Bn nanotube interfacial phase strengthened and toughened carbon fiber reinforced ceramic matrix composite material and preparation method thereof

A composite material and fiber reinforced technology, applied in the field of composite materials, can solve the problems of reducing the comprehensive mechanical properties of materials, reducing fiber content, low mechanical properties, etc., and achieving the effect of improving synergistic bearing capacity, improving fatigue resistance, and short heat treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

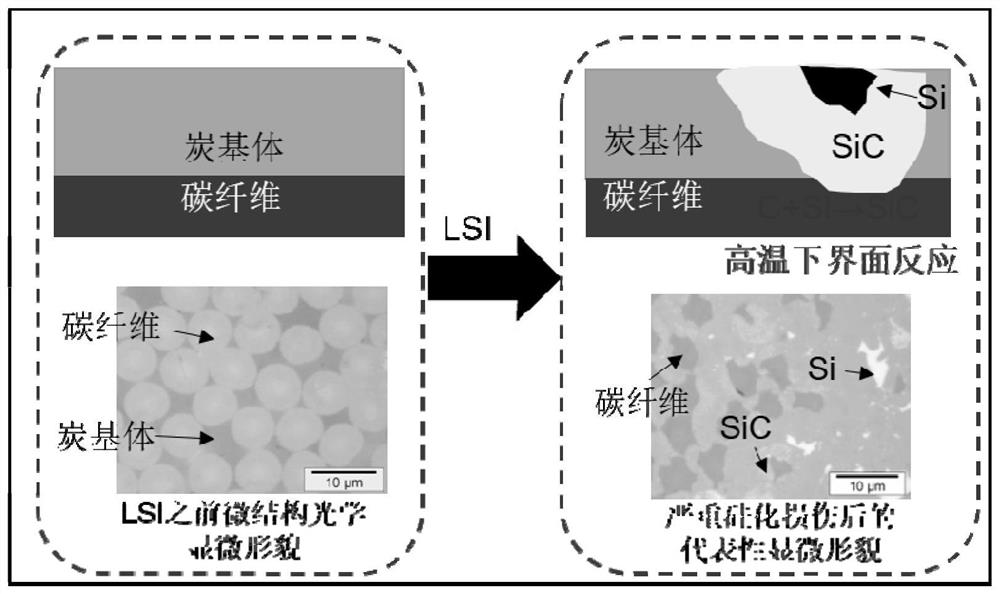

Problems solved by technology

Method used

Image

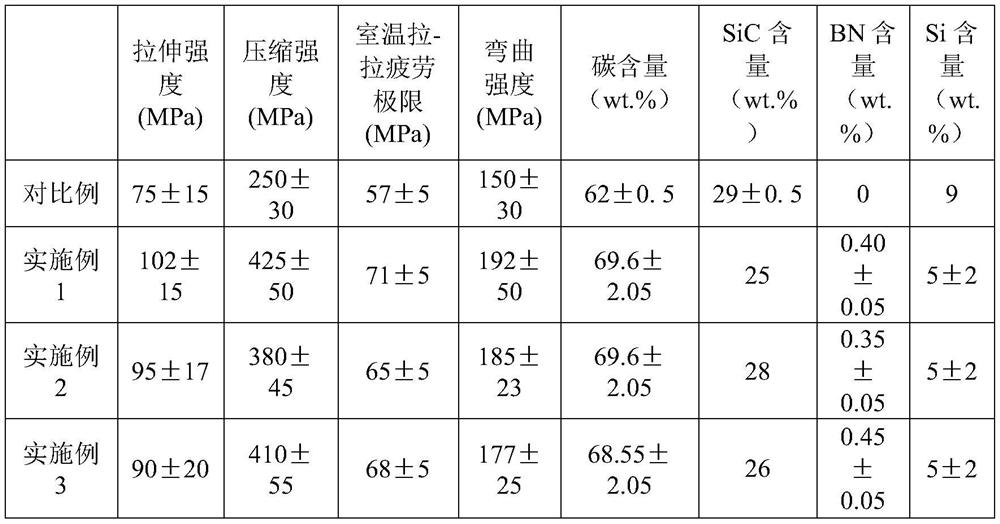

Examples

Embodiment 1

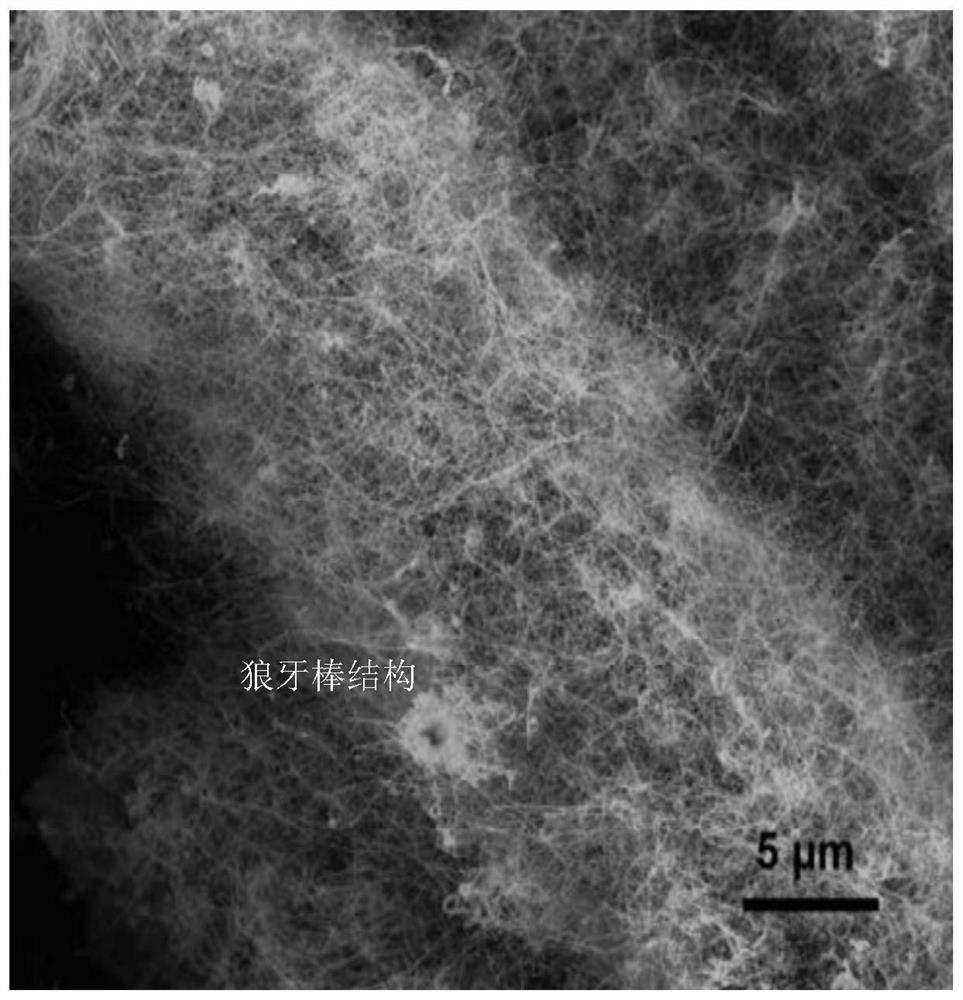

[0051] This embodiment provides a BN nanotube interface phase toughened carbon fiber reinforced ceramic matrix composite material, the specific preparation steps are as follows:

[0052] Degumming treatment: arrange the carbon fiber weaving in a vacuum sintering furnace, and under the protection of argon, heat up to 800℃ at a heating rate of 15°C / min. After the fiber is degummed, it is cooled to room temperature with the furnace to obtain a degummed carbon fiber woven cloth ;

[0053] S1. Preparation of impregnation solution: Boron oxide powder, boric acid powder, magnesium oxide powder and FeCl 3 The powder is mixed according to the ratio of 20:65:5:10 by mass percentage, and placed in a zirconia ceramic ball mill jar filled with isopropanol for ball milling to obtain an impregnation solution; wherein: the mass ratio of isopropanol to the mixed powder is 200: 10. The mass ratio of ball to material is 120:1, the ball milling speed is 250rpm, and the ball milling time is 100h;...

Embodiment 2

[0060] This embodiment provides a BN nanotube interface phase toughened carbon fiber reinforced ceramic matrix composite material, the specific preparation steps are as follows:

[0061] Degumming treatment: Arrange the carbon fiber weaving in a vacuum sintering furnace, and under the protection of argon, heat it up to 900℃ at a heating rate of 15°C / min. After the fiber is degummed, it is cooled to room temperature with the furnace to obtain a degummed carbon fiber woven cloth ;

[0062] S1. Preparation of impregnation solution: Boron oxide powder, boric acid powder, magnesium oxide powder and FeCl 3 The powder is mixed according to the ratio of 25:60:5:10 by mass, and placed in a zirconia ceramic ball mill jar filled with isopropanol for ball milling to obtain an impregnation solution; wherein: the mass ratio of isopropanol to the mixed powder is 200: 10. The mass ratio of ball to material is 120:1, the ball milling speed is 250rpm, and the ball milling time is 100h;

[006...

Embodiment 3

[0068] This embodiment provides a BN nanotube interface phase toughened carbon fiber reinforced ceramic matrix composite material, the specific preparation steps are as follows:

[0069] Degumming treatment: Arrange the carbon fiber weaving in a vacuum sintering furnace, and under the protection of argon, heat it up to 900℃ at a heating rate of 15°C / min. After the fiber is degummed, it is cooled to room temperature with the furnace to obtain a degummed carbon fiber woven cloth ;

[0070] S1. Preparation of impregnation solution: Boron oxide powder, boric acid powder, magnesium oxide powder and FeCl 3 The powder is mixed according to the ratio of 40:45:5:10 by mass, and placed in a zirconia ceramic ball mill jar filled with isopropanol for ball milling to obtain an impregnation solution; wherein: the mass ratio of isopropanol to the mixed powder is 200: 10. The mass ratio of ball to material is 120:1, the ball milling speed is 250rpm, and the ball milling time is 100h;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com