A straightening machine applied to round section steel

A straightening machine and section technology, applied in the field of straightening machines, can solve the problems of inability to adjust the inclination angle of the concave-convex roll, producing defective products, and substandard processing results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

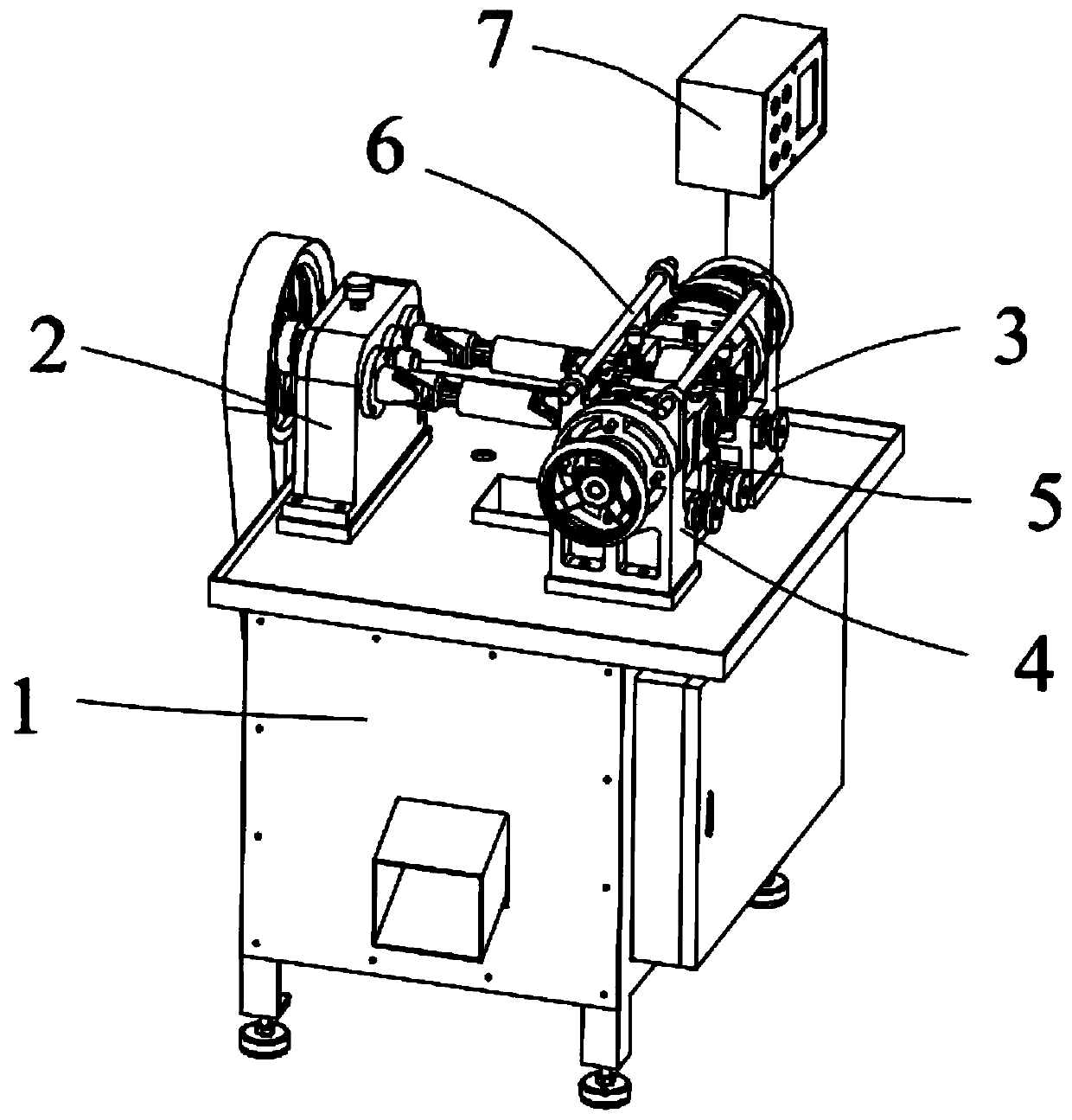

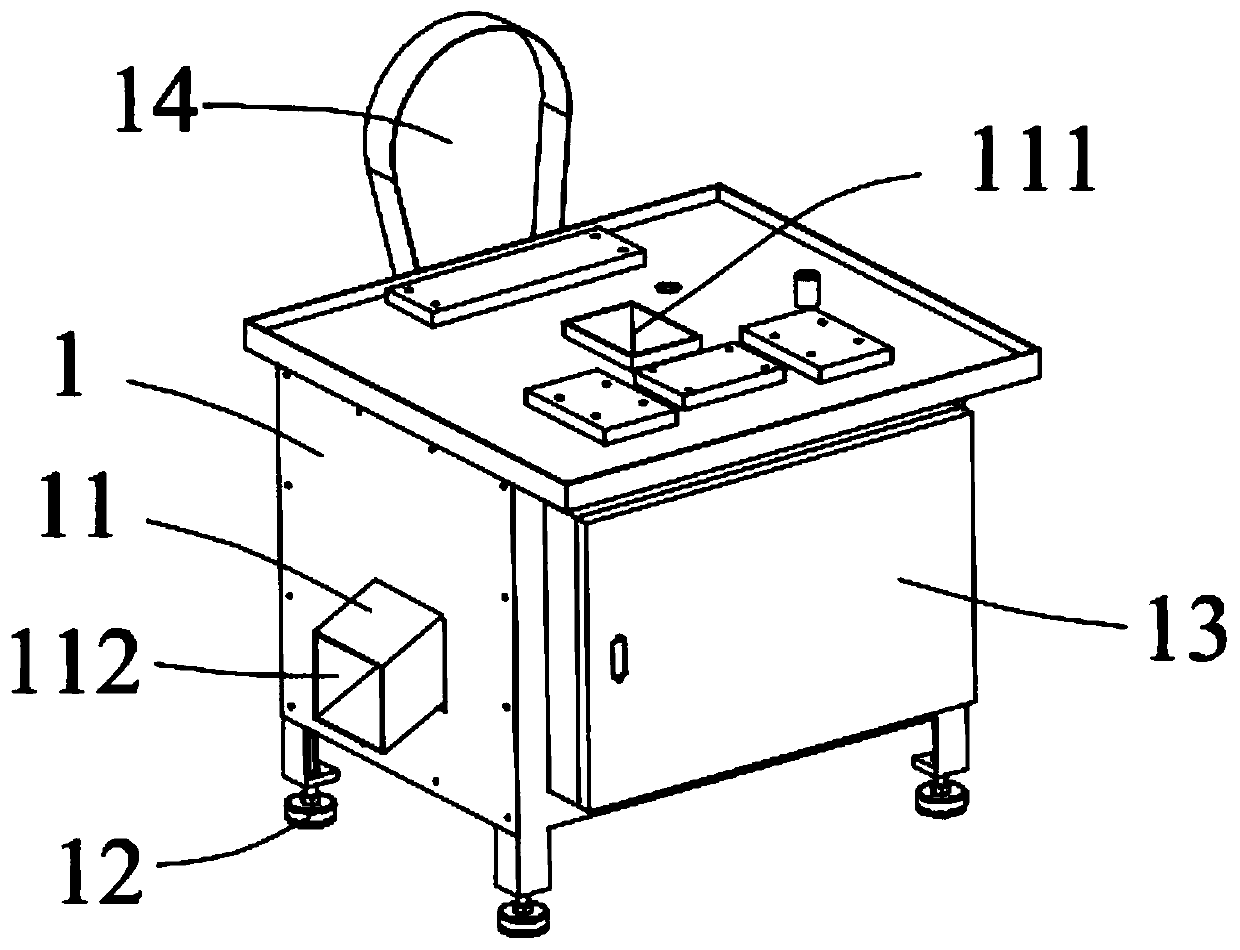

[0036] Please refer to figure 1 and 2Shown are the three-dimensional schematic diagram and the structural schematic diagram of the machine body of the straightening machine applied to the circular cross-section steel in the embodiment, respectively.

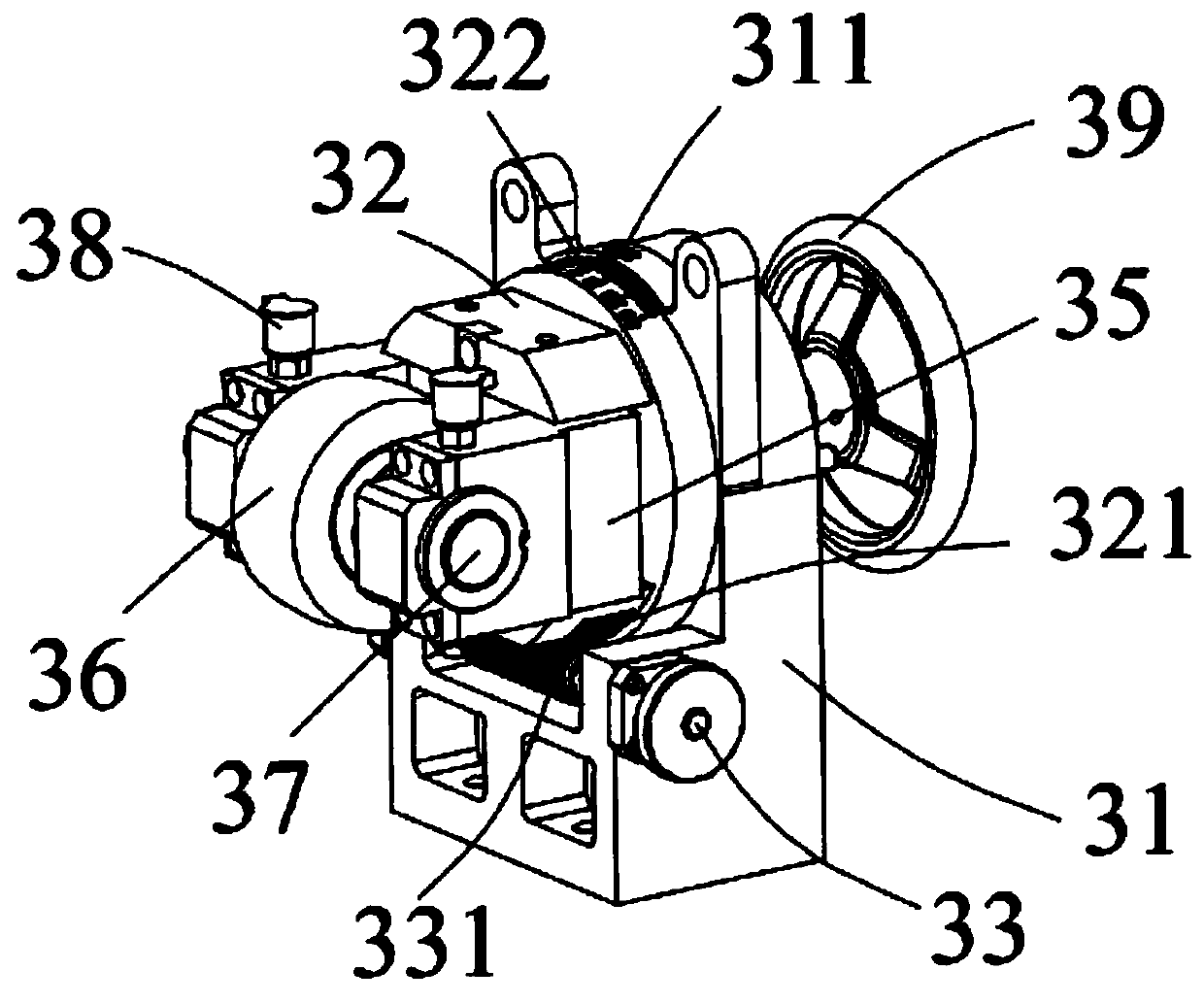

[0037] This embodiment provides a straightening machine applied to round-section steel, which is a device for straightening round-section steel, which includes a body 1, a reduction box device 2 installed on the body 1, and a first pressure wheel Device 3, the second pressure roller device 4 and the blade device 5, wherein the first pressure roller device 3, the second pressure roller device 4 and the blade device 5 are located on the same side of the reduction box device 2, and the blade device 5 is located on the first Between the pressure wheel device 3 and the second pressure wheel device 4 , the reduction box device 2 is connected to the first pressure wheel device 3 and the second pressure wheel device 4 respectively. Amo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com