Condensation generation determination method and device, condensation control method and device, and electronic device

A technology of condensation and equipment, applied in the direction of non-electric variable control, control/regulation system, and simultaneous control of multiple variables, etc., can solve problems such as failure to use normally, damage to switch cabinets, and electrical failures in switch cabinets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

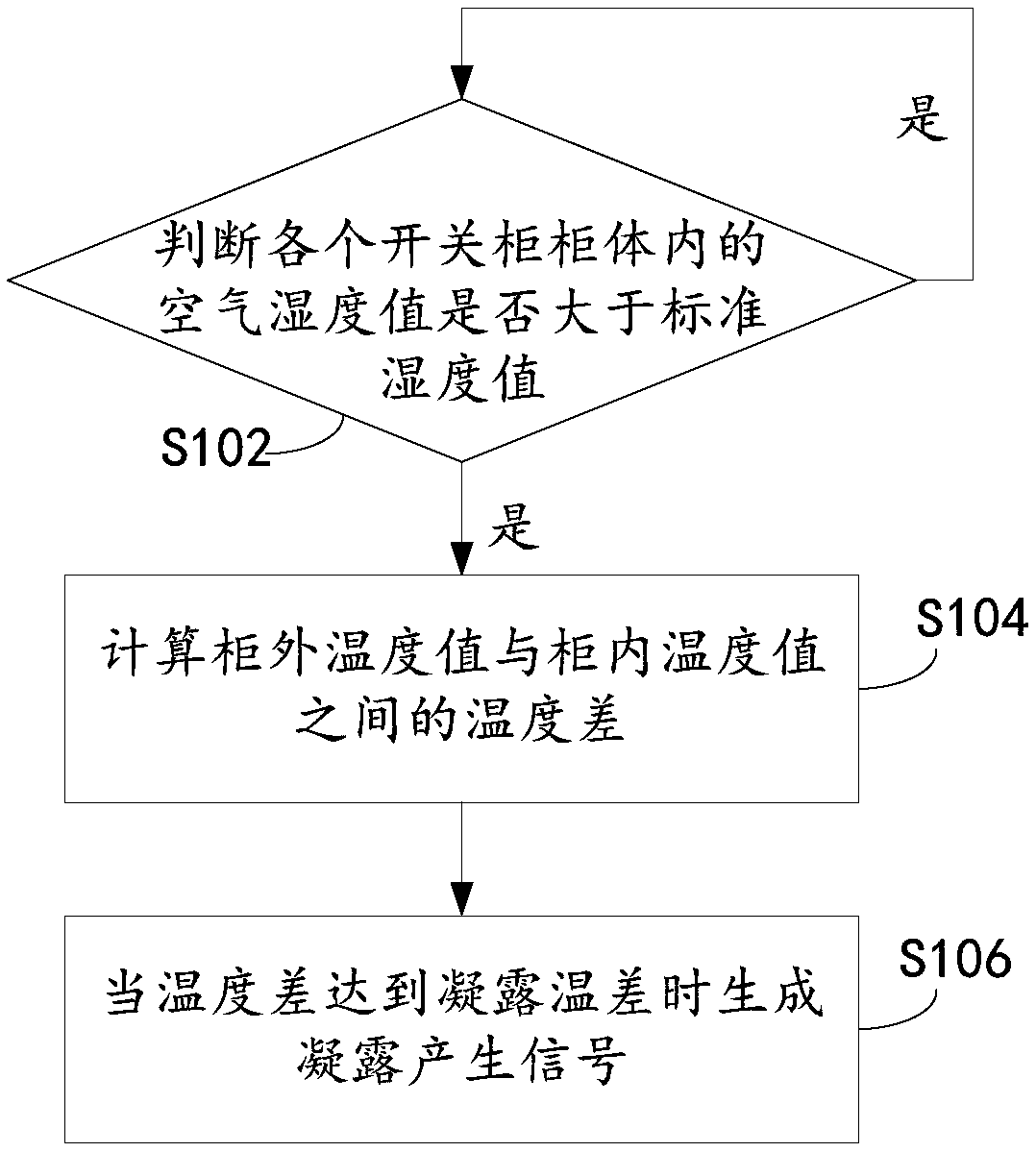

[0048] see figure 1 , the method for judging the generation of condensation proposed in this embodiment, the method is applied to the server, and specifically includes the following steps:

[0049] Step S102: judging whether the air humidity value in each switchgear cabinet is greater than the standard humidity value.

[0050]It should be noted that in the application process of power equipment, the main function of the switchgear is to open and close, control and protect electrical equipment during the process of power generation, transmission, distribution and power conversion in the power system. In order to facilitate management, usually a plurality of switch cabinets are placed together in one area, and each switch cabinet is connected to the above-mentioned server respectively.

[0051] During the implementation process, the server receives the air humidity values from each switch cabinet respectively. When it comes to the condensation judgment of a single switch cabi...

Embodiment approach

[0052] A preferred embodiment of obtaining the above-mentioned air humidity value is given below, which specifically includes the following process:

[0053] (1) The air humidity data collected by the humidity sensor is sampled at preset time intervals, wherein the humidity sensor corresponds to a single switch cabinet.

[0054] In order to collect the air humidity value in the switch cabinet more accurately and effectively, the humidity sensor in the switch cabinet is used for data collection. During implementation, the humidity sensor collects air humidity data continuously. In order to simplify the amount of calculation, the air humidity data collected by the humidity sensor is sampled according to the preset time interval. The preset time interval can be flexibly set according to the actual usage scenario. The preset time interval, in areas with low air humidity, 30 minutes is used as a preset time interval.

[0055] It should be noted that the specific installation posi...

Embodiment 2

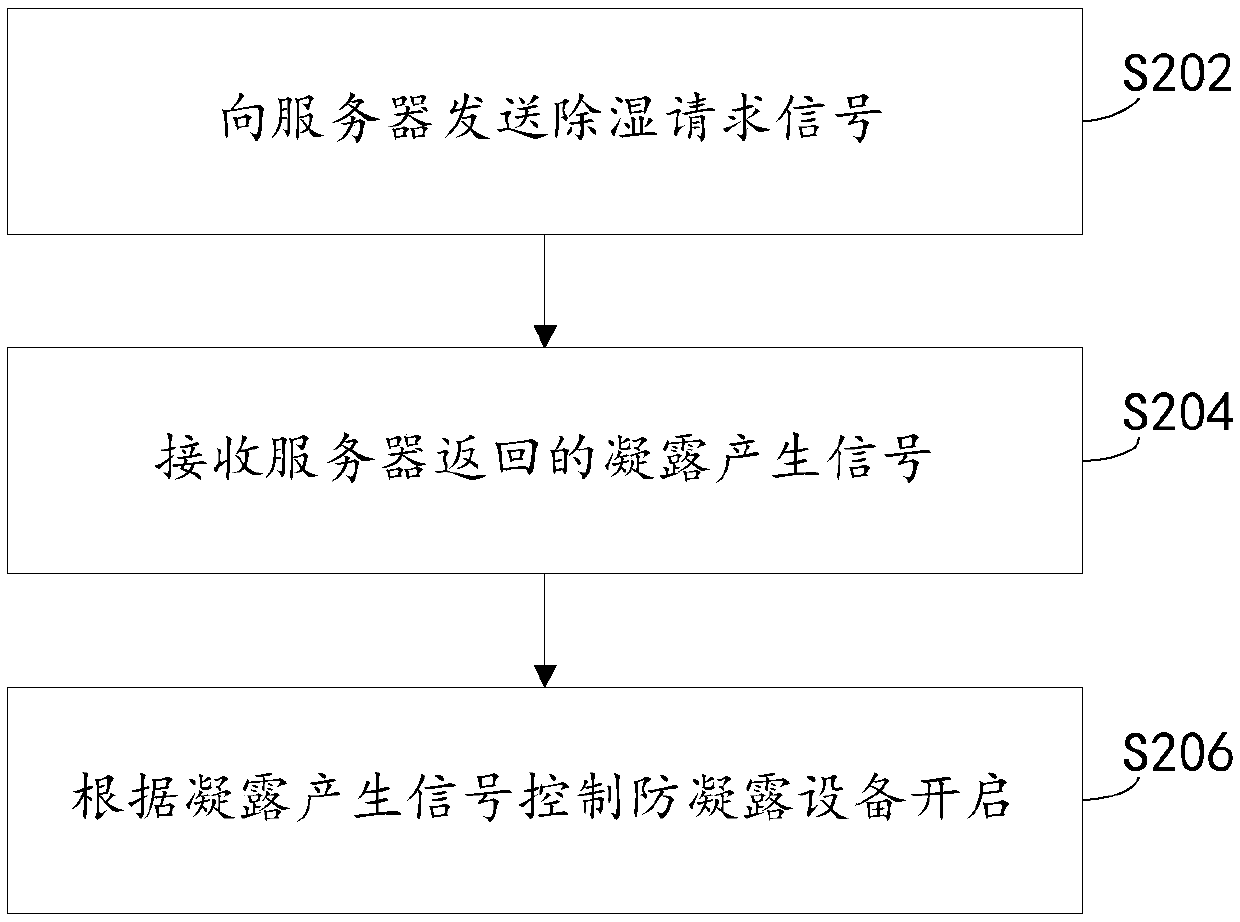

[0076] The accumulation of condensation in the switchgear will cause various electrical failures in the switchgear, and even damage the switchgear so that it cannot be used normally. After effectively judging the generation of condensation in the switch cabinet, it is necessary to take further corresponding treatment measures to remove the condensation generated in the switch cabinet. Therefore, the controller and the corresponding heating device, dehumidification device, etc. are pre-installed inside the control cabinet, and the specific installation positions of the controller, heating device, and dehumidification device can be flexibly set according to the use of the switch cabinet. Especially when there are multiple switchgears, in order to eliminate condensation accurately, the elimination process is carried out individually according to each different control cabinet, which can effectively save resources.

[0077] see figure 2 , this embodiment provides a condensation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com