Connecting device suitable for light railway vehicle

A railway vehicle and connecting device technology, which is applied in the direction of railway car body parts, traction devices, transportation and packaging, etc., can solve the problems of heavy weight, small rail vehicles that are not applicable, and large volume, so as to achieve small installation space and ease vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

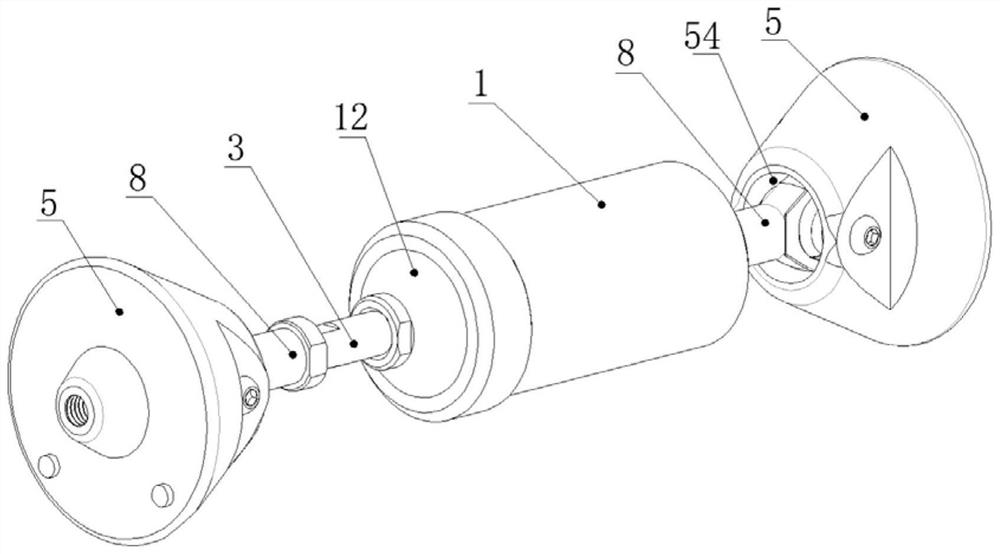

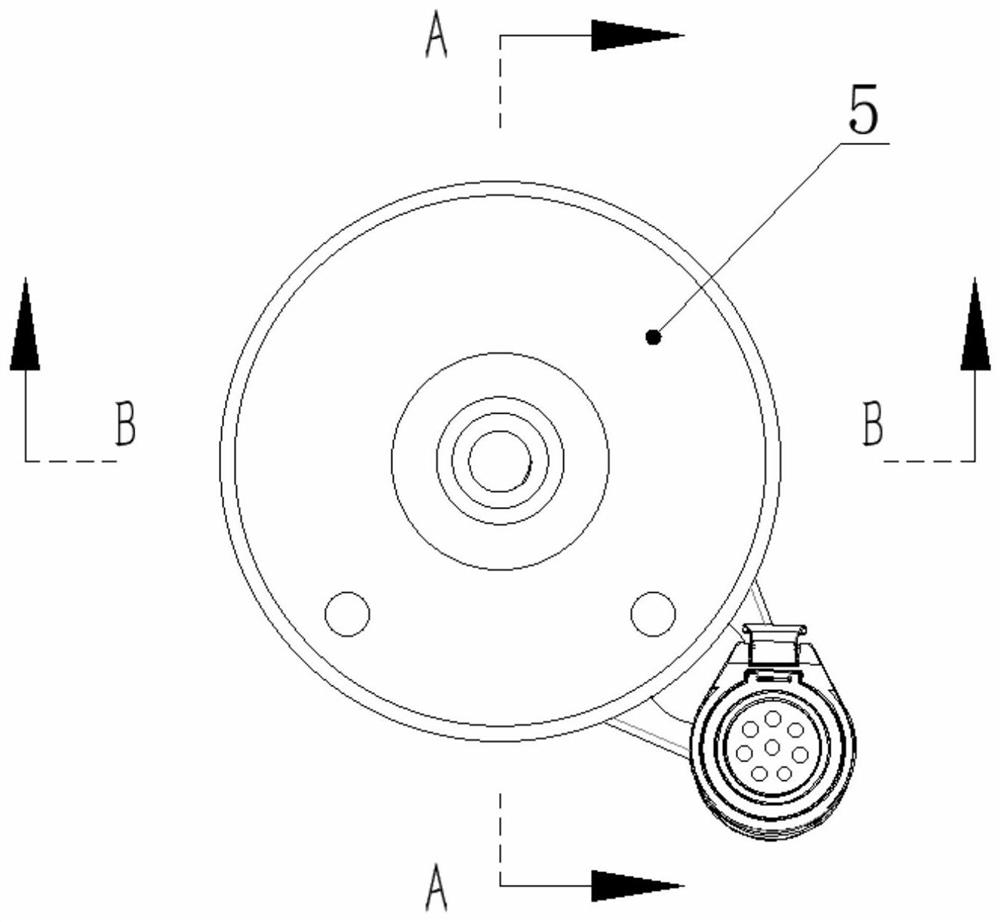

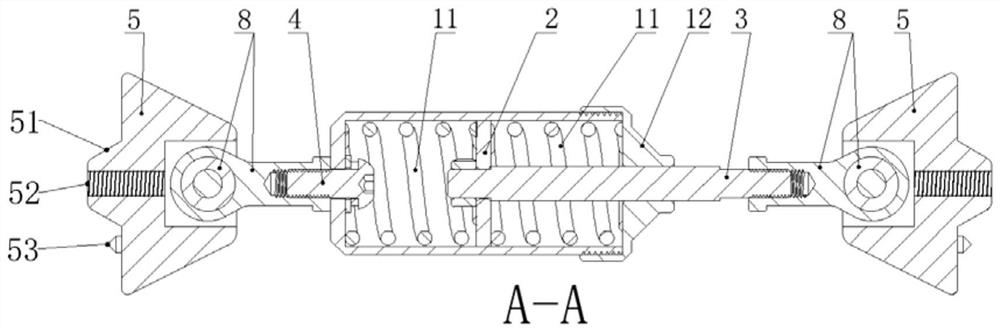

[0030] like Figure 1 to Figure 4 As shown, the present invention provides a connection device suitable for light railway vehicles, including a sleeve housing 1, which has a push-pull body 2 that can float left and right, and the left and right inner sides of the sleeve housing 1 Left and right buffer spring bodies 11 are mounted on the top between the wall and the push-pull body 2 respectively. It should be noted that, under no external force, the initial position of the push-pull body is in the middle of the sleeve housing. When an external force acts on the push-pull When the body is on the body, the push-pull body can move left or right. Once the external force disappears, under the elastic action of the left and right buffer springs, the push-pull body will return to the initial position.

[0031] It also includes a long pull rod 3, which is connected to the push-pull body 2, and a channel opening (not shown) for the long pull rod 3 to pass freely is provided on the side ...

Embodiment 2

[0043]Some special rail vehicles not only need to realize the mechanical connection between the front and rear adjacent vehicles, but also need to realize the electrical connection. The traditional method is to connect a cable between the two vehicles after the coupler is connected to the front and rear vehicles. This will increase the number of processes and reduce work efficiency. Therefore, in this embodiment, the combination of mechanical locking and electrical connection is chosen. Specifically, such as Figure 5 As shown, the connection device also includes a cable fixing bracket 6 connected to the sleeve housing 1 , a cable 7 is installed on the cable fixing bracket 6 , and the cable 7 has plugs 71 at both ends. In addition, it should be noted that the cable itself is flexible, and its length should not be too short, that is, it should not be shorter than the limit distance that can be produced by the two end connectors. The limit distance is when the push-pull body mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com