Multi-function valve core for regulating flow and stopping water

A technology of multi-functional valve and flow regulating valve, which is applied in the field of bathroom products, can solve problems such as difficult to accurately adjust the flow rate, the adjustment effect is not obvious, and does not meet the user's flow adjustment needs, achieving the effect of wide adaptability and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

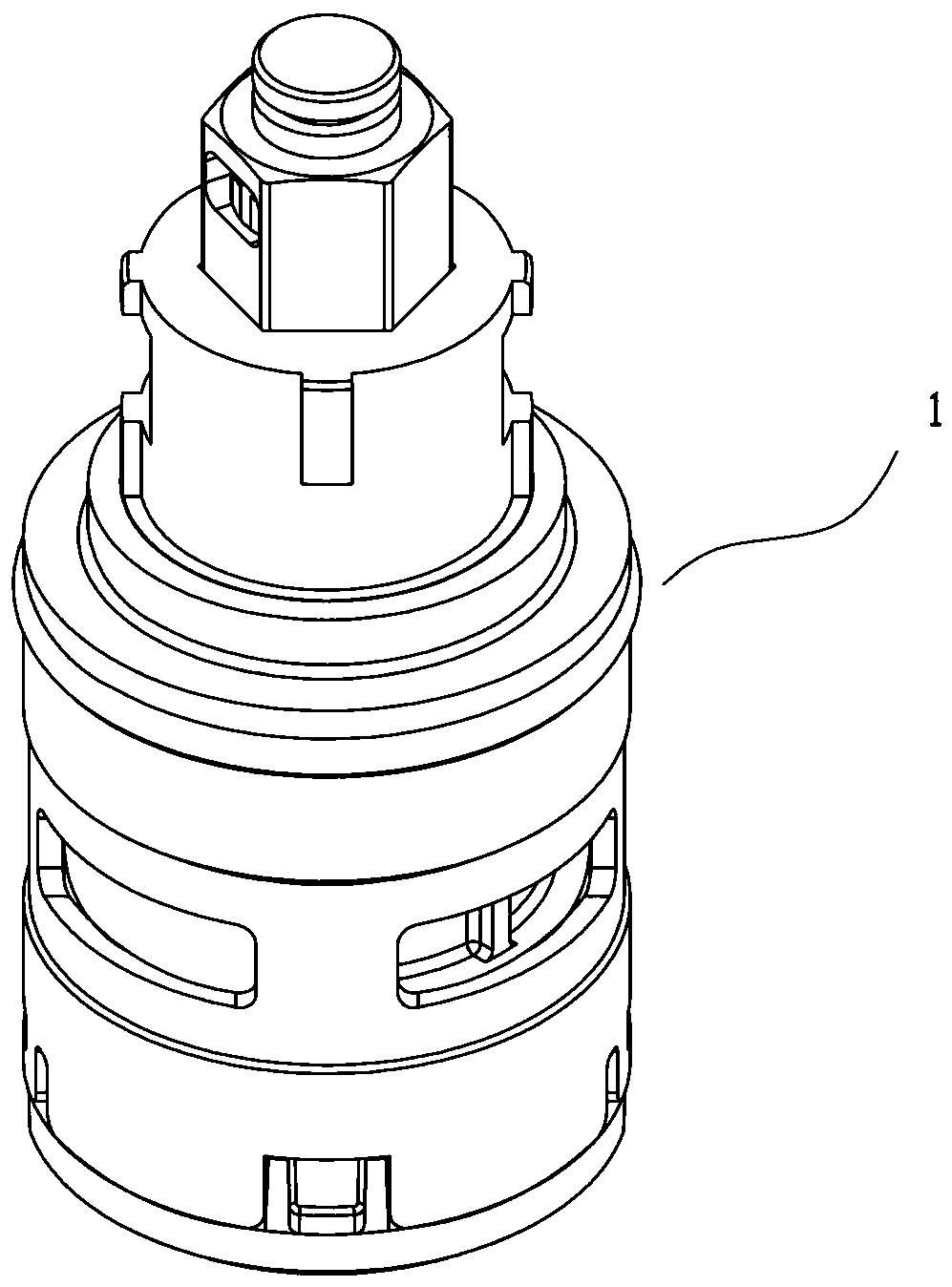

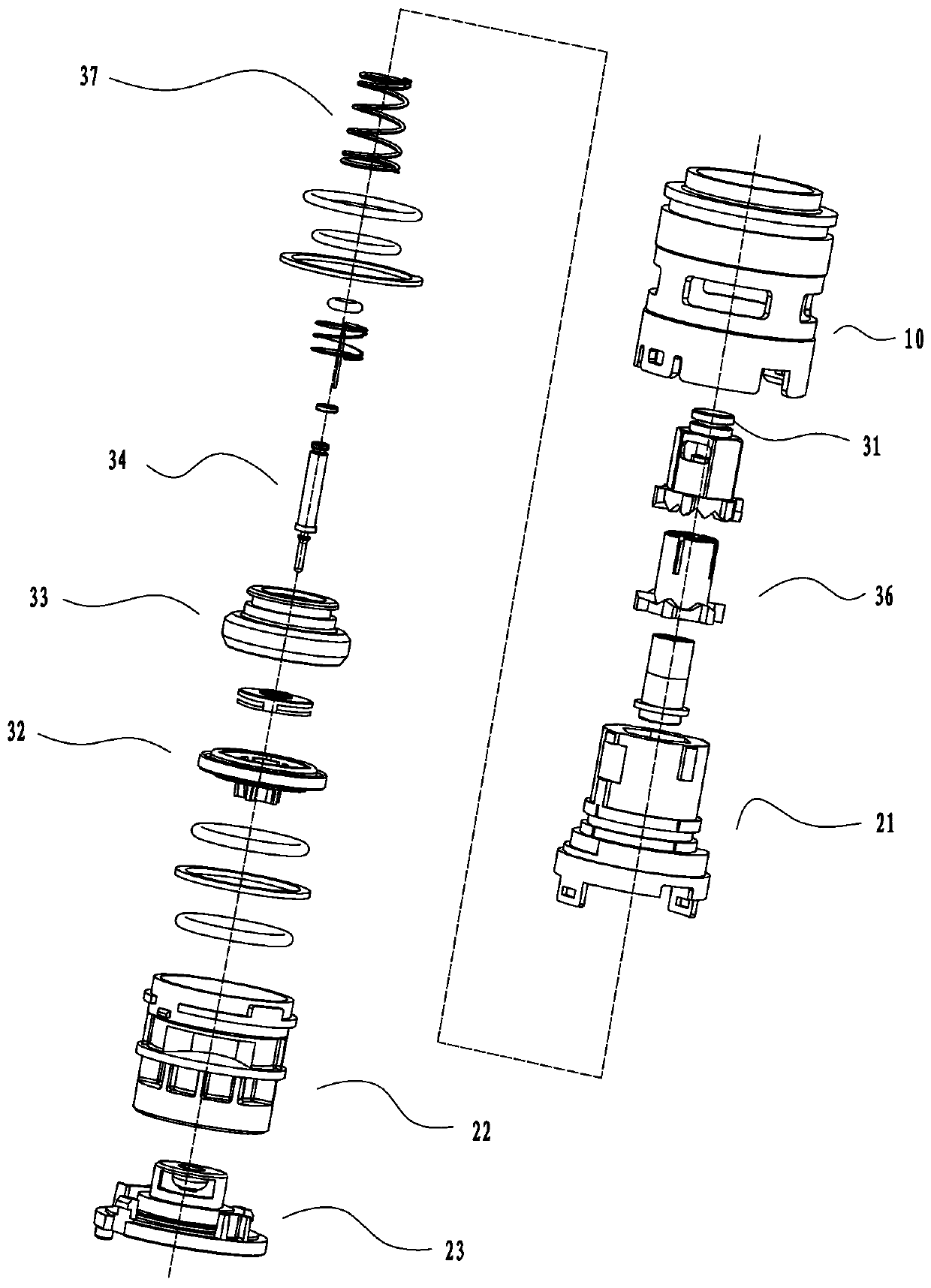

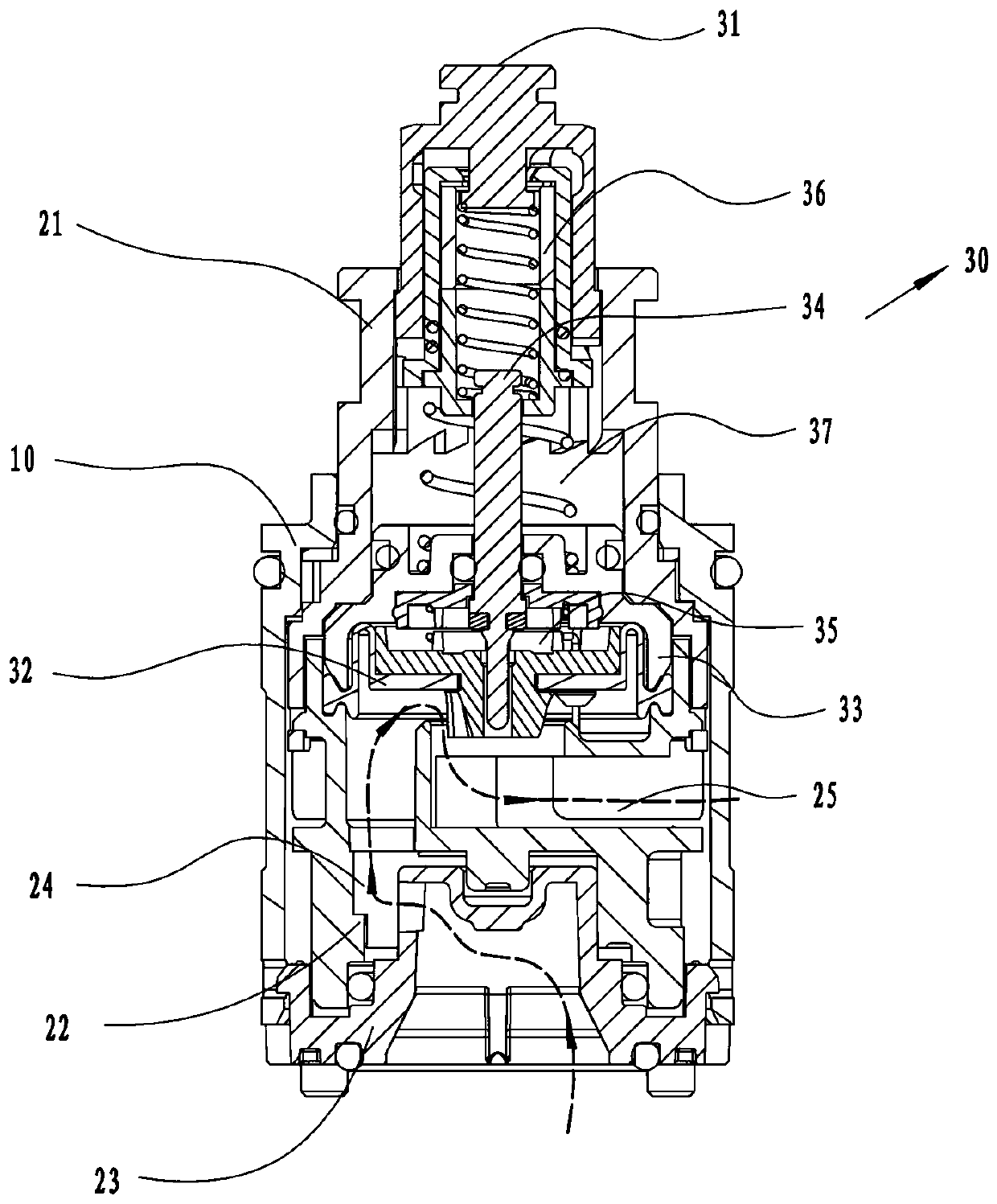

[0074] First reference Figure 1-4 , The multifunctional valve core 1 of this embodiment includes a valve housing 10 in which a flow regulating component 20 and a water stop component 30 are provided.

[0075] The flow regulating assembly 20 includes a rotary actuator 21, a receiving seat 22, and a fixed seat 23. The receiving seat and the fixed seat have a first water outlet 221 and a second water outlet 231, respectively. The two water outlets cooperate to be assembled A first water flow channel 24 with a variable cross-sectional area is formed in the receiving seat and the fixing seat. The rotating actuating member 21 is arranged in conjunction with the receiving seat 22 to drive it to rotate relative to the fixed seat 23, thereby controlling the flow cross section overlapped by the first water passage and the second water passage to change accordingly. In this embodiment, the rotary actuator 21 and the receiving seat 22 are connected by buckles and claws.

[0076] At the same ...

Embodiment 2

[0099] reference Figure 14-20 The main difference between this embodiment and the first embodiment is that the eccentric relationship between the corresponding water passages of the receiving seat 22 and the fixed seat 23 is exchanged. In the specific structure, the receiving seat and the fixing seat are still integrated. The lower end of the receiving seat 22 is provided with a protruding post 223. The bottom of the protruding post is hollowed out with a through hole connected upward to the third water outlet 222, and the through hole constitutes The first water outlet 221. The through hole 221 has a constant cross-sectional area along the inflow direction of the water flow, and a cross section perpendicular to the direction of the water flow does not have the characteristic that the rate of change of the cross-sectional area changes monotonously along the direction of the rotation stroke, so its rotation relative to the fixed seat 23 always Have the same rate of change in cr...

Embodiment 3

[0105] reference Figure 21-25 The main difference between this embodiment and Embodiment 1 is that the receiving seat 22 and the fixing seat 23 are both separated. In a specific structure, the receiving base 22 includes a continuous receiving upper base 223 and a movable ceramic sheet 224, and the fixed base 23 includes a fixed base 232 and a fixed ceramic sheet 233 that are fixed to each other. The movable ceramic sheet 224 is provided with a first flow hole to form the first water outlet 221; the fixed ceramic sheet 233 is provided with a second flow hole to form the second water outlet 231.

[0106] The hole edge of the first flow hole 221 is formed by connecting and transitioning two arcs with the same radius of curvature, and the hole edge of the second flow hole 231 is formed by connecting and transitioning two arcs with different radii of curvature. Therefore, through the foregoing analysis, it can be easily obtained: the structure of the first flow hole 221 is similar to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com