Wind power tower drum

A technology for wind power towers and towers, which is applied to wind turbine components, wind turbines, mechanical equipment, etc., can solve problems such as single function, influence on wind energy utilization, and loosening of joints connected to each other, so as to ensure normal operation, Extends service life and reduces vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

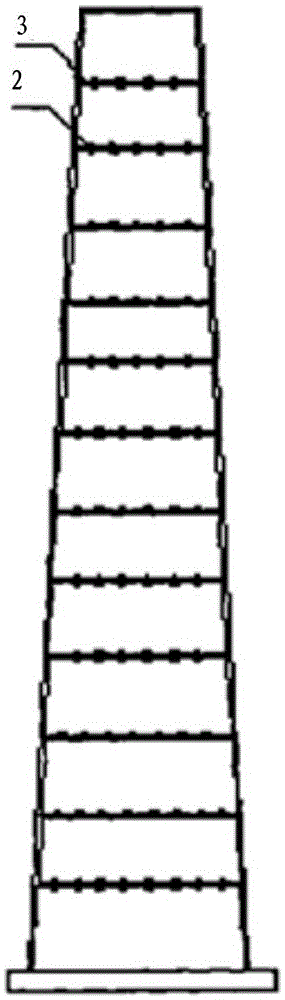

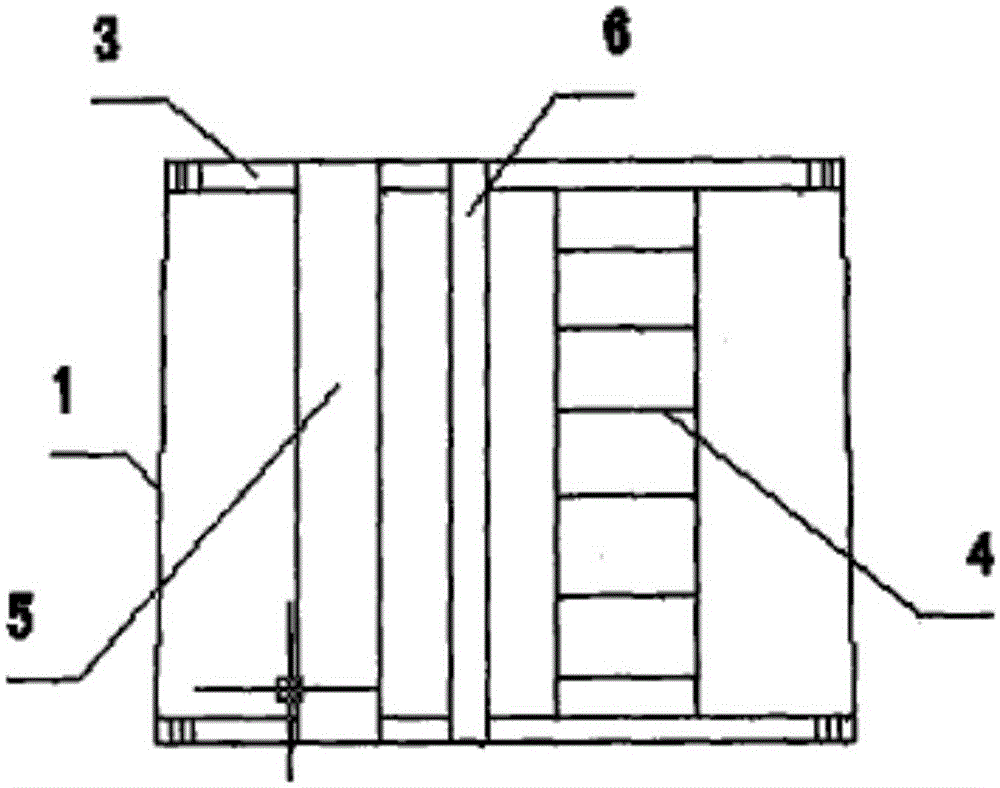

[0014] Example: see attached figure 1 , 2 , The wind power tower is provided with a tower body, and the tower body is composed of several sections of steel cones 1 connected end to end by several fixing bolts 2 in turn, and both ends of the cones are welded with steel joints. Lan 3, the tower body is provided with 3 sections of base ring steel cones, 3 sections of steel cones for the lower section of the tower, 4 sections of steel cones for the middle section of the tower, and 3 sections of steel cones for the upper section of the tower. Among the steel cones of the 4-section middle section of the tower, there is 1 section of middle and lower steel cones and 3 sections of middle and upper steel cones; the maximum diameter of the bottom of the tower body is 4>4200mm, and the minimum diameter of the top is (i>3005mm; The deviation angle between the top center of the tower body and the bottom center of the tower body and the ideal center line does not exceed 0.3 degrees, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The maximum diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com