Anti-caking crushing valve

An anti-caking and crushing device technology, applied in grain processing and other directions, can solve the problems of excessive fluctuation of powder conveying, affecting the normal flow rate of powder, and achieve the advantages of less flow interference, improved powder conveying efficiency, and improved crushing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

[0028] In this application, "front end" or "rear end" is a relative concept, not an absolute determination of the position. In this embodiment, the powder first passes through the control valve and then passes through the crushing device as an example. Therefore, the The direction of the control valve is the front end, and the crushing device is the rear end. Relative to the crushing device, the end close to the control valve is the front end, and the opposite end is the rear end.

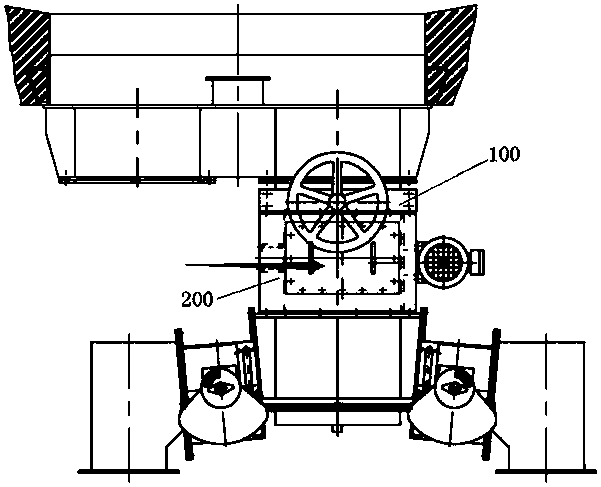

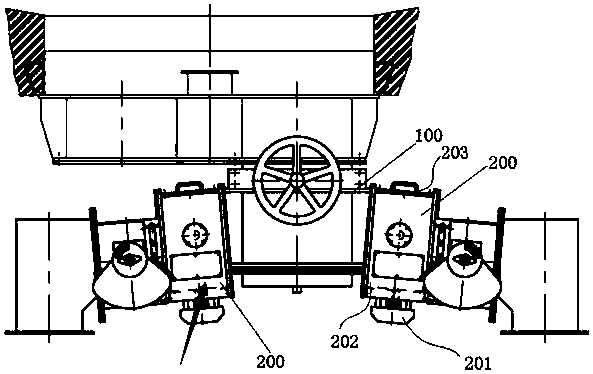

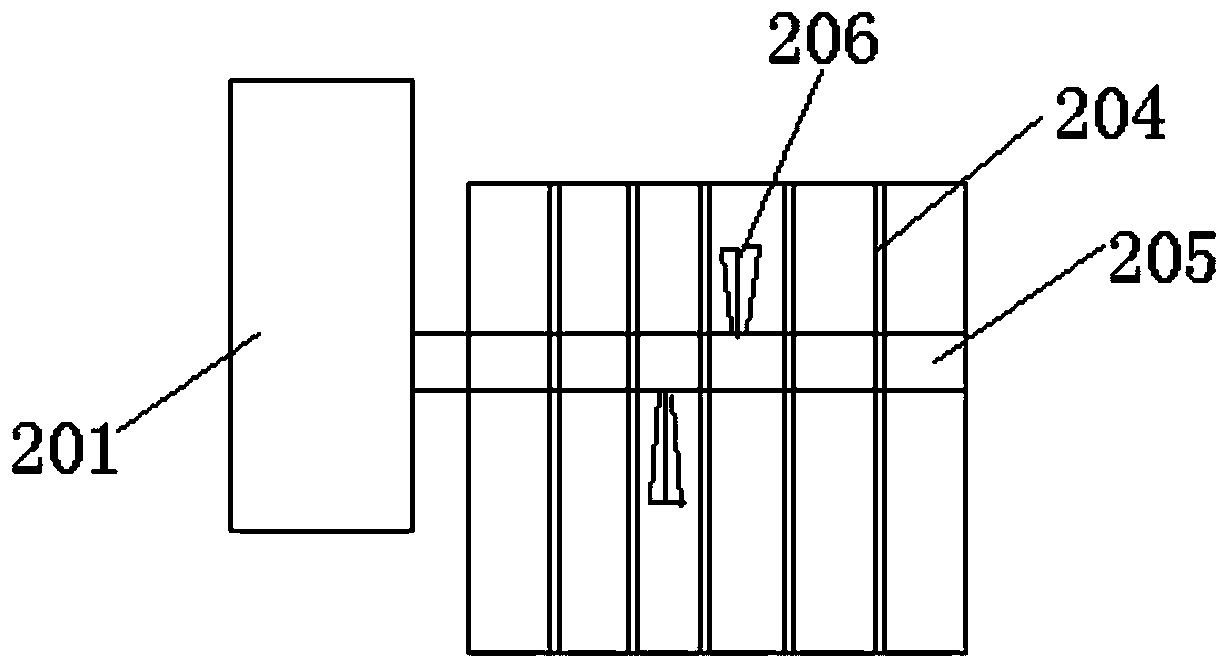

[0029] The application provides an anti-caking broken valve, such as Figures 1 to 3 As shown, it includes a control valve 100 and a crushing device 200 ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap