Plate and plate manufacturing process

A manufacturing process and plate technology, which is applied in the field of plate and plate manufacturing technology, can solve the problems of deformation and displacement of each layer, warping plate deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

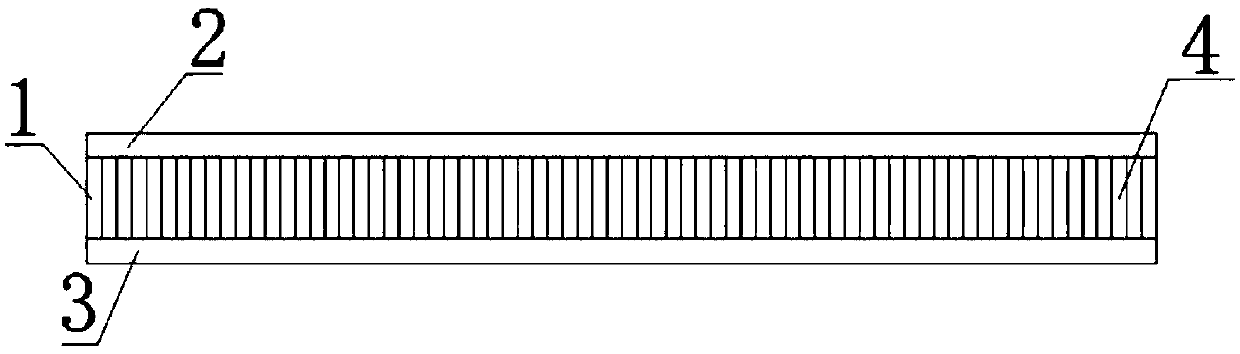

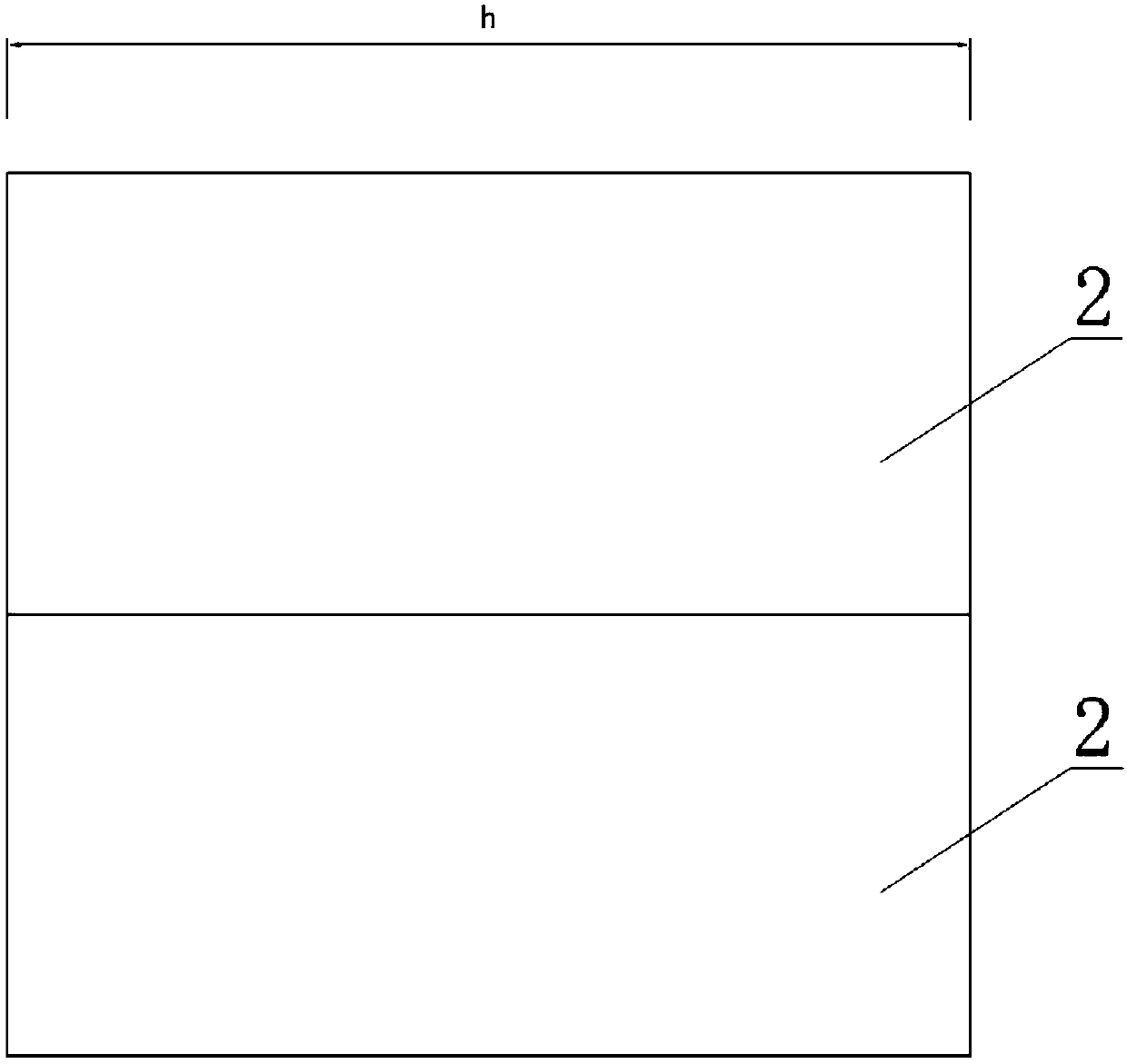

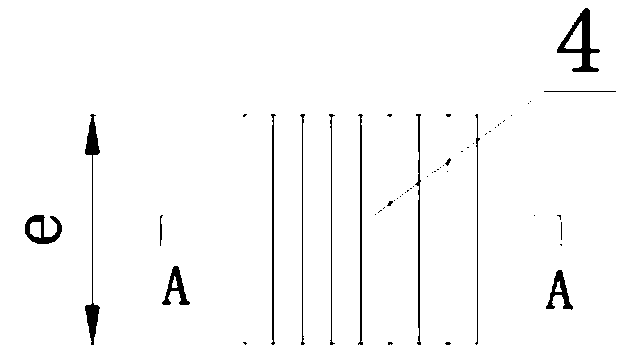

[0024] This embodiment proposes a plate, such as Figure 1-Figure 4 As shown, including a middle board 1, the upper surface and the lower surface of the middle board 1 are respectively pasted with an upper board 2 and a lower board 3, the thickness of the middle board 1 is greater than the thickness of the upper board 2 or the thickness of the lower board 3, and the middle board 1 It is formed by splicing and pasting several upright and equal-height strip-shaped multi-layer boards. The middle board 1 can also be made by pasting several upright and equal-height single-layer boards. The upper board 2 and the lower board 3 The grain direction h is perpendicular to or interlaced with the length direction g of several vertical multi-layer b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com