Outdoor heat exchanger and heat pump air conditioning system

A technology for outdoor heat exchangers and heat exchange tubes, which is applied in air conditioning systems, household heating, heating methods, etc., and can solve the problem of underutilization of the heat exchange area of outdoor heat exchangers, less liquid refrigerant, and more liquid refrigerant, etc. problems, to reduce the risk of frosting, reduce the surface temperature difference, and improve the heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

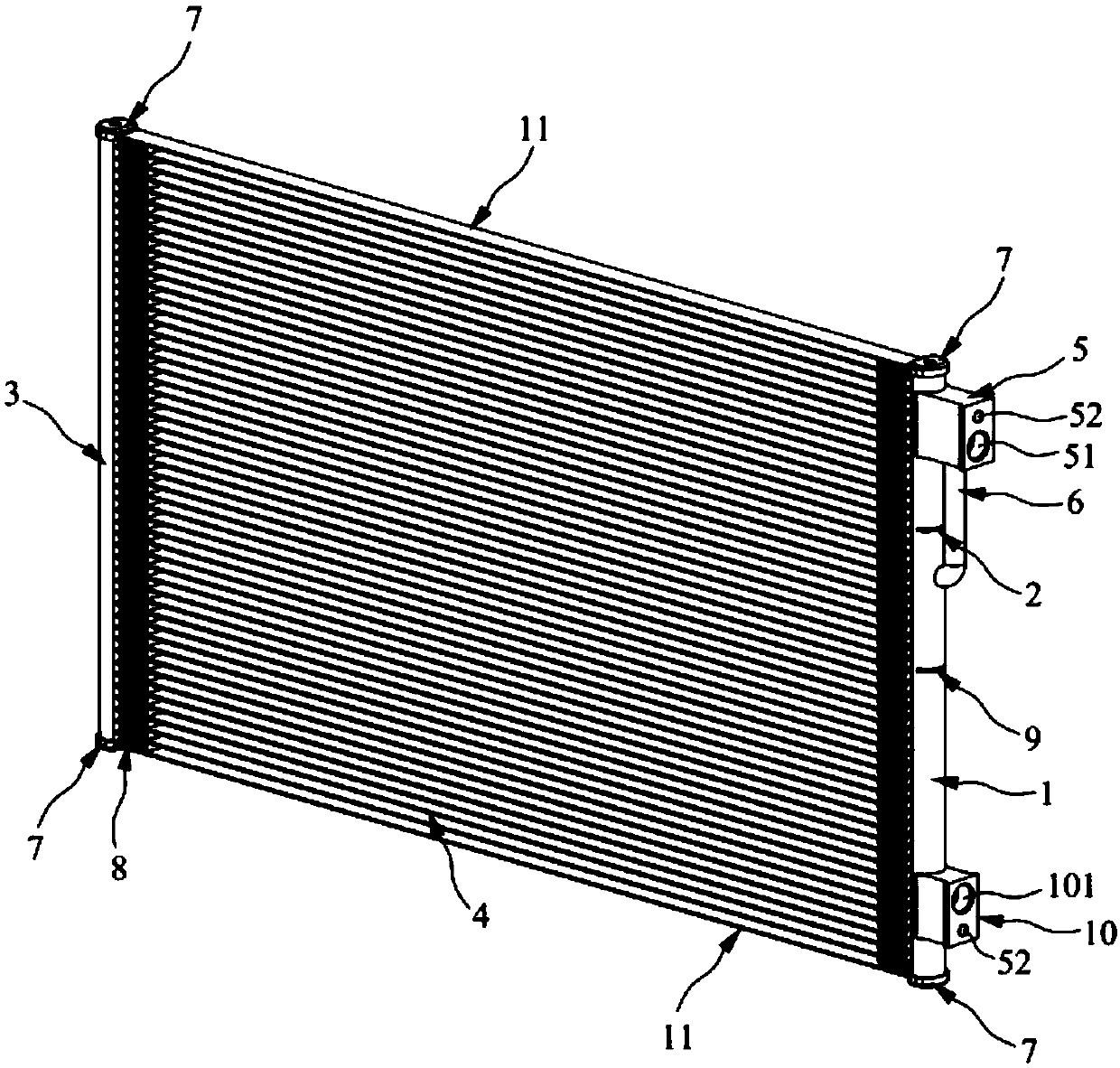

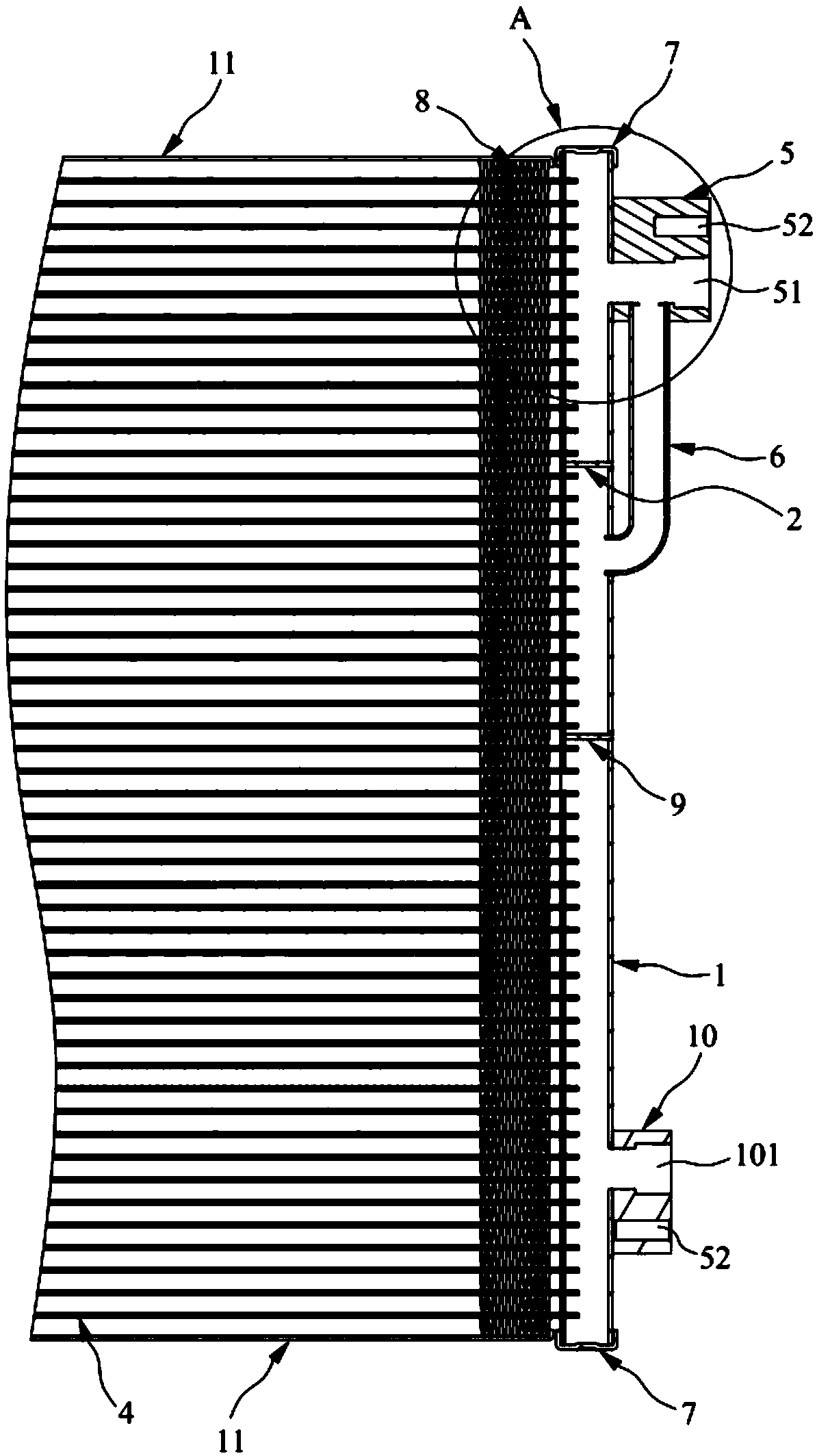

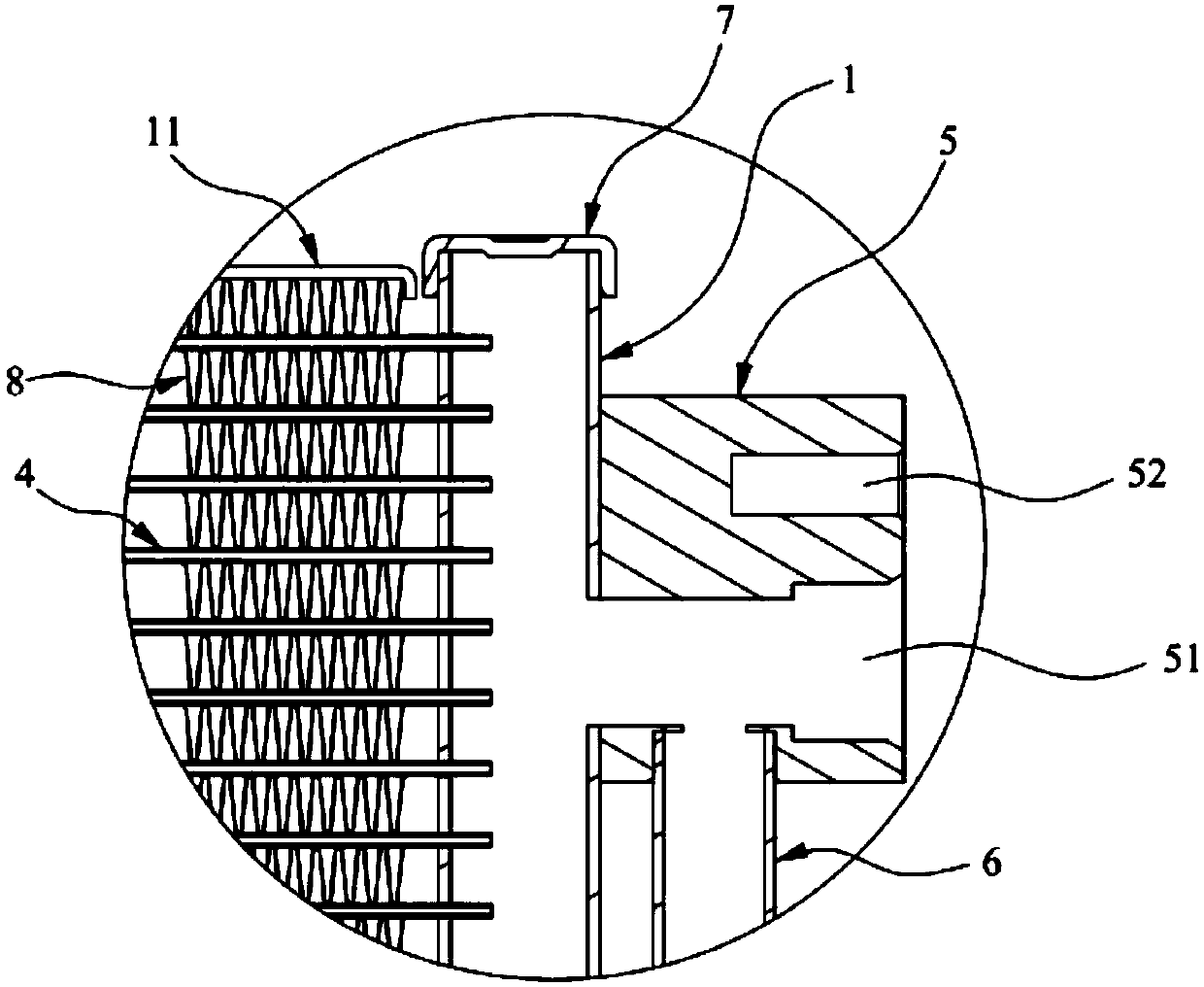

[0041] This embodiment provides an outdoor heat exchanger, such as figure 1 As shown, the outdoor heat exchanger includes: a first header 1, a second header 3, a plurality of heat exchange tubes 4, a plurality of fins 8, a side plate 11, an inlet pressure plate 5, an outlet pressure plate 10, a drainage Tube 6 , first partition plate 9 and second partition plate 2 .

[0042] Wherein, the first header 1 and the second header 3 are arranged parallel to each other, and both ends of the first header and the second header are provided with end caps 7 to play a sealing role; multiple heat exchange The tubes 4 are vertically arranged between the first header 1 and the second header 3, and the two ends of each heat exchange tube 4 are respectively inserted into the first header 1 and the second header 3 to communicate with them. , and the connecting part is provided with a sealing device; fins 8 are arranged between two adjacent heat exchange tubes 4, and the fins 8 are fixed on the ...

Embodiment 2

[0053] The outdoor heat exchanger provided in this embodiment has the same structure as the outdoor heat exchanger provided in Embodiment 1. The difference is that an adjustment hole is opened on the second partition plate 2 in this embodiment, and the cross-sectional area of the adjustment hole is It is 10%-30% of the cross-sectional area of the refrigerant inlet.

[0054] When heating, the refrigerant flowing into the outdoor heat exchanger generally has a certain pressure. This pressure may lead to uneven flow of refrigerant flowing into the refrigerant inlet and diversion port. There will be too much refrigerant.

[0055] In order to further ensure the uniformity of refrigerant distribution, an adjustment hole is provided on the second partition plate 2, so that the refrigerant above the second partition plate 2 can properly flow into the space between the second partition plate 2 and the first partition plate 9, Realize the secondary distribution of the refrigerant f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com