Method for automatic cooking machine and automatic cooking machine

A cooking machine, automatic technology, applied in the direction of timing control ignition mechanism, kitchen utensils, household utensils, etc., can solve the problem of difficult to reflect the process of time cooking, and achieve the effect of ensuring the taste and flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

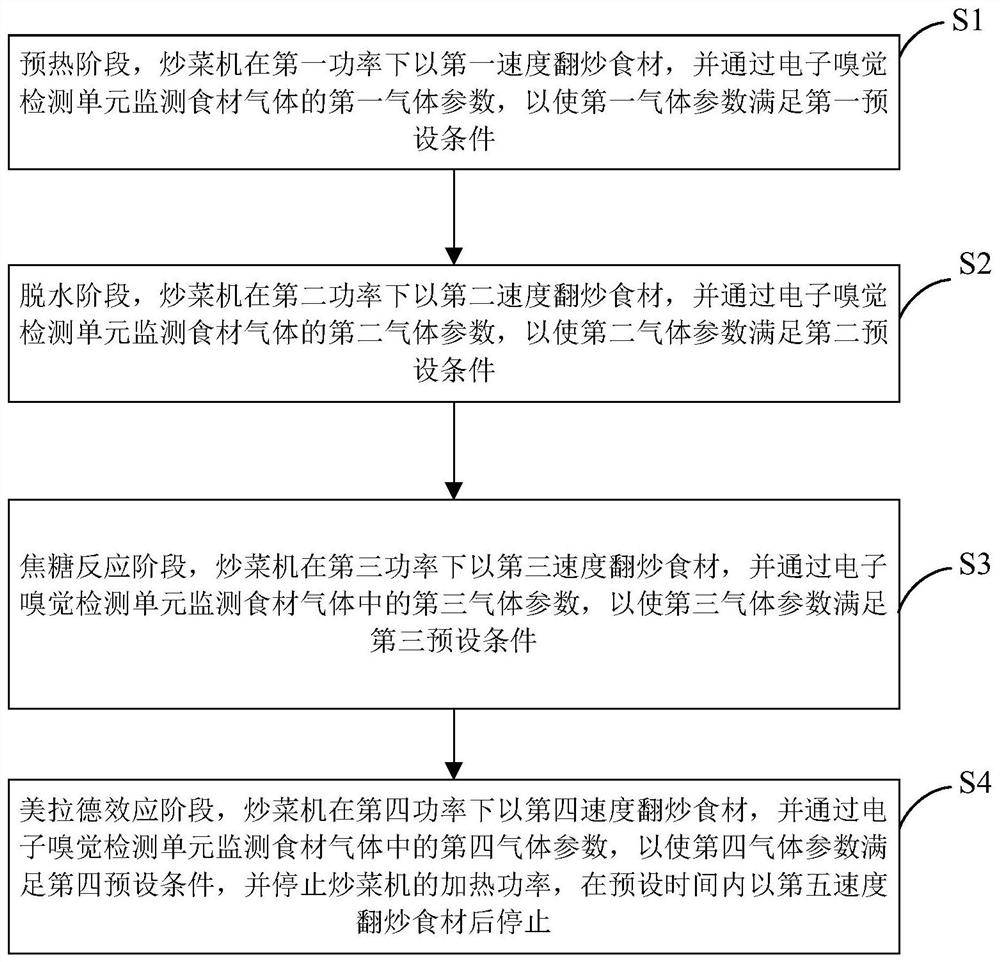

[0037] like figure 1 , In an automatic cooking machine cooking method of the present invention in a first embodiment, comprising the steps of:

[0038] Sl, preheating stage, cooking machine at a first power at a first speed stir ingredients, and detecting means by an electronic olfactory first gas parameter monitoring gas ingredients, so that the first gas parameter meets a first preset condition; Specific of ingredients when added immediately wok, food cooking machine power is carried out at a first heating, and stir the ingredients at a first speed, while detecting the first gas parameter at this stage by an electronic olfactory detection unit, a first gas confirmed when the parameter meets a first preset condition, complete this stage, the next stage, be apprec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com