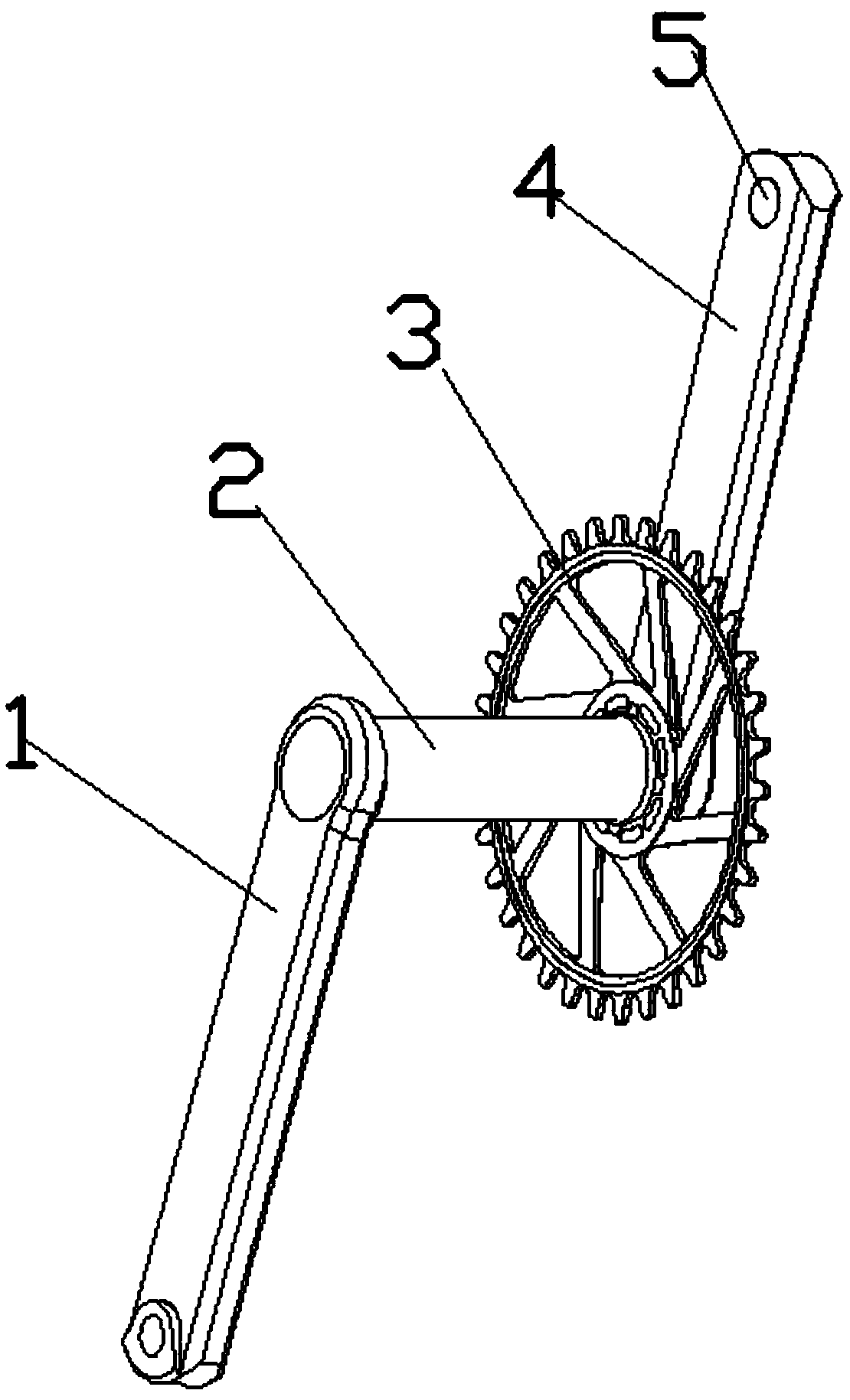

[0023] Such as figure 1 As shown, this embodiment provides a bicycle crank shaft assembly, including a left crank 1, a shaft 2, a chainring 3 and a right crank 4; wherein, the left end of the left crank 1 and the shaft 2 are set as an integrated structure , the right end of the axle rod 2 passes through the crankshaft 3 and is fixedly connected with the right crank 4, and the crankshaft 3 is fixedly connected with the right crank 4.

[0024] Based on the bicycle crank shaft assembly with the above structure, since the left crank and the shaft are integrally formed, the left crank and the shaft do not need to be fixed and installed by locking screws or through additional strength design or additional fasteners, the structure is more It is simple so that it is easier to install and disassemble, and the stress generated is less so that the existing stress is smaller, so the overall rigidity of the crank and the bottom bracket is not easy to deform, and the integral molding struct...

Embodiment 2

[0033] Such as figure 1 As shown, this embodiment provides a bicycle crank shaft assembly, including a left crank 1, a shaft 2, a chainring 3 and a right crank 4; wherein, the left end of the left crank 1 and the shaft 2 are set as an integrated structure , the right end of the axle rod 2 passes through the chain plate 3 and is fixedly connected with the right crank 4, and the chain plate 3 is fixedly connected with the right crank 4.

[0034] Preferably, the right crank 4 and the chainring 3 are integrally formed.

[0035] Based on the bicycle crank shaft assembly with the above structure, since the left crank and the shaft are integrally formed, the right crank and the chainring are also integrally formed; therefore the left crank and the shaft, the right crank and the chainring do not need to pass Tight screw fixed installation or through extra strength design or adding extra fasteners, the structure is simpler and easier to install and disassemble, and the stress generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com