Aspheric optical lens compression molding machine

A technology of optical lenses and forming machines, which is applied in glass forming, glass pressing, glass manufacturing equipment, etc. It can solve the problems of high pass rate and special-shaped lenses cannot be processed by grinding, and achieves high pass rate and is conducive to precision The effect of high degree of control and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments of the specification:

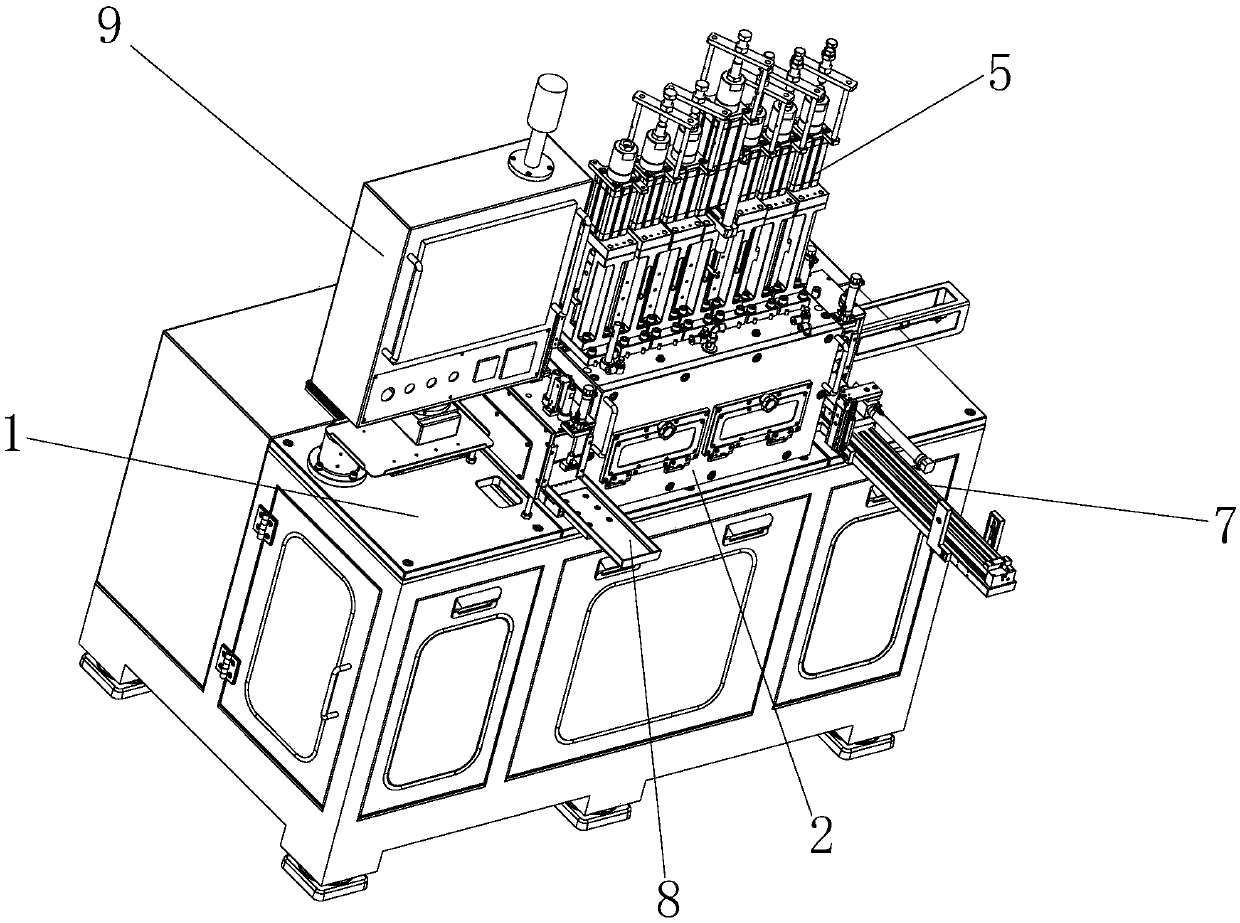

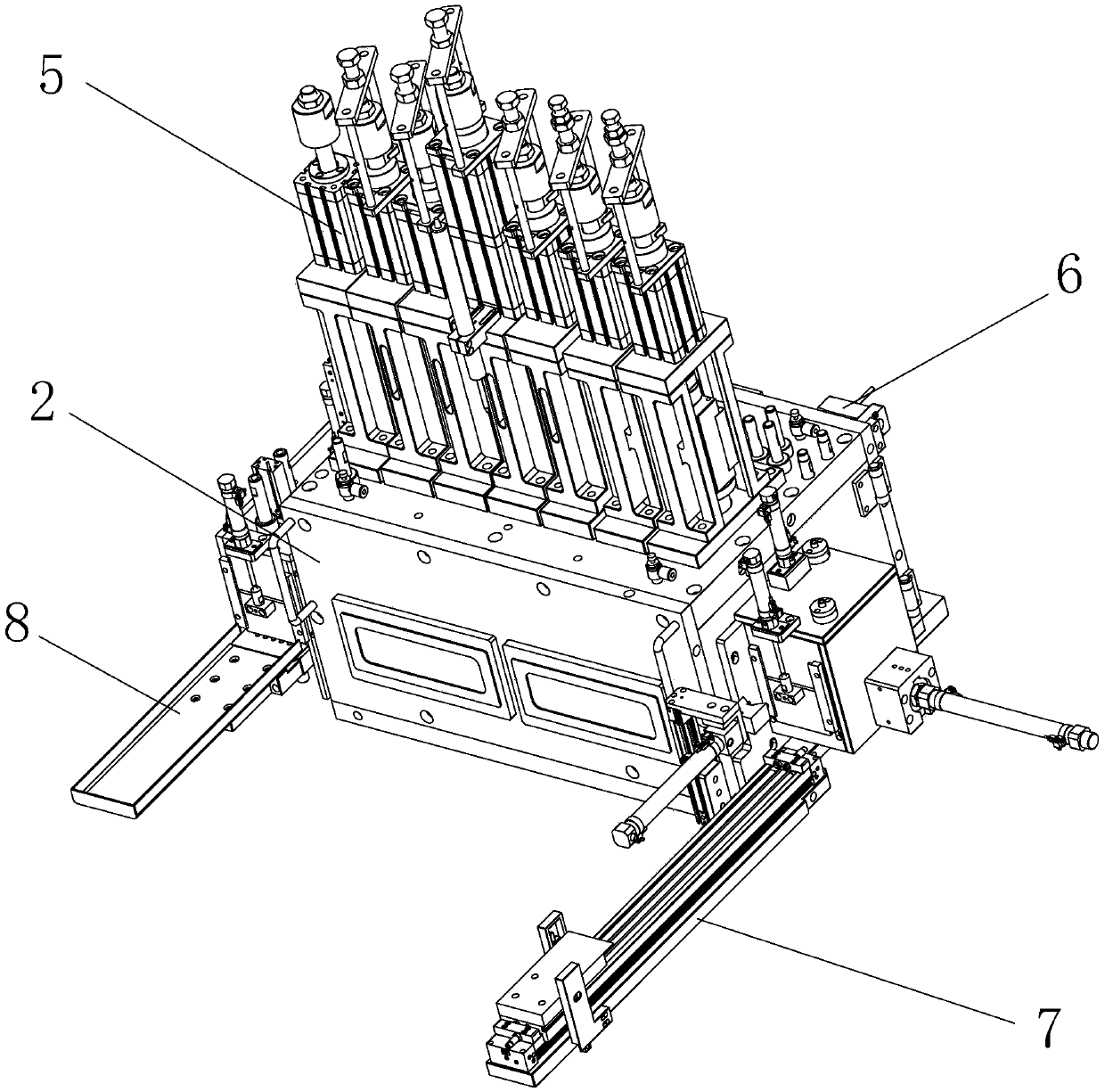

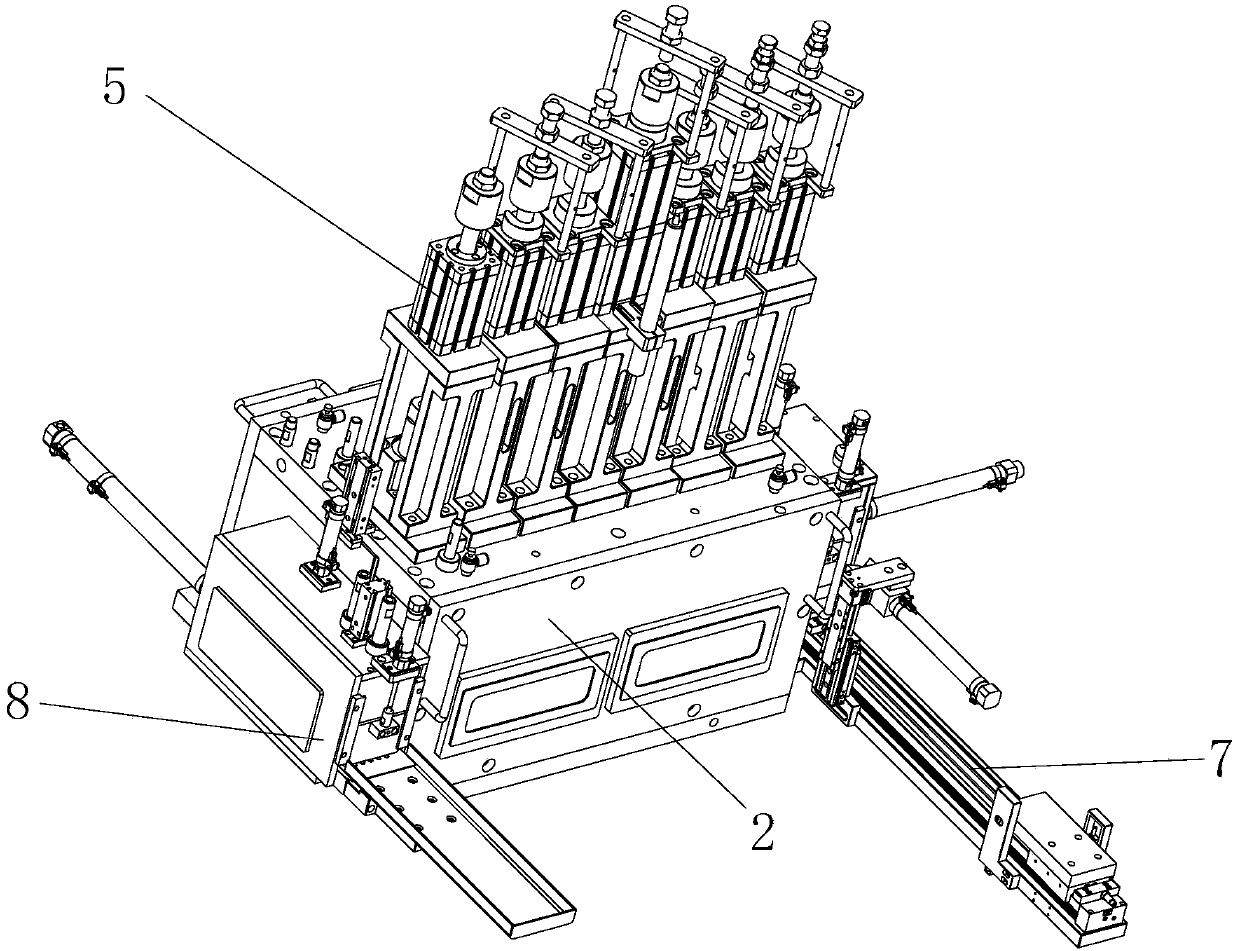

[0032] Such as figure 1 - Figure 8 As shown, it is an aspheric optical lens molding machine provided by the present invention, which is characterized in that it includes a frame 1, a molding and sealing cavity 2 arranged on the frame 1, and a molding and sealing cavity 2 sequentially arranged in the molding and sealing cavity 2. A plurality of molding stations 3, the molding machine also includes a molding die 4 fixed on the upper end surface of the molding sealing cavity 2 and located above each molding station 3 for heating or cooling each molding station 3 Or the pressing unit 5 for applying pressure and the transfer unit 6 arranged in the forming and sealing cavity 2 for synchronously moving the forming mold 4 on each station forward for a distance of one station. In this embodiment, each action of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com