A slide radial pressing device

A technology of a pressing device and a skateboard, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings and examples.

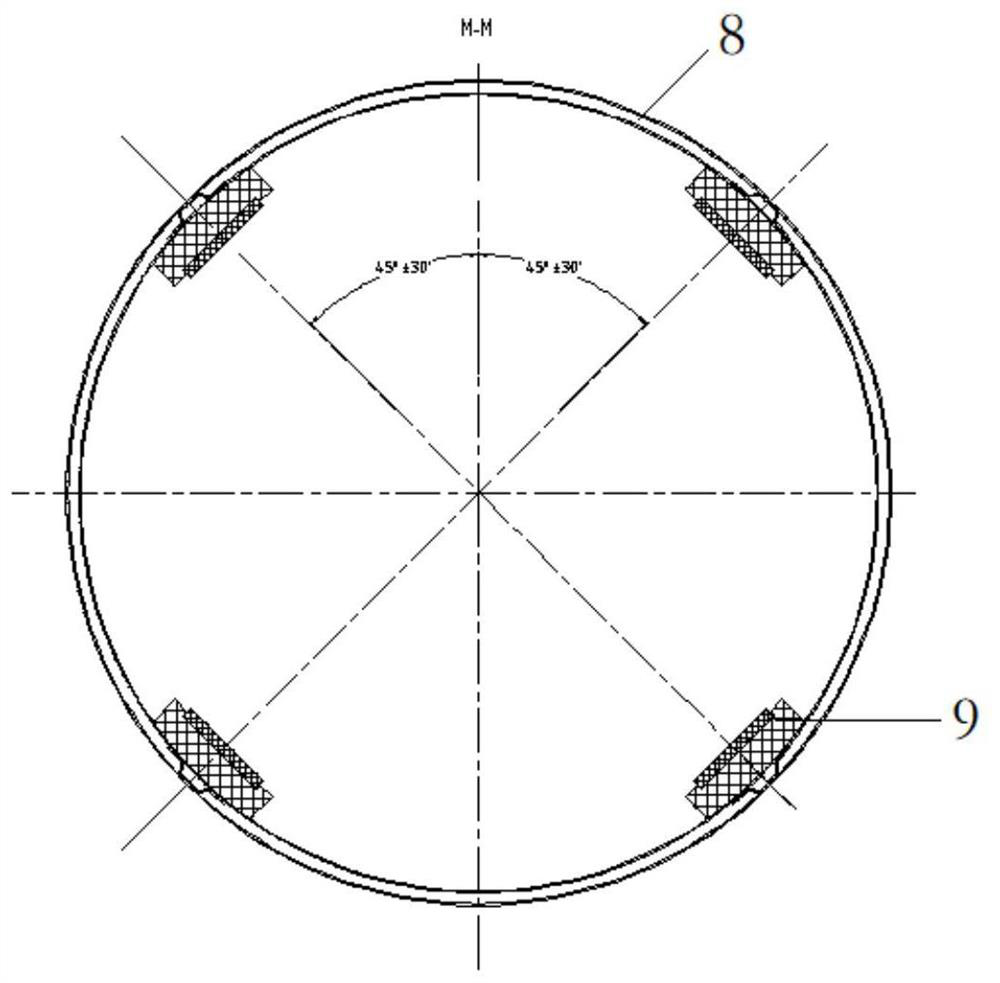

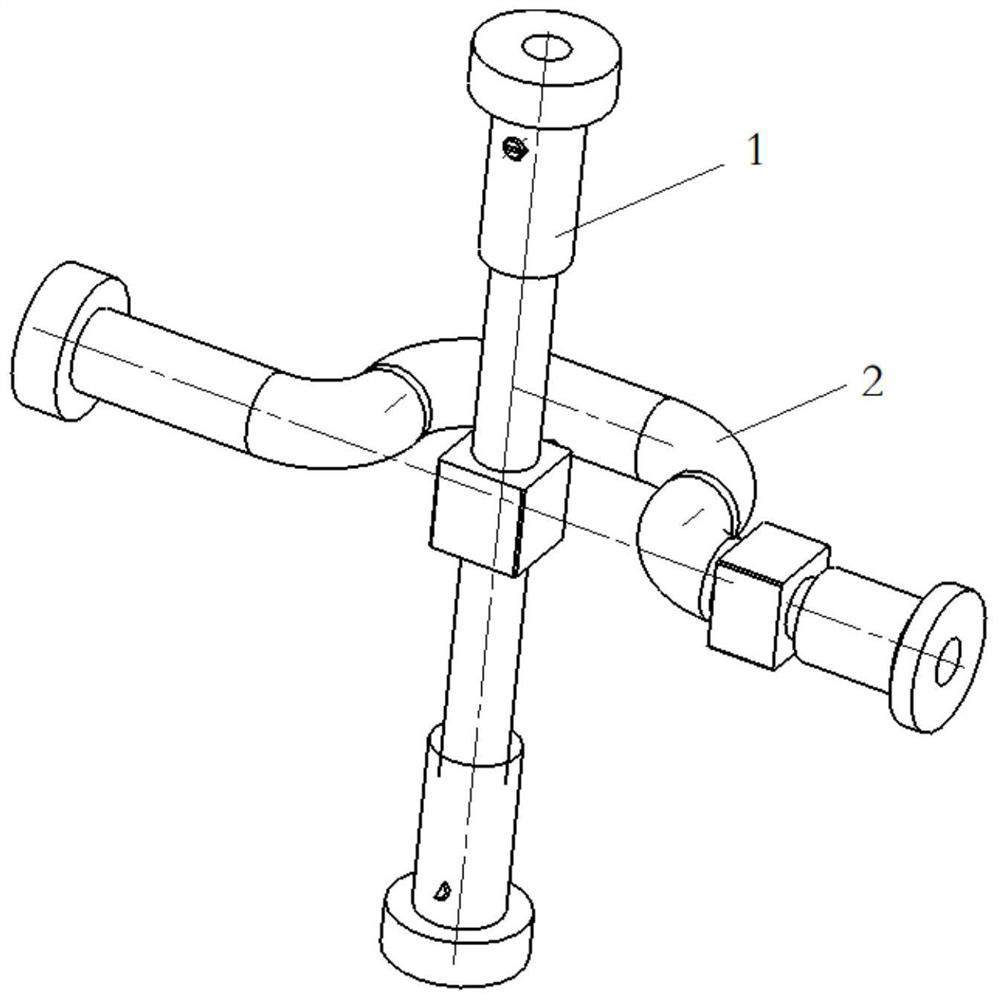

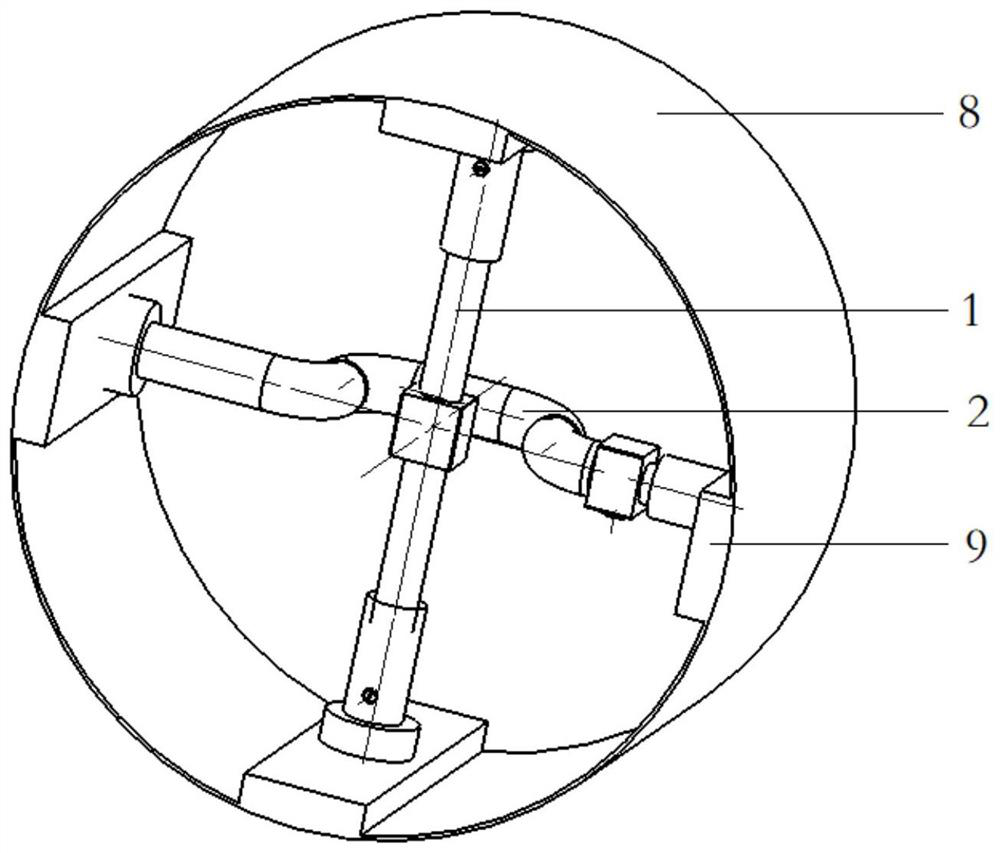

[0018] as attached figure 2 As shown, the present invention provides a slide radial pressing device, which includes a linear support assembly 1 and a curved support assembly 2; as attached image 3 As shown, the linear support assembly 1 and the curved support assembly 2 are orthogonally distributed inside the flame cylinder, the curved part of the curved support assembly 2 avoids the intersection point of the two in the plane, and the linear support assembly and the curved support assembly The two ends of the assembly are respectively in contact with the slide plate assembly 9 inside the flame tube 8, and by respectively applying rotational moments to the linear support assembly 1 and the curved support assembly 2, the linear support assembly 1 and the curved support assembly 2 are displaced in the length direction And radial pressure is applied to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com