Weight running parcel reverse action eliminating back frame

A reverse, action technology, applied in applications, home appliances, travel or camping equipment, etc., can solve the problems of human impact, prone to falling, increased pressure, etc., to reduce the slap force, wide range of applications, easy to disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

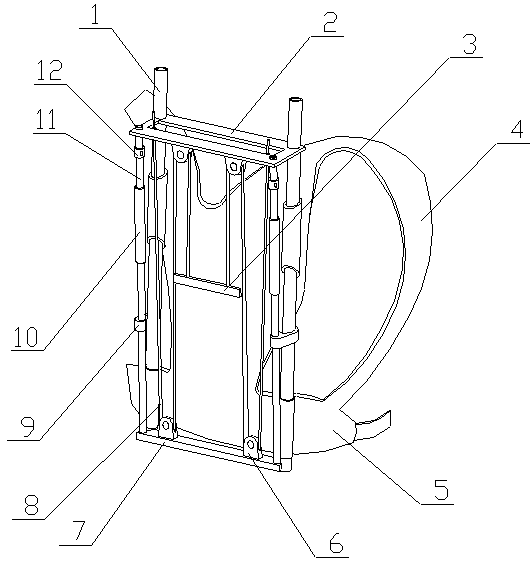

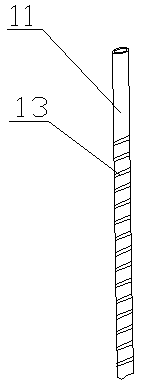

[0025] The back frame for eliminating the reverse action of the load-bearing and migrating package of the present invention is realized in the following way: the back frame for eliminating the reverse action of the load-bearing and migrating package of the present invention consists of a main body tube (1), a fixed frame (2), and a loading plate (3 ), shoulder strap (4), waist belt (5), fixed pulley (6), bottom support plate (7), elastic rope (8), connecting buckle (9), guide tube (10), guide rod (11), Composed of a limit ring (12) and a spiral magnetized strip (13), the fixed frame (2) is placed directly above the bottom support plate (7), and one end of the two guide rods (11) is respectively placed on the bottom support plate (7) , the other ends are respectively placed on the fixed frame (2), the guide rod (11) is placed vertically, the surface of the guide rod (11) is provided with a spiral magnetized strip (13), and the two guide tubes (10) are respectively set Placed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com