Machine tool adjusting device

A technology for adjusting devices and machine tools, which is applied in the direction of metal processing machinery parts, large fixed members, maintenance and safety accessories, etc. It can solve the problems of machine tool elevation, time-consuming and labor-intensive, etc., and achieve the effect of alleviating vibration and improving the processing dimensional accuracy and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

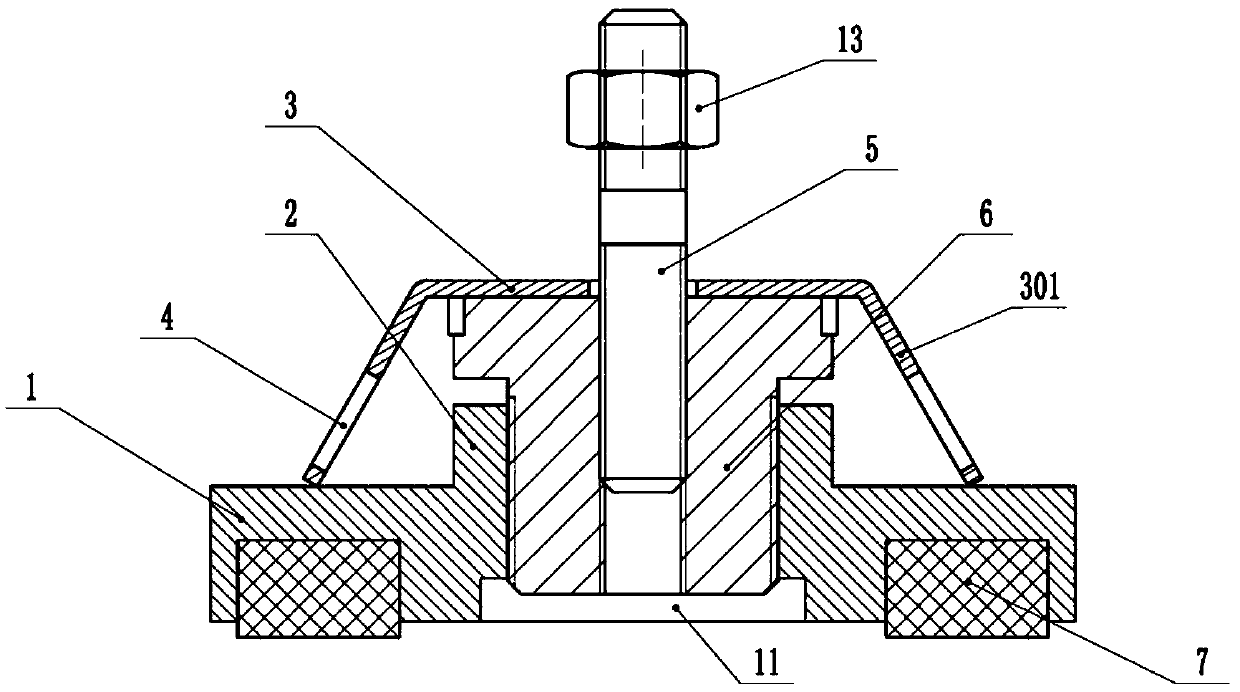

[0027] The embodiment is basically as attached figure 1 Shown: a machine tool adjustment device, including a base 1 and bolts 5, the base 1 is cylindrical, a boss 2 is provided in the middle of the base 1, the boss 2 and the base 1 are integrally formed in this embodiment, the device also includes The adjustment column 6 extends into the boss 2 and the base 1 and is threadedly connected with the boss 2 and the base 1 , the bottom of the base 1 and the center of the base 1 is provided with a bearing plate 11 .

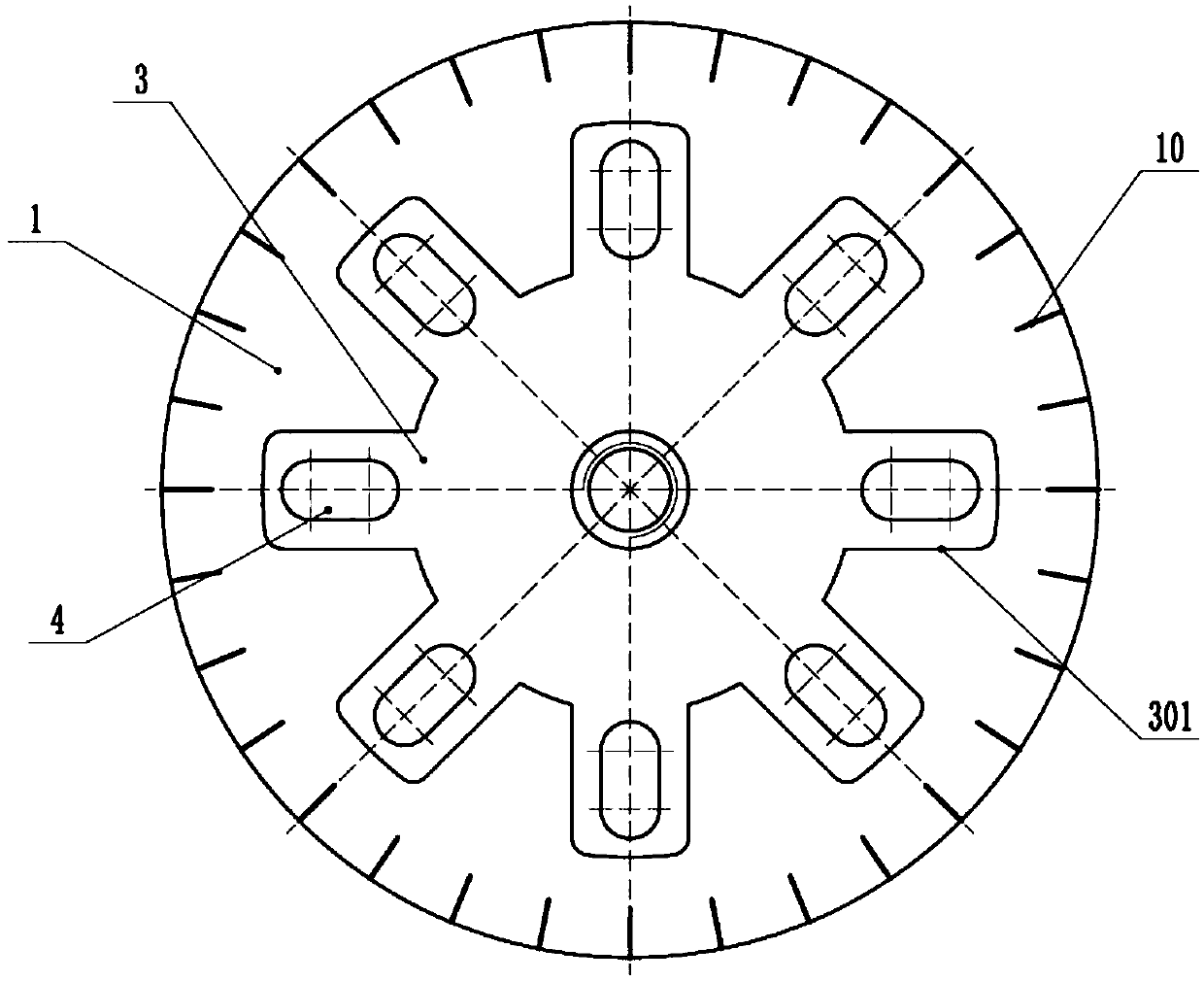

[0028] The top of the adjustment column 6 is fixedly connected with a cover plate, the cover plate includes a connecting plate 3 and a rotating plate 301, the connecting plate 3 is annular, the connecting plate 3 is fixedly connected with the top of the adjusting column 6, and there are multiple rotating plates 301. The number of rotating plates 301 in the example is eight, and the eight rotating plates 301 are evenly arranged along the circumference of the connecting p...

Embodiment 2

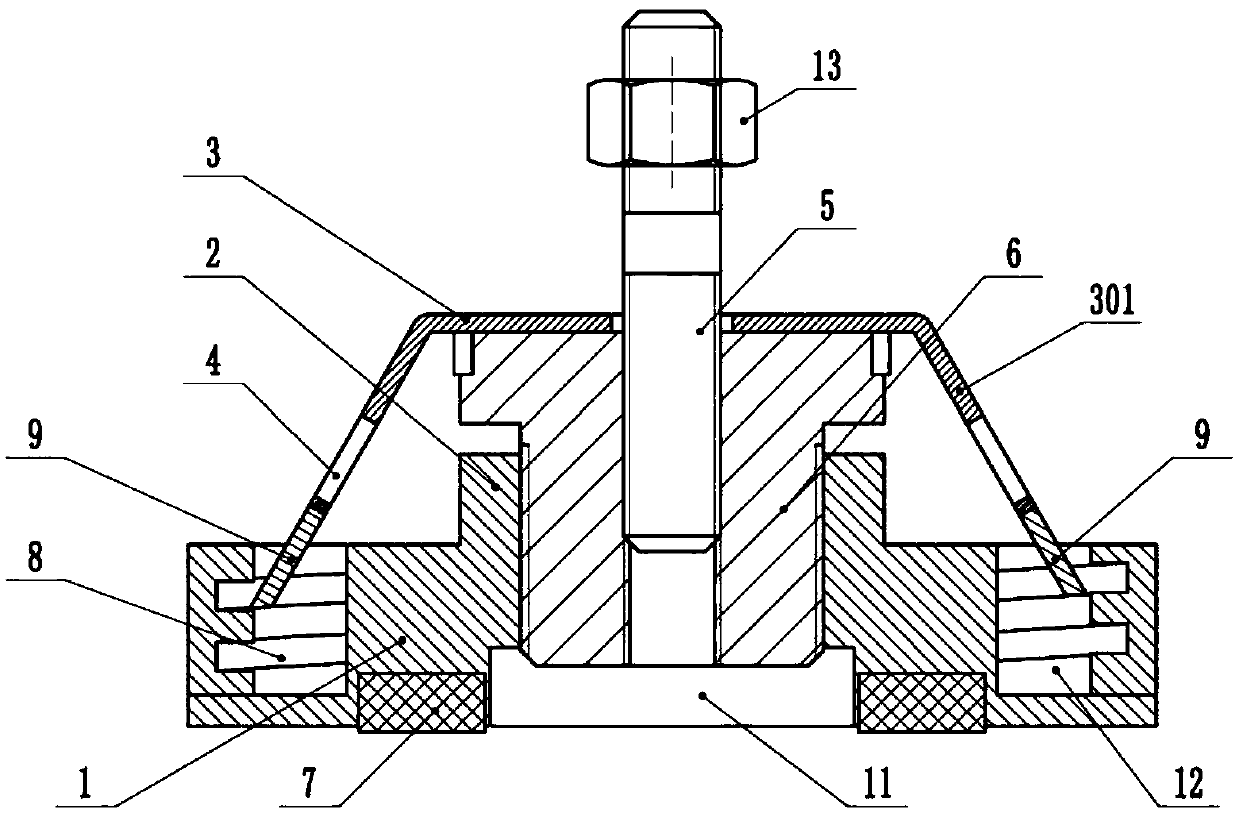

[0033] Such as image 3 and Figure 4 As shown, the difference between the present embodiment and the first embodiment is that there is a groove 12 in the base 1, and a spiral groove 8 is formed on the side wall of the groove 12, and the thread pitch of the spiral groove 8 is equal to that of the adjusting column 6 and The screw pitch of the boss 2 is matched, and the end of the rotating plate 301 away from the connecting plate 3 is fixedly connected with a support rod 9, and the supporting rod 9 is in the spiral groove 8. When the rotating plate 301 is pulled to rotate and the adjustment column 6 is raised or lowered During the process, since the thread pitch of the spiral groove 8 is equal to the thread pitch of the adjustment column 6 and the boss 2, the support rod 9 can move up or down along the spiral groove 8 synchronously with the rotation of the rotating plate 301. During this process, The support rod 9 can always be in the spiral groove 8, and has an upward supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com