Circuit board and driving power supply with the same

A circuit board and copper board technology, applied in circuit substrate materials, printed circuits, printed circuits, etc., can solve problems such as damage to power devices, use of labor, poor heat dissipation, etc., to achieve low manufacturing costs, improve production efficiency, and solve grounding problems. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

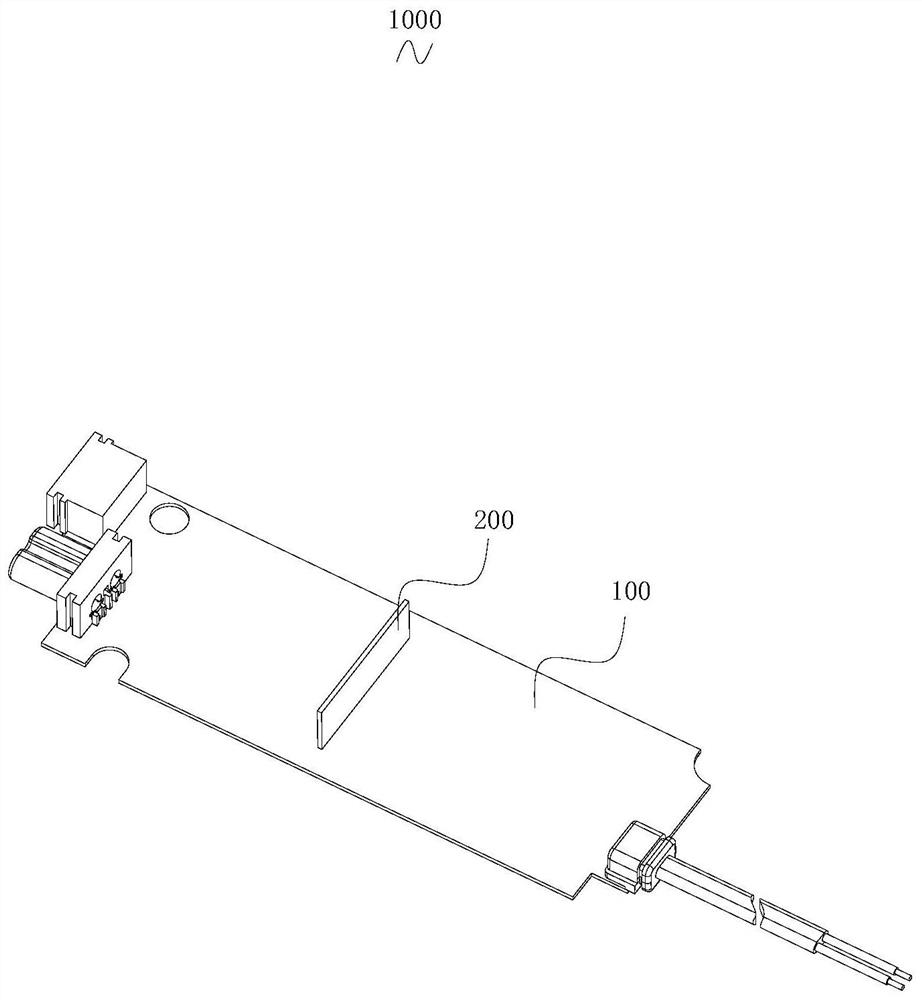

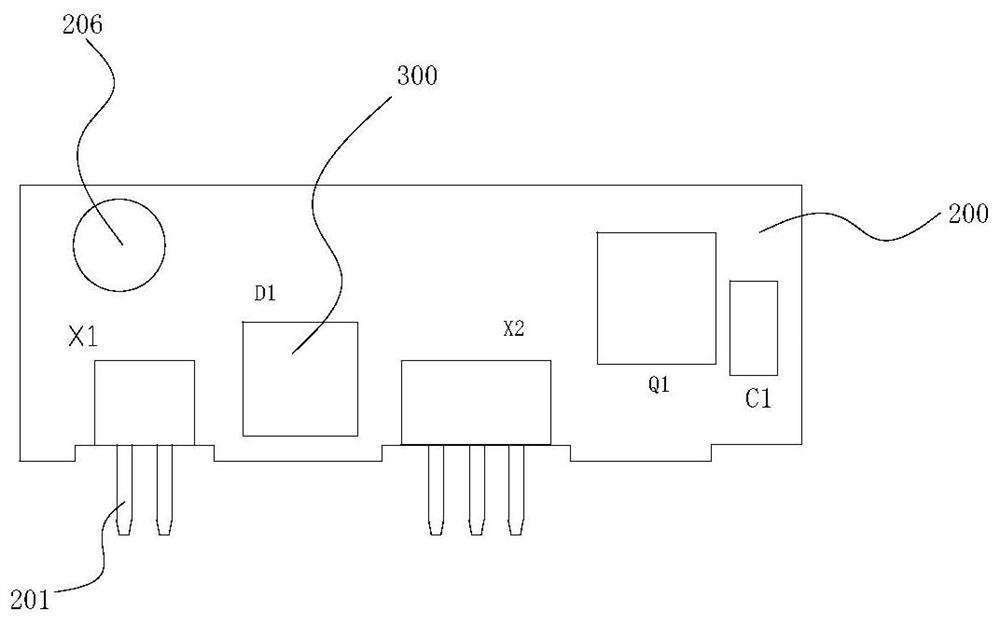

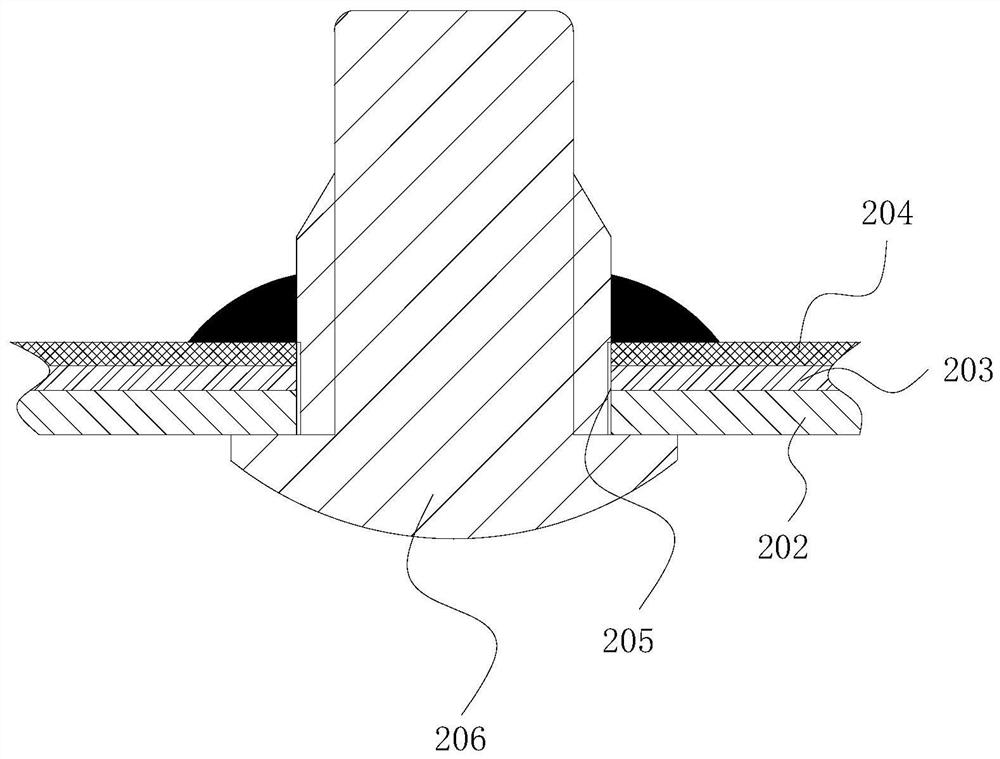

[0023] Such as Figure 1~3 As shown, the circuit board 1000 of this embodiment includes a main board 100 whose base material is made of insulating material and at least one metal-based copper-clad laminate 200 .

[0024] The base material of the main board 100 is generally classified by the insulating part of the base board, and the common materials are bakelite board, glass fiber board, and various plastic boards. Manufacturers generally use an insulating part made of glass fiber, non-woven material, and resin, and then press epoxy resin and copper foil to form a "prepreg" for use. The manufacturing cost is low and the application range is wide.

[0025] The metal-based copper-cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com