Tool clamp, device and inclined plane pad pasting method for mobile phone volume key SMT mounting

A volume key, mounting technology, applied in the direction of electrical components, electrical switches, circuits, etc., can solve the problems of poor effect, difficult control and maintenance, increase equipment complexity, etc., to achieve good film effect, high mounting efficiency, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

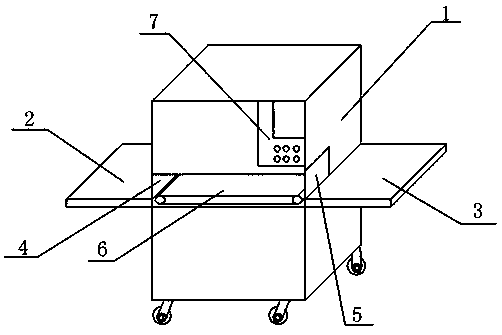

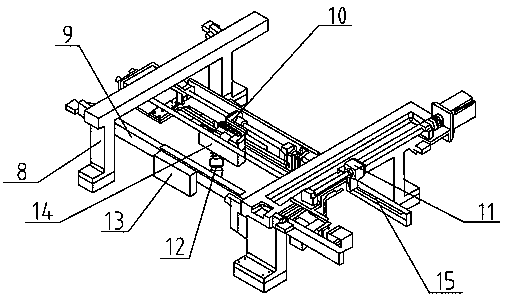

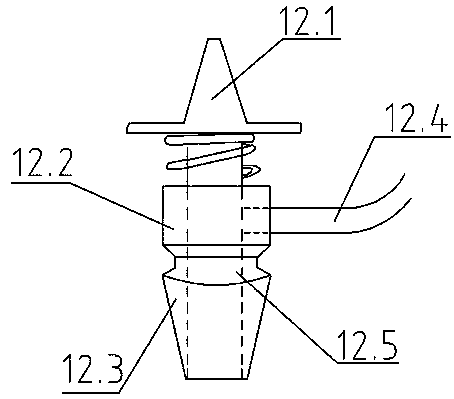

[0030] Such as Figure 1~3 As shown, a device for SMT placement of mobile phone volume keys consists of a chassis 1, a feed table 2, a discharge table 3, a feed port 4, a discharge port 5, a conveying assembly 6, a control panel 7, a fixed Frame 8, camera fixing plate 9, X-axis drive assembly 10, Y-axis drive assembly 11, suction head 12, vacuum connection nozzle 12.1, connection block 12.2, suction nozzle 12.3, air blowing passage 12.4, air pipe passage 12.5, camera installation box 13 , Z-axis drive assembly 14 and straight plate 15 are formed.

[0031] Such as Figure 4 As shown, a tooling seat for the SMT mounting of the volume key of a mobile phone is composed of a pressing plate 16, a base plate 17, a volume key placement groove 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com