Automobile transmission shaft torsion damper

A technology of a torsional shock absorber and a transmission shaft, which is applied in the field of automobile transmission system, can solve the problems of worsening the vibration of the floor seat in the car, the noise in the car, the overturning deformation of the coupling, and the change of the included angle, etc., so as to ensure the power transmission. , the effect of reducing noise and improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

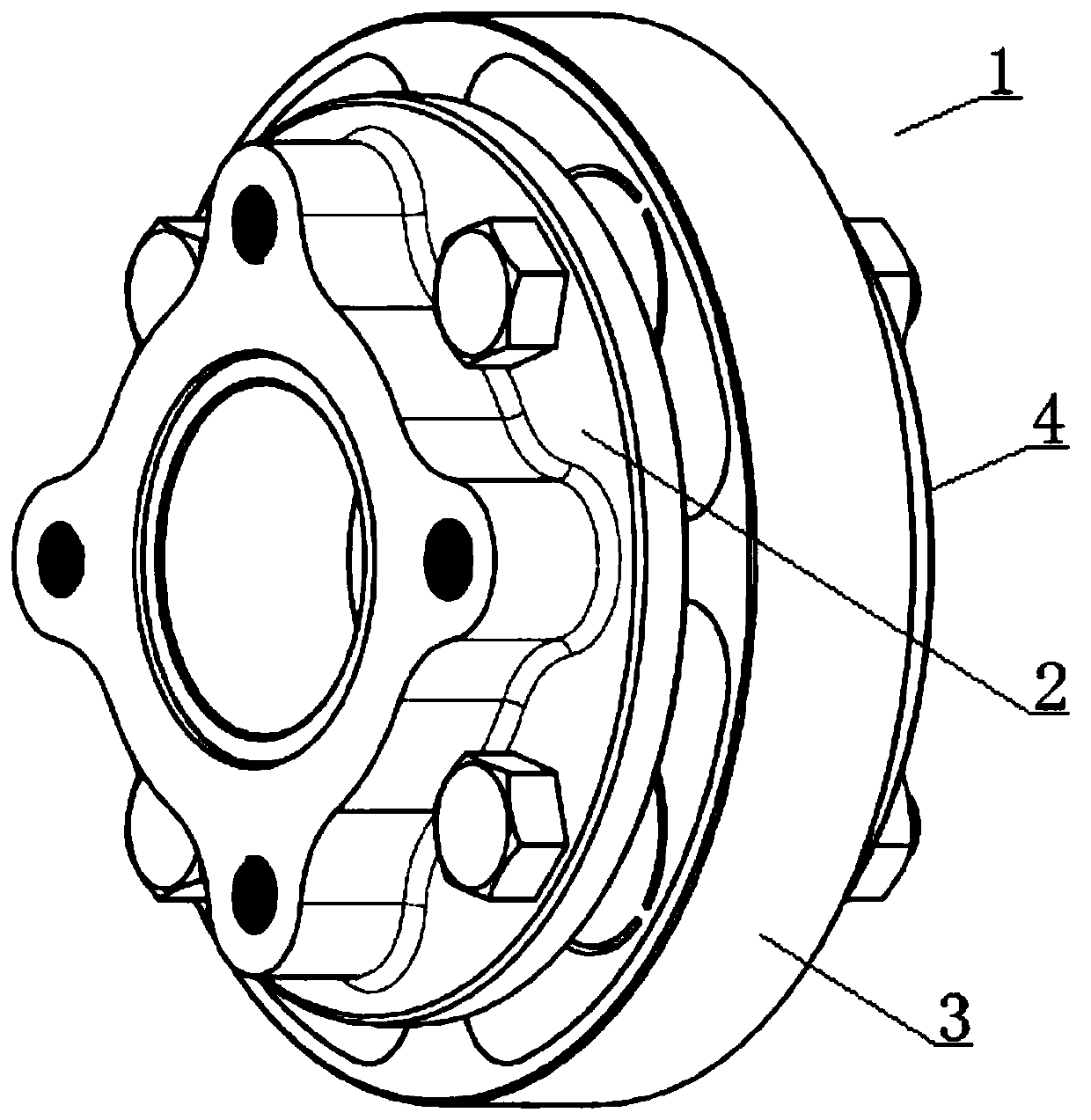

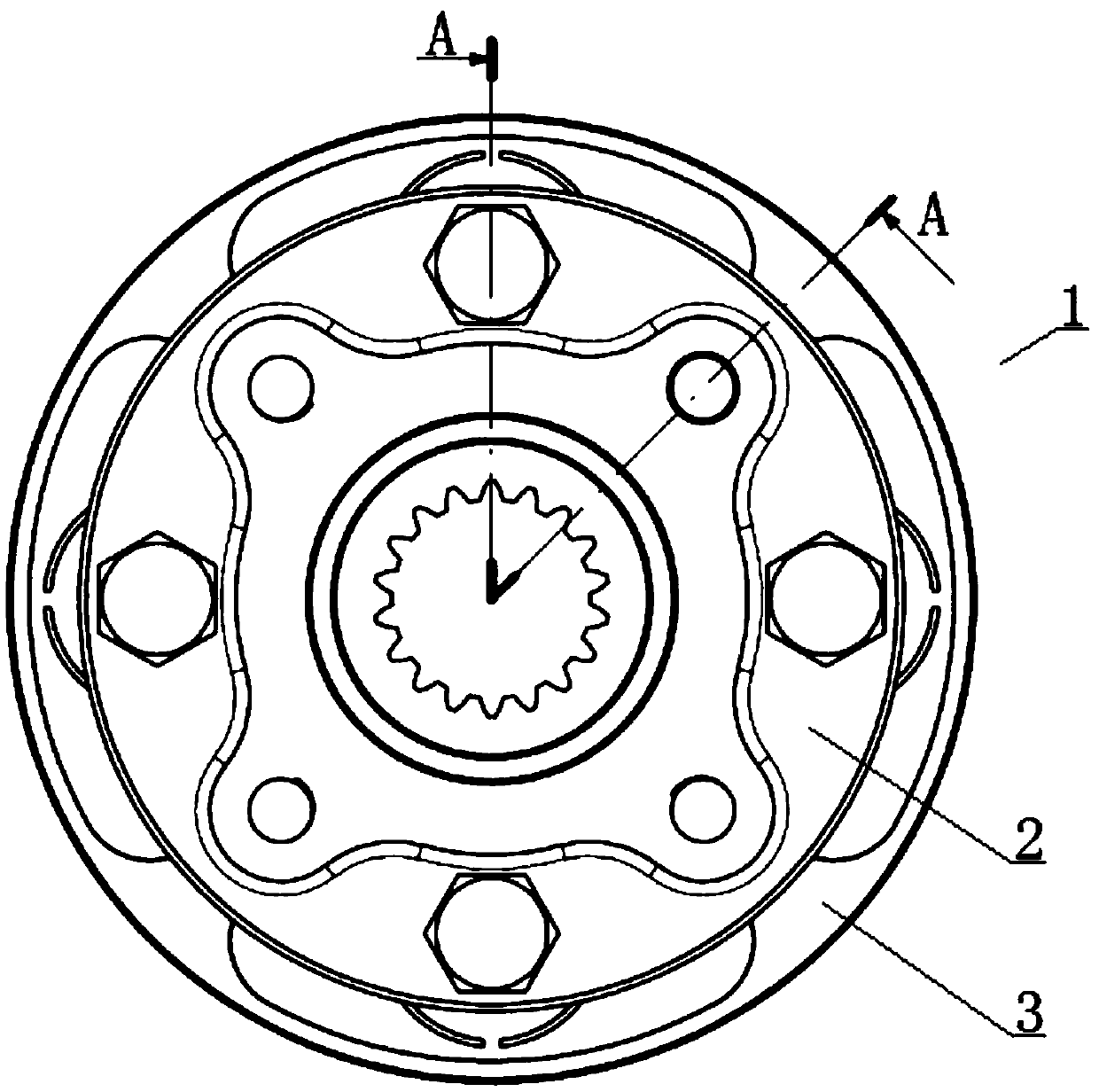

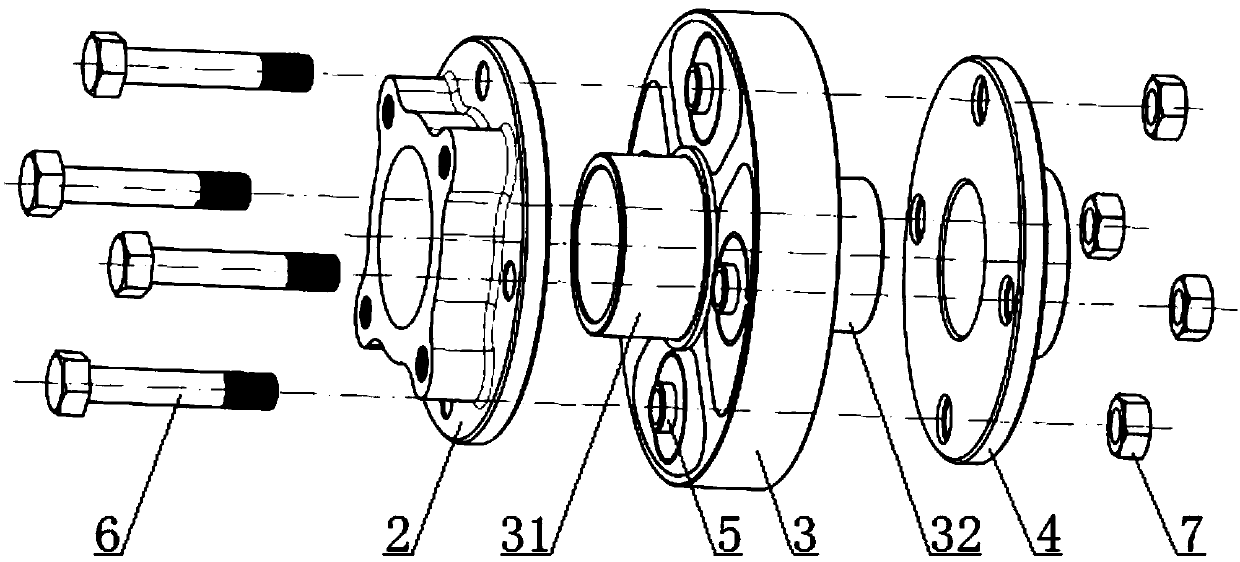

[0026] see Figure 1 to Figure 8 The shown torsional shock absorber for a transmission shaft of an automobile includes a torsional shock absorber body 1 that is arranged between the drive shaft 9 and the pinion shaft 10 of the final drive and is connected with both, and is characterized in that: the torsional The shock absorber body 1 includes a driving flange 2 that is mated with the transmission shaft 9, a driven flange 3 that is matched with the driving flange 2 at the front, and a driven flange 3 that is matched with the rear of the driven flange 3 and that is connected with the driven flange 3. The supporting flange 4 fastened to the active flange 2; the active flange 2, the driven flange 3 and the supporting flange 4 are coaxially arranged, and the driven flange 3 is connected to the active flange 2 and The supporting flanges 4 are axial cleara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com