A control method for automatic operation of ring roller mill

A control method and automatic operation technology, applied in the field of ring roller mill control, can solve the problems of unstable grinding particle size, cumbersome control and fault detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

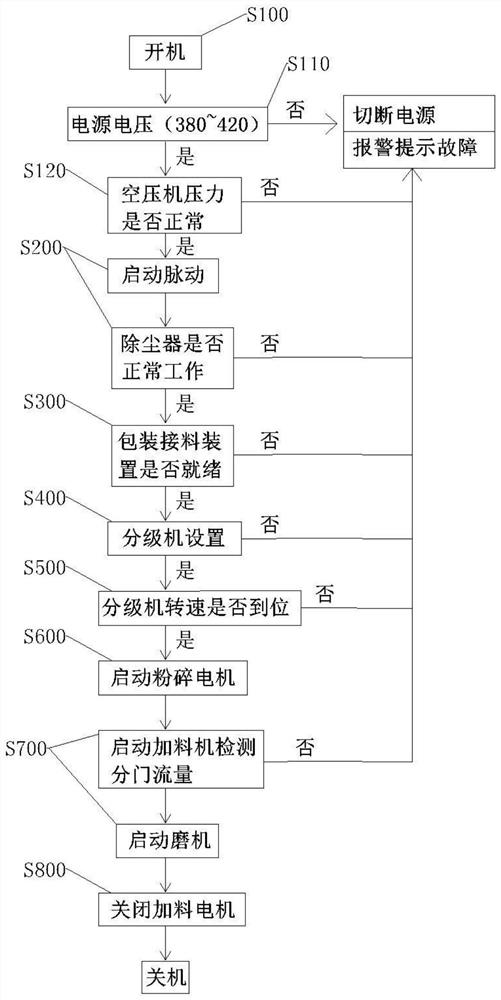

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific drawings.

[0028] The application of the control method of the present invention is realized by installing various detection and control equipment on the mixed roller mill and connecting with the control cabinet and the control host through a circuit. The present invention will be further described through a specific implementation mode below.

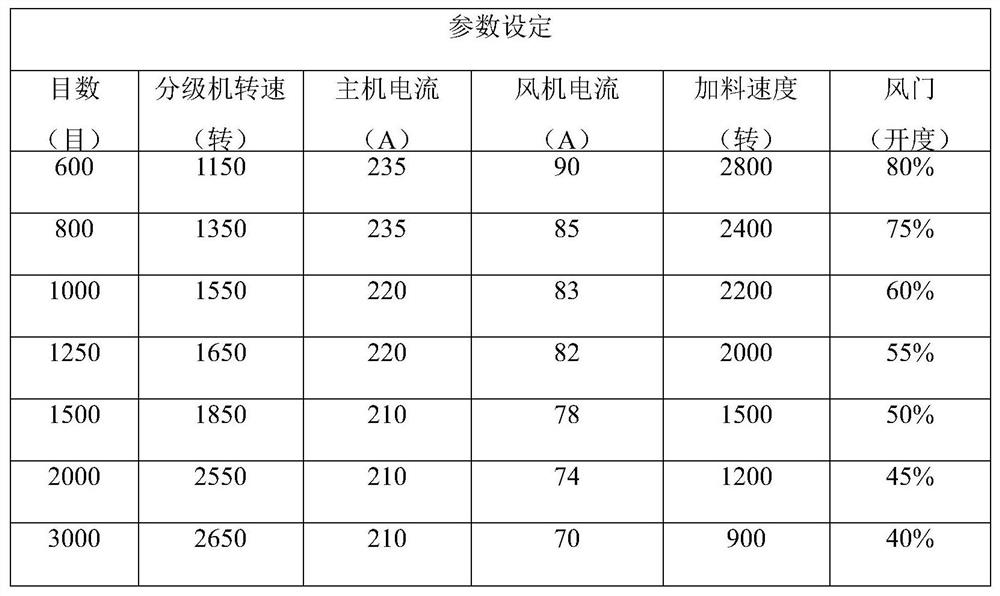

[0029] The system control loop for realizing the present invention adopts a touch screen and PLC to form a man-machine interface, and the control cabinet includes a touch screen, an emergency stop button, a total voltmeter, a total ammeter, a secondary circuit 220v indicator light, a secondary circuit 24v indicator light and an alarm. The control cabinet includes control parts: host control, fan control, classifier contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com