Automatic defect optical inspection method of display screen

A technology of automatic optical detection and display screen, which is applied in the direction of optical testing for flaws/defects, material analysis through optical means, and measuring devices. The effect of customer satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Embodiment: A test system that supports multiple working modes of OLED screens

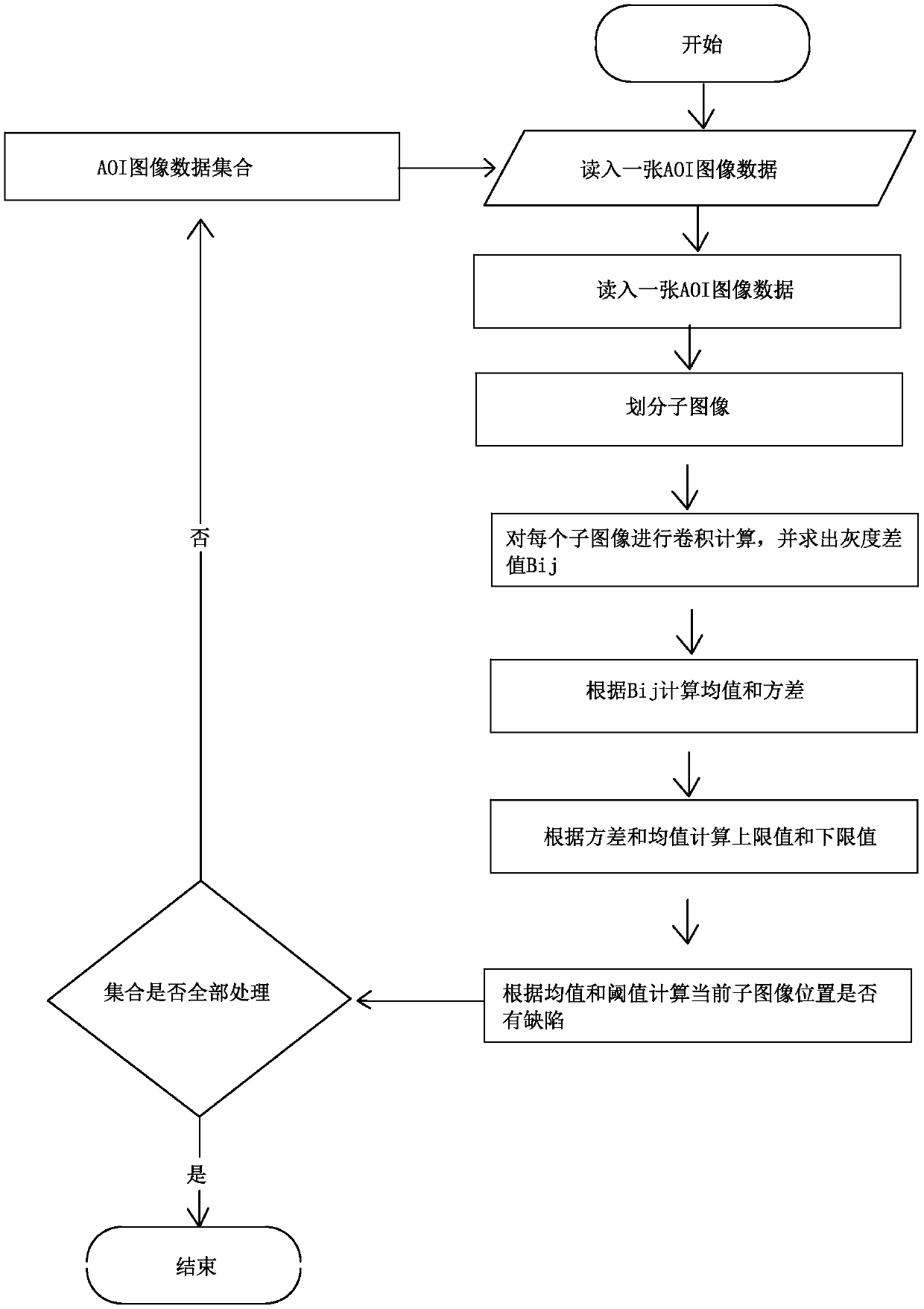

[0024] See attached figure 1 , follow these steps:

[0025] In the first step, an automatic optical inspection image of a display screen is read in.

[0026] In the second step, the collected AOI (automatic optical inspection) image data is cut out for the ROI area to obtain the image data to be inspected.

[0027] In the third step, the image to be detected is evenly divided into sub-images with a size of S*S, and the number of effective sub-images is: where N sh and N sw Respectively represent the number of effective sub-images along the height and width directions of the image, H is the height of the image, and W is the width of the image.

[0028] In the fourth step, each sub-image is equally divided into N*N parts.

[0029] The 5th step, set current sub-image as Aij, the calculation formula of this current sub-image feature quantity is Where (i, j) represents the subscript of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com