High-strength connecting structure for concrete-filled steel tubular support

A steel pipe concrete and connection structure technology, applied in the direction of pillars/supports, earth square drilling, mining equipment, etc., can solve the problems of large shrinkage, influence of connection strength, and reinforcement of unconnected parts, so as to improve the axial connection tension, Guaranteed radial connection force and improved connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

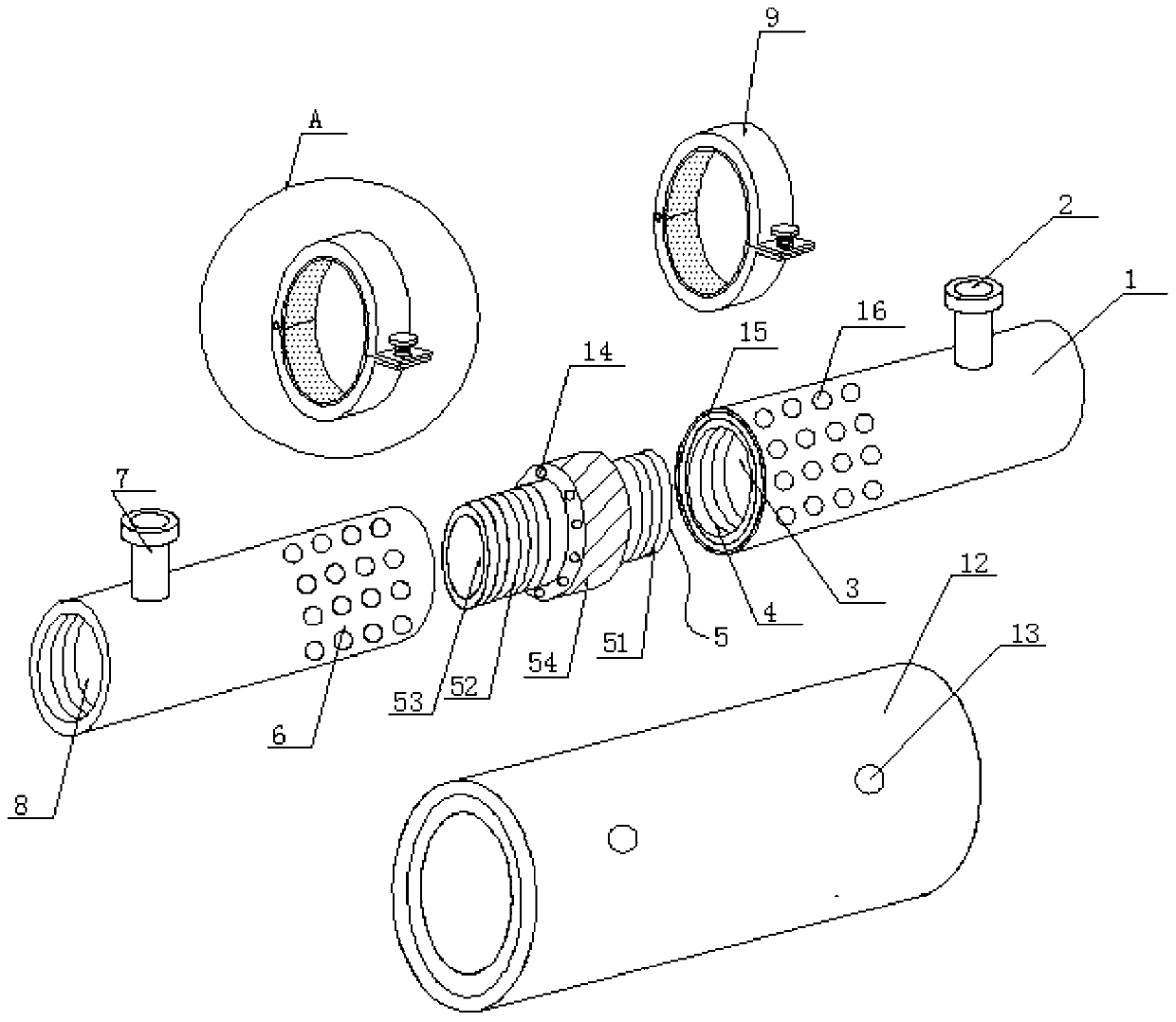

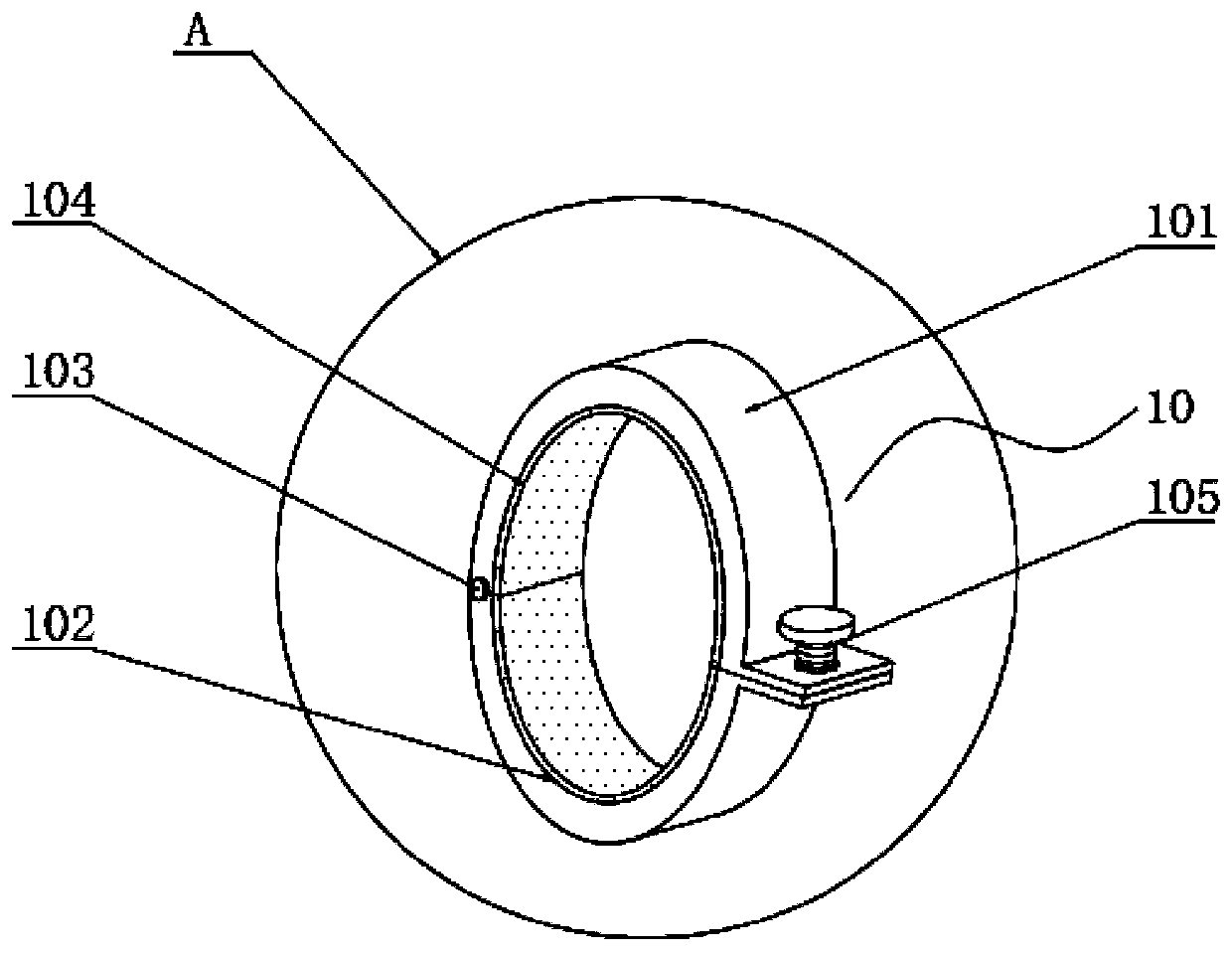

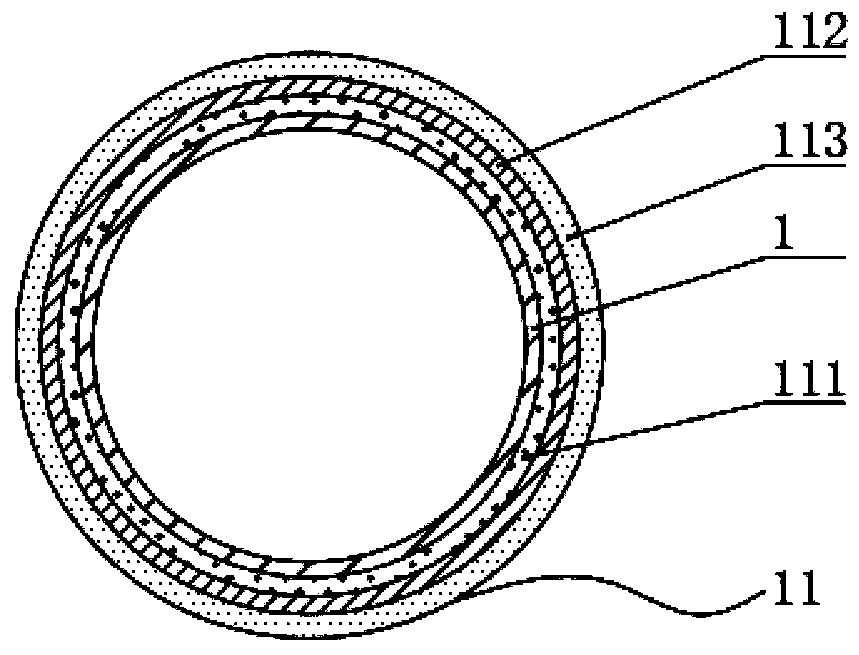

[0033] see Figure 1~5 , in an embodiment of the present invention, a high-strength connection structure for a steel pipe concrete support, comprising a first section of a steel pipe concrete support 1, a second section of a steel pipe concrete support 6, an inner connector 5 and an outer connector 12, wherein the The upper surface of the first section of concrete-filled steel pipe support 1 is embedded with a first grouting port 2, the upper surface of the second section of steel pipe concrete support 6 is embedded with a second grouting port 7, and the inner connector 5 is A stepped structure with a large cross-sectional area in the middle and small ends, the two ends of the inner connector 5 are threaded to connect the first section of the steel pipe concrete support 1 and the second section of the steel pipe concrete support 6 together; it is characterized in that,

[0034] An accommodating gap is provided between the two sides of the end face of the intermediate step with...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap