Automatic glue-coating device for steel sheet in automotive waist-line sealing strips

A technology of automatic gluing and sealing strip, applied in the field of mechanical engineering, can solve the problems of uneven gluing, affecting product quality, dripping, etc., to ensure the gluing effect, improve cleanliness and service life, and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, technical features, invention objectives and technical effects realized by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

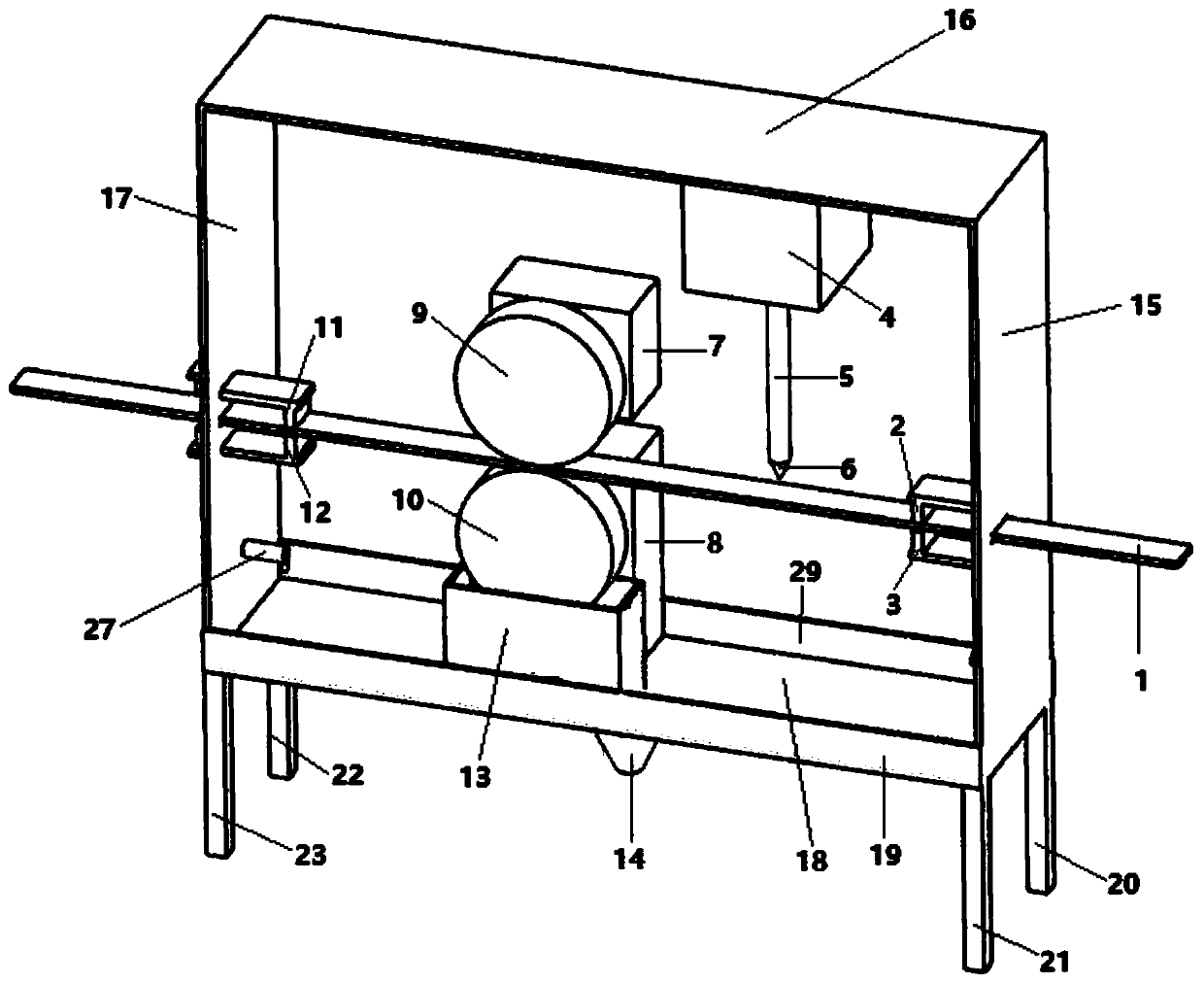

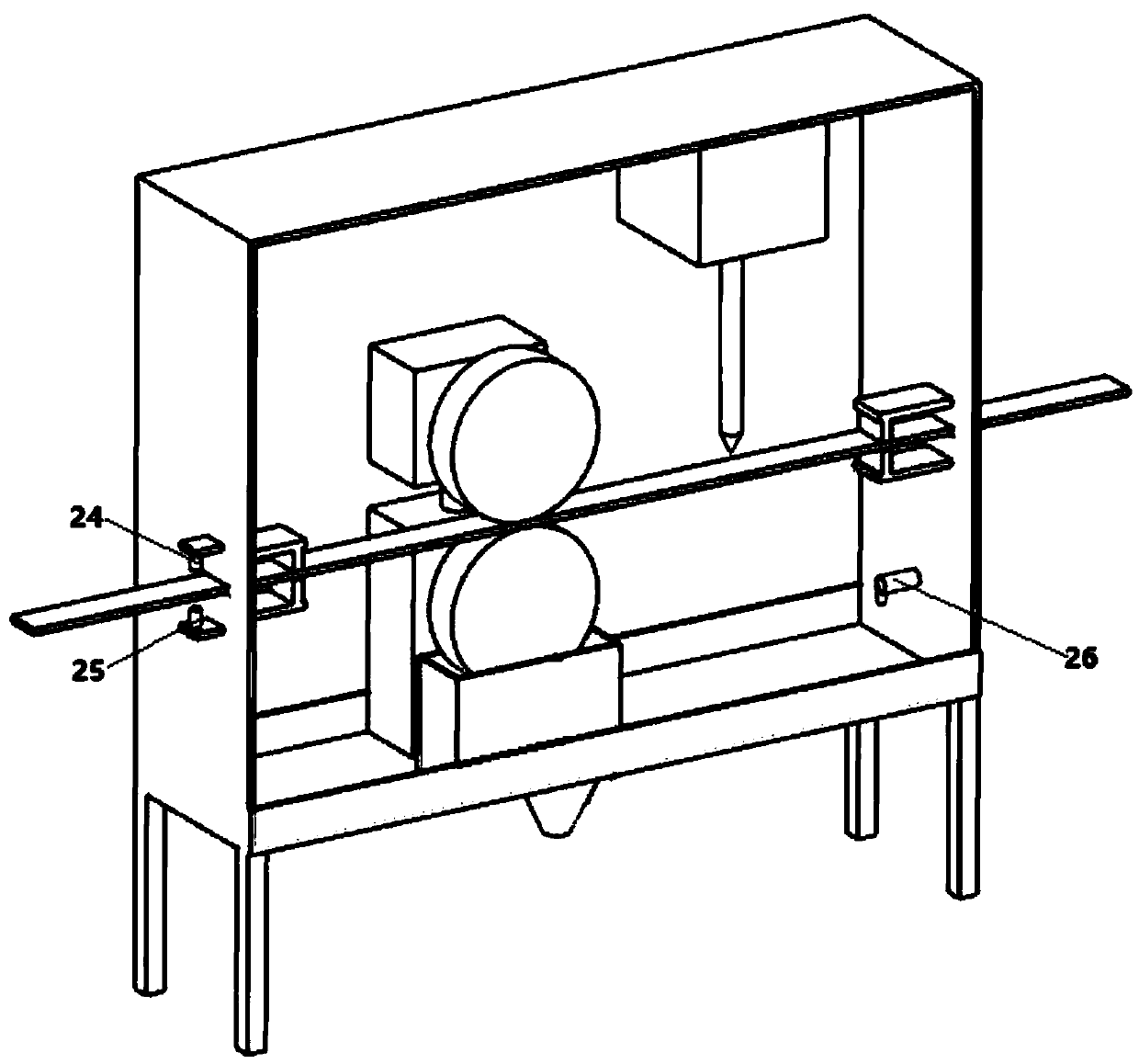

[0022] Such as figure 1 figure 2 and image 3 As shown, the automatic gluing device for the inner steel sheet of the automobile waistline sealing strip according to the specific embodiment of the present invention includes a gluing and detection system, a frame, and a cleaning system.

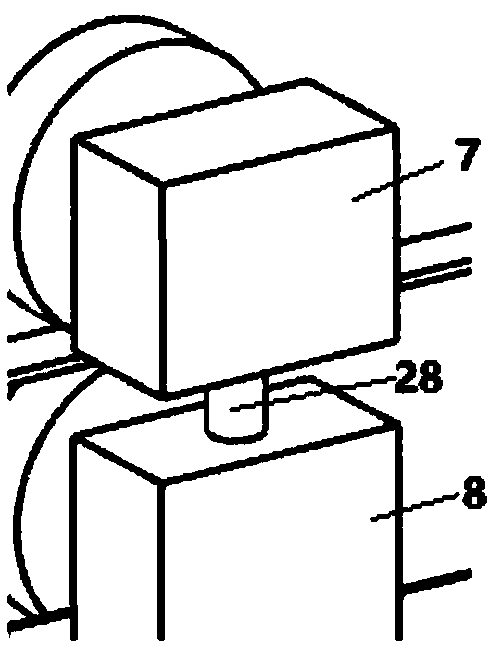

[0023] The glue application and detection system includes steel sheet 1, cleaning plate, glue tank 4, glue delivery pipe 5, glue nozzle 6, first power chamber 7, second power chamber 8, push rod 28, upper roller 9, lower roller 10, Lower roller glue box 13, brush head and camera; frame includes top board 16, side board, bottom board 18, bottom board coaming 29 and supporting legs; described cleaning system is used for cleaning bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com