Outdoor high-voltage cable head grounding structure and method

A high-voltage cable head and grounding structure technology, applied in conductive connection, electrical component connection, connection, etc., can solve the problems of operation and maintenance work, high safety hazards for maintenance personnel, and cables without suitable grounding wires, so as to avoid ground electric shock. The effect of risk, easy operation and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

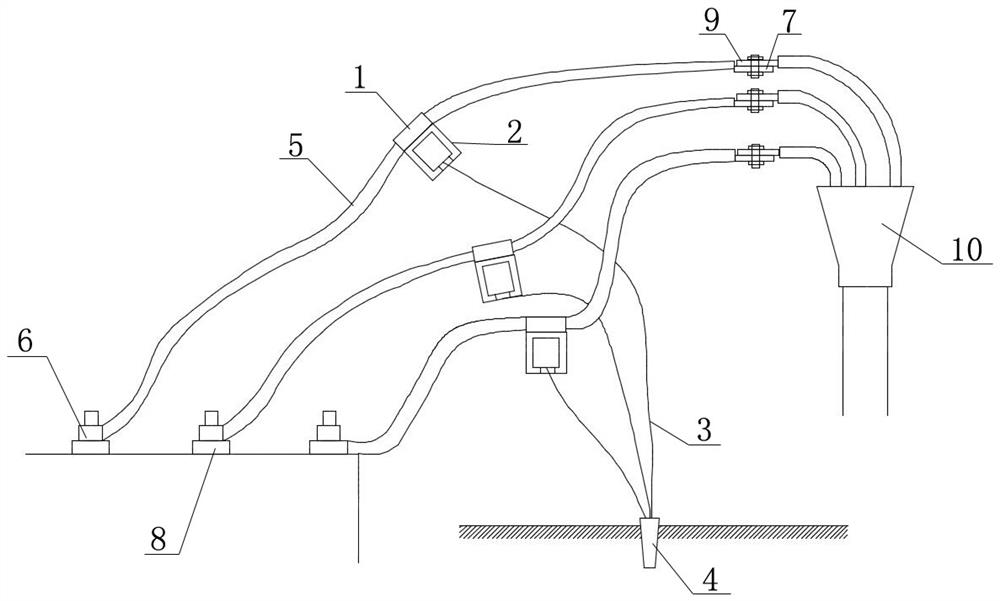

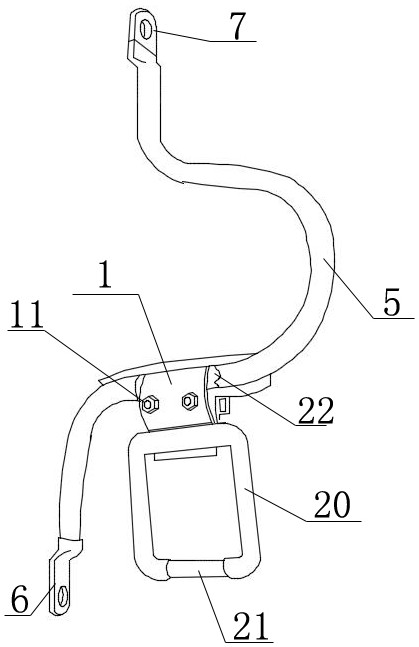

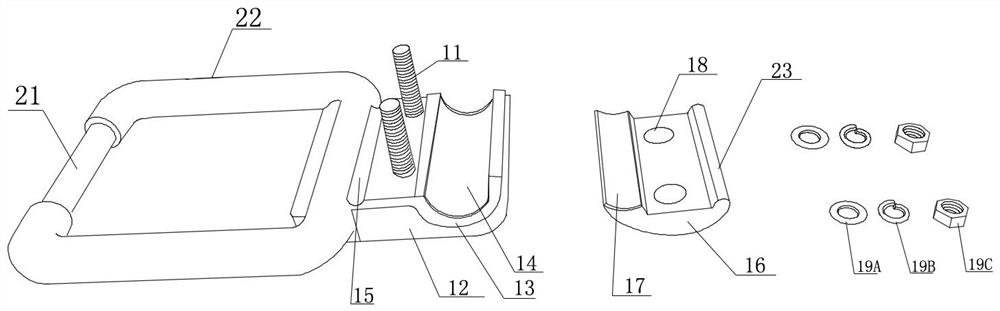

[0017] An outdoor high-voltage cable head grounding structure, the three power terminal posts 8 of the power supply equipment and the three outlet joints 9 of the high-voltage cable head 10 are respectively connected by three power connection lines, and the power connection lines include flexible connection lines 5 and setting The first copper-aluminum joint 6 and the second copper-aluminum joint 7 at both ends of the flexible connecting line 5, the first copper-aluminum joint 6 is connected to the power terminal 8, and the second copper-aluminum joint 7 is connected to the outlet joint 9; one section of the flexible connecting line 5 The outer layer of insulation is not covered, and the wire core 22 is exposed. The hooking device is arranged in this section. The hooking device is composed of two parts: the merged wire clamp assembly 1 and the grounding ring 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com