Self-priming non-clogging clean water pump

A non-clogging, clear water pump technology, applied in the direction of pumps, pump components, driving pumps, etc., can solve problems such as large noise, inconvenient connection of conduits, poor stability, etc., to achieve the goal of improving stability, reducing noise, and alleviating vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

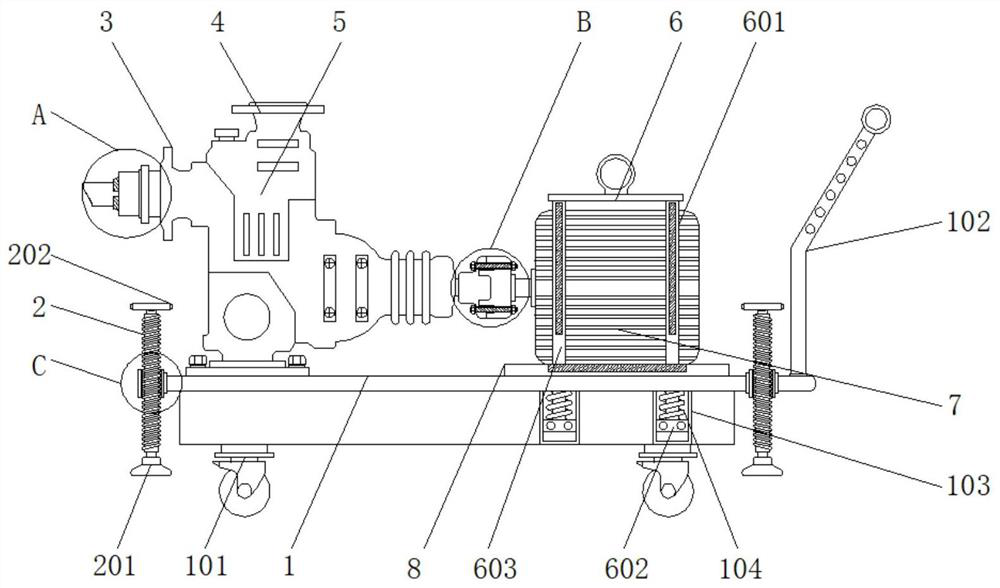

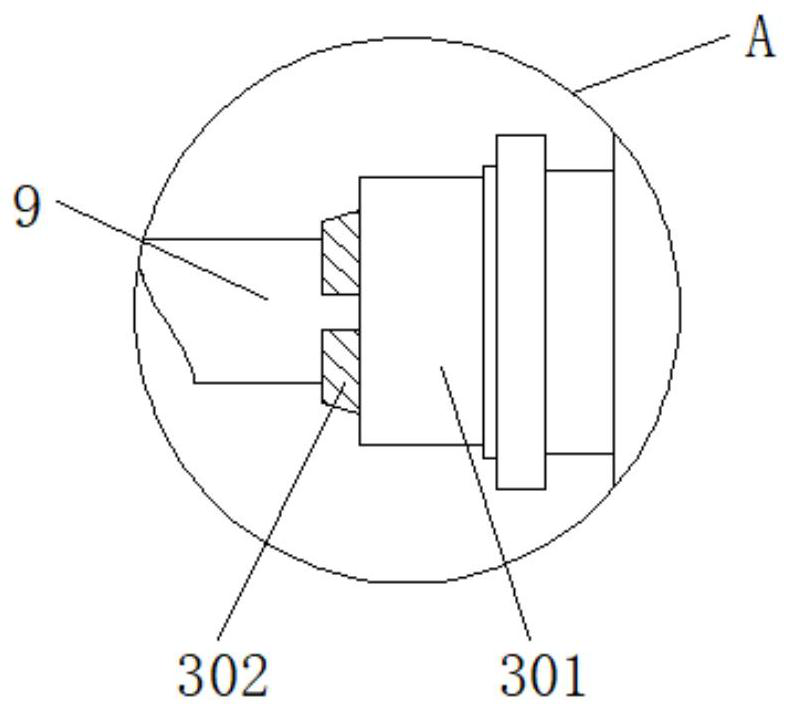

[0033] Implementation Case 1: See Figure 1-6 , an embodiment provided by the present invention: a self-priming non-clogging clean water pump, including a base 1, an inlet flange 3, a pump body 5, a motor 7 and a placement seat 8, both sides of the bottom of the base 1 are fixedly connected with screw Sleeve 105, a hollow block 103 is fixedly connected to one side of the bottom end of the base 1, and a spring 104 is fixedly connected to the top inside the hollow block 103, a push rod 102 is fixedly connected to one side of the top end of the base 1, and both sides of the bottom end of the base 1 All are fixedly connected with pulley 101;

[0034] Specifically, such as figure 1 and Figure 6 As shown, the shackle 604 can be pulled by a tool, and the shackle 604 will pull the connecting plate 6, so that the connecting plate 6 will pull the first snap ring 601 and the second snap ring 603 to move, so that it can pull the sliding block 602 Slide inside the hollow block 103 and ...

Embodiment example 2

[0035] Implementation example 2: the spiral sleeve 105 is movably connected to the screw rod 2, the bottom end of the screw rod 2 is fixedly connected to the outrigger 201, and the top end of the screw rod 2 is fixedly connected to the rotating rod 202;

[0036] Specifically, such as figure 1 and Figure 6 As shown, the screw rod 2 can be driven to rotate by rotating the rotating rod 202, and the screw rod 2 will move inside the helical sleeve 105, so that the screw rod 2 will drive the legs 201 to slowly contact the ground, so that the legs 201 can When the base 1 is supported, the base 1 can slide through the pulley 101, and can also be stably supported by the outrigger 201, which improves the stability of the water pump during use;

Embodiment example 3

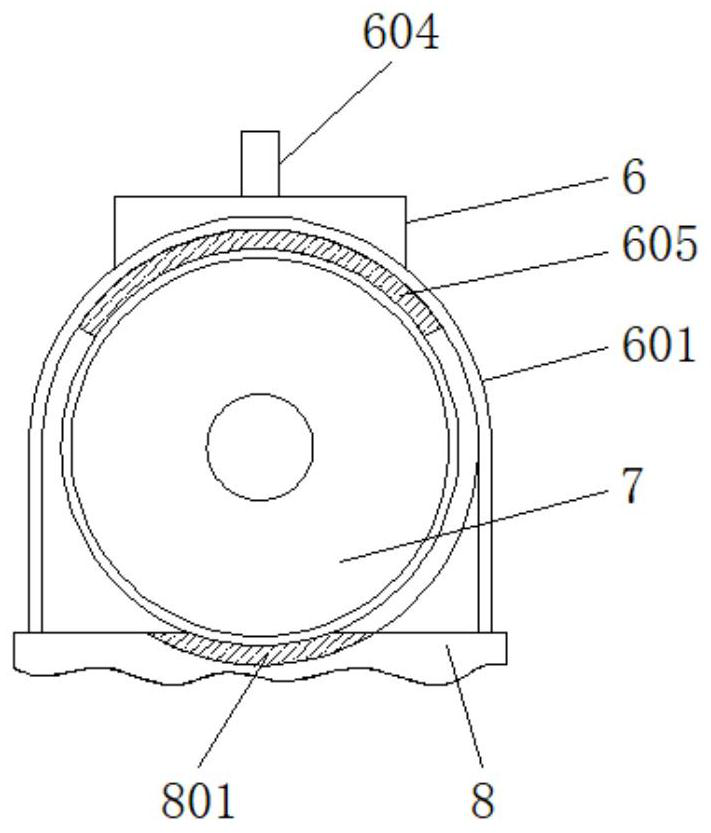

[0037] Implementation example 3: One side of the top of the base 1 is fixedly connected with a placement seat 8, and the inside of the placement seat 8 is fixedly connected with a rubber pad 801, and the top of the placement seat 8 is provided with a motor 7, and one side of the motor 7 is fixedly connected with a second Coupling 701, and both ends of the motor 7 are provided with perforations 702, the other side of the top of the base 1 is fixedly connected to the pump body 5, one side of the pump body 5 is provided with a pump shaft 501, and one side of the pump shaft 501 The side is fixedly connected with a first coupling 502, the inside of the first coupling 502 is provided with a limit bolt 504, and the outside of the limit bolt 504 is movably connected with a fastening nut 503;

[0038] Specifically, such as figure 1 , figure 2 and Figure 5As shown, the second coupling 701 can be spliced with the first coupling 502, and then the limit bolt 504 can be inserted into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com