Mechanical hand device

A technology of manipulators and manipulator guide rails, applied in the direction of conveyor objects, transportation and packaging, furnaces, etc., can solve the problems of complex layout, large space occupation, and insufficient efficiency, and achieve the effect of extensive industrial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

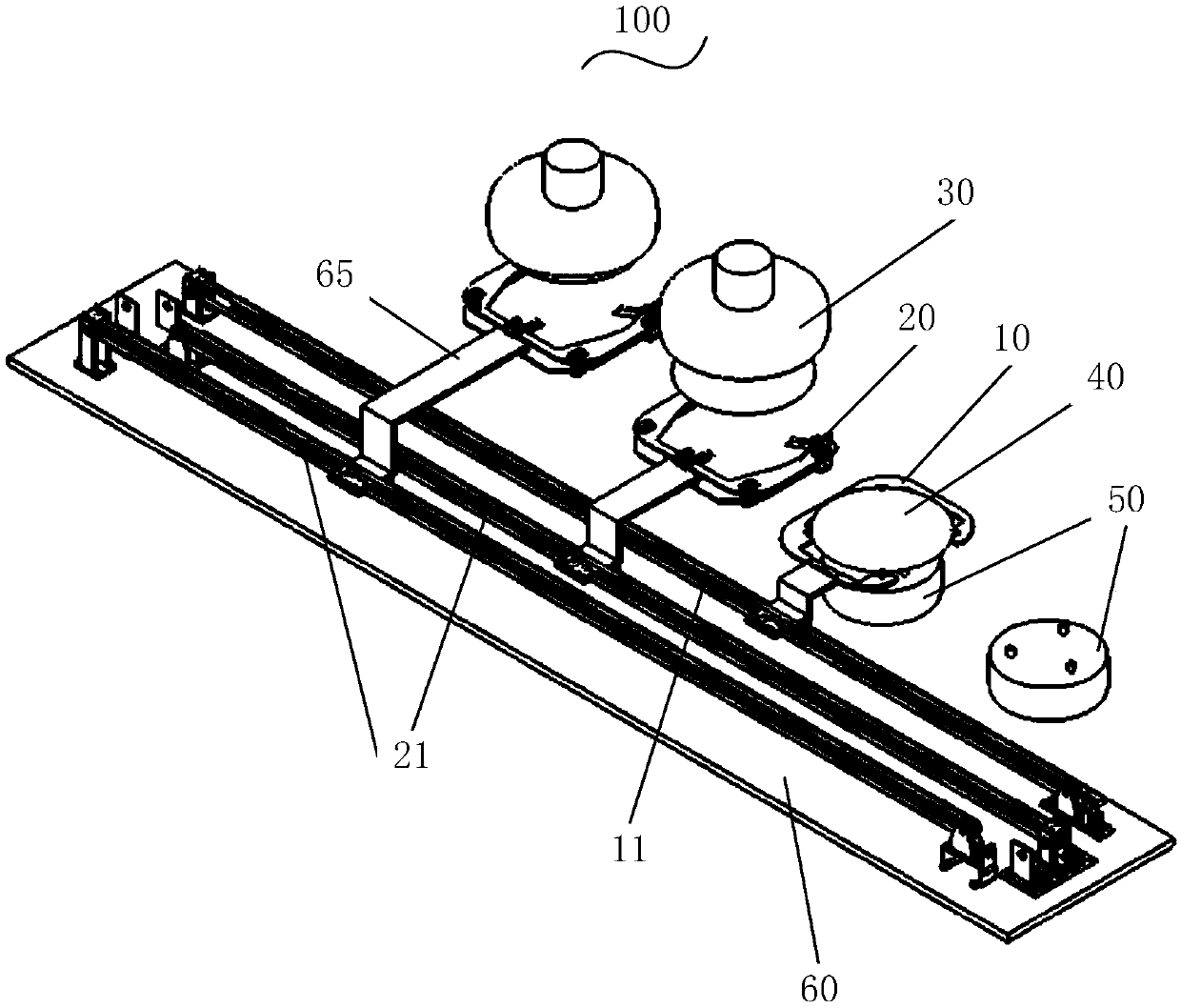

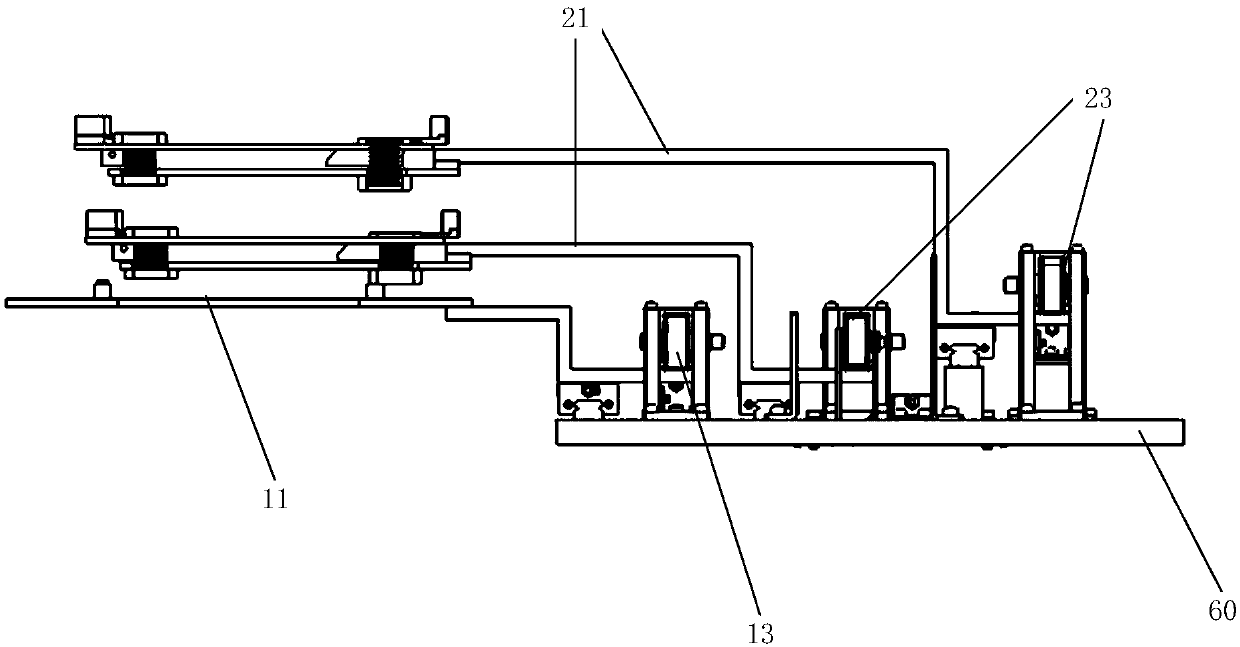

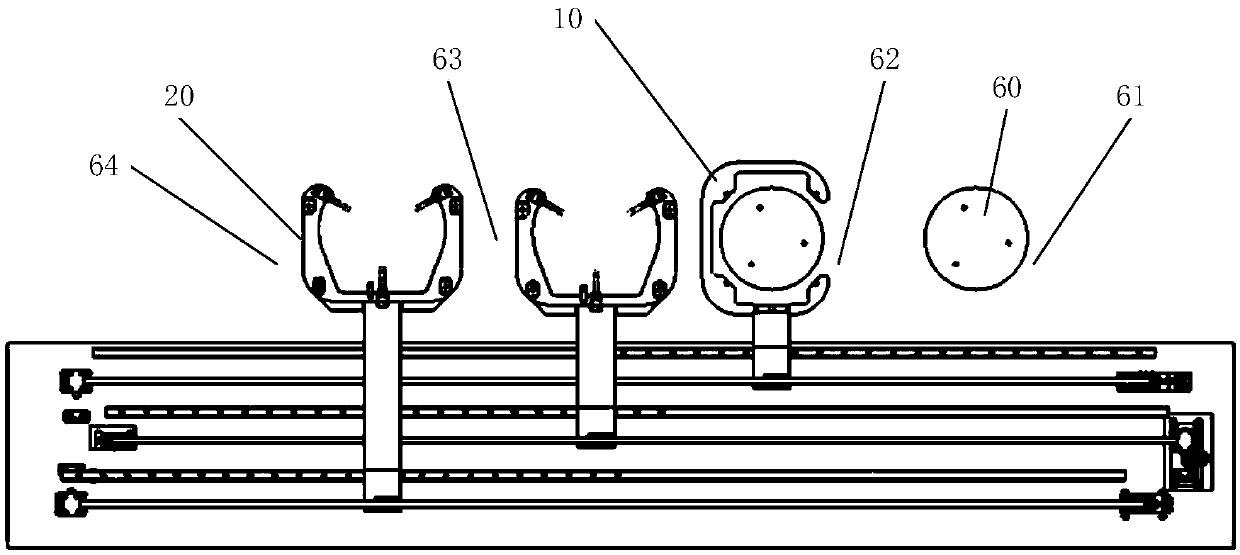

[0035] Such as Figure 1-6 .

[0036] The manipulator device 100 includes a positioning manipulator 10 for driving the external substrate 40 to move and place it at a preset position, and an external device for removing the substrate 40 from the preset position and processing it. An unloading manipulator 20 for unloading the substrate 40, the unloading manipulator 20 moves the substrate 40 to a preset station;

[0037]The manipulator device 100 also includes a positioning manipulator guide rail 11 for installing the positioning manipulator 10, an unloading manipulator guide rail 21 for installing the unloading manipulator 20, and the positioning manipulator guide rail 11 and the unloading manipulator guide rail 21 are parallel to each other. , the level of the unloading manipulator 20 is higher than the level of the positioning manipulator 10 .

[0038] above, such as image 3 , 4 As shown, the positioning manipulator 10 can place the substrate 40 at a preset position for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com